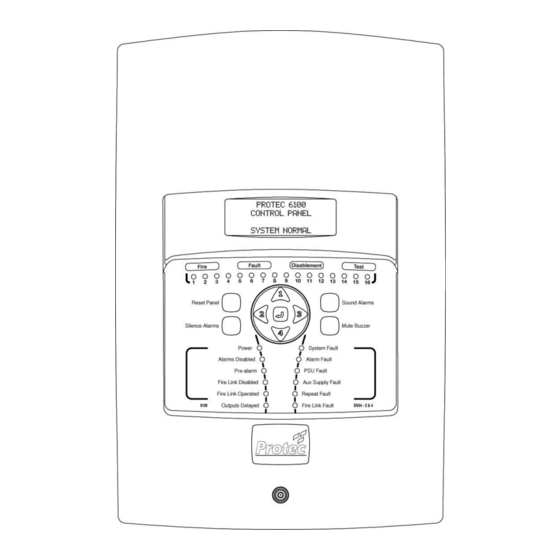

Protec 6100 Pc Programming Manual

Single loop digital addressable fire alarm control panel

Hide thumbs

Also See for 6100:

- User manual (34 pages) ,

- Installation and commissioning manual (52 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Protec 6100

- Page 1 6100 SINGLE LOOP DIGITAL ADDRESSABLE FIRE ALARM CONTROL PANEL PC PROGRAMMING MANUAL Protec Fire Detection PLC, Protec House, Churchill Way, Nelson, Lancashire, BB9 6RT. Telephone: +44 (0) 1282 717171 Fax: +44 (0) 1282 717273 Web: www.protec.co.uk Email: sales@protec.co.uk...

- Page 2 Document Revision Details Issue Modification Detail Author Date Document Creation 20 / 06 / 2012 N 93-531-79 ISSUE 1 NH Page 2 of 32 © Protec Fire Detection PLC 2012...

-

Page 3: Table Of Contents

Creating a Blank Site File ......................15 Creating a Site File Using the Loop Commissioning Booklet ............15 Creating a Site File by Logging and Mapping Devices Directly on the 6100 ........ 16 10.0 PROGRAMMING LOOP DEVICE DATA ..................16 10.1... - Page 4 Programming Dual Fire Link Outputs ..................27 14.0 VIEWING HISTORIC EVENT LOGS ....................28 15.0 UPLOADING AND DOWNLOADING SITE FILES TO THE 6100 ........... 28 15.1 Uploading a Site File from the 6100 ..................28 15.2 Downloading a Site File to the 6100 ..................28 15.3...

-

Page 5: Important Notes - Please Read Carefully

MUST carry out any internal maintenance work. The policy of Protec Fire Detection plc is one of continuous improvement and as such we reserve the right to make changes to product specifications at any time and without prior notice. -

Page 6: Glossary Of Terms

Site-file Refers to the site configuration data file that is stored the 6100, this file contains the data about loop devices, panel settings, loop device text, zone text, panel text and cause and effect ( matrix ) information. When this file is uploaded using the Windows commissioning software any historic event logs are automatically appended to it. - Page 7 There is no need for a USB dongle. Managed System If the system is managed, then a dongle is required ( available from Protec ) to access all features in the commissioning software. Without a dongle, or with an incorrect dongle fitted, the commissioning software will not connect to the 6100.

-

Page 8: Introduction

The Protec 6100 Fire Alarm Control Panel has been designed and manufactured in the United Kingdom. The 6100 complies fully with current standards dictating fire alarm system design practice ( EN54 parts 2 and 4 ). The 6100 panel is a single loop fire alarm control panel incorporating an on-board power supply and high power loop driver circuitry that allow communication to a maximum of 192 Protec 6000Plus series devices. -

Page 9: Information Required Prior To Commissioning

A commissioning form is available upon request which should be filled in with the relevant information. Items Required to Commission the 6100 Using a PC PC / Laptop Requirements The PC used to connect to the 6100 must conform to the following minimum specification. 1 GHz processor. •... -

Page 10: Loading The 6100 Commissioning Software Onto A Pc

DO NOT touch any connections or cabling. The PC connects to the 6100 using a standard USB cable ( see section 5.0 ). The USB port on the 6100 is accessed by removal of the enclosure front cover, as shown in figure 7.0. -

Page 11: Connecting The Pc To The 6100

The USB communication port is located on the centre left of the 6100 PCB housing ( see figure 7.0 ). Ensuring the 6100 is powered up connect the USB cable to a free USB port on the host PC, then carefully plug the other end of the USB cable into the USB port on the 6100. -

Page 12: Overview Of 6100 Commissioning Software Environment

Selecting a menu option brings it to the main screen. Information entered in a menu option is retained when swapping between menus. To open the commissioning software double click on the 6100 icon ( usually present on the PC’s desktop ). The main screen will open as illustrated in figure 8.0. -

Page 13: The File Menu

This option loads a previously saved site file. The user must navigate to the file and open it. All site files have the .psf file extension. Import Text Text previously exported from the Protec Excel text editor can be imported into the site file using this function. Save / Save As Allows the site file currently loaded to be saved ( as filename.psf ). -

Page 14: The View Menu

( relevant dongle must be installed ). The Help menu This menu allows the user to generate an emergency access code ( if the entry codes for the 6100 have been forgotten ), check for updates to the commissioning software or download relevant 6100 documentation from the internet. -

Page 15: Creating A Site File

When all devices have been scanned in from the Loop Commissioning Booklet the site file must be downloaded into the 6100 and the loop logged and mapped, at this point the software version and map node are added to the site file ( it becomes a complete site file ) and it must be uploaded from the 6100 for backup purposes. -

Page 16: Creating A Site File By Logging And Mapping Devices Directly On The 6100

Creating a Site File by Logging and Mapping Devices Directly on the 6100 The alternate method for creating a site file is to log and map loop devices on the 6100, then upload the site file into the commissioning software. Any loop device parameters or panel options may then be edited as required and the file downloaded into the 6100. -

Page 17: Programming Loop Sounder Volume Levels

Non-latching devices cause the 6100 to automatically reset when they return to normal after being activated. Note that the 6100 will only automatically reset if no other activations are present on the system. If several non-latching devices are active, the 6100 will only reset when all devices have returned to the normal state. -

Page 18: Setting Automatic Detector Sensitivities

LED ( consult the datasheet for the specific product for connection details ). Each loop address on the 6100 can be allocated a Repeat Group in the range 1 to 32. The Repeat Group number is related to an 6100 output group activation ( output groups range from 1 to 32 ). -

Page 19: Programming Cause And Effect Sequences ( Matrix )

C ( continuous ). 11.2 Setting up Output Group Delays The 6100 supports delays to output groups. Delays times can be set from 5 seconds to 10 minutes, in 5 second steps. If an output group activation changes from OFF to ON ( C, P or W ) the change will not be actioned until the programmed delay time has expired. -

Page 20: Programming The Output Group Type

Figure 11.1 shows the matrix when both the Class Change and Remote Alarm inputs are enabled. Figure 11.1 Class Change, Remote Alarm and Sound Alarms matrix lines N 93-531-79 ISSUE 1 NH Page 20 of 32 © Protec Fire Detection PLC 2012... -

Page 21: Setting Up Coincidence Operation

11.5 Setting up Coincidence Operation The 6100 offers coincidence programming to EN54-2 ( Type C Dependency ). Using the Edit -> Coincidence open the coincidence programming window ( as illustrated in Figure 11.2 ) Choose the required number of coincidence input groups by clicking on the relevant ‘Number of Groups’... -

Page 22: Entering Device, Zone And Panel Text

12.0 Entering Device, Zone and Panel Text The 6100 can store 20 characters of text per loop address, 20 characters of text per zone and two lines of 20 characters for the panel text. To enter or edit text use the Edit->Text editor option. -

Page 23: Programming Panel Configuration Data

To edit panel configuration settings use the Edit->Panel info option. The window shown in Figure 13.0 is displayed. Figure 13.0 13.1 Programming the Panel Access Codes The 6100 uses four codes to access various parts of the system. The codes are: User code Allows access level 2 functions to be accessed... -

Page 24: Programming The Fire Link Delay

13.3 Programming the Fire Link Delay In some situations it is advantageous to introduce a delay from when the 6100 detects a fire until the fire link output is activated. The activation of the fire link output can be delayed by up to 10 minutes ( in 5 second steps ). -

Page 25: Programming Talking Sounder Options

C ( continuous ) and P ( pulsing ) options in the matrix. 13.8 Programming the Pulsing Alarm Timeout and Tone An option is included in the 6100 for pulsing output groups to timeout to an alternate tone. Only pulsing, non talking outputs groups are affected by this feature. -

Page 26: Programming Day And Night Sensitivity Times

To enable Class Change operation the Class Change Input option should be selected. Input group 30 is used for class change programming and cannot be re-used for loop devices. If Class Change is not enabled operation of the Class Change input on the 6100 PCB will have no effect. 13.13 Programming Loop Beacon Operation The 6100 supports synchronised loop controlled beacons, the operation of them can be programmed using the ‘Beacon’... -

Page 27: Overriding System Delays On A Second Knock Coincidence Activation

13.17 Programming Dual Fire Link Outputs The 6100 normally provides a single Fire Link output ( operates on automatic and manual fires ) and a pair of conventional alarm outputs. It is possible to alter this configuration so that the standard Fire Link output operates only on automatic activations, and the conventional alarm output ( ALARM 1+ and 1- ) changes function to become a second Fire Link output which operates only on manual activations. -

Page 28: Viewing Historic Event Logs

( see section 7.0 ). 15.1 Uploading a Site File from the 6100 Site files must be uploaded from the 6100 in order to edit them, save them for backup purposes or to view the historic events. Using the Panel->get settings from panel window retrieve the site file from the 6100. This process should take around 5 seconds, after which the site file will be loaded into the 6100 commissioning environment. -

Page 29: Checking For Updates To The Commissioning Software

Commissioning Software are offered. Before agreeing to the update, the user must be certain that updated commissioning software is compatible with the 6100 being used. If in doubt contact Protec ( with the software version of the 6100 ) for advice. - Page 30 BLANK PAGE N 93-531-79 ISSUE 1 NH Page 30 of 32 © Protec Fire Detection PLC 2012...

- Page 31 BLANK PAGE N 93-531-79 ISSUE 1 NH Page 31 of 32 © Protec Fire Detection PLC 2012...

- Page 32 Protec Fire Detection PLC, Protec House, Churchill Way, Nelson, Lancashire, BB9 6RT. Telephone: +44 (0) 1282 717171 Fax: +44 (0) 1282 717273 Web: www.protec.co.uk Email: sales@protec.co.uk N 93-531-79 ISSUE 1 NH Page 32 of 32 © Protec Fire Detection PLC 2012...

Need help?

Do you have a question about the 6100 and is the answer not in the manual?

Questions and answers