Table of Contents

Summary of Contents for Bender ATICS-2-63A-ISO

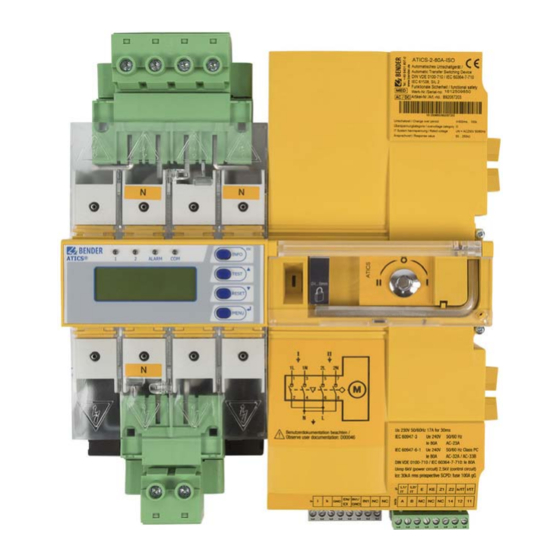

- Page 1 Manual ATICS-2-63A-ISO ATICS-2-80A-ISO Automatic transfer switching devices with monitoring functions for unearthed safety power supplies Software version: D333 V1.2x/D334 V1.2x D335 V1.0x/D308 V1.2x ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

- Page 2 Bender GmbH & Co. KG © Bender GmbH & Co. KG All rights reserved. P.O. Box 1161 • 35301 Gruenberg • Germany Londorfer Straße 65 • 35305 Gruenberg • Germany Reprinting only with permission Tel.: +49 6401 807-0 • Fax: +49 6401 807-259 of the publisher.

-

Page 3: Table Of Contents

Table of Contents 1. Important information ................... 7 How to use this manual ......................7 Technical support: service and support ................8 1.2.1 First level support ........................8 1.2.2 Repair service ..........................8 1.2.3 Field service ..........................8 Training courses ........................9 Delivery conditions ......................... - Page 4 Table of Contents 3.5.1.1 Time diagram: Changeover between the preferred and the redundant line . 3.5.1.2 Time diagram: Staggered switching after complete power failure ....20 3.5.1.3 Time diagram: Changeover to generator mode ..........21 3.5.2 IT system monitoring ......................22 3.5.3 Monitoring the device functions ..................

- Page 5 Table of Contents 5.1.1 Configure MK… or TM… ....................42 5.1.2 ATICS® messages on the BMS bus (channel use) ............42 5.1.3 Tests, decommissioning ..................... 43 Setting and testing according to the checklist ............44 Addressing examples ......................45 6. Operation ....................... 47 Operating and display elements ..................

- Page 6 Table of Contents 7.3.4.8 Settings menu 8: Language ..................75 7.3.4.9 Settings menu 9: Interface ................... 75 7.3.4.10 Settings menu 10: Clock ....................76 7.3.4.11 Settings menu 11: Password ..................77 7.3.4.12 Settings menu 12: Service ................... 78 7.3.5 Menu 5: Control ........................79 7.3.6 Menu 6: Digital input ......................

-

Page 7: Important Information

This manual describes how to operate the ATICS® automatic transfer switching device. Before using the devices, please read this operating manual, the supplement entitled "Important safety instructions for Bender products" and the instruction leaflets supplied with the individual sys- tem components. -

Page 8: Technical Support: Service And Support

Important information This manual has been compiled with great care. It might nevertheless contain errors and mistakes. Bender cannot accept any liability for injury to persons or damage to property resulting from errors or mistakes in this manual. ATICS® is a registered trademark of Bender GmbH & Co. KG. -

Page 9: Training Courses

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m. 1.3 Training courses Bender is happy to provide training regarding the use of test equipment. The dates of training cours- es and workshops can be found on the Internet at www.bender-de.com -> Know-how -> Seminars. -

Page 10: Disposal

introduced to the market after 13 August 2005 must be taken back by the manufacturer and disposed of properly. For more information on the disposal of Bender devices, refer to our website at www.bender-de.com -> Service & support. ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 11: Safety Instructions

2.1 General safety instructions Part of the device documentation in addition to this manual is the enclosed "Safety instructions for Bender products". 2.2 Work activities on electrical installations Only qualified personnel are permitted to carry out the work necessary to in- stall, commission and run a device or system. -

Page 12: Device-Specific Safety Instructions

2.5 General safety instructions Bender devices are designed and built in accordance with the state of the art and accepted rules in respect of technical safety. However, the use of such devices may introduce risks to the life and limb of the user or third parties and/or result in damage to Bender devices or other property. -

Page 13: System Description

3. System description 3.1 Properties 3.1.1 Product description The ATICS® transfer switching devices provide all functions for changeover between two independ- ent power supplies and for monitoring unearthed power supplies. The integration of both the elec- tronic system and the switching elements in one flat, compact device reduces space requirements in the switchgear cabinet, minimises the amount of wiring, and reduces the fault probability. -

Page 14: Functional Safety

Responsibility during the life cycle: Production Commissioning Maintenance Decommissioning Recycling Bender plant operator Bender For detailed information refer to chapter "5. Commissioning, settings and testing" on page 41 chapter "9. Periodic verification and service" on page 87 ... -

Page 15: Application Examples

System description 3.3 Application examples 3.3.1 Application example operating theatre ATICS-2-63A-ISO: Changeover between the preferred and redundant line while monitoring the medical IT system with transformer load and temperature monitoring IR426-D47: Monitoring the operating theatre light IT system (optional) ... -

Page 16: Example Intensive Care Unit

System description 3.3.2 Example intensive care unit ATICS-2-63A-ISO: Changeover between the preferred and redundant line while monitoring the medical IT system with transformer load and temperature monitoring EDS151: Insulation fault locator for fast insulation fault localisation (recommended) ATICS-BP: Bypass switch for uninterrupted test/maintenance (recommended) ... -

Page 17: Atics® Tasks

System description 3.4 ATICS® tasks The ATICS® transfer switching device has the following capabilities: Two-pole changeover of the power supply Voltage monitoring for the preferred supply (Line 1) Voltage monitoring for the second supply (Line 2) Voltage monitoring at the transfer switching device output (line 3) ... - Page 18 If ATICS® detects a supply failure or a fault, an alarm appears on the LCD, the "ALARM" LED lights up, the alarm relay trips (if set) and this alarm is forwarded to other Bender devices (such as an alarm in- dicator and test combination) via the BMS bus.

-

Page 19: Time Diagram: Changeover Between The Preferred And The Redundant Line

System description 3.5.1.1 Time diagram: Changeover between the preferred and the redundant line Example: Line 1 is set as the preferred line. ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 20: Time Diagram: Staggered Switching After Complete Power Failure

System description 3.5.1.2 Time diagram: Staggered switching after complete power failure After a complete power failure (i.e. no voltage on either of the power supplies) it is often necessary to switch to the supply at staggered intervals. This prevents all loads being switched on simultane- ously. -

Page 21: Time Diagram: Changeover To Generator Mode

System description 3.5.1.3 Time diagram: Changeover to generator mode ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 22: It System Monitoring

If any of the measured values does not fall within the limits, an alarm is triggered. A message appears on the LCD, the "ALARM" LED lights up, the alarm relay trips (if set) and this alarm is forwarded to oth- er Bender devices (such as an alarm indicator and test combination) via the BMS bus. Locating current injector When an insulation fault is detected in an IT system, the integrated locating current injector gener- ates a defined locating current signal to locate the insulation fault. -

Page 23: Power Supply

System description For systems with generator: total power failure possible If the preferred line fails, ATICS® will start the generator connected to the redun- dant line. If the generator does not start, the line downstream of the transfer WARNING switching device will be dead. When the generator is switched off, ATICS®... -

Page 24: The Atics-2-Iso Front View

System description 3.6 The ATICS-2-ISO front view Legend Green plug connector for line 1 and line 2 Control buttons Inspection window for switch position Manual mode of the transfer switching device, indicates the switch position Allen key for manual mode Transparent cover for changeover switch (manual mode), sealable Wiring diagram for lines 1, 2 and 3 Three coded connector plugs... -

Page 25: Installation And Connection

4. Installation and connection Risk of electrocution due to electric shock! Touching live parts of the system carries the risk of electric shock. Before fitting the device and prior to working on the device connections, make sure that the DANGER power supply has been disconnected. -

Page 26: Removing The Terminal Covers

Installation and connection 4.1.2 Removing the terminal covers 1. Push back the locking hook (B) in the middle of the top and bottom terminal cover (A) using a screwdriver. 2. Remove the terminal cover. 4.1.3 Mounting on DIN rail 1. Place ATICS® on the top edge of the rail. 2. -

Page 27: Screw Mounting On Plate

Installation and connection 5. Always tighten the mounting screws (D) (PZ1, 8,8 lb-in, 1 Nm). If the screws are not tight- ened, the vibration occur- ring during the switching CAUTION process damage ATICS®. 4.1.4 Screw mounting on plate Provide for sufficient clearance to live conductors (voltage clearance) by using mounting screws with flat screw heads and flat washers. -

Page 28: Connection

Installation and connection 4.2 Connection 4.2.1 Short-circuit protection When choosing the short-circuit protective devices in the supply cables and output cables of the transfer switching devices, follow the requirements of DIN VDE 0100-710 (VDE 0100 Part 710). Transformers for the IT system: ... - Page 29 Installation and connection Selecting a short-circuit protective device for several loads ATiCS Circuit breaker This circuit branches into several load groups. This means that each fuse of each load group is moved downstream of the transfer switching device. However, the maximum possible back-up fuse is cal- culated in the same way as described above.

-

Page 30: Connecting Atics® Safely

Installation and connection 4.2.2 Connecting ATICS® safely Risk of fatal injury from electric shock If any of the supplies are switched on, some of the parts of the system which are not yet fully installed may be live. DANGER Open the transparent cover of the device for manual mode selection and wait until the display shows "Manual mode". - Page 31 Connection measuring current transformer T3 (STW3) for monitoring the load current downstream the transfer switching device (short-circuit monitoring) GND, En/Ex Connection must not be used. Intended for Bender-internal purposes only (12 V). IN1/GND, Digital input, configurable (see "Settings menu 6: Digital input" on page 72)

-

Page 32: Connection Example: Atics® Basic Configuration

Installation and connection 4.2.3 Connection example: ATICS® basic configuration Risk of destruction if connected incorrectly The terminals marked "*" are intended for Bender-internal purposes only. If this is ignored, the ATICS® automatic transfer switching device may be damaged. CAUTION ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 33: Connection Example: Atics® With Bypass Switch

Installation and connection 4.2.4 Connection example: ATICS® with bypass switch Risk of destruction if connected incorrectly The terminals marked "*" are intended for Bender-internal purposes only. If this is ignored, the ATICS® automatic transfer switching device may be damaged. CAUTION ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 34: Connection Example: Atics® With Bypass Switch And Eds151

4.2.5 Connection example: ATICS® with bypass switch and EDS151 Risk of destruction if connected incorrectly The terminals marked "*" are intended for Bender-internal purposes only. If this is ignored, the ATICS® automatic transfer switching device may be damaged. CAUTION ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 35: Connection Example: Atics® For 400-Volt Systems

4.2.6 Connection example: ATICS® for 400-volt systems Risk of destruction if connected incorrectly The terminals marked "*" are intended for Bender-internal purposes only. If this is ignored, the ATICS® automatic transfer switching device may be damaged. CAUTION Risk of ineffective voltage monitoring ATICS®... -

Page 36: Instructions For Connection

DIN VDE 0100-710 (VDE 0100 Part 710) for transformers for medical IT systems. 4.2.7.2 Temperature sensors Bender IT system transformers are equipped with the required temperature sensors according to their insulation class. These temperature sensors (maximum of 6 sensors connected in series) are connected to terminals Z1 and Z2. -

Page 37: Fastening, Inserting And Securing Connections

Installation and connection 4.2.8 Fastening, inserting and securing connections Connect the terminals according to the wiring diagram to the plug connectors (A, B) and the three connector plugs (C). Connect the lines 1, 2 and 3 to the plug connectors (A, B). Consider a stripping length of 20 mm ... -

Page 38: Other Functions

Installation and connection 4.3 Other functions 4.3.1 Sealing the transparent cover of the transfer switching device The transparent cover can only be sealed when it is closed (automatic mode). 4.3.2 Manual mode Risk of injury from rotating Allen key When the transparent cover is closed, ATICS® is in automatic mode. ATICS® de- tects this by means of the button being pressed under the transparent cover. -

Page 39: Locking The Transfer Switching Device With A Padlock

Installation and connection 4.3.3 Locking the transfer switching device with a padlock It is only possible to lock the selector switch in manual mode (transparent cover open). The locking device can only be locked in switch position "0". Padlock shackle diameter: 4 mm … 8 mm (3/16” … 5/16”) Locking the transfer switching device: 1. - Page 40 Installation and connection ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 41: Commissioning, Settings And Testing

5. Commissioning, settings and testing 5.1 Design and installation Risk of erroneous measurements ATICS® contains an insulation monitoring device. If another insulation monitor- ing device is connected, the devices will affect one another. This will lead to false CAUTION measurements. Therefore, only one insulation monitoring device should be con- nected on each interconnected IT system! Risk of missing or false messages on the display on MK..., TM... -

Page 42: Configure Mk

Commissioning, settings and testing 5.1.1 Configure MK… or TM… Configure MK… or TM… in a meaningful way In addition to the alarm, also configure a brief message of what to do or who to notify. Examples: - IT system overload. Switch off unnecessary loads. - IT system insulation fault. -

Page 43: Tests, Decommissioning

Commissioning, settings and testing Messages for alarm on the digital input The following operational status and alarm messages may appear depending on the settings in the "Settings menu 6: Digital input": Menu Function of digital input Alarm on BMS bus BMS channel setting Digital input switched off... -

Page 44: Setting And Testing According To The Checklist

Commissioning, settings and testing 5.2 Setting and testing according to the checklist The settings made at the factory take into account a total changeover period t ≤ 0.5 s and switching back to the preferred supply within 10 seconds on voltage recovery. The response delay t(on), the dead time t(0), the delay on release t(off) and the return transfer delay time t(2->1) of ATICS®... -

Page 45: Addressing Examples

Commissioning, settings and testing 5.3 Addressing examples Insert terminating resistors correctly Communication via the BMS bus is only guaranteed when there is a terminating resistor at the beginning and at the end of the BMS bus. Other terminating resis- tors cause malfunctions and must not be used. Please note the information in the "BMS bus"... - Page 46 Commissioning, settings and testing Two automatic transfer switching devices one with an insulation fault locator with two alarm indicator and test combinations each and one central monitoring Device Parameter Address settings Bus address ATICS® for area A Address First MK…...

-

Page 47: Operation

6. Operation This chapter can also be used as a quick reference guide by technical operating personnel. 6.1 Operating and display elements ALARM COM LED and LCD Illuminated graphic LCD LED "1" lights up when line 1 is ready LED "2" lights up when line 2 is ready LED "Alarm"... -

Page 48: Quick Reference Guide

Operation 6.2 Quick reference guide 6.2.1 Display under normal operating conditions There is no alarm message. The LCD shows the standard information. Example: 228V 231V 50.0Hz 50.0Hz 160kΩ 14:11 12.10.2010 Legend Line 1: Measured values of mains voltage and frequency Switch position of the transfer switching device Line 2: Measured values of mains voltage and frequency Display of the load in the IT system in %. -

Page 49: Display During Fault Condition

Operation 6.2.2 Display during fault condition There is an alarm message. The yellow "Alarm" LED lights up. A detailed message appears on the LC display. Example: Line 2 has no voltage 228V 0.00V 50.0Hz 0.00Hz 160kΩ 14:11 Undervoltage Press the button "↵"... -

Page 50: Test Function

Operation 6.2.3 Test function A test is used to test the functioning of the device. There are several ways to call up a test menu: Select standard display and then press the "TEST" button on the front panel of the device for at ... -

Page 51: Test Menu 1: It System

Operation For technical reasons the menu items "Control> Test > Manual changeover" "Control > Test >Generator" and "Control > Test > Communication" cannot be accessed via a gateway (COM465…, CP700, …). If manual mode is selected for changeover (transparent cover open or digital in- put set to "manual changeover") then no changeover can take place under the test menu "Autom. -

Page 52: Test Menu 2: Autom. Changeover

Operation 6.2.3.2 Test menu 2: Autom. changeover Autom. changeover Autom. changeover Cancel Autom. changeover Test of the changeover function. The device changes to the redundant line. The changeover period t(1->2) is displayed. After the set time t(test) has elapsed, the device changes back to the preferred line. Cancel Back to test menu TEST... -

Page 53: Test Menu 4: Last Switch

Operation Manual mode aborts manual test When the transparent cover is opened after changing over to the redundant line, ATICS® switches to manual mode. The test will be aborted. After closing the transparent cover, ATICS® switches back to the preferred line. No entry will be made in the test data logger. -

Page 54: Test Menu 5: Generator

Operation 6.2.3.5 Test menu 5: Generator Executing this function makes sense only when a generator is connected to the redundant line and the associated settings have been carried out (see "Settings menu 1: Changeover" on page 66). To avoid voltage interruptions, in the test menu "Generator", ATICS®... -

Page 55: Reset Function

Operation Example of an alarm simulation: "Channel 5: MANUAL MODE" is selected. Channel disabled Manual mode :-- Exit Exit Channel:-- Channel:5 MODE ATICS® stays in this menu until it is exited by pressing the "ESC" button. During this time, all the alarms on the BMS bus have the word "TEST". Only the alarm messages listed in the following table can be simulated: "ATICS®... -

Page 56: Reset Menu 1: Alarm

Operation 6.2.4.1 Reset menu 1: Alarm Delete Delete Cancel Delete Resets alarm and fault messages on the device. The progress of the test is shown on the display. The reset is required if one or more alarm-triggering parameters are not con- stantly monitored so that the end of the alarm condition was not detected. -

Page 57: Reset Menu 3: Changeover

Operation 6.2.4.3 Reset menu 3: Changeover ATICS® monitors the parameters important for its service life. On reaching the set limits, the unit dis- plays an alarm message. Replacement of the device must be initiated. During the period until it is re- placed the annoying alarm can be "deleted"... - Page 58 Operation ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 59: Menu Mode: Operation And Setting

7. Menu mode: Operation and setting 7.1 Switching on and calling up the main menu When the device is connected to the power supply, the following information appears on the display for approx. 3 seconds. If the device has been without power for several days, the time and date must be reset. -

Page 60: Menu Overview Diagram

Menu mode: Operation and setting 7.2 Menu overview diagram The following diagram will help you to navigate through the menus: Exit Exit 1.History 1.Alarm/meas.values 2.Data logger 3.Config. logger 2.Changeover 4.Test data logger 3.History/Logger 5.Service logger Exit 1.Changeover 2.Voltage 3.Current 4.IT system 5.Relay 6.Digital Input 4.Settings... -

Page 61: Main Menu Functions

Menu mode: Operation and setting 7.3 Main menu functions Menu item Function Page Exit Exit menu mode 1. Alarm/meas.values Displays saved status messages, alarm messages and measured values 2. Changeover Displays information on the changeover function (number, test) 3. History/Logger Displays the history memory, data logger, config. -

Page 62: Menu 1: Alarm/Meas.values

Menu mode: Operation and setting 7.3.1 Menu 1: Alarm/meas.values Displays current status messages, alarm messages and measured values. The device shows the alarm status for each menu item: no alarm, alarm. Menu Meaning Exit Exit "Alarm/meas. values" menu; go up one menu level Line 1: Measured value mains voltage Line 1: 228V Line 2: Measured value mains voltage... -

Page 63: Menu 3: History/Logger

Menu mode: Operation and setting Menu Meaning Operating hours counter (h=hours, d=days, mo=months) In operation: xxh Number of changeovers performed which were carried out with overcurrent Changeover I>: xx of short-circuit current. These changeovers reduce the service life of the ATICS®... -

Page 64: Operating Example: History

"off" to "0". The last line contains an identification code for the type of modification (in this case: [4/1]). Channel 1 means that the first digital input has been changed. Please contact the Bender service and provide the identification number, when the modifica- tion led to an undesirable behaviour of the device. -

Page 65: Menu 4: Settings

"TEST" menu. Adjustable in each case: Change password, enable/disable password 12. Service These settings can only be made by authorised Bender service personnel. Retrieve information about the device status, enter settings for special oper- ating conditions and execute a firmware update. -

Page 66: Settings Menu 1: Changeover

Menu mode: Operation and setting 7.3.4.1 Settings menu 1: Changeover The times set in this menu determine the timing of a changeover. Also note the time charts on page 19 et seq. The following settings for the changeover are available: Menu Meaning Exit... - Page 67 Menu mode: Operation and setting Menu Meaning 6. SwitchBackLock Switching back interlocking function is switched on Switching back interlocking function is switched off Also refer to "Time diagram: Changeover between the preferred and the redun- dant line" on page 19. 7.

-

Page 68: Settings Menu 2: Voltage

Menu mode: Operation and setting 7.3.4.2 Settings menu 2: Voltage In this menu, you can adjust settings for monitoring the voltage on line 1 and line 2 individually or together. Example: Line 1 is set to "Undervolt: 184 V". If the voltage on line 1 falls below 184 V, the device displays an alarm message. -

Page 69: Settings Menu 3: Current

Exit settings menu "Current"; go up one menu level 1. Mode Current monitoring is switched on Current monitoring switched off 2. CT STW3 Bender measuring current transformer STW3 STW4 Bender measuring current transformer STW4 3. CT monitor CT connection monitoring is switched on CT connection monitoring switched off Note: External interference from loads can cause false tripping. -

Page 70: Settings Menu 4: It System

Menu mode: Operation and setting 7.3.4.4 Settings menu 4: IT system In this menu, you can adjust settings for IT system monitoring. Menu Meaning Exit Exit settings menu "IT system"; go up one menu level 1. Insulation Setting range: 50…250 kΩ Resolution of setting: starting at 5 kΩ... -

Page 71: Settings Menu 5: Relay

Menu mode: Operation and setting 7.3.4.5 Settings menu 5: Relay In this menu, you adjust settings for the mode of operation and function of the relay output (alarm re- lay) of ATICS-2-ISO. The function can be set for the relay as follows: alarm message, operational status message, generator start. -

Page 72: Settings Menu 6: Digital Input

Menu mode: Operation and setting Menu Meaning 8. Service interv Relay switches when service is due (interval elapsed). 9. Digital input Alarm digital input. To ensure that the relay responds to the digital input, the functions "ALARM" or "R-OPL" must be additionally set in the "Settings ->... - Page 73 Menu mode: Operation and setting Adjusting the settings: Meaning Menu Exit Leave the "Digital Input" settings menu; go up one menu level 1. Function Note: A parameter change may cause an immediate changeover. Digital input switched off Manual/Automatic. Manual mode means that automatic changeover can no longer take place.

-

Page 74: Settings Menu 7: Data Logger

Menu mode: Operation and setting 7.3.4.7 Settings menu 7: Data logger The settings for six data loggers of the device are adjusted in this menu. These data loggers (see "Menu 3: History/Logger" on page 63) display the history of measured values: Voltage line 1 Voltage line 2 Switch position of the transfer switching device... -

Page 75: Settings Menu 8: Language

Menu mode: Operation and setting Menu Meaning 2. Overwrite Once the maximum number of measured values which can be saved is reached, the current measured value overwrites the oldest entry. Once the maximum number of measured values which can be saved is reached, no further measured values are saved. -

Page 76: Settings Menu 10: Clock

Menu mode: Operation and setting Menu Meaning 4. Failure monitoring Indicates when communication with the BMS master has not been detected (anymore). The presence of a BMS master is not monitored. This setting is required when ATICS® is used as a "Stand-alone" device without BMS master. When this setting is selected, the conditions for functional safety (SIL2) are no longer met. -

Page 77: Settings Menu 11: Password

Menu mode: Operation and setting 7.3.4.11 Settings menu 11: Password The device has two separate passwords for the "Settings" menu and the "TEST" menu. Menu Meaning Exit Exit settings menu "Password"; go up one menu level 1. Settings Change the password for the "Settings" menu, switch the password "on/off". Fac- tory setting: Password: Status:... -

Page 78: Settings Menu 12: Service

Password protection is disabled. 7.3.4.12 Settings menu 12: Service Only Bender service personnel are authorised to make settings in the Service menu. It is only acces- sible to Bender service. In the Service menu, information about the device status can be called up and settings for specific operating conditions can be made. -

Page 79: Menu 5: Control

Line 2: Date, time Line 3: Address set on the BMS bus Line 4: Serial number of the device Line 5…8: Software versions of the four controllers of the device … Bender address, website … Exit. Exit standard information. ATICS-2-ISO_D00046_03_M_XXEN/08.2017... - Page 80 Menu mode: Operation and setting ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 81: Troubleshooting

8. Troubleshooting 8.1 Fault and alarm messages In the event of an alarm, the messages of ATICS® will enable you to narrow down the possible causes. Some messages may point to several causes. The following possible faults are indicated by messages on the ATICS®... -

Page 82: Messages With Error Code Or Service Code

BMS bus the "Fail- ure monitoring" (see "Settings menu 9: Interface" on page 75) must be deactivated. Service: __ (date) Reminder for next service - Agree date with Bender service. Functional test: Reminder for next test - Plan date for test. __ (date) - Run test. - Page 83 Changeover due to overcurrent or short - Have personnel assess the short-circuit circuit detected. These changeovers load. Contact Bender service. Alarm can reduce the life of the device. Currents be acknowledged (see "Reset menu 3: which are measured in excess of 130 times Changeover"...

-

Page 84: Frequently Asked Questions

3. Keep the article and serial number of the device to hand. 4. Speak to Bender Service, describe the type of fault and quote the three-digit error code. 8.2 Frequently asked questions A series of clicks is always heard at around noon. What does that mean? ATICS®... - Page 85 Why does writing back reports/backups lead to error messages? ATICS® can – like many Bender devices – be monitored and configured by means of a Bender gate- way CP700, COM46x… etc. The gateways are operated via a web user interface which is represented by means of an Internet browser.

- Page 86 Troubleshooting ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 87: Periodic Verification And Service

Time interval according to DIN VDE 0100-710 (VDE 0100 Part 710):2002-11: 6 months. Thereby the minimum requirements are satisfied. Bender recommends a monthly test to ensure that the operating personnel is familiar with the test- ing procedure in the event of a fault. -

Page 88: Maintenance

Periodic verification and service 9.2 Maintenance The ATICS® system does not contain any parts that must be maintained. Despite this, the intervals specified for periodic verification should be adhered to. We also recommend regularly checking the Allen screws at the ATICS® and the Torx® screws of the connectors on the incoming and outgoing lines of the automatic transfer switching device to make sure they are tight. -

Page 89: Replace Atics

Periodic verification and service Conditions for operation with the bypass switch Wiring must be carried out according to "Connection example: ATICS® with bypass switch" on page 33. The following settings are to be set in the "Settings menu 6: Digital input" menu: ... -

Page 90: Removing The Existing Atics

Periodic verification and service 9.5.1 Removing the existing ATICS® 1. Record settings on the existing ATICS®. The settings should match the entries on the checklist (see checklist in the appendix of this manual or, if necessary, update checklist). 2. Make device dead or switch on bypass switch. Switch existing ATICS® to manual mode and switch to switch position "0"... - Page 91 Periodic verification and service Remove the lower and upper terminal covers (E, F) by using a screwdriver to push back the locking hook located approximately in the middle of the cover in each case. Use a screwdriver to pull the lower yellow slide lock (G) downwards and raise the ATICS®...

- Page 92 Periodic verification and service Remove ATICS® from screw mounting Remove the lower and upper terminal covers (D, E) by using a screwdriver to push back the locking hook located approximately in the middle of the cover in each case. Undo the Allen screws of the terminals (F). Remove the green connectors (G) top and bottom.

-

Page 93: Installing A New Atics

Periodic verification and service 9.5.2 Installing a new ATICS® 1. Install ATICS®: "Mounting on DIN rail" see page 26 "Screw mounting on plate" see page 27 2. Connect ATICS® Insert bottom green plug connector (B) and secure with mounting screws. After that, insert top green plug connector (A) and secure with mounting screws. - Page 94 Periodic verification and service ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 95: Technical Data

10. Technical data 10.1 Tabular data Insulation coordination acc. to IEC 60664-1/IEC 60664-3 Overvoltage category ................................ III Pollution degree outside, inside ............................2 Rated insulation voltage..............................250 V Protective separation between ................Line 1 – Line 2; Line 1, 2, 3 – RS-485 ....................Line 1, 2, 3 –... - Page 96 Technical data IT system monitoring Insulation monitoring Nominal system voltage (operating range)....................80…275 V Measuring range ............................10 kΩ…1 MΩ Measurement method ....................AMP (adaptive measuring pulse) Response value (ALARM 1) ........................50…250 kΩ Relative uncertainty ..............................±15 % Hysteresis ................................≤ 25 % Response time = 0.5 x = 1 μF ....................≤...

- Page 97 Technical data Input Digital inputs ..................................1 Galvanic separation .................................yes Control ............................via potential-free contacts Mode of operation..................active at 0 V (low) or 24 V (high), adjustable Voltage range high/low.................... AC/DC 10…30 V/AC/DC 0…0.5 V Adjustable function ......switching back interlocking function, manual/automatic mode, bypass mode, .......................functional test, changeover to the preferred line, ................alarm input for operating theatre lights, alarm input for other devices Output...

- Page 98 Rated peak withstand current I (kA peak) Utilisation category acc. to DIN EN 60947 Type Ie AC-23A Ie AC-23B Ie AC-32A Ie AC-32B Ie AC-33B ATICS-2-63A-ISO 63 A 63 A 63 A 63 A 63 A ATICS-2-80A-ISO 80 A 80 A...

-

Page 99: Tüv Test Report According To Vde0100 Part 710

Technical data 10.2 TÜV test report according to VDE0100 Part 710 ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 100: Tüv Certificate Regarding Functional Safety

Technical data 10.3 TÜV certificate regarding functional safety ATICS-2-ISO_D00046_03_M_XXEN/08.2017... -

Page 101: Standards And Certifications

Technical data 10.4 Standards and certifications The transfer switching device conforms to the following standards: DIN VDE 0100-710 (VDE 0100 Part 710):2002-11* DIN VDE 0100-710 (VDE 0100 Part 710):2012-10* DIN VDE 0100-710 (VDE 0100 Part 710) supplement 1:2014-06 ... -

Page 102: Ordering Details

10.5 Ordering details Rated operatio Type Description Art. No. current ATICS-2-63A-ISO Two-pole transfer switching device AC 63 A B92057202 : AC 230 V, U : AC 230 V) with integrated IT system insu- lation, load and temperature monitoring, 1 dig. input, 1 relay output, short-circuit detection in the... -

Page 103: Additional Documents

Bypass switch set for ATICS® STW2, STW3, STW4 Measuring current transformers BMS bus Bender measuring device interface BMS-Ethernet gateway for the connection of the Bender measuring device interface to TCP/IP networks EDS150 Insulation fault locator EDS151 Insulation fault locator ... - Page 104 Technical data ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

-

Page 105: Index

Technical data 95 Monitoring 22 Temperature sensors 36 Test communication 54 Backup 85 Training courses 9 Bender service personnel 78 Transformers for the IT system 28 BMS bus (channel use) 42 Navigation 60 Troubleshooting 81 Class II - distribution board 36... - Page 106 INDEX ATICS-2-ISO_D00046_03_M_XXEN/08.2017...

- Page 108 Bender GmbH & Co. KG P.O. Box 1161 • 35301 Gruenberg • Germany Londorfer Straße 65 • 35305 Gruenberg • Germany Tel.: +49 6401 807-0 • Fax: +49 6401 807-259 E-mail: info@bender.de • www.bender.de Fotos: Bender Archiv.

Need help?

Do you have a question about the ATICS-2-63A-ISO and is the answer not in the manual?

Questions and answers