Advertisement

H3H Shown

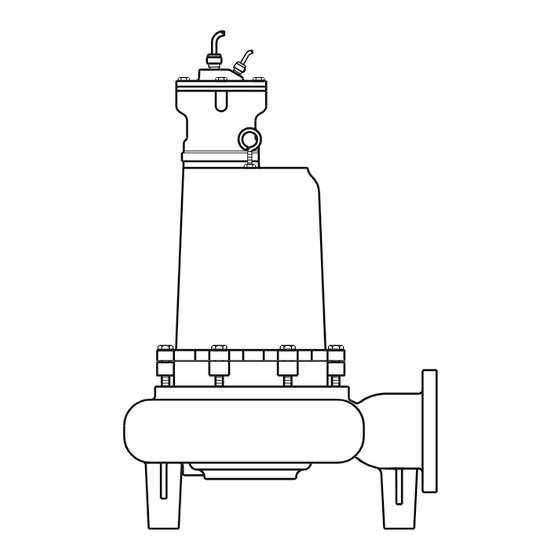

S4HRC Shown

S4M Shown

MODELS H3H, H4H, S4M,

S4P, S4HRC and S4MRC

SUBMERSIBLE

SOLIDS HANDLING PUMPS

INSTALLATION AND SERVICE MANUAL

For use with product built with GE

motor.

®

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-467 | Part # 5625-467-1 | © 2013 Pentair Pump Group, Inc. | 11/06/13

Advertisement

Table of Contents

Summary of Contents for Pentair HYDROMATIC H3H

- Page 1 NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Item # E-03-467 | Part # 5625-467-1 | © 2013 Pentair Pump Group, Inc. | 11/06/13...

-

Page 2: General Information

Pumps with tungsten carbide seals sensor opens. The motor starter is General must have impellers manually equipped with overload heaters so Information rotated (6 revolutions) after all normal over loads are protected setting non-operational for 3 by the starter. Attention: weeks or longer and prior to IMPORTANT: If Hydromatic ®... -

Page 3: Installation Instructions

Alarm Controls: corresponding horsepower NEMA 4 Junction Box surface motor, so heaters must be (Optional): The alarm level is usually set sized by the nameplate rating. above the override level so the A NEMA 4 junction box should alarm will signal only if the be used to make power and IMPORTANT: Make certain override... -

Page 4: Pump Operations

7. Turn both switches to Auto More distance between turn-on Pump Operations po si tion and both pumps and turn-off controls can be used, Starting System: should start and operate but sew age may become septic, together until level drops to and excessive solids may collect 1. -

Page 5: Pump Maintenance

the seal failure con nect ing replacing housing on pump. Pump Maintenance wire must be dis con nect ed This is important as leads before housing is com plete ly must be tucked behind the Lubrication or other maintenance removed. windings by using hands up is not required, as the motors are through rotor core. -

Page 6: Pump Troubleshooting

10. After all leads are reconnected replacing. Pressing on outer 4. Lift rotating assembly (rotor, in the connection box, make face can damage the bearing. shaft and impeller) from pump a high voltage ground test case and place horizontally IMPORTANT: DO NOT USE on each wire. - Page 7 Pump operates with selector 5. If pump has been in service switch in Hand position but will for some time and capacity not operate in Auto position. falls off, remove pump and check for wear or 1. This indicates trouble in clogged impeller.

- Page 8 H3H Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 001500121 O-Ring 008530001 Wire Conn 575 Volt All hp 001500471 O-Ring 151480003 Spacer 071380015 Connection Box 200/575/3/60 071380015 Connection Box 230/1/60 071380005 Connection Box 230/460/3/60 000640041...

- Page 9 H4H Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 001500121 O-Ring 008530001 Wire Conn 575 Volt All hp 071380015 Connection Box 200/575/3/60 071380015 Connection Box 230/1/60 071380005 Connection Box 230/460/3/60 024940001 Wire Connector 200/3/60 7.5–15 hp 024940001...

- Page 10 S4M Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 19101A010 Hex Hd. Bolt 008530001 Wire Connector 460/3/60 All hp 008530001 Wire Connector 575V All hp, 200V 3 & 5 hp 071380015 Connection Box 230/1/60 071380005...

- Page 11 S4P Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 001500121 O-Ring 008530001 Wire Conn 575 Volt All hp 071380015 Connection Box 200/575/3/60 071380015 Connection Box 230/1/60 071380005 Connection Box 230/460/3/60 002380031 Hex Hd.

- Page 12 S4HRC Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 008530001 Wire Connector 460V 008530001 Wire Connector 575V 000640041 Load Spring 071380005 Connection Box 230V/460V 071380015 Connection Box 200V/575V 001500121 O-Ring 024940001 Wire Connector (Dual Cord)

- Page 13 S4MRC Parts List For use with product built with GE motor. ® Ref. Part Part Description Qty. 35' Cord Assembly 008530001 Wire Connector 460/3/60 All hp 008530001 Wire Connector 575V All hp, 200V 3 & 5 hp 002380031 Hex Hd. Bolt 071380015 Connection Box 200/575/3/60 071380005...

- Page 14 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 15 THIS PAGE INTENTIONALLY LEFT BLANK...

-

Page 16: Standard Limited Warranty

Pentair Hydromatic will cover only the lower seal and labor thereof for all dual seal pumps. under no circumstance will Pentair Hydromatic be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight expenses to and from the factory or an authorized Pentair Hydromatic service facility.

Need help?

Do you have a question about the HYDROMATIC H3H and is the answer not in the manual?

Questions and answers