Table of Contents

Advertisement

Quick Links

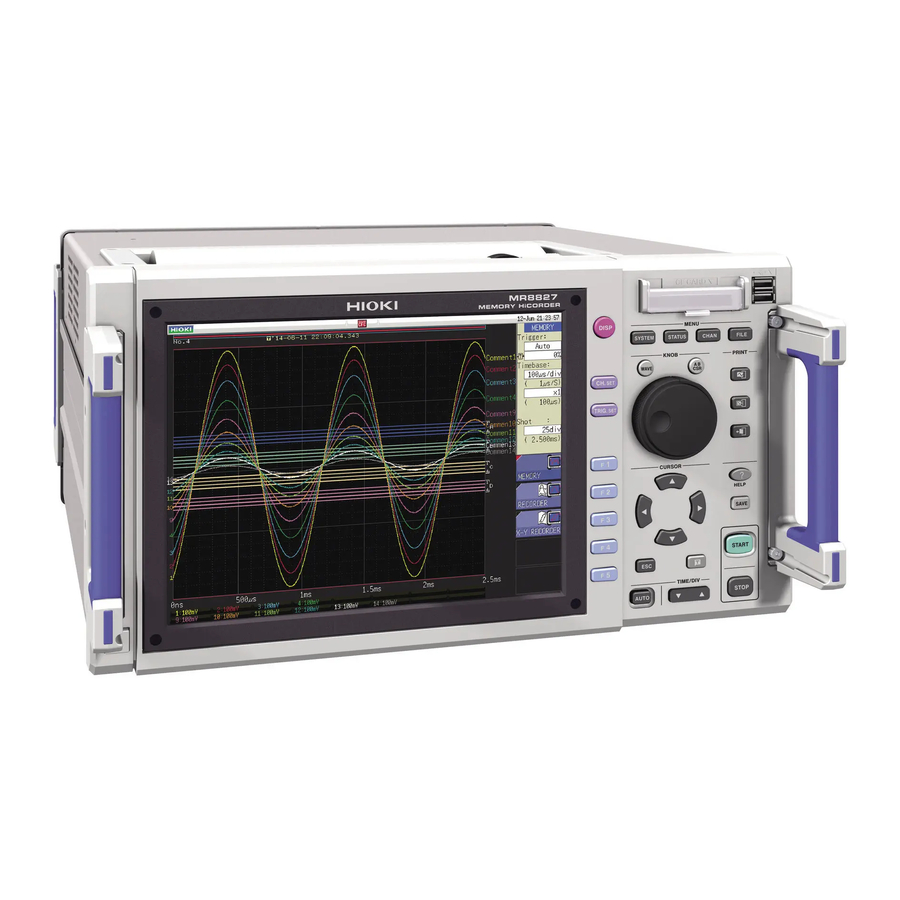

MR8827

MEMORY HiCORDER

Be sure to read this manual

before using the instrument.

When using the instrument

for the first time

Part Names and Functions

Measurement Preparation

Oct. 2018

Revised edition 4

MR8827A981-04

18-10H

Safety Information

Troubleshooting

Maintenance and Service

p.16

Error Messages

p.25

Instruction Manual

p.3

p.383

p.389

EN

Advertisement

Table of Contents

Summary of Contents for Hioki MR8827

- Page 1 MR8827 Instruction Manual MEMORY HiCORDER Be sure to read this manual Safety Information p.3 before using the instrument. When using the instrument Troubleshooting for the first time Part Names and Functions Maintenance and Service p.383 p.16 Measurement Preparation Error Messages p.25...

-

Page 2: Table Of Contents

Contents Contents Usage Index ..........1 Start and Stop Measurement ..68 Introduction ..........2 Measurement With Automatic Package Contents ........2 Range Setting (Auto-ranging Safety Information ........3 Function) ......... 70 Operation Precautions ......6 X-Y Recorder Function 71 Overview 4.1 Measurement Workflow .... - Page 3 Contents Set the Waveform Position Waveform Screen (Variable Function) ....... 158 Monitoring and Fine Adjustment of Input Values Analysis (Vernier Function) ......161 Invert the Waveform (Invert Function) ......162 Read Measurement Values Copy Settings to Other (Using the AB Cursors) ....122 Channels (Copy Function) ..

- Page 4 Contents 13.3.8 Emphasize Analysis Results (Phase Numerical Calculation Spectra Only) ..........255 Functions 13.3.9 Analysis Mode Settings ......256 13.3.10 Set the Display Range of the Vertical Axis (Scaling) ............ 260 10.1 Numerical Calculation Workflow 210 13.3.11 Set and Change Analysis Conditions on 10.2 Numerical Value Calculation the Waveform Screen ........

- Page 5 Contents 16.2.3 Operate the Instrument With an Internet 18.6.8 Model 8973 Logic Unit ....... 370 Browser ............. 317 18.6.9 Model MR8990 Digital Voltmeter Unit ..371 16.3 Access Files on the Instrument 18.6.10 Model U8974 High Voltage Unit ....373 18.6.11 U8793 Arbitrary Waveform Generator Unit .

-

Page 6: Usage Index

Usage Index Usage Index Basic Measurement Workflow 1 Install (p. 25) Measuring with automatic range setting Install this instrument (p. 70) To install a module Catching Changes in Input Signals (p. 187) Connect cables Applying a Manual Trigger (p. 200) Insert recording paper* Adding Comments (p. -

Page 7: Introduction

Introduction Introduction Thank you for purchasing the HIOKI MR8827 Memory HiCorder. To obtain optimal performance from this instrument, please read this manual and keep it handy for future reference. The optional clamps (p. A9) are called by a generic name of “clamp sensor.”... -

Page 8: Safety Information

Safety Information Safety Information This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment. However, using the instrument in a way not described in this manual may negate the provided safety features. Before using this instrument, read and understand the following safety notes. - Page 9 Safety Information Symbols Affixed to the Instrument Indicates cautions and hazards. When this symbol is printed on the instrument, refer to the corresponding topic in this Instruction Manual. Indicates the ON or OFF side of the power switch. Indicates a grounding terminal. Indicates AC (Alternating Current).

- Page 10 Safety Information Accuracy We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and setting values, with the following meanings: f.s. (maximum display value The maximum displayable value or scale length. or scale length) For this instrument, the maximum displayable value is the range (V/div) times the number of divisions (20) on the vertical axis.

-

Page 11: Operation Precautions

• Verify that the instrument operates normally to ensure that no damage occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or reseller. Instrument Installation WARNING To avoid accidents or damage to the instrument, do not install the instrument in locations that are: •... - Page 12 If you lose any screw or find that any screws are damaged, please contact your Hioki distributor for a replacement. CAUTION • To avoid damage to the instrument, protect it from physical shock during transport and handling.

- Page 13 Operation Precautions Handling the Printer and Recording Paper WARNING The print head and surrounding metal parts can become hot. Be careful to avoid touching these parts. CAUTION Be careful not to cut yourself with the paper cutter. • Please use only the specified recording paper. Using non-specified paper may not only result in faulty printing, but printing may become impossible.

- Page 14 Be sure to back up any important data stored on the built-in drive (SSD) or removable media. • Use only CF Cards sold by Hioki. (No adapter will be required when the card is inserted into the instrument.) •...

- Page 15 Operation Precautions Before Connecting Cables DANGER When measuring power line voltage • Connecting cables should only be connected to the secondary side of a breaker Even if there is a short circuit on the secondary side of the breaker, the breaker cuts off the electric supply.

- Page 16 Operation Precautions Before Connecting a Logic Probe to the Measurement Object DANGER To avoid electric shock and short circuit accidents or damage to the instrument, confirm the following: • The ground pin in the LOGIC connector (plug) of Models 9320-01 and 9327 Logic Probes is not isolated from the instrument’s ground (common ground).

- Page 17 Operation Precautions Before Connecting to an External Device DANGER To avoid electrical hazards and damage to the instrument, do not apply voltage that exceeds the maximum input voltage to the external control terminals. I/O terminals Maximum input voltage Instrument START/.IN1 -0.5 V to 7 V DC STOP/IN2 -0.5 V to 7 V DC...

- Page 18 • Keep discs inside a protective case and do not expose to direct sunlight, high temperatures, or high humidity. • Hioki is not liable for any issues your computer system experiences in the course of using this disc. When the Instrument is Not Used for a Long Period •...

- Page 19 Operation Precautions...

-

Page 20: Overview

1.1 Product Overview The MR8827 Memory HiCorder is an instrument that allows simultaneous measurement of multiple signals. The MR8827 is easy to operate and allows quick and efficient measurement and analysis. Its major uses are monitoring, facility diagnosis and various tests. -

Page 21: Part Names And Functions

Part Names and Functions 1.2 Part Names and Functions Front Side USB connector (Type A) Connect USB memory stick and Model U8350 Printer Unit USB mouse here. (p. 40) Handle Handle (Optional) CF card slot POWER switch (p. 45) Display Operation key (p. - Page 22 Part Names and Functions Operation Keys SYSTEM Displays the System screen (p. 305) DISP STATUS Displays the Waveform screen Displays the Status screen CHAN WAVE Displays the Channel screen (Lights up in red when selected) FILE Assigns the jog and shuttle Displays the File screen (p.

- Page 23 Part Names and Functions PRINT Prints waveforms and lists (p. 107) COPY Prints a hard copy of the display screen (p. 118) FEED Feeds paper HELP Opens help information (p. 22) SAVE (Lights up in blue while media is being accessed.) Saves data to storage media.

-

Page 24: Screen Organization

Screen Organization 1.3 Screen Organization The screen configuration is as listed below. Each screen or window appears when the listed key is pressed. The trigger settings window and channel settings window can be brought up on the Waveform screen. Waveform Screen Use this screen to view the waveform. - Page 25 Screen Organization Explanation of Screen Contents Waveform Screen Title comment Trigger time Media icon Current date and time Shows the specified Shows the date and Shows the media Shows the internal clock title comment. time of the last trigger status. (p. 40) date and time.

-

Page 26: Basic Key Operations

Basic Key Operations 1.4 Basic Key Operations CURSOR Press the key and move the cursor to the item you want to change. Cursor Check the interface and press the function key ( key) for the setting you want to change. The assignment of the keys is different for each item. - Page 27 Basic Key Operations 1.4.1 Using the HELP Key When you press the Help key a simple explanation will appear at the cursor position. Cursor Position Help Move the cursor to the item for which you want to display help. HELP [Cursor Pos Help] Press the key.

-

Page 28: Use A Mouse To Perform Key Operations

Basic Key Operations 1.4.2 Use a Mouse to Perform Key Operations You can use a commercially available USB mouse to perform the same operations as the keys on the instrument. • There are a variety of mice available, and not all devices will work with the instrument. •... - Page 29 Basic Key Operations The operation keys of the instrument and the menu displayed when you right-click the mouse are related as follows: To operate and carry out settings for CH.SET, WAVE, and AB CSR click the icons displayed when a mouse is connected.

-

Page 30: Measurement Preparation

Measurement Preparation Procedure (p. 6) Install this instrument Install or remove modules (p. 26) (When adding or replacing modules) Connect logic probes to the Standard (p. 28) LOGIC terminals (When measuring logic signals) Connect connection cables to the module (p. 28) (When measuring analog signals) Probes and cables will differ depending on the type of measurement being performed. -

Page 31: Install Or Remove Modules

Install or Remove Modules 2.1 Install or Remove Modules Read “Handling the Instrument and Modules” (p. 7) carefully. Modules specified when the instrument is ordered are supplied preinstalled. Use the following procedures to add, replace, or remove modules from the instrument. •... -

Page 32: X84; Channel Allocation

Install or Remove Modules Channel Allocation Module number one is at the top, and channel number one is at the top left. Information about the modules installed in the instrument can be verified in the System Configuration list. (p. 395) Module 1 Module 9 CH17... -

Page 33: Connection Cables

Connection Cables 2.2 Connection Cables Measuring voltage Read Refer to “Before Connecting Cables” (p. 10). carefully. For detailed precautions and instructions regarding connections, refer to the instruction manuals for your modules, connection cables, etc. Connect with: connection cables Applicable Modules •... - Page 34 Connection Cables Measuring Frequency, Number of Rotations and Count Refer to p. 28 for details about connecting to BNC terminals. Connect with: connection cables Applicable Modules • Model 8970 Freq Unit • Model L9197 Connection Cord (Maximum input voltage: 600 V) Large alligator clip type Connect to the BNC jack on a module.

- Page 35 Connection Cables Measuring temperature Connect with: thermocouples Applicable Modules Thermocouple Connect to terminal block • Model 8967 Temp Unit (Compatible wire: 0.4 mm to 1.2 mm diameter) Connect to the terminal block on the module. To Connect to the Terminal Block Required device and tool: 25 mm Thermocouple, flat-blade screwdriver (2.6-mm...

- Page 36 Measuring vibration or displacement with a strain gauge transducer The following device can be connected to the module. Applicable Module • Strain gauge transducer (Not available from Hioki) • Model U8969 Strain Unit • Model 8969 Strain Unit Connect L9769 or 9769 Conversion Cable to the strain gauge transducer.

- Page 37 Connection Cables Connector pin-out Model L9769 Conversion Cable Model U8969 Strain Unit (Strain gauge transducer end) Applied voltage: bridge voltage of 2 V The metal shell is connected to The metal shell is connected to the GND of the instrument. the GND of the instrument.

- Page 38 Connection Cables Example: Connecting the strain gauge transducer to Model 8969 Strain Unit via Model 9769 Conversion Cable 8969 Strain Unit Required items: Model 9769 Conversion Cable, strain gauge transducer Connect Model 9769 to a connector on the module. Insert the connector of Model 9769 with the orange part facing upward.

- Page 39 Connection Cables Measuring current Connect with: Clamp sensors Applicable Modules • Model 8971 Current Unit • Model 9272-10 Clamp on Sensor • Models 9709, CT6862, CT6863, CT6865 Connect Model 9318 Conversion Cable to AC/DC Current Sensor • Models CT6841, CT6843, the module jack.

- Page 40 Connection Cables Measuring logic signals Read “Before Connecting a Logic Probe to the Measurement Object” (p. 11) carefully. For more information about logic probe specifications, see the instruction manual that came with the logic probe you plan to use. Connect with: Logic Probes Applicable Modules •...

- Page 41 Connection Cables Measuring voltage with a high degree of accuracy (Digital Voltmeter) Connect with: Model L2200 Test Leads Applicable Modules • Model MR8990 Digital • Model L2200 Test Lead Voltmeter Unit (Maximum input voltage: 1000 V) Connect to the banana jacks on a module. To Connect to Banana Jacks Required tools: Test leads above Connect the test leads...

- Page 42 Connection Cables Measuring high voltage Required item: Model L4940 Connection Cable Set Applicable Module • Model L4940 Connection Cable Set: • Model U8974 High Voltage (Maximum input voltage: 1000 V) Unit Connect to the banana jacks on a module. To Connect to Banana Jacks Required items: Connect the Connection cable Model L4940 Connection Cable Set...

- Page 43 Connection Cables Output Waveform Required item: Model L9795-01 / Applicable Modules L9795-02 Connection Cable • Model U8793 Arbitrary Waveform Generator Unit • Model L9795-01 Connection Cable (Electrical clips) • Model MR8790 Waveform Generator Unit Connect to the SMB jack on a module. •...

- Page 44 Connection Cables Output Pulse Waveform Required items: Commercially available cable Applicable Module (Half-pitch 50 pins) • Model MR8791 Pulse Generator Unit To Connect to Output Connector Output connector Required items: Commercially available cable Connect the connection cable to Output Connector of module. Connect the connection cable to the object to Connect the Connection cable which the waveform is being applied.

-

Page 45: Prepare Storage Media

Prepare Storage Media 2.3 Prepare Storage Media Read “Handling Media” (p. 9) carefully. 2.3.1 Storage Media (Inserting a CF Card and USB Memory Stick) Media icons Icons indicating the status of storage media are always shown at the top of the screen. : Media is inserted CF card Built-in... - Page 46 Prepare Storage Media Storage media Insertion procedure and notes • Do not connect any devices other than USB memory sticks. • Not all commonly available USB memory sticks are supported. • To use a USB memory stick, suitable unit settings must be made, as described next page. Front side To insert a USB memory stick USB Memory...

-

Page 47: To Format Storage Media

Prepare Storage Media 2.3.2 To Format Storage Media Possible targets for formatting are CF card, USB memory stick, built-in drive, and internal memory. During the formatting process, a folder named “HIOKI_MR8827” will be created. Note that formatting storage media deletes all the information on the storage media and deleted information is unrecoverable. -

Page 48: Load Instrument With Recording Paper (When Model U8350 Printer Unit Is Installed)

Load Instrument With Recording Paper (When Model U8350 Printer Unit is installed) 2.4 Load Instrument With Recording Paper (When Model U8350 Printer Unit is installed) Read “Handling the Printer and Recording Paper” (p. 8) carefully. Procedure Required items: Model MR9231 Recording Paper, Paper roll axle (Supplied with the instrument) Press the button to open the printer cover. -

Page 49: Power Supply

Power Supply 2.5 Power Supply Read “Before Turning the Power Supply On” (p. 11) carefully. 2.5.1 Connect the Power Cord Procedure Connect the power cord to the power inlet on the instrument. Back side Plug the power cord into the mains outlet. 2.5.2 Ground the Functional Earth of This Instrument When measuring in a noisy environment, you can improve the noise immunity... -

Page 50: Turn The Power On And Off

Power Supply 2.5.3 Turn the Power On and Off Turn Power On Press the power switch. Front side The startup screen appears first, then the Waveform screen is displayed. Power switch Before Starting Measurement To obtain precise measurements, allow about 30 minutes for warm-up after turning power on to allow the internal temperature of the modules to stabilize. -

Page 51: Set The Clock

Set the Clock 2.6 Set the Clock Set date and time for the built-in clock as follows. The clock has an automatic calendar with leap year correction and 24-hour format. The functions listed below make use of the clock. Ensure that the clock is set correctly before using these functions. -

Page 52: Adjust The Zero Position (Zero-Adjust)

Adjust the Zero Position (Zero-Adjust) 2.7 Adjust the Zero Position (Zero-Adjust) This procedure compensates for module differences and sets the reference potential of the instrument to 0 V. The compensation procedure is performed for all channels and ranges. Before Performing Zero-Adjust •... -

Page 53: Perform Calibration (When Model Mr8990 Is Installed)

Perform Calibration (When Model MR8990 is installed) 2.8 Perform Calibration (When Model MR8990 is installed) This procedure compensates for MR8990 Digital Voltmeter Unit differences. The compensation procedure is performed for all channels and ranges. Before Performing Calibration • Before performing this procedure, allow the equipment to warm up for about 30 minutes after the power is turned on so the internal temperature of the modules can stabilize. -

Page 54: Measurement

Measurement 3.1 Measurement Workflow 1 Pre-measurement Inspection Refer to “3.2 Pre-measurement Inspection” (p. 51). 2 Basic Measurement Settings Refer to... Select a suitable recording method for the “3.3.1 Measurement Function” (p. 52) measurement target “3.3.2 Timebase and Sampling Rate” Set sampling rate (p. - Page 55 Measurement Workflow 5 Start Measurement Refer to... “3.5 Start and Stop Measurement” (p. 68) “5 Save/Load Data and Manage Files” (p. 77) “6 Printing (When Model U8350 Printer Unit is installed)” (p. 107) “7.1 Read Measurement Values (Using the AB Cursors)” (p. 122) “7.3.2 Scroll With Jog and Shuttle Knobs (Scroll)”...

-

Page 56: Pre-Measurement Inspection

3.2 Pre-measurement Inspection Verify that the instrument operates normally to ensure that no damage occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or reseller. (1) Peripheral Device Inspection When using probes and connection cables... -

Page 57: Measurement Configuration

Measurement Configuration 3.3 Measurement Configuration Set measurement conditions as follows. You can immediately verify the effect of settings on the waveform by calling up the Waveform screen and using the Settings window to make basic settings. Basic settings can also be made by calling up the [Status] Status screen and selecting the sheet. - Page 58 Measurement Configuration Recorder Function Values With the Recorder function, each data sample consists of the maximum and minimum values acquired in the specified sampling rate. This means that each data sample has its own amplitude breadth. 1 2 3 4....100 One Sample Maximum value...

-

Page 59: Timebase And Sampling Rate

Measurement Configuration 3.3.2 Timebase and Sampling Rate The timebase setting establishes the rate of input signal waveform acquisition, specified as time-per- division on the horizontal axis (time/div). The sampling setting specifies the interval from one sample to the next. (The sampling rate is shown in brackets under the timebase for the Memory function (see illustration at right). - Page 60 Measurement Configuration To select the timebase Refer to the table below when setting the timebase. For example, to measure a 100 kHz waveform, the maximum display frequency setting range according to the table is 200 kHz - 800 kHz. If the maximum display frequency is set to 400 kHz, setting the time axis range to 10 μs/div is recommended.

- Page 61 Measurement Configuration The sampling rate is automatically set to 1/100 of the selected timebase. If MR8990 Digital Voltmeter Unit is installed, that channel's sampling rate is automatically set to 1/50 of the selected timebase. Example: When 8966 is installed as unit 1 (CH1 and CH2) and MR8990 as unit 2 (CH3 and CH4), and the timebase is set to 1 s/div Sampling rate of unit 1 (8966): 10 ms Sampling rate of unit 2 (MR8990): 20 ms...

-

Page 62: Recording Length (Number Of Divisions)

Measurement Configuration 3.3.3 Recording Length (Number of Divisions) Set the length (number of divisions) to record each time data is acquired. Procedure DISP Press the key to open the Waveform screen. With the Memory Function Move the cursor to [Shot]. Select the type. - Page 63 Measurement Configuration Recording Length and Data Samples Each division of the recording length consists of 100 data samples. The total number of data samples for a specified recording length is: Set recording length (divisions) × 100 + 1. However, if the MR8990 Digital Voltmeter Unit is installed, the number of data samples is as follows. •...

-

Page 64: Screen Layout

Measurement Configuration 3.3.4 Screen Layout You can specify the format in which the input signal is shown on the Waveform screen. This setting will also affect how the waveform will be printed. Selecting X-Y1 screen or X-Y4 screen allows waveform X-Y synthesis. (This applies to the Memory and X-Y Recorder functions.) Refer to “7.4 Perform Waveform X-Y Synthesis”... -

Page 65: Select Input Channels

Select Input Channels 3.4 Select Input Channels Set which channels are analog and logic. To Open the Channel Settings Window Refer to “Variable Function Settings for All Channels” (p. 160). CH.SET Pressing repeatedly cycles through the available sheets. [Analog] [Variable] [Logic] [WaveCalc] (When [Wave Calculation] is... -

Page 66: Channel Setting Workflow

Select Input Channels 3.4.1 Channel Setting Workflow The workflow below shows how to choose settings for analog channels (CH1 to CH32). 1 Input and screen display related settings Refer to... Select input coupling (p. 63) Match range to measurement target input value (p. - Page 67 Select Input Channels • When input coupling is set to GND, the waveform will have no amplitude and you cannot set the range. • Due to the influence of filter attenuation, correct range setting may not be possible. • When choosing trigger settings, set the vertical axis (voltage axis) range first. If the range is changed after specifying the trigger, the trigger setting may change.

-

Page 68: Choose Analog Channel Settings

Select Input Channels 3.4.2 Choose Analog Channel Settings For information about specific settings for Model 8967 Temp Units, 8969 Strain Unit, U8969 Strain Unit, 8970 Freq Unit, 8971 Current Unit, 8972 DC/RMS Unit, MR8990 Digital Voltmeter Unit, and U8974 High Voltage Unit, refer to “8.10 Detailed Settings for Modules”... - Page 69 Select Input Channels 4. Vertical Axis Vertical axis (voltage axis) zoom-up or zoom-down settings can be selected separately for each channel. These settings will be used for display and printout. (Voltage Axis) Zoom is based on the zero position. The measurement resolution does not change. Zoom Refer to “7.5.3 Vertical Axis (Voltage Axis) Magnification”...

- Page 70 Select Input Channels Zoom factor Module ×1/10 ×1/5 ×1/2 ×1 ×2 ×5 ×10 ×20 ×50 ×100 Model 8966 (Analog) Model 8971 20000 10000 4000 2000 1000 (Current) (4000) (4000) Model 8972 (DC/RMS) Model 8967 200000 100000 40000 20000 10000 4000 2000 1000 (Temperature)*...

-

Page 71: Logic Channel Settings

Select Input Channels 3.4.3 Logic Channel Settings The channel settings window (Logic sheet) is shown when the display format is 1, 2, 4, 8 or 16 screens. Procedure DISP CH.SET Press the key to open the Waveform screen, and then press the key to open the channel settings [Logic] window (... -

Page 72: Displayed Sheet

Select Input Channels 3.4.4 Displayed Sheet The input channel settings can be set differently for each displayed sheet. Up to four sheets can be set. You can set desired waveforms for displaying to different sheets and switch them. Sheet switching (1 to 4) •... -

Page 73: Start And Stop Measurement

Start and Stop Measurement 3.5 Start and Stop Measurement Procedure DISP Press the key to open the Waveform screen. To Start Measurement START Press the key to start measurement. • When a measurement is started, waveform data displayed on the screen is cleared. •... - Page 74 Start and Stop Measurement Measurement and Internal Operations Measurement methods are normal measurement (start recording when measurement starts) and trigger measurement (start recording when trigger criteria are satisfied). In this manual, “Measurement start” START means when you press the key and “Recording start” means when recording begins on the waveform screen.

-

Page 75: Measurement With Automatic Range Setting (Auto-Ranging Function)

Measurement With Automatic Range Setting (Auto-ranging Function) 3.6 Measurement With Automatic Range Setting (Auto-ranging Function) This applies only to the Memory function and analog modules. AUTO [Auto Range] When you press the key after inputting a signal to an analog unit, and select , the horizontal axis range (timebase), vertical axis (voltage axis) range, and zero position will be selected and measurement started, all automatically. -

Page 76: Y Recorder Function

X-Y Recorder Function • The X-Y waveform generated from the input signal is displayed in real time. • By saving the displayed data in memory, data can be stored as well as printed. • Similar to an X-Y pen recorder, waveform drawing can be controlled by simulated pen up/down operation. -

Page 77: Measurement Workflow

Measurement Workflow 4.1 Measurement Workflow 1 Pre-measurement Inspection Refer to “3.2 Pre-measurement Inspection” (p. 51). 2 Basic Measurement Settings Refer to... Select X-Y recorder as measurement function “Function” (p. 73) Set sampling rate “Sampling” (p. 73) Determine screen layout format “Format”... -

Page 78: Measurement Configuration

Measurement Configuration 4.2 Measurement Configuration STATUS To set measurement parameters, press the key to bring up the Status screen and select [Status] sheet. (Settings for measurement function and sampling rate can also be made on the Waveform screen.) Setting Descriptions Function Set the measurement function to X-Y recorder. -

Page 79: Start And Stop Measurement

Start and Stop Measurement 4.3 Start and Stop Measurement DISP Press the key to go to the Waveform screen. Start measurement. START Press the key to start measurement. Set the pen to Up/Down. This setting can be chosen before or during measurement. When the pen is set to Down, the waveform is being drawn. -

Page 80: Waveform Observation

Waveform Observation To Redraw With Different Waveform Display Settings • After clearing the waveform display, waveform data is still retained by the unit. This makes it possible to change the settings for display format, display color, synthesis channels, channel [Redraw] [Redraw] zoom and offset before redrawing the waveform by selecting . - Page 81 Start and Stop Measurement...

-

Page 82: Save/Load Data And Manage Files

Save/Load Data and Manage Files This chapter explains how to save and load data and manage files on your Hioki Memory HiCorder. [File Save] Before saving data, configure the save settings on the sheet. You can load data and manage files from the File screen. - Page 83 To Open the File Screen Indicated the order in which the files are displayed. r: Ascending order s: Descending order Press this key. The selected file is indicated by a flashing cursor. Use the Right/left CURSOR keys to move between folder levels. Use the Up/down CURSOR keys to select files.

-

Page 84: Data That Can Be Saved And Loaded

Data That Can Be Saved and Loaded 5.1 Data That Can Be Saved and Loaded : Possible, —: Not possible Save File File type Icon File extension and description Load PC readable format Auto Manual Settings data (Measurement Settings data Binary —... - Page 85 Data That Can Be Saved and Loaded ® This is a standard Windows graphics format. Files in this format can be handled by many graphics programs. It is possible to print out loaded waveforms with text files created on a PC. Other processing operations are not available.

-

Page 86: Save Data

Save Data 5.2 Save Data 5.2.1 Save Types and Workflow There are basically three types of save operations. To automatically save data To save data manually with the SAVE key (p. 88) during measurement (p. 82) Save data immediately Select data and save Auto-save Quick Save Selection Save... -

Page 87: Automatically Save Waveforms

Save Data 5.2.2 Automatically Save Waveforms This function acquires measurement data for the recording length then saves the waveform data automatically. The save location and data to be saved must be selected before measurement starts. Procedure Press the SYSTEM key to open the System screen. → [File Save] sheet Enable auto-save. - Page 88 Save Data Set the file name. Move the cursor to [Save Name], and enter a file name. Refer to “8.1.3 Alphanumeric Input” (p. 143). When [LAN] is set as the save destination, [Save Name] is ignored and the files will be named in the previously-determined format.

- Page 89 The number of data items is reduced to 1/2 the original amount. Save destination Data can also be saved to a USB flash drive in real time, but for data protection we recommend using Hioki’s optional CF card instead. Select the channels to save. [Save Ch].

- Page 90 Save Data Set the save method for when the storage media runs out of space. Move the cursor to [Save method]. Normal Automatic saving stops when the storage Save media is full. Delete Old files are deleted and automatic saving Save is continues when the storage media is full.

- Page 91 Folder name will be in the HIOKI_ “AUTO + hours/minutes/seconds.” Up to 5,000 files MR8827 folder (Example: 1:45:30) Save method Delete Save Folder to save Off When the number of files in the folder has reached 5,000, or when the storage media is full, files in the AUTO014530 folder (or specified folder) will automatically be deleted in sequence, starting from the oldest file, and replaced by new files.

- Page 92 Waveform files Specified folder WAVE123015.MEM 192.168.1.1 14-01-10 HIOKI 9333 WAVE123245.MEM Folder name will be Model 14-01-11 MR8827 IP WAVE123245.TXT address. File names will be “WAVE + hours/ Folder names minutes/seconds.” will be “YY-MM-DD.” Numerical calculation files PARAMETER.TXT 14-01-20 PARAMETER_1.TXT...

-

Page 93: Save Data Selectively (Save Key)

Save Data 5.2.3 Save Data Selectively (SAVE Key) To use the SAVE key for quick saving, you first need to set the saving conditions. The following types of data can be saved: setting data, waveform data, display screens, waveform screen, and numerical calculation results. - Page 94 Save Data Set the file name. Move the cursor to [Save Name], and enter a file name. Refer to “8.1.3 Alphanumeric Input” (p. 143). When [LAN] is set as the save destination, [Save Name] is ignored and the files will be named in the previously-determined format.

- Page 95 Save Data Set to save. Move the cursor to [Save Type]. Save the settings data. Wave Binary Save waveform data in binary format. Select this to be able to reload the waveform on the instrument. Wave Text Save waveform data in text format. Select this to use the waveform data on a PC.

- Page 96 Save Data Advanced settings Available settings will differ depending on the save type. Save Settings Description types Setting Wave Division (Off, 16 M, 32 M, 64 M) Binary Select this to divide large files into several files when saving. A folder with the specified name will be created and data saved as multiple files in that folder.

-

Page 97: Save Waveform Output Data To The Media

Save Data 5.2.4 Save Waveform Output Data to the Media The pulse pattern data registered in Model MR8791, arbitrary waveform data registered in Model U8793, or program data is saved in the media. Before attempting to save the data, make sure that the storage media is inserted and the loading target is correctly specified. -

Page 98: Load Data

Load Data 5.3 Load Data Data saved on storage media or in the internal memory of the instrument can be reloaded. Load Data Workflow Before attempting to load data, make sure that the storage media is inserted and the loading target is correctly specified. - Page 99 Insert the storage media before selecting the media. Other limitations • Data saved with Memory HiCorders other than the MR8827 cannot be loaded. • When loading waveform data, the settings for the unit will change to the same settings as when the data was saved.

- Page 100 Load Data Batch Load of Waveform Data When the following index files are loaded, waveform data can be loaded as a batch. With the following settings, index files are created along with waveform files. Extension Explanation Divided files are loaded together. (To create index files, use [Division] on the...

-

Page 101: Automatically Load Settings (Auto-Setup Function)

Automatically Load Settings (Auto-setup Function) 5.4 Automatically Load Settings (Auto-setup Function) When settings are saved as described below, they can be loaded automatically at power-up. The auto-setup function is compatible with CF cards only. If the STARTUP file is on the built-in drive, USB memory stick, or RAM (internal memory), it will not be referenced. -

Page 102: Manage Files

Manage Files 5.5 Manage Files Press the FILE key to display the File screen. Data saved to storage media can be managed on the File screen. Use the CURSOR keys to select a file from the file list. Before performing an operation, insert the storage media (except for the optional built-in drive). When [NO FILE] no storage media is inserted, appears in the file list of the File screen. -

Page 103: Save Data

Manage Files 5.5.1 Save Data You can save settings data, waveform data, or waveform genaration data on storage media. Data will be saved in the folder indicated by the cursor. By using the AB cursor pair, portions of waveform data can be saved. Procedure Press the FILE... - Page 104 Manage Files (When the selected save type is [Wave Binary]) Select whether to save divided files. Move the cursor to [Division]. Files are not divided when saved. If a file is too large, it cannot be saved. 16M, 32M, Select the size for Divided Save. Refer to “About divided saving”...

-

Page 105: Check The Contents Of A Folder (Open A Folder)

Manage Files 5.5.2 Check the Contents of a Folder (Open a Folder) Opening a folder allows you to inspect its contents. (Moves to the folder.) Procedure Press the FILE key to open the File screen. To change the storage media: (p. 78) Move the cursor to the folder whose contents you want to see. -

Page 106: Delete Files And Folders

Manage Files 5.5.4 Delete Files and Folders Follow this procedure when you need to delete files or folders from your Memory HiCorder. Procedure Press the FILE key to open the File screen. To change the storage media: (p. 78) Select the file or folder you want to delete. Select Select [Del... -

Page 107: Sort Files

Manage Files 5.5.5 Sort Files You can change the sort type and order of the file list. Procedure Press the FILE key to open the File screen. To change the storage media: (p. 78) Select [Sort] then select [Type]. Select No sorting. -

Page 108: Rename Files And Folders

Manage Files 5.5.6 Rename Files and Folders Follow this procedure when you want to rename a file or folder. Procedure Press the FILE key to open the File screen. To change the storage media: (p. 78) Select the file or folder you want to rename. Select Select [Rename]. -

Page 109: Copy A File Into A Specified Folder

Manage Files 5.5.7 Copy a File Into a Specified Folder This function allows to organize your files by copying files into specified folders. Procedure Press the FILE key to open the File screen. To change the storage media: (p. 78) Move the cursor to the file you want to copy. -

Page 110: Print The File List

Manage Files 5.5.8 Print the File List The file list of the File screen can be printed. Details for all displayed items in the file list will print. Only folder names are printed for folders. Information on the contents of folders is not printed. Before printing, make sure the recording paper is loaded correctly. - Page 111 Manage Files...

-

Page 112: Printing (When Model U8350 Printer Unit Is Installed)

Printing (When Model U8350 Printer Unit is installed) [Printer] sheet lets you set the print method and detailed printer options. To Open the [Printer] Sheet Press this key repeatedly to display the various sheets. [Environment] [Init] [File Save] [Printer] [Interface] Operations available from the [Printer] sheet To select the print method Printer settings... -

Page 113: Print Type And Workflow

Print Type and Workflow 6.1 Print Type and Workflow There are three basic types of printing. Print data automatically Selectively print data after Print data in bulk after measurement during measurement measurement by pressing the PRINT Auto-print Selection Print Quick Print Print content when the PRINT When the Memory function* is used,... -

Page 114: Auto-Print Settings

Auto-print Settings 6.2 Auto-print Settings This applies to the Memory, Recorder, and FFT functions. These settings must be set before starting measurement. Measurement data will print automatically when you press the START key to start measurement. For printer output, make sure that the recording paper is loaded correctly. For LAN output, make sure that the PC connected via LAN is prepared. - Page 115 Auto-print Settings Set the margins in automatic print Move the cursor to the [Feed]. Margin (Default setting) No margins* * There is a margin of about 2 mm. [Feed] are also applicable to normal printing. Check the measurement conditions and start the measurement.

- Page 116 Auto-print Settings Simultaneous Printing of Numerical Calculation Results From the Status screen, select the [Num Calc] sheet and set [Print Calc Result] to [On]. Refer to “10.5 Print Numerical Calculation Results” (p. 221).

-

Page 117: Manual Printing With The Print Key (Selective Printing)

Manual Printing With the PRINT Key (Selective Printing) 6.3 Manual Printing With the PRINT Key (Selective Printing) PRINT Using the key from the Waveform screen, you can specify a printing range and data type. This can help prevent inadvertent printing due to operator error. Procedure Press the SYSTEM... - Page 118 Manual Printing With the PRINT Key (Selective Printing) Start and stop the measurement. Press the START key to start measurement. Press the STOP key to stop measurement. Printing is not possible during measurement. Measurement must be stopped before printing is started. Select print contents and execute printing When you press the PRINT...

-

Page 119: Setting The Print Density Of The Waveform

Setting the Print Density of the Waveform 6.4 Setting the Print Density of the Waveform The printing density of the waveform can be set for each channel. Procedure Press the CHAN key to open the Channel screen, and then select the [Unit List] sheet or [Each Ch]... -

Page 120: Printer Settings

Printer Settings 6.5 Printer Settings Choose settings on the [Printer] sheet of the System screen. Printer Settings To open the screen, press the SYSTEM key → [Printer] sheet (p. 118) (p. 119) Select the print speed (quality). Fast/Coarse ( Default setting ), Normal, Slow/Fine Move the cursor to [Print Speed]. - Page 121 Printer Settings (p. 118) (p. 119) Select the horizontal axis (time axis) Time* Print the time from trigger event (unit is display value. fixed). (Default setting) Move the cursor to [Time Value]. Time (60)* Print the time from trigger event <Print Example>...

- Page 122 Printer Settings Set the upper and lower limit value Do not print upper and lower limits. ( Default setting ) Move the cursor to [Up/Low Print]. <Print Example> Print upper and lower limits. Upper and Lower Limit Set the zero-position comment Print the channel number.

-

Page 123: Miscellaneous Printing Functions

Miscellaneous Printing Functions 6.6 Miscellaneous Printing Functions You can print a hard copy of the screen display, reports, or lists. 6.6.1 Screen Hard Copy Press COPY key while the screen you want to is displayed. The printer will produce a hard copy of the screen contents. -

Page 124: List Print

Miscellaneous Printing Functions 6.6.3 List Print This function prints out function status information and channel setting information in list format. The list settings are the same as for the List function. Refer to “Print a list of settings” (p. 116). Press the PRINT key at a screen other than the Waveform screen. - Page 125 Miscellaneous Printing Functions...

-

Page 126: Waveform Screen Monitoring And Analysis

Waveform Screen Monitoring and Analysis Analytical operations such as display magnification, compression, and search are available on the Waveform screen. The measurement condition or other configuration can also be changed on this screen. To Open the Waveform Screen A Cursor B cursor Scroll bar (p. -

Page 127: Read Measurement Values (Using The Ab Cursors)

Read Measurement Values (Using the AB Cursors) 7.1 Read Measurement Values (Using the AB Cursors) • Time difference, frequency and potential difference (and when scaling is enabled, scaling values) can be read as numerical values using the AB cursors on the Waveform screen. The cursors also allow you to specify the calculation and print X-Y synthesis range. - Page 128 Read Measurement Values (Using the AB Cursors) Read Measurement Values on Waveform Screen (for 1, 2, 4, 8 screens) Press the DISP key to open the Waveform screen. Screen display (time axis cursor) A Cursor B cursor Cursor A Value Values Between AB cursors Time Values Cursor B Value...

- Page 129 Read Measurement Values (Using the AB Cursors) Reading Measurement Values on Waveform Screen (for X-Y1, 4 screens) DISP Press the key to open the Waveform screen. <Screen display (X axis measurement value)> X-Y synthesis of CH1 and CH2 waveform Cursor A Value Channel A Cursor B cursor...

-

Page 130: Specify A Waveform Range (Ab Cursor)

Specify a Waveform Range (AB Cursor) 7.2 Specify a Waveform Range (AB Cursor) When the waveform is shown as a time display, the range can be specified with the div cursor or trace cursor. The specified range will be used for file saving, printing, X-Y synthesis, and numerical calculation. The range selection will be retained when the waveform display format is changed. -

Page 131: Move The Waveform Display Position

Move the Waveform Display Position 7.3 Move the Waveform Display Position This applies to the Memory and Recorder functions. 7.3.1 About the Display Position From the scroll bar you can verify the relative position and size of the displayed portion of a waveform within the overall recorded waveform. -

Page 132: Change Position (Jump Function)

Move the Waveform Display Position 7.3.3 Change Position (Jump Function) You can specify the portion to be displayed immediately. Display location can be specified as follows: • Trigger Point • AB cursor location • Specified location (from the beginning [0%] to the end [100%] of the waveform) 100% Procedure Press the... -

Page 133: Perform Waveform X-Y Synthesis

Perform Waveform X-Y Synthesis 7.4 Perform Waveform X-Y Synthesis This applies to the Memory and X-Y Recorder functions. • To perform waveform X-Y synthesis, go to the Status screen, select the [Status] sheet, and set [Format] to X-Y1 screen or X-Y4 screen. By assigning any analog channel to the X axis and Y axis, up to 8 X-Y combo displays can be generated. - Page 134 Perform Waveform X-Y Synthesis Procedure DISP CH.SET Press the key to open the Waveform screen, and then press the key to open the X-Y settings window. Set the waveform color in the graph The waveform is not displayed. When display. [Disp Ch], this [Save Channel] is set to...

-

Page 135: Magnify And Compress Waveforms

Magnify and Compress Waveforms 7.5 Magnify and Compress Waveforms 7.5.1 Magnify and Compress Horizontal Axis (Time Axis) This applies to the Memory and Recorder functions. (However, with the Recorder function, waveform magnification is not available.) Data details can be observed by magnifying the waveform along the horizontal axis (time axis). Also, by compressing the time axis, overall waveform fluctuations can be observed easily. -

Page 136: Zoom Function (Magnifying A Section Of The Horizontal Axis [Time Axis])

Magnify and Compress Waveforms 7.5.2 Zoom Function (Magnifying a Section of the Horizontal Axis [Time Axis]) This applies to the Memory function only. A magnified section of a waveform can be displayed together with the unmagnified view by splitting the screen horizontally. With the waveform displayed normally on the upper half of the screen, a section magnified along the time axis can be displayed on the lower half. -

Page 137: Vertical Axis (Voltage Axis) Magnification

Magnify and Compress Waveforms To view the entire waveform (Memory function only) Move the cursor to the ratio item in the settings window and select [All Wave]. The waveform information for the entire recording length will be displayed. About logic waveform display When the Zoom function is enabled and the logic waveform display position is at less than [50pos], the logic waveform will not be displayed. -

Page 138: Monitor Input Levels (Level Monitor)

Monitor Input Levels (Level Monitor) 7.6 Monitor Input Levels (Level Monitor) 7.6.1 Level Monitor All input waveform levels can be monitored in real time. Analog channels and logic channels can be displayed at the same time. Procedure Press DISP to open the Menu → Display Menu Analog channel Monitor values of analog and logic Selecting... -

Page 139: Numerical Value Monitor

Monitor Input Levels (Level Monitor) 7.6.2 Numerical Value Monitor Input values can be monitored as numerical value same as in DMM (Digital multimeter). Procedure To open the screen: press the DISP key twice. Display Menu When mouse is connected, you can display numerical value (DMM) by clicking on [DMM] icon appears at the upper right of Waveform screen. -

Page 140: Switch The Waveform Screen Display (Display Menu)

Switch the Waveform Screen Display (Display Menu) 7.7 Switch the Waveform Screen Display (Display Menu) The display menu allows you to bring up additional information such as upper/lower limit value indication and comment display. It also allows you to set the waveform display width. Refer to “About level monitor”... -

Page 141: Show Upper/Lower Limit On Waveform Screen

Switch the Waveform Screen Display (Display Menu) 7.7.1 Show Upper/Lower Limit on Waveform Screen Select [Limit Value] to show the upper/lower limit value indication on the Waveform screen. 7.7.2 Show Comments on Waveform Screen Select [Comment] to show the comment indication on the Waveform screen. •... -

Page 142: View Block Waveforms

View Block Waveforms 7.8 View Block Waveforms This applies to the Memory function only. You can check if blocks have been used when recording with memory division. Furthermore, the desired block can be selected and the recorded waveform displayed. When memory division is not used, depending on the recording length, it is possible to display the last 16 measured waveforms. - Page 143 View Block Waveforms...

-

Page 144: Utility Functions

Utility Functions Applicable measurements and settings Add Comments (p. 140) • Display Waveforms During Recording (p. 147) • Overlay with past recorded waveforms (p. 148) Convert input values (Scaling) (p. 151) Detailed module settings (p. 164) Set the waveform display freely (p. 158) •... -

Page 145: Add Comments

Add Comments 8.1 Add Comments 8.1.1 Add a Title Comment When you enter a title comment, it can be displayed at the top of the Waveform screen, and can also be printed. (Allowed number of characters: up to 40) Refer to “6.6.2 Report Print (A4 Size Print)” (p. 118). Procedure Press the CHAN... -

Page 146: Add A Channel Comment

Add Comments 8.1.2 Add a Channel Comment Comments added for each channel can be displayed on-screen. Comments can also be printed on recording paper. (Allowed number of characters: up to 40) To copy a comment to another channel [Comment] sheet can be used to copy comments. Refer to “8.9 Copy Settings to Other Channels (Copy Function)”... - Page 147 Add Comments To select from preset terms Pressing the WAVE key after activating text input brings up a list of preset terms. It is also possible to select words from previously entered analog channels (History List). Refer to “Enter Text From a Term List or History List” (p. 145). Select the print content for each logic Comments are not printed.

-

Page 148: Alphanumeric Input

Add Comments 8.1.3 Alphanumeric Input Move the cursor to the setting item for which you with to input text and choose the content with the keys. Entering Text Move the cursor to the comment field and select [Enter Char]. The virtual keyboard will be displayed. Select characters with the CURSOR keys from the virtual keyboard, and select... - Page 149 Add Comments To Enter units and symbols Characters entered as units may be saved differently. (Saving of numerical calculation results or text format information) Ω → ^2, → ^3 , μ → → o, ε → e, ° → c , ± → Characters not allowed in file names can not be entered.

- Page 150 Add Comments Enter Text From a Term List or History List While the virtual keyboard is displayed, pressing the WAVE key brings up a “Term List” and pressing the AB CSR key brings up a “History List.” This can be used to enter preset terms or reuse text from previous input sessions. Move the cursor to the comment field and select [Enter Char].

- Page 151 Add Comments Entering Numerals By Incrementing/Decrementing Move the cursor to the numeric input field and select [Up-Down]. A virtual keyboard for digit input will be displayed. Enter numerals at the virtual keyboard. (Use to move digit position, and use to increase or decrease the value.) Select [Confirm] to accept the entry.

-

Page 152: Display Waveforms During Recording (Roll Mode)

Display Waveforms During Recording (Roll Mode) 8.2 Display Waveforms During Recording (Roll Mode) This applies to the Memory function only. You can display and print the waveform at the same time as the data is acquired (if auto-print is enabled). (p. 109) •... -

Page 153: Display New Waveforms Over Past Waveforms (Overlay)

Display New Waveforms Over Past Waveforms (Overlay) 8.3 Display New Waveforms Over Past Waveforms (Overlay) This applies to the Memory function only. Displayed waveforms are retained on-screen and overlaid with new waveforms. • Use this to compare new waveforms with those recorded immediately before. (When the trigger mode is [Repeat] or [Auto]) (p. - Page 154 Display New Waveforms Over Past Waveforms (Overlay) When the overlay function is enabled ([Auto] or [Manual]). • The Roll Mode function (p. 147) and Overlay function (p. 148) cannot be enabled at the same time. When the Roll Mode function is enabled, the overlay is automatically set to [Off]. And when the overlay function is enabled, roll mode is set to [Auto].

-

Page 155: Setting Channels To Use (Extending The Recording Length)

Setting Channels to Use (Extending the Recording Length) 8.4 Setting Channels to Use (Extending the Recording Length) This applies to the Memory function only. Select the analog and logic channels to use. Maximum recording length is available when the fewest necessary channels are enabled for use. Minimizing the number of channels in use allows memory to be reallocated to those channels being used. -

Page 156: Convert Input Values (Scaling Function)

Convert Input Values (Scaling Function) 8.5 Convert Input Values (Scaling Function) About the Scaling Function Use the scaling function to convert the measured voltage units output from a sensor to the physical units of the parameter being measured. Hereafter, “scaling” refers to the process of numerical value conversion using the Scaling function. Gauge scales, scale values (upper and lower limits of the vertical axis [voltage axis) and AB cursor measurement values can be displayed in scaled units. - Page 157 [Scale P2]. • When saving text or the results of numerical calculation, some characters and symbols used for display on the instrument will be converted as follows. (“MR8827 display” to “saved string”) Ω • to ^2, to ^3, μ to o, ε...

-

Page 158: Scaling Examples

Convert Input Values (Scaling Function) To reset scaling settings Move the cursor to [Setting], and select [Reset]. To copy the scaling setting to another channel The Channel screen - [Scaling] sheet can be used to copy a setting. Refer to “8.9 Copy Settings to Other Channels (Copy Function)” (p. 163) To use a combination of the Scaling and Variable functions (p. - Page 159 Convert Input Values (Scaling Function) To Select a Clamp Sensor 1. Move the cursor to [Clamp], and select [Select] The cursor moves to [Model]. 2. Select [9000~] The cursor moves to [Clamp]. 3. Select [9018-50] from the clamp list with key, and select [Confirm] Units, scaling method, and ratio will be set automatically.

- Page 160 Convert Input Values (Scaling Function) Scaling signals from the strain gauge transducer enabled them to be displayed as physical values. Values at the Cursors A and B and gauges are displayed and printed as physical values. Refer to “Gauge” (p. 116) or “Cursor AB Value” (p.

- Page 161 Convert Input Values (Scaling Function) When the strain gauge transducer’s inspection record provides the calibration factor [Method] on the [Scaling] sheet to [Ratio]. Example 3 To display the data measured with the strain gauge transducer with a calibration factor of 0.001442 G / 1 6 strain* in terms of gees (G).

- Page 162 Convert Input Values (Scaling Function) When using the dB value Example 5 Acquiring the conversion rate to convert 40 dB input to 60 dB For scaling, set the [Method] to [Ratio]. Move the cursor to the conversion rate setting. Select [dB Scaling] in the function column.

-

Page 163: Set The Waveform Position (Variable Function)

Set the Waveform Position (Variable Function) 8.6 Set the Waveform Position (Variable Function) The waveform height and display position can be arbitrarily set along the vertical axis (voltage axis). Precautions when using the Variable Function • Verify that the vertical axis (voltage axis) range is set properly for the input signal. •... - Page 164 Set the Waveform Position (Variable Function) Variable Function Settings per Channel Procedure Press the CHAN key to open the Channel screen, and then select the [Each Ch] sheet. Enable the Variable function. Move the cursor to [Variable], and select [On]. Set the display range per division Move the cursor to [Range(div)], and enter a numerical value.

- Page 165 Set the Waveform Position (Variable Function) Variable Function Settings for All Channels Procedure Press the DISP key to open the Waveform screen, and then press the CH.SET key to open the display range window. Enable the Variable function. Move the cursor to [Variable], and select [On]. Set the upper and lower limits.

-

Page 166: Fine Adjustment Of Input Values (Vernier Function)

Fine Adjustment of Input Values (Vernier Function) 8.7 Fine Adjustment of Input Values (Vernier Function) Fine adjustment of input voltage can be performed arbitrarily on the Waveform screen. When recording physical values such as noise, temperature and acceleration using sensors, amplitude can be adjusted to facilitate calibration. -

Page 167: Invert The Waveform (Invert Function)

Invert the Waveform (Invert Function) 8.8 Invert the Waveform (Invert Function) This applies to analog channels only. You can invert the positive and negative sides of waveforms. Example: With a spring or similar, if pulling it towards the observer is taken as the minus direction and pushing it away from the observer as the plus direction, the output will be plus (positive) for pulling and minus (negative) for pushing. -

Page 168: Copy Settings To Other Channels (Copy Function)

Copy Settings to Other Channels (Copy Function) 8.9 Copy Settings to Other Channels (Copy Function) Settings can be copied to other channels and calculations (When using the FFT function) at the following screens. • Channel settings window • Display range window •... -

Page 169: Detailed Settings For Modules

Detailed Settings for Modules 8.10 Detailed Settings for Modules Using the [Each Ch] sheet accessed from the Channel screen, you can make detailed settings for each module. To Open [Each Ch] and Make a Channel Selection Shows the channel number and channel position. - Page 170 Detailed Settings for Modules Logic channel allocation when using Standard LOGIC terminals Memory for each channel (16 bits) Module 4 bit 4 bit 4 bit 4 bit CH1* Analog CH1 Analog CH2* Analog CH2 CH3* Logic — CH4* Analog CH5 Analog Analog CH6 Logic...

-

Page 171: Settings For The Anti-Aliasing Filter (A.a.f.) (Model 8968 High Resolution Unit)

Detailed Settings for Modules 8.10.1 Settings for the Anti-Aliasing Filter (A.A.F.) (Model 8968 High Resolution Unit) Refer to “To Open [Each Ch] and Make a Channel Selection” (p. 164). A.A.F Enable the anti-aliasing filter to remove aliasing distortion. The cutoff frequency automatically changes according to the timebase or, when the FFT function is used, the frequency range setting. -

Page 172: Setting Model 8967 Temp Unit

Detailed Settings for Modules 8.10.3 Setting Model 8967 Temp Unit Refer to “To Open [Each Ch] and Make a Channel Selection” (p. 164). Mode Choose the option that matches the type of thermocouple being used. Selections Measurement range Selections Measurement range Temp-K −... -

Page 173: Setting Model 8969 And U8969 Strain Unit

Detailed Settings for Modules 8.10.4 Setting Model 8969 and U8969 Strain Unit The Model 8969 or U8969 Strain Unit can perform auto-balance. Executing the auto-balance adjusts the reference output level of the transducer to the specified zero position. This function can be used for Model 8969 or U8969 Strain Unit only. The instrument describes Model U8969 as “8969.”... -

Page 174: Setting Model 8970 Freq Unit

Detailed Settings for Modules 8.10.5 Setting Model 8970 Freq Unit When the standard logic display (LA, LB, LC, LD, LE, LF, LG, and LH) is on, 8970 Freq Units installed as unit 1, 2, 9, or 10 cannot be used. Refer to “To Open [Each Ch] and Make a Channel Selection”... - Page 175 Detailed Settings for Modules Slope For each measurement mode, set the direction in which the specified level is crossed. ↑ Rises above the specified level are detected. (Default setting) ↓ Drops below the specified level are detected. Divide Determines the frequency for each set pulse. 1(Default setting) to 4096 Select the value using the keys.

- Page 176 Detailed Settings for Modules Refer to “To Open [Each Ch] and Make a Channel Selection” (p. 164). Level This is enabled only when [Mode] [Pulse Width] [Duty]. In pulse width/duty rate measurements, set which level is detected when the threshold is exceeded. HIGH Measures above the threshold value.

-

Page 177: Setting Model 8971 Current Unit

Detailed Settings for Modules 8.10.6 Setting Model 8971 Current Unit There is no need to change the setting since it is set when the clamp sensor is automatically recognized. Refer to “To Open [Each Ch] and Make a Channel Selection” (p. 164). Mode 20A/2V Sets this option when Model 9272-10 (20 A range), 9277, or CT6841... -

Page 178: Setting Model Mr8990 Digital Voltmeter Unit

Detailed Settings for Modules 8.10.8 Setting Model MR8990 Digital Voltmeter Unit • When the Model MR8990 Digital Voltmeter Unit is installed as unit 1, 2, 9, or 10, the standard logic channels cannot be used. • The resolution of the data measured by the recorder function is 16 bits. Refer to “To Open [Each Ch] and Make a Channel Selection”... -

Page 179: Setting Model U8974 High Voltage Unit

Detailed Settings for Modules • The calibration time is approximately 150 ms. During this period measurement is not performed. • If synchronization between channels is performed, a signal to stop integration is sent to each module when measurement is started and the wait process is performed until the first integration finishes. The wait time required for this process is (10 ms + integration time*). -

Page 180: Setting Model Mr8790 Waveform Generator Unit

Detailed Settings for Modules 8.10.10 Setting Model MR8790 Waveform Generator Unit Channels installed with Model MR8790 cannot be measured. Refer to “To Open [Each Ch] and Make a Channel Selection” (p. 164). Type Selects the waveform type. DC output (Default setting) Sine Sine wave output Frequency... - Page 181 Detailed Settings for Modules Offset For DC output: Sets DC voltage. For sine wave output: Sets the offset voltage. The output voltage with guaranteed accuracy is the sum of the amplitude and the offset, between -10 V and +10 V. If the sum of the amplitude and the offset is set outside the guaranteed accuracy range, parts of the waveform will be clamped to the upper limit, approximately +14 V and the lower limit, approximately -14 V.

-

Page 182: Setting Model Mr8791 Pulse Generator Unit

Detailed Settings for Modules 8.10.11 Setting Model MR8791 Pulse Generator Unit Channels installed with Model MR8791 cannot be measured. Refer to: “To Open [Each Ch] and Make a Channel Selection” (p. 164) Mode Select the type of output. Pulse Pulse output (Default settings) Pattern Pattern output Refer to the instruction manual of Models U8793, MR8790, and MR8791 regarding... - Page 183 Detailed Settings for Modules Out-Config Sets the output status. TTL output Open collector output Output Turns waveform output On/Off. Outputs waveform. Does not output the waveform. Control Sets the waveform output. Starts output. PAUSE Pauses output. While output is paused, the output at the time [PAUSE] was pressed will be output.

-

Page 184: Setting Model U8793 Arbitrary Waveform Generator Unit

Detailed Settings for Modules 8.10.12 Setting Model U8793 Arbitrary Waveform Generator Unit Channels installed with U8793 cannot be measured. Refer to: “To Open [Each Ch] and Make a Channel Selection” (p. 164) Type Selects the waveform type. DC output (Default setting) Sine Sine wave output Square... - Page 185 Detailed Settings for Modules Amplitude Sets the amplitude of output signal. The output voltage with guaranteed accuracy is the sum of the amplitude and the offset, between -10 V and +15 V. If the sum of the amplitude and the offset is set outside the guaranteed accuracy range, parts of the waveform will be clamped to the upper limit, approximately +16 V and the lower limit, approximately -11 V.

- Page 186 Detailed Settings for Modules Method Selects the control method for waveform output. Manual Restricts control of signal output to Signal Generation screen. Sync. Augments manual control with signal output in synchronization with the start and end of measurement. START key: Starts output when measurement starts. STOP key: Stops output when measurement stops.

-

Page 187: Register The Waveform In The U8793 Arbitrarywaveform Generator Unit

Register the Waveform in the U8793 ArbitraryWaveform Generator Unit 8.11 Register the Waveform in the U8793 ArbitraryWaveform Generator Unit ou can register waveform in the Model U8793. Registered waveforms can be output from the Model U8793. Procedure To open the screen: press the CHAN key to open the Channel screen, and then select [Generator]... - Page 188 Register the Waveform in the U8793 ArbitraryWaveform Generator Unit Register From Files Select [Register..from file] using keys Select [to File scrn] using the CH.SET key. Move to the file screen. Select arbitrary waveform file WFG or TFG on the file screen and then register.

- Page 189 Register the Waveform in the U8793 ArbitraryWaveform Generator Unit Register From Measured Data Select [Register..from measurement data] using keys Select the waveform to be registered using keys. Analog Ch Registers the waveform of the measured analog channel. Wave Calc. Z Registers the waveforms with waveform calculation result.

-

Page 190: Save The Waveforms Registered In The Model U8793 In The Media

Save the Waveforms Registered in the Model U8793 in the Media 8.12 Save the Waveforms Registered in the Model U8793 in the Media You can save the arbitrary waveform data registered in U8793 in the media. For saving methods, refer to “5.2.4 Save Waveform Output Data to the Media” (p. 92). 8.13 Setting Output Waveform Parameters Parameters (frequency, amplitude, and offset) for the output waveform that was configured on the Generator screen (signal generation setting screen) can be changed on the Waveform screen. - Page 191 Setting Output Waveform Parameters...

-

Page 192: Trigger Settings

Trigger Settings Triggering allows you to start and stop measurement using signals or conditions. When recording is started or stopped by a specific signal, we say the trigger is “applied” or “triggering occurs.” You can configure triggers inform the Trigger settings window of the Waveform screen. Triggers cannot be set with the X-Y Recorder function. -

Page 193: Setting Workflow

Setting Workflow 9.1 Setting Workflow This setting controls whether the instrument (p. 189) Trigger Mode Settings continues to accept triggers after measuring. Make trigger source-related settings. Trigger Type Settings • Analog trigger (p. 190) • Logic trigger (p. 195) • Timer Trigger (p. -

Page 194: Set The Trigger Mode

Set the Trigger Mode 9.2 Set the Trigger Mode This setting controls whether the instrument continues to accept triggers after measuring. If all trigger sources are disabled (Off, with no trigger setting), measurement starts immediately (free- running). Procedure Press the DISP key to open the Waveform screen. -

Page 195: Analog Signal Triggers

Analog Signal Triggers 9.3 Analog Signal Triggers The process below explains how to set up the different types of analog triggers. These settings can be configured on the Trigger settings window ([Analog Trg.] sheet). Procedure DISP TRIG.SET Press the key to open the Waveform screen, and then press the key to open the trigger settings window ([Analog Trg.]... - Page 196 Analog Signal Triggers 1. Level Trigger A trigger is applied when the input signal crosses the specified trigger level (threshold voltage). Trigger Level Input Waveform Trigger Slope: ↑] ↓] In this manual, indicates a “trigger point,” the time at which a trigger is applied. Type Parameters (Level)

- Page 197 Analog Signal Triggers 3. Voltage Sag Trigger ( Only) Triggering occurs when the voltage peak drops below a preset level for more than half a cycle. The allowable timebase is 20 μs to 50 ms/div. 1/2 Period Trigger Level Type Parameters (Level) Sets the level (voltage value) for the trigger.

- Page 198 Analog Signal Triggers 5. Glitch Trigger ( Only) Triggering occurs when the input signal crosses the trigger level (threshold voltage) if its pulse width is shorter than the specified width. Glitch Width Trigger Level Input Waveform Trigger Slope: [↑] Type Parameters (Level) Sets the level (voltage value) for the trigger.

- Page 199 Analog Signal Triggers About period range settings The period range settings for period triggering depend on the sampling period (sampling rate). (Changing the timebase also changes the period setting range.) The [Sampling Rate] setting can be verified on the Status screen - [Status] sheet.

-

Page 200: Logic Signal Triggers (Logic Trigger)

Logic Signal Triggers (Logic Trigger) 9.4 Logic Signal Triggers (Logic Trigger) Follow the steps for below to configure logic triggers. These settings can be configured from the [Logic Trig] sheet of the Trigger settings window. • Input signals on logic channels serve as the trigger source. Triggering occurs when the specified trigger pattern and logical probe combination criteria (AND/OR) are met. - Page 201 Logic Signal Triggers (Logic Trigger) 3. Trigger Pattern Set the logic trigger pattern. Ignore signal. (Default setting) Trigger at LOW signal level. Trigger at HIGH signal level To copy the setting to another channel The Trigger settings window ([Logic Trig] sheet) can be used to copy the settings between channels.

-

Page 202: Trigger By Timer Or Time Interval (Timer Trigger)

Trigger by Timer or Time Interval (Timer Trigger) 9.5 Trigger by Timer or Time Interval (Timer Trigger) This trigger allows you to record at fixed times. • Triggering occurs at the specified interval from the specified Start time until the Stop time. •... - Page 203 Trigger by Timer or Time Interval (Timer Trigger) About start and stop times • Start and Stop times should be set as times elapsed since the START key was pressed. • When the trigger mode is [Single] and the timer trigger is [On], only one timer trigger specified as the Start trigger will be recognized.

- Page 204 Trigger by Timer or Time Interval (Timer Trigger) When a trigger is applied from a trigger source other than a timer trigger Trigger sources set to [On] are all enabled. However, trigger timing depends on the trigger source settings. • When trigger criteria are combined with OR (Trigger Source: OR) Depending on the other trigger sources, triggering can occur before the specified trigger Start time, after the specified Stop time, or outside of the specified Interval.

-

Page 205: Apply An External Trigger (External Trigger)

Apply an External Trigger (External Trigger) 9.6 Apply an External Trigger (External Trigger) An external signal applied to the External Control terminal can serve as a trigger source. It can also be used to drive synchronized parallel triggering of multiple instruments. Procedure DISP TRIG.SET... -

Page 206: Pre-Trigger Settings

Pre-trigger Settings 9.8 Pre-trigger Settings This applies to the Memory and FFT functions only. By setting a portion (number of divisions or percentage) of the recording length to occur before triggering, the waveform can be recorded before as well as after the trigger point. You can also set the duration of a waveform to be recorded after a trigger point. - Page 207 Pre-trigger Settings About pre-triggering and the recording period (recording length) Trigger Point Pre-trigger setting examples 95% of the recording length is recorded before the trigger point 50% of the recording length is recorded before and 50% after −95% the trigger point −95% The recording length is recorded after 95% of the recording length after the trigger point...

-

Page 208: Set Trigger Acceptance (Trigger Priority)

Pre-Trigger Settings Pre-trigger Settings 9.8.2 Set Trigger Acceptance (Trigger Priority) This applies to the Memory function only. You can set whether triggers are recognized (accepted) if trigger criteria are met during the Pre-trigger wait period. • When pre-triggering is enabled, trigger events are normally ignored for a certain period after measurement starts (while recording the specified pre-trigger period). -

Page 209: Set Trigger Timing

Set Trigger Timing 9.9 Set Trigger Timing This applies to the Recorder function only. Use the below procedure to control waveform recording operation when a trigger event occurs. Procedure DISP TRIG.SET Press the key to open the Waveform screen, and then press the key to open the trigger settings window. - Page 210 Set Trigger Timing Example: When the trigger type is Level Trigger, Level = 0.000 V, and Slope = ↑(rising) Setting of [Timing] [Start] [Stop] [Start & Stop] START START Press key to record. Recording starts when a Start Records for specified Records until a trigger occurs.

-

Page 211: Combined Trigger Logic (And/Or) For Multiple Trigger Sources

Combined Trigger Logic (AND/OR) for Multiple Trigger Sources 9.10 Combined Trigger Logic (AND/OR) for Multiple Trigger Sources Analog, logic, external and timer trigger criteria can be combined using AND/OR logic to define complex trigger criteria. Procedure Press the DISP key to open the Waveform screen, and then press the TRIG.SET key to open the trigger settings window. -

Page 212: Use Trigger Settings To Search Measurement Data

Use Trigger Settings to Search Measurement Data 9.11 Use Trigger Settings to Search Measurement Data Trigger settings can be used to search measurement data. Locations that match the set trigger criteria in the measurement data are searched for and displayed sequentially. - Page 213 Use Trigger Settings to Search Measurement Data Search results Locations that match the criteria are displayed in the center of the screen and marked with an S. When no matches are found, a message stating that Matches Were Found] is displayed. •...

-

Page 214: Numerical Calculation Functions

Numerical Calculation Functions Numerical calculations can only be used with the Memory function. Results calculated from the acquired waveform are displayed as numerical values on the Waveform screen. These calculation results can be judged for evaluation. Numerical calculation settings are made on the Status screen - [Num Calc] sheet. -

Page 215: Numerical Calculation Workflow

Numerical Calculation Workflow 10.1 Numerical Calculation Workflow There are two different ways of performing calculation. • Calculate While Measurent: Settings for numerical calculation must be chosen before starting measurement. • Apply Calculations to Existing Data: Calculation can be performed on waveform data after measurement is completed, and for data saved on storage media. - Page 216 Numerical Calculation Workflow Apply Calculations to Existing Data (Load Data) (To load measurement data from storage media for (p. 93) calculation) Choose Calculation Choose calculation settings on the [Num Calc] sheet (p. 212) Settings (p. 216) When judging based on calculation results Execute Calculation Select [Exec]...

-

Page 217: Numerical Value Calculation Settings

Numerical Value Calculation Settings 10.2 Numerical Value Calculation Settings Procedure Press the STATUS key to open the Status screen, and then select the [Num Calc] sheet. Enable the Numerical Calculation function. Move the cursor to [Numerical Calc]. Select [On]. Specify the waveform calculation range. Move the cursor to [Calc Area]. - Page 218 Numerical Value Calculation Settings Select the channel for calculations. When printing or saving calculation Move the cursor to the item for the calculation target, and results during measurement select the channel. Settings must be made before the (Logic channels can also be selected for Time to Level, Pulse measurement.

- Page 219 Numerical Value Calculation Settings Parameter Table Calculation type Parameter Parameter description Calculation is based on the interval (time) when the level is Period L (Level) crossed. Frequency Pulse Width Only when the measurement signal has crossed the level Pulses and has not crossed the level again within the specified F (Filter) Duty Ratio* filter width, it is taken as a valid event.

-

Page 220: Display Numerical Calculation Results

Numerical Value Calculation Settings 10.2.1 Display Numerical Calculation Results Numerical calculation results are displayed on the Waveform screen Calculation Results If the display is hard to view because the Press the DISP key. numerical values and waveforms overlap, Numerical values and waveforms will be displayed separately. -

Page 221: Calculation Result Judgment

Calculation Result Judgment 10.3 Calculation Result Judgment Set the judgment criteria (upper and lower threshold values) to use when judging numerical calculation results. Judgment criteria can be set for every numerical calculation. Waveform acquisition processing depends on the trigger mode setting (Single or Repeat) and the criteria specified to stop measuring upon judgment ([GO], [NG], or [GO&NG]). - Page 222 Calculation Result Judgment Procedure Press the STATUS key to open the Status screen, and then select the [Num Calc] sheet. Choose calculation settings. (p. 212) Enable the judgment function. Move the cursor to [Judge] for the Calculation on which you Upper limit value Lower l i m i t val u e want to use judgement, and select [On].

-

Page 223: Display Judgment Results And Signal Output

Calculation Result Judgment 10.3.1 Display Judgment Results and Signal Output Numerical calculation judgment results are displayed on the Waveform screen. Within the judgment threshold range: GO judgment Out of the judgment threshold range: NG judgment (displayed in red) When printing, judgment results for each parameter will also be printed. When the judgment result is GO ―... -

Page 224: Save Numerical Calculation Results