Subscribe to Our Youtube Channel

Summary of Contents for Memmert UNB 100

- Page 1 Operating instructiOns Universal ovens Sterilisers Incubators UNB 100 - 500 SNB 100 - 400 INB 200 - 500 UFB 400 - 500 SFB 400 - 500...

- Page 2 BASIC page 2...

-

Page 3: Table Of Contents

9.1 Temperature limiter (TB) ...................... 14 9.2 Monitor relay ........................14 Sterilisers .............................15 10.1 Purpose definition for MEMMERT hot air sterilisers .............. 15 10.2 Note in accordance with Medical Products Guidelines ............15 10.3 Guidelines for sterilisation ....................15 10.4 Steriliser cassettes ........................ 17 Cleaning ............................18... -

Page 4: General Notes And Safety Notes

General notes and safety notes You have purchased a technically fully proven product which has been produced in Germany with the use of high-grade materials and the application of the latest manufacturing techniques; it has been factory tested for many hours. In addition we guarantee the supply of spare parts over 10 years. -

Page 5: Installation Facilities (Accessories)

8 cm. Generally it is essential to have adequate air ventilation around the oven. Information on accessories will be found in our leaflet or on our internet page www.memmert.com. Please note the installation instructions for our accessories. 3.1 Subframe (accessory) Oven model 500 can be mounted on a subframe 3.2 Wall bracket (accessory) -

Page 6: Initial Start-Up

Please note that the MEMMERT ovens described here are not explosionproof (they do not conform to the Industrial Association Specification VBG 24) and are therefore not suitable for drying, evaporating and burning-in of paints, enamels or similar materials whose solvents may produce an inflammable mixture with air. -

Page 7: Technical Data

Technical data Supply plug Model Chamber width A [mm] Chamber height B [mm] Chamber depth C [mm] Oven width D [mm] Oven height E [mm] Oven depth F [mm] Chamber volume [litre] Weight [kg] Power, ovens UNB/UFB/SNB/SFB [W] 1100 1200 1400 2000 Power, ovens INB [W]... -

Page 8: Standard Equipment Of Basic Ovens

4.2 Material quality For external housing MEMMERT employs stainless steel (Mat.Ref. 1.4016). The chamber is made from stainless steel (Mat.Ref. 1.4301) which exhibits high stability, optimum hgygienic properties and corrosion resistance against many (not all) chemicals (warning against e.g. chlorine compounds). -

Page 9: Electrical Equipment

Controller protected by an 80 mA fuse (200 mA on 115 V) ‡ When connecting a MEMMERT oven to the electrical supply you have to observe any local ‡ regulations which apply (e.g. in Germany DIN VDE 0100 with FI protection circuit) ‡... -

Page 10: Oven Construction And Operation

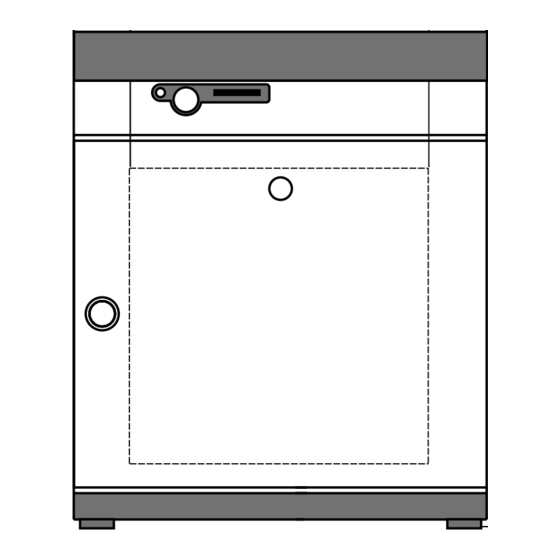

Oven construction and operation Ovens Series UNB, INB and SNB have natural ventilation. In Series UFB amd SFB ovens, air circulation is provided by a fan on the back wall of the chamber. chamber air valve air discharge ventilation slots preheat chamber air supply fresh air... -

Page 11: Controls And Indications

5.2 Controls and indications timer display heating alarm indication operating mode temperature display indication STERI DEFRO IN 1 IN 2 IN 1 IN 2 °C °C loop AUTO PRINT SETUP set-key push/turn control air slider Ill : UNB 500 (main switch) 5.3 Switching on The oven is switched on by pressing the push/turn control. -

Page 12: Selecting The Operating Mode

Selecting the operating mode Normal Timer operation operation After holding down the SET key (approx. 3 sec), the current operating mode flashes on the display. A different operating mode can be selected with the push/turn control while the SET key is being held down. After the SET key has been released the controller operates in the new operating mode. -

Page 13: Timer Operation

Timer operation In this operating mode the oven operates on the timer; it heats/controls to the set temperature and maintains this temperature until the set time has elapsed. The clock symbol is flashing during timer operation, then the heating is switched off; on UFB/SFB ovens the fan runs on for 30 minutes. The timer display shows END. - The time can always be set to OFF, the heating is then switched off and the timer display shows END. -

Page 14: Temperature Monitor And Protection Devices

Temperature monitor and protection devices 9.1 Temperature limiter (TB) All ovens of the BASIC series are equipped with a mechanical temperature limiter (TB) Protection Class 1 to DIN 12 880. If the electronic monitor system should fail during operation and the fixed factory-set maximum temperature is exceeded by approx. -

Page 15: Sterilisers

MEMMERT cabinet. The operation of the MEMMERT hot air steriliser is also subject to the Standard DIN 58 947 Part 6. A few examples of the correct preparation for different medical products are summarised in the following... - Page 16 The total sterilisation time to be selected consists of the heating-up time (i.e. the time until the desired temperature has been established within the entire steriliser chamber), the actual sterilisation time, and a safety margin. The following table gives typical values for the total sterilisation time to be set, with different amounts of load, for sterilisers with and without fan.

-

Page 17: Steriliser Cassettes

Especially with heavy loading of the steriliser it is not sufficient to use these typical values without further tests. Reliable sterilisation requires validation of the individual sterilisation process, e.g. with the aid of additional temperature probes or by using biological or chemical indicators. Note: In sterilisation processes the vent valve on the oven must be closed after the moist sterilisation load has been dried! -

Page 18: Cleaning

Silicone grease, and to check that the hinge screws are tight. A well-closing door is essential on an oven. On Memmert ovens, tight closure of the door is ensured by a seal on the oven and another one on the door. In continuous operation the flexible sealing material may take a permanent set. -

Page 19: Error Messages

In case there is a fault on the oven, please get in touch with an authorised service organisation or contact the MEMMERT customer service department. When dealing with the service department always quote the product serial number on the oven label. -

Page 20: Ce Conformity Declaration

14 CE Conformity Declaration EC Declaration of Conformity Manufacturer´s name and address: MEMMERT GmbH + Co. KG Äußere Rittersbacher Straße 38 D-91126 Schwabach Product: Universal oven Type: UNB … / UFB … / UNE ... / UFE … / UNP … / UFP …... - Page 21 EC Declaration of Conformity Manufacturer´s name and address: MEMMERT GmbH + Co. KG Äußere Rittersbacher Straße 38 D-91126 Schwabach Product: Incubators Type: INB … /INE … / INP … Sizes: 200 / 300 / 400 / 500 / 550 / 600 / 700 / 800...

- Page 22 EC Declaration of Conformity Manufacturer´s name and address: MEMMERT GmbH + Co. KG Äußere Rittersbacher Straße 38 D-91126 Schwabach Product: Sterilisers Type: SNB … / SFB … / SNE … / SFE … / SFP … Sizes: 100 / 200 / 300 / 400 / 500 / 550 / 600 / 700 / 800...

-

Page 23: Address And Customer Service

Please note also all further regulations in this context. 15 Address and customer service MEMMERT GmbH+Co.KG Customer service: PO Box 17 20 Phone: 00 49 9122 / 925-143... -

Page 24: Index

16 Index accessories 9 normal operation 12 address 23 air changes 11 air slider 11 operating mode indication 11 air supply 10 operating mode selection 12 air valve 10 operating time 13 alarm indication 11 operation 10 alarm symbol 14 Protection Class 1 14 CE conformity declaration 20 protection devices 14... - Page 25 Notes: page 25 BASIC...

- Page 26 Notes: BASIC page 26...

- Page 27 page 27 BASIC...

- Page 28 Memmert gmbH + co. Kg | Postfach 1720 | D-91107 Schwabach | Tel. +49 (0) 9122 / 925 - 0 | Fax +49 (0) 9122 / 145 85 | E-Mail: service@memmert.com | www.memmert.com 12.08.2009 BASIC english D09803...

Need help?

Do you have a question about the UNB 100 and is the answer not in the manual?

Questions and answers

materials needed or PPE's required for Memmert Incubator INB 200

I would like to know the cos(phi) for UNB500 device.