Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for formlabs Form 2

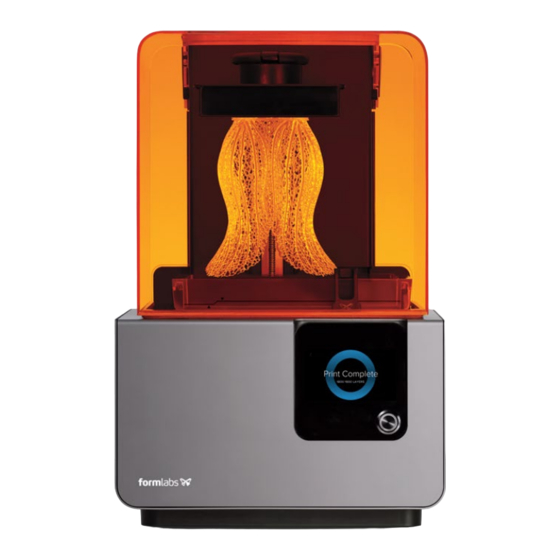

- Page 1 Installation and Usage Instructions Form 2 Desktop Stereolithography 3D Printer...

- Page 2 Installation and Usage Instructions Form 2 Desktop Stereolithography 3D Printer Original English instructions Please read this manual carefully and keep it for future reference. November 2018 REV 02 © Formlabs 1801099-IU-ENUS-0...

-

Page 3: Table Of Contents

Maintaining the Form 2 . . . . . . . . . . . . . . . . . . -

Page 4: Preface

Read and understand this manual and its safety instructions before using the you have any suggestions for improvements or amendments or have found Form 2. Failure to do so can result in serious injury or death. Keep all safety errors in this publication, please notify us. -

Page 5: Introduction

EU (FR) formlabs.com/fr/support/terms-of-service/eu/ Do not modify – The Form 2 is intended for use as-is. Modifying the printer without explicit approval and directions from Formlabs will invalidate your WARNING warranty, and could potentially ruin the machine and cause you bodily harm. -

Page 6: Technical Data

Sound Emission Does not exceed 70 dB(A). product terminology Radiation Information The Form 2 is a Class 1 Laser product. Accessible radiation is within Class 1 limits. Ethernet Connectivity RJ-45 Ethernet (10BASE-T/100BASE-TX) LAN Port Use a shielded CAT-5 Ethernet cable (not included). -

Page 7: Safety Warnings

The laser beam is harmful to the eyes, so avoid direct contact. The Form 2 contains used in accordance with the instruction manual, may cause harmful interference an interlock system to automatically shut off the laser when the cover is open. -

Page 8: Personal Protective Equipment (Ppe)

Depth: 43 cm Height: 76 cm manufacturer or supplier for detailed safety information. Allow additional space for accessories, such as the Form 2 Finish Kit, Form Wash, NOTICE and Form Cure. Carefully follow the safety instructions provided with the isopropyl alcohol that you purchase. -

Page 9: Connecting The Form 2

Manually slide the wiper mount to the center before removing a resin tank. The Form 2 must be completely level before printing can begin. If prompted, use NOTICE the leveling tool to raise or lower each foot of your printer. To level the Form 2: 4.3.4 Insert Build Platform 1. -

Page 10: Transporting The Form 2

Refer to the Technical Specifications for product weight and dimensions. Keep the pack- 1. Plug one end of the USB cable into the back of the Form 2. aging for transportation or shipping. The printer’s complete packaging kit consists of: 2. -

Page 11: Using The Form 2

7. Select which printer to upload the file to from the printer dialogue. 5.2.4 Confirm Print on Printer 1. From the home or print queue view, the Form 2’s touchscreen displays the FORM file’s upload in progress. 2. Select the file name. -

Page 12: Finishing

The Form 2 regulates the volume of resin in the tank through a sensor called the Move the part(s) to the second rinse bucket, then agitate and soak the °... -

Page 13: Emergency And Exceptional Situations

Checking and Maintaining the Resin Temperature handling of Formlabs materials. The Form 2 heats resin to a set temperature before starting. Resin is heated from the metal tank carrier below the resin tank, and the resin temperature is In an emergency involving resin, always refer to the safety data sheet (SDS) sensed by an infrared sensor behind the resin tank. -

Page 14: Maintaining The Form 2

Form 2. The Form 2 shall only be WARNING Shell Inspect the Shell 6.4.8 maintained by a qualified and trained person. Do not open the Form 2 and/ Shuttle Cover Inspect the Shuttle Cover 6.4.9 or investigate internal components unless under the guidance of Formlabs... - Page 15 Open to begin uploading the firmware file onto the Form 2. lead to print failures or inaccuracies. 9. Once the firmware upload is complete, follow the prompts on the Form 2 2. Carefully lift the tank using an overhand grip on the tank grips. Tilt the tank—...

- Page 16 To clean the standard Resin Tank: 6.2.4 Resin Tank LT: Maintenance and Care • Print failures: For detailed guidance and visual assistance, search on support.formlabs.com. Remove and discard any print failures by hand or with the scraper. To inspect the Resin Tank LT interior: °...

-

Page 17: Inspection Tasks Between Prints

Inspecting Resin Tank and Resin Tank LT Exterior 1. Press the vent cap closed. See 6.2 Planned Maintenance Procedures. 2. Hold the cartridge handle and lift to remove from the Form 2. 6.4.3 Protect the ID Chips on the Resin Tank and Resin Cartridge... - Page 18 3. Inspect the optical surface for dust, oil streaks, fingerprints, or cured resin. paper towels. Oil streaks appear as a blue or purple haze. In the case of a crack in the shuttle cover, contact Formlabs or a certified distributor. To clean the glass optical window: 6.4.10 Inspect the Z-Axis 1.

-

Page 19: Troubleshooting And Repair

After experiencing any error or out of the resin tank until the resin is purely liquid. unusual behavior on the Form 2, include the diagnostic logs with other relevant 3. Filter the resin observations and details when contacting Formlabs Support. -

Page 20: Troubleshooting And Repair By Non-Skilled Persons

Provide clear, focused photographs of the test print to help diagnose the issue. Troubleshooting and Repair by Non-Skilled Persons In the case of an error or abnormal activity with the Form 2, reference the following Error Cause Solution errors, causes, and proposed solutions. - Page 21 • Check that the resin cartridge bite additional prints. • To delete all prints on the Form 2, open valve does not leak. Print with a the touchscreen’s Settings menu, different resin cartridge to try to select Storage, then select Delete replicate the issue.

-

Page 22: Troubleshooting And Repair By Skilled Persons

Disposal Troubleshooting and Repair by Skilled Persons All steps that involve opening the Form 2 and/or investigating internal components should be done by skilled persons under the guidance of WARNING Formlabs or a certified distributor. Disassembly The following tools, equipment, and materials are needed for reparation tasks:... -

Page 23: Index

Technical Specifications Index Dimensions 35 × 33 × 52 cm amber cover 28, 41 maintenance 1, 20, 21, 22, 23, 25, 26, 27, 32, 13.5 × 13 × 20.5 in Weight 13 kg bite valve 11, 26, 32, 34, 40 28.5 lbs build platform 7, 11, 13, 15, 16, 18, 27, 28, 29, 33, Open Mode 18 34, 35, 40, 41, 42 operation 1, 6, 7, 19... -

Page 24: Glossary

This flexible seal regulates resin dispensing. Resin flows out when the Laser The laser is the source of curing energy in the Form 2. It has a 405 nm cartridge dispense arm squeezes the valve open. violet diode and a maximum output of 250 mW. The Form 2 is a Build Platform The aluminum base provides a surface for prints to attach to. - Page 25 The LCD displays print information, settings, and error messages. It serves as the user interface for the Form 2. USB Port The Form 2 can connect to a computer via USB. The port is connected to the motherboard and can be accessed from the back of the machine.

Need help?

Do you have a question about the Form 2 and is the answer not in the manual?

Questions and answers