Summary of Contents for Kobold ZDM Series

- Page 1 ZDM Positive Displacement Flow Meter User Instructions Canada 1801 Parkway View Drive 9A Aviation Pittsburgh, PA 15205 Point Claire, QC H9R 4Z2 PH 412-788-2830 PH 514-428-8090 www.koboldusa.com ZDM_manual_11-10...

-

Page 2: Table Of Contents

Table of Contents Topic Page General ............1 Description . -

Page 3: General

For safety reasons, please read the cautionary information located at the end of this manual, before attempting installation. General Congratulations on your purchase of a Kobold ZDM Positive Displacement flowmeter. The ZDM is one of the most precise and reliable low volume, liquid flow measuring products available today. -

Page 4: Description

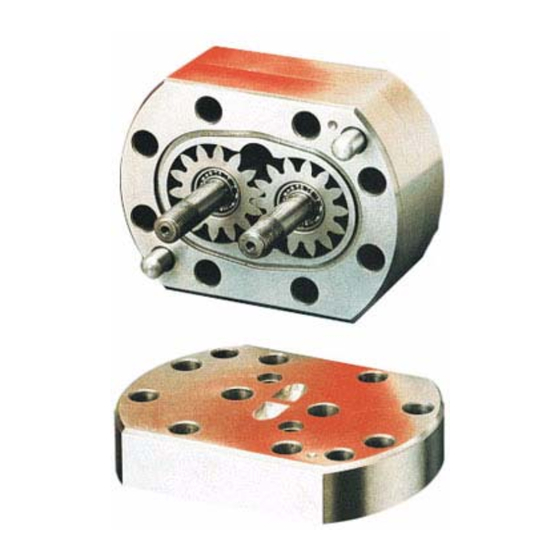

Description Principle of Operation The ZDM operates on the volumetric displacement principle. The meter moves pockets of liquid from the inlet port to the exit port in discrete segments of known volume. These pockets are defined by the space between adjacent gear teeth and the internal housing wall. -

Page 5: Filtration Requirements

Filtration Requirements 10 µM (1600 mesh) ZDM-XX02, -XX04, -XX07: 20 µM (750 mesh) ZDM-XX08, -XX09: 50 µM (250 mesh) ZDM-XX10, -XX20, -XX40: Maximum Pressure Rating: Cast Iron: 4500 PSIG St. Steel: 6500 PSIG Maximum Temperature Rating Standard: -40 to 248°F Accuracy: ±0.3% of reading with viscosity >20 cSt. -

Page 6: Pressure Loss

2.2.2 Pressure Loss Pressure loss is a function of the viscosity of the liquid being metered, and its rate of flow. Detailed pressure loss information may be found in Appendix A of this manual. Installation Instructions CAUTION: For safety reasons, please read the cautionary information located at the end of this manual, before attempting installation. -

Page 7: Connecting Piping To The Sensor

3.1.4 Connecting Piping to the Sensor The procedure for attaching piping to the sensor depends on the type of thread that was ordered with the sensor. The most common thread in North America is NPT (series ZDM-3XXX and ZDM-4XXX sensors.) Occasionally, the European pipe thread (BSP) is ordered because of its superior leak resistance. -

Page 8: Operating Instructions

Operating Instructions Turning the Unit On Supply power. Flow Measurement The ZDM transmits a frequency based electronic signal in response to flow through its mechanism. This signal takes the form of a square wave, the amplitude of which is the supply voltage (V ) minus 1.0 VDC. -

Page 9: Turning The Unit Off

If damage is visible, notify your local carrier at once. The carrier is liable for a replacement under these circumstances. If your claim is refused, please contact KOBOLD Instruments. Maintenance The ZDM is continuously lubricated by the medium flowing through its internal components, so no extra lubrication is required. -

Page 10: Appendix A: Pressure Loss Vs. Flow Rate At Various Viscosities

Appendix A: Pressure Loss vs. Flow Rate at Various Viscosities FM Rev. 11/10... - Page 11 FM Rev. 11/10...

- Page 12 FM Rev. 11/10...

- Page 13 ZDM-0010 Pressure Loss FM Rev. 11/10...

- Page 14 FM Rev. 11/10...

- Page 15 CAUTION PLEASE READ THE FOLLOWING WARNINGS BEFORE ATTEMPTING INSTALLATION OF YOUR NEW DEVICE. FAILURE TO HEED THE INFORMATION HEREIN MAY RESULT IN EQUIPMENT FAILURE AND POSSIBLE SUBSEQUENT PERSONAL INJURY. FM Rev. 11/10...

- Page 16 • User's Responsibility for Safety: KOBOLD manufactures a wide range of process sensors and technologies. While each of these technologies are designed to operate in a wide variety of applications, it is the user's responsibility to select a technology that is appropriate for the application, to install it per these installation instructions, to perform tests of the installed system, and to maintain all components.

Need help?

Do you have a question about the ZDM Series and is the answer not in the manual?

Questions and answers