Summary of Contents for Rice Lake TE Series

- Page 1 Rice Lake TE Series Tuning Fork Enhanced Balance Operation Manual February 26, 2018 PN 185193 Rev A...

- Page 2 All information contained within this publication is, to the best of our knowledge, complete and accurate at the time of publication. Rice Lake Weighing Systems reserves the right to make changes to the technology, features, specifications and design of the equipment without notice.

-

Page 3: Table Of Contents

3.15 Comparator Function ................26 Technical training seminars are available through Rice Lake Weighing Systems. - Page 4 Balance Manage Menu ............... 50 Rice Lake continually offers web-based video training on a growing selection of product-related topics at no cost.

- Page 5 Functional Specifications ..............49 Technical training seminars are available through Rice Lake Weighing Systems.

- Page 6 Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Rice Lake continually offers web-based video training on a growing selection of product-related topics at no cost. Visit www.ricelake.com/webinars Visit our website www.RiceLake.com...

-

Page 7: Introduction

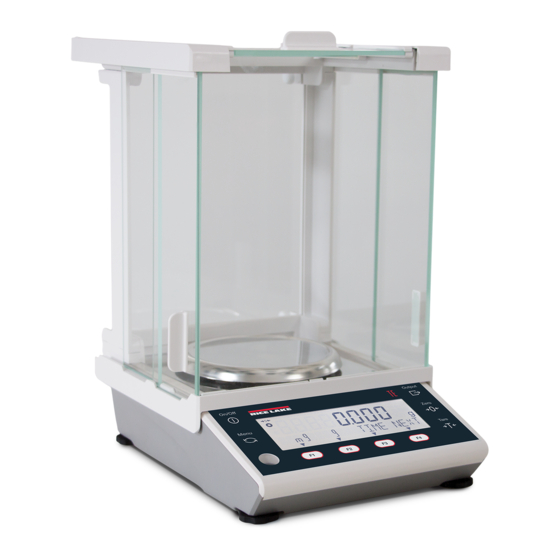

Manuals can be viewed or downloaded from the Rice Lake Weighing Systems website at www.ricelake.com/manuals Limited Warranty The Rice Lake TE Series Tuning Fork Enhanced Balance comes with a five year limited warranty. For more information refer to the Rice Lake Weighing Systems website at www.ricelake.com/warranties Figure 1-1. - Page 8 Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Part No. Model No. Description 186030 TE-623 620 g x 0.001 g 186034 TE-1203 1,200 g x 0.001 g 186035 TE-3202 3,200 g x 0.01 g 186036 TE-6202 6,200 g x 0.01 g...

-

Page 9: Safety

Do not operate or work on this equipment unless this manual has been read and all instructions are understood. Failure to follow the instructions or heed the warnings could result in injury or death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. -

Page 10: Front Panel

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Front Panel 25 25 25 Figure 1-2. Display Overview Item No. Description Power – press to turn unit on; a long press to turn off Menu – press to enter/exit the setting menu; cancels setting value selection; returns to the measuring mode Output –... -

Page 11: Installation

• remove any dust or liquid from the pan and/or pan base prior to operation. • ensure that no dust or liquid enters the balance when cleaning • frequent cleaning of the balance is required ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 12: Unpack Balance

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Unpack Balance Unpack the balance and inspect the contents. Report missing or damaged components to the shipper and Rice Lake Weighing Systems immediately. Windshield Square Pan Square Pan Base Round Pan... -

Page 13: Connections And Part Locations

Section 2.7 on page 10 Weighing pan Level Feet/Adjusters Display Battery case AC adapter jack USB connector (Type B) RS-232C connector (D-sub 9 pin male) Option slot Adapter with attachments Table 2-1. Parts and Locations ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 14: Assemble Balance

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Assemble Balance Use the following steps to assemble the balance. 2.4.1 Round Base Assembly Figure 2-3. Assemble Base 1. Ensure the lock plate is in the unlocked position. 2. Set the pan base on the balance. -

Page 15: Leveling The Balance

Figure 2-7. Level the Balance 2. Turn feet/adjusters until the bubble level is centered in the center circle. Figure 2-7 indicates directions to turn the feet/ adjusters to move the bubble in the center. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 16: Shield Assembly

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Shield Assembly The shield for the balance must be assembled using the following steps. Back Side Brace Back Side Brace Bolt Bottom Frame Figure 2-8. Install Rear Side Braces 1. Place the bottom frame on a flat level surface. - Page 17 Rollers into the top frame, ensure they are in the outside guides. Figure 2-12. Insert Side Assemblies ©Rice Lake Weighing Systems ● All Rights Reserved...

- Page 18 Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 10. Place the glass side panels together ensuring the rollers are on the outside. Use one panel with the handle and one without as a pair. 11. With the panel with the handle facing toward the outside and the panels held tightly together insert the rollers into the...

- Page 19 Back Side Panels (Left and Right) Level Feet/Adjusters Display Battery case AC adapter jack USB connector (Type B) RS-232C connector (D-sub 9 pin male) Option slot Adapter with attachments Table 2-2. Shield Parts List ©Rice Lake Weighing Systems ● All Rights Reserved...

-

Page 20: Operation

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Operation This section walks through using the eight modes of operation and the other functions used during the operation of the balance. Always adjust the level of the balance before use. -

Page 21: Standby

Net icon display. 3. Place the product to be weighed in the container. The net weight displays. 4. Removing the product and container from the balance. 5. Press to remove the tare. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 22: Preset Tare

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 3.5.1 Preset Tare When a tare weight is already known, the tare subtraction can be configured as a Preset Tare parameter. Five preset tare values can be stored. See Section 4.4.2 on page To use a preset tare: 1. -

Page 23: Weigh Mode

HIGH Displays onW or NUM. Select onW to display current limit high, press NUM to enter a new limit high. WEIG Press to display weigh mode Table 3-3. Counting Mode F-key Commands ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 24: Actual Value Setting - No Change

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance F-Key Selections Descr iption COUN Press to display count mode PCNT Press to display percent mode NEXT Press to move between menu selections Table 3-3. Counting Mode F-key Commands (Continued) 3.7.1 Actual Value Setting –... -

Page 25: Percentage Mode

• Numeric value (NUM) – use to enter the reference weight and press (OK) 6. Weigh the product, the ratio of the weight of the product to the reference weight is displayed in percent. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 26: Coefficient Mode

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Coefficient Mode Measured weight is multiplied by the preset coefficient. This mode is not available in Legal for Trade units. Figure 3-4. Coefficient Mode F-Keys F-Key Selections Descr iption CSET Set the Coefficient value •... -

Page 27: Specific Gravity Mode

. The current operation mode displays. 2. If needed, press . The currently displayed mode flashes. 3. Use to scroll to SPGR. 4. Press , then press to return to operation mode. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 28: Statistics Mode

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 5. Select the reference liquid by pressing • OTHER – liquid other than water • H20 – water 6. Enter the specific gravity of the reference liquid and press to save. -

Page 29: Animal Mode

Manually press to hold the weight WEIG Press to display weigh mode COUN Press to display count mode PCNT Press to display percent mode NEXT Press to move between menu selections Table 3-8. Animal Mode F-Keys Descrptions ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 30: Weigh Animal Using Manual Hold

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance When the external output is activated, the output condition is fixed as following: • Output once after the indication is held except when the HOLD is pushed (step ???). • Output once after is pressed during the indication is held. -

Page 31: Data Review

. 11 MODE and the current operation mode displays. 3. Press to scroll to UNIT. 4. Press to change the display unit. 5. Press to scroll to the desired unit. See Table 4-2 on page ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 32: Comparator Function

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 6. Press to save the operation mode. 7. Press to return to operation display. 3.15 Comparator Function The comparator Function is used to preset threshold values (limits) and determine if a measured value is within the preset range. -

Page 33: Plus Side Addition

See Section 4.7.2 on page 1. Place a first specimen to be weighed. displays. 2. Press . displays. For Addition Accumulating 1. Perform steps 1-2 under Section 3.16.1. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 34: View/Delete Total Value

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 2. Remove the specimen. displays. 3. Press . The weighed value is stored and SUM TOTAL displays momentarily. 4. Repeat this procedure until all additions have been completed. For Net Addition 1. -

Page 35: Stabilization Wait Function

BARGRAPH. 4. Press . The current setting begins to flash. 5. Press to select ON or OFF. 6. Press to save the setting. 7. Press to return to operation display. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 36: Back Light Display

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 3.21 Back Light Display The back light can be set to 3MIN, 5MIN, 10MIN, 30MIN, ON or OFF. The back light will be on for the set number of minutes or always on if ON is selected. -

Page 37: Set Scs Method

SIMPLE SCS. 4. Press . The current setting begins to flash. 5. Press to select ON or OFF 6. Press to save the setting. 7. Press to return to operation display. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 38: Configuration

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Configuration Flashing Digit Menu Name Figure 4-1. Navigation for Configuration Use the keys to navigate through the menus and settings. • enter menu, cancels an input value, returns to previous menu, returns to weigh mode •... -

Page 39: Application Menu

15 T REMINDER 16 Z REMINDER 17 WT STABLE 18 BARGRAPH 3MIN 30MIN 1A BACKLIGHT 5MIN 10MIN 10MIN 1B AUTO OFF 30MIN 3MIN 5MIN 1C SIMPLE SCS Figure 4-2. 1-Applications Menu Layout ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 40: Operation Modes

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Menu Par ameter s Descr iption Menu Par ameter s Descr iption 15 T REMINDER Tare on Reminder 11 MODE Select operation mode, see Section 4.2.1 on page 34 Disabled WEIG... -

Page 41: Units

UNIT. 4. Press to change the display unit. 5. Press to scroll to the desired unit. 6. Press to save the operation mode. 7. Press to return to operation display. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 42: Comparator Menu

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 4.2.3 Comparator Menu 13 COMPARATOR 131 ACTIVATE HIGH FULL 132 CONDITION STBL 133 RANGE FULL ABSOL 134 METHOD RELAT Figure 4-3. Applications Comparator Menu Layout Menu Par ameter s Descr iption... -

Page 43: Addition

1. Press displays. applICations 2. Press . 11 MODE and the current operation mode displays. 3. Press to scroll to ADDITION. 4. Press to enter the menu. ACTIVATE displays with current setting. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 44: Performance Menu

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 5. Press . The current setting begins to flash. 6. Press to select desired setting. 7. Press to save the setting. 8. Press to scroll to OPERATION. 9. Press . The current setting begins to flash. -

Page 45: Stability

The larger the value is set in this menu, the more stable the balance display becomes in unstable conditions. 1. Press displays. applICations 2. Press to scroll to PERFORMANCE. 3. Press . 21 STABLE and the current setting displays. 4. Press to scroll to 22 RESPONSE. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 46: Zero Tracking

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 5. Press . The current setting begins to flash. 6. Press to select desired setting. 7. Press to save the setting. 8. Press to return to operation display. 4.3.3 Zero Tracking The zero tracking function makes it possible to automatically correct the zero-point fluctuation when 0 is displayed, through which the 0 display is maintained. -

Page 47: User Information

Setting value input Multiply Ref Multiply Low Table 4-6. User Information Menu 4.4.1 Preset Tare Mode A preset tare can be selected prior to weighing. See Section 3.5.1 on page 16 for more information. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 48: Input Preset Tare Value

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 4.4.2 Input Preset Tare Value There are two ways of inputting a preset tare weight value. • Actual value setting method (onW) – weighing a sample with a scale and then making it a setting value •... - Page 49 • Comparator setting for Weighing mode: 33 COMPARE WEIGHT • Comparator setting for Percentage mode: 34 COMPARE PERCENT • Comparator setting for Counting mode: 35 COMPARE COUNT • Comparator setting for Multiplied by Coefficient mode: 36 COMPARE MULT ©Rice Lake Weighing Systems ● All Rights Reserved...

-

Page 50: External Input/Output Functions

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance External Input/Output Functions This function is used for communication through the external peripheral devices. There are RS-232C (D-SUB 9P) and USB (Type B) interface as standard equipment, and each interface slot for option. See Section 5.0 on page 52... - Page 51 Fill with a blank space (0 x 20) ZERO Fill with 0 (0 x 30) RESPONSE A00 Exx format ACK, NAK format STATUS Not added Append OP LIMIT (Option) ACTIVATE Operation Relay Output Stop Table 4-8. External Input/Output Parameters ©Rice Lake Weighing Systems ● All Rights Reserved...

-

Page 52: Lock Functions

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Lock Functions Limitations can be imposed on key operation and in accessing menu items. 5 LOCK 51 ALL UNLOCK 52 KEY LOCK 53 MENU LOCK 531 OPERATION 532 PERFORM 533 USER 534 I/O Figure 4-8. -

Page 53: Menu Lock Function

The current setting flashes. 8. Press to display ON or OFF. 9. Press . Setting stops flashing. 10. When all menus are set, press to return to the weigh mode. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 54: Admin/Adjust Menu

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Admin/Adjust Menu Perform setting of the balance ID, the span adjustment and the date and time 6 ADMIN/ADJUST 61 SHORT CUT MODE WEIG 611 F1 KEY SPGR COUN STAT 612 F2 KEY... -

Page 55: Set Short Cut Mode

11. Repeat Steps 5-9 until all Free Keys are set. 12. Press to return to operation display. 4.7.3 Maintenance Settings 1. Press displays. applICations 2. Press . 11 MODE and the current operation mode displays. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 56: Balance Manage Menu

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 3. Press to scroll to ADMIN/ADJUST. 4. Press . The current sub-menu displays. 5. Press to MAINTENANCE. 6. Press . The current parameter displays. 7. Press to scroll to desired parameter. - Page 57 Span adjustment with internal weight at power on Disabled FORCE Enabled SELEC Selectable 64C DIRECT ST Direct start setting Disabled Enabled 64D INITIALIZE Initialize Cancel Execute Table 4-10. Controlling and Adjusting – Balance Manage Parameters ©Rice Lake Weighing Systems ● All Rights Reserved...

-

Page 58: Communications

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Communications The balance can be connected to a computer using a compatible third party software program. Connections can be made using RS-232 or USB interfaces. Basic specifications include: • RS-232C full duplex or USB half duplex •... -

Page 59: Usb Connections

U1, U2 (two characters) indicates the unit used to show numeric data 0x4D 0x47 mg (milligram) (SP) 0x20 0x47 g (gram) 0x43 0x54 ct (carat) 0x4D 0x4F mom (momme) Table 5-3. Data Description ©Rice Lake Weighing Systems ● All Rights Reserved... - Page 60 Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Symbol Code Description 0x4F 0x5A oz (ounce) 0x4C 0x42 lb (pound) 0x4F 0x54 ozt (troy ounce) 0x44 0x47 dwt (penny weight) 0x47 0x52 GN (grain) 0x54 0x4C tlH (Hong Kong tael)

-

Page 61: Cbm Data Output Format

0x5D (SP) Spaces fill the top of the data Output to the least significant digit in the absence of a decimal point Unused high-oder digit Table 5-4. Data Description ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 62: Input Commands

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Symbol Code Description [U1, U2] (2 characters) Represents the unit of numeric value data. 0x4D 0x47 (milligram) (SP) 0x20 0x47 (gram) 0x43 0x54 (carat) 0x4D 0x4F mom (momme) 0x4F 0x5A (ounce) -

Page 63: Input Command Composition 1

Table 5-7. Zero Point Adjustment/Tare/Output Control Setting Command Code (C1) Code (C2) Description Response 0x44 0x44 Date output request Date data 0x44 0x54 Time output request Time data Table 5-8. Data Output Request and Time Output Request ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 64: Input Command Composition 2

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 5.6.1 Input Command Composition 2 This is composed of 15 characters including the terminator (CR=0xDH/LF=0xAH). C3 has a 10 digit maximum (including the polarity +/-, comma and point). Do not include the measuring unit. -

Page 65: Response

41A STATUS, 42A STATUS and 43A STATUS cannot be selected. The net value status is always appended. Use the following steps to activate the desired communication source. 1. Press displays. applICations 2. Press to select EXTERNAL I/O ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 66: Set Communication Parameters

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 3. Press . The current setting displays. 4. Press to select the communication source desired. 5. Press to enter the menu. 6. Press to display ACTIVATE 7. Press . The current setting begins flashing. -

Page 67: Usb Communication And Bus Power Inputs

7 – go to the power management tab of the Silicon Labs SP210xUSB to UART Bridge (COM) to open the properties window • Un-check the Allow the computer to turn off this device to save power, check-box, then press the OK key ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 68: Print Examples

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 5.12 Print Examples English Spanish English Spanish English Spanish English Spanish GLP Header GLP Footer Time & Date Statistics mode header Visit our website www.RiceLake.com... -

Page 69: Troubleshooting And Maintenance

• Dirt or liquids on the weighing pan can cause errors or an unstable weight reading. • Clean the balance frequently, ensuring that dust or liquids don’t enter into the internal parts of the balance. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 70: Error Messages

Ensure the specimen weight/reference weight are higher than the lower limit Counting/Percentage mode is below the lower limit ERR001 System error Record the error code and notify the dealer or Rice Lake Weighing Systems ERR099 ERR703 Operation key pushed when unit in standby... - Page 71 Preset tare setting (0g to maximum capac- ity) ERR741 631 EX CAL is executed while the external span Contact the dealer or Rice Lake Weighing Systems adjustment function is disabled ERR742 633 INT CAL, 634 INT SPAN TEST or 636 REF CAL Connect to AC adapter;...

- Page 72 Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Error Message/ Error Code Cause Solution ERR756 Weight of the sample is out of the importing range at Choose sample which weighs within the importing range Statistics/Formulation mode (0g to maximum capac-...

-

Page 73: Basic Maintenance

3. Wipe away dirt with a dry, soft clean cloth. If heavily soiled, remove the weigh pan and the pan base and clean with a clean cloth slightly dampened with a neutral detergent or solvent. ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 74: Dimensions

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance Dimensions TE-223 TE-1203 TE-1502 TE-15001 Figure 6-3. TE Model Dimensions Visit our website www.RiceLake.com... -

Page 75: Specifications

0 - 620.090 Internal and External TE1203R 1200 0.01 0.001 0 - 1200.090 TE3202R 3200 0.01 0 - 3200.90 TE6202R 6200 0.01 0 - 6200.90 TE15001R 15000 0 - 15009.0 Table 6-1. Model Specifications ©Rice Lake Weighing Systems ● All Rights Reserved... -

Page 76: Functional Specifications

Rice Lake TE Series Enhanced High-Precision Tuning Fork Balance 6.5.3 Functional Specifications Item Description Weighing System Tuning fork vibration method Weighing Modes Weighing/counting/percentage/multiplied by coefficient/animal/specific gravity/statistical/formulation modes Functions related to the operation — comparator/adding/tare-subtraction reminder/zero-point adjustment reminder/stability waiting/bar graph/backlight/auto power off/simple SCS Function related to the performance —... - Page 78 Specifications subject to change without notice. Rice Lake Weighing Systems is an ISO 9001 registered company. 230 W. Coleman St. • Rice Lake, WI 54868 • USA U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319...

Need help?

Do you have a question about the TE Series and is the answer not in the manual?

Questions and answers