Advertisement

INSTALLATION AND SERVICE MANUAL

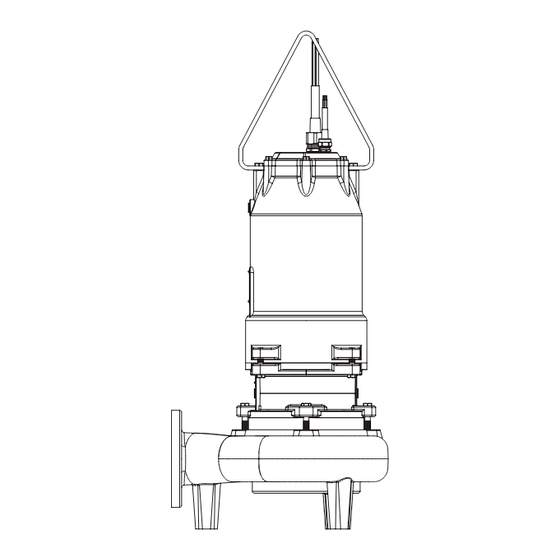

SUBMERSIBLE

SOLIDS HANDLING

PUMP

HYDROMATIC

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-557 | Part # 056255571 | © 2018 Pentair plc | 09/25/18

ENGLISH: PAGES 2-12

Installation and Service Manual

For use with product built with Premium

Efficient motor.

Make sure this manual is provided to the owner

of the equip ment or to the responsible party who

maintains the system.

(Hazardous Location

Motor End)

Models

C4S(X)P, H3H(X)P,

H4H(X)P, S4M(X)P,

S4P(X)P, S4HV(X)P

and S4MV(X)P

(Class I, Division 1, Groups C & D): FM

Advertisement

Table of Contents

Summary of Contents for Pentair Hydromatic C4SP

- Page 1 NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Item # E-03-557 | Part # 056255571 | © 2018 Pentair plc | 09/25/18...

-

Page 2: General Information

General Information This circuit must be connected to a Pump Installation sensing unit and signaling device. This Attention: Installing Sump Level Controls Float is supplied in a Hydromatic built control ® Controls: This manual contains important panel. information for the safe use of this In either simplex, duplex or triplex NOTE: Failure to install such a device product. -

Page 3: Pump Operations

THIS IS IMPORTANT, AS ONE GROUNDED separate the cord cap casting from the Connect amprobe to pump power WIRE CAN CAUSE CONSIDERABLE motor housing, the assembly is airtight cord and turn pump on. The pump will TROUBLE. and will have a vacuum effect when show high amp draw momentarily, disassembling. -

Page 4: Pump Maintenance

10. Check voltage when pumps are leads, a test light is provided on The quick disconnect cords, upper operating and check the amp draw intrinsically safe Hydromatic panels as and lower seal, volute and impeller of each pump. Check amps on each standard equipment. -

Page 5: Pump Troubleshooting

Pump does not deliver proper Adjust Cutter Clearance on Pump Troubleshooting capacity. Chopper Pump Below is a list of common problems and 1. Discharge gate valve may be the probable causes: WARNING: Disconnect power before partially closed or partially clogged. adjusting chopper clearance;... - Page 6 C4S(X)P, H3H(X)P, H4H(X)P, S4M(X)P, S4P(X)P, S4HV(X)P and S4MV(X)P Parts List For use with product built with Premium Efficient motor. 3, 4 Ref. Part Part Ref. Part Part Description Qty. Description Qty. 28010D000 MOTOR HOUSING 19103A048 CAPSCREW – S4M(X)P, S4MV(X)P, S4HV(X)P 27818D010 BEARING HOUSING 19103A060...

- Page 7 Hydraulic End Parts List S4MXP S4MVXP D6 D5 S4PXP H3HXP D10 D8 D9 D12 D11 D13 S4HVXP C4SXP D5 D6 H4HXP Item No. Description S4M(X)P S4MV(X)P S4HV(X)P S4P(X)P H3H(X)P H4H(X)P C4S(X)P O-RING 001500581 001500581 001500581 05876A136 05876A136 05876A136 05876A136 IMPELLER KEY 083460033 083460011 083460011...

- Page 8 Motor Parts Group 10 – 15 hp 10 – 15 hp 10 – 15 hp 7.5 hp 7.5 hp 7.5 hp 208-230/3/60 460/3/60 575/3/60 208-230/3/60 460/3/60 575/3/60 Item 2-Pole 3450 RPM STATOR 27889D003 27889D003 27889D603 27887D003 27887D003 27887D603 A2 ROTOR/SHAFT ASSEMBLY 27887D011 27887D011 27887D011...

- Page 9 Impeller Parts List S4HV(X)P S4M(X)P Description Part No. Voltage/ph Cord Trim Impeller Description Part No. Voltage/ph Cord Trim Impeller 3450 RPM 1750 RPM S4HV(X)P750DD 528000087 208/3 4.63 082130172 S4M(X)P500BC 528010177 208/1 6.75 070710312 S4HV(X)P750ED 528000097 230/3 4.63 082130172 S4M(X)P500CC 528010187 230/1 6.75 070710312...

-

Page 10: Wiring Diagrams

Wiring Diagrams... - Page 11 THIS PAGE INTENTIONALLY LEFT BLANK...

-

Page 12: Standard Limited Warranty

Pentair Hydromatic will cover only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight expenses to and from the factory or an authorized Pentair Hydromatic service facility.

Need help?

Do you have a question about the Hydromatic C4SP and is the answer not in the manual?

Questions and answers