Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KUHN Merge Maxx 900

- Page 1 OPERATOR'S MANUAL KN093CGB C Merger - English - 04-2010 KN093CGB C...

-

Page 3: Merge Maxx

Merge Maxx 900 $Dear Owner In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and improvement. You will find, as have thousands of owners all over the world, that you have the best that engineering skill and actual field testing can produce. -

Page 4: Table Of Contents

Merger Merge Maxx 900 $Contents Dear Owner ........................1 Contents .........................2 Identification of the machine..................4 Front view (working position) ......................4 Rear view (working position)......................4 Model identification plate ........................5 Optional equipment..........................5 Safety..........................6 Description of symbols used in this document................6 Safety instructions ...........................7 Location and description of safety decals on the machine ............19... -

Page 5: Table Of Contents

Merger Merge Maxx 900 Instructions for work ....................50 Putting the machine into work position ..................50 Adjustments in working position....................53 Machine use............................ 66 Optional equipment ..................... 78 Wide wheels............................ 78 Maintenance and storage.................... 79 Frequency chart ..........................79 Lubrication............................ -

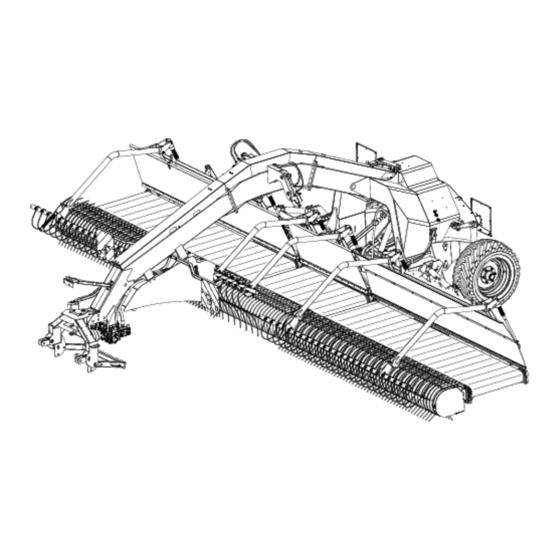

Page 6: Identification Of The Machine

Merger Merge Maxx 900 $Identification of the machine 1. Front view (working position) 2. Rear view (working position) Identification of the machine... -

Page 7: Model Identification Plate

Please write below the type and serial number of the machine. This information is to be indicated to the dealer for all spare parts orders. Type: MERGE MAXX 900 Serial no.: 4. Optional equipment Tick box corresponding to the equipment fitted on your machine: Kit no. -

Page 8: Safety

Merger Merge Maxx 900 $Safety 1. Description of symbols used in this document This symbol indicates a potentially hazardous situation that if not avoided, could result in serious bodily injury. This symbol is used to identify special instructions or procedures which, if not followed strictly, could result in machinery damage. -

Page 9: Safety Instructions

Never let anyone operate the machine who is not trained to do so. Should you have any difficulties in understanding certain parts in this manual, please contact your KUHN dealer. Precautions to be taken before carrying out any operations on the machine... - Page 10 Merger Merge Maxx 900 Precautions to take before using the machine Do not wear loose clothing which could become caught up in moving parts. Wear the appropriate protective clothing for the work in hand (gloves, shoes, goggles, helmet, ear defenders, etc.).

- Page 11 Merger Merge Maxx 900 Precautions when driving on public roads Dimensions Depending on the dimensions of the machine, contact the relevant authorities to ensure that it can be legally transported on public roads. If the machine is over the maximum legal size, follow the local regulations for special transportation of oversize equipment.

- Page 12 Merger Merge Maxx 900 For machines with hoppers or tanks: - If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance with the countrie's legislation, empty the hopper to travel on public roads. - In any case, we recommend to travel on public roads with empty hoppers and tanks.

- Page 13 Merger Merge Maxx 900 Stage 2: - Couple the machine to the tractor. To measure: - Load on front axle (t1): • Tractor + machine (transport position). To do: - If the front axle load (t1) is below 20% of the tractor tare (T), add ballast weights (M1) to exceed the minimum load on the front axle.

- Page 14 Merger Merge Maxx 900 Stage 4: To measure: - Load on rear axle (t2): • Tractor + machine (transport position). • Ballast weights. Checking: - Check in the tractor's operator's manual that the value measured is below the maximum allowed tractor rear axle load.

- Page 15 Merger Merge Maxx 900 Precautions when coupling Before attaching the machine, make sure that it cannot accidentally start moving (chock the wheels) and that the parking stand is in the right position. The machine must only be attached to the hitch points provided for this purpose.

- Page 16 Merger Merge Maxx 900 PTO shaft Use only PTO shafts supplied with the machine or recommended by the manufacturer. The protective shield of the tractor PTO stub, the PTO shaft guards and the protective covering of the machine input shaft must always be in place and in good condition.

- Page 17 Merger Merge Maxx 900 Precautions during manoeuvres When moving the machine from the transport position to the working position and vice versa, make sure that nobody is within the machine pivoting area. Remote controlled components Danger of crushing and shearing can exist when components are operated by hydraulic or pneumatic controls.

- Page 18 Merger Merge Maxx 900 Safety decals Safety warning decals are placed in pictorial form on various parts of the machine. They are there to warn you of potential dangers and to tell you how to avoid accidents. Always keep the safety decals clean and readable, and replace them when they are worn, damaged, missing or illegible.

- Page 19 Merger Merge Maxx 900 Precautions for maintenance and repair work Before leaving tractor before adjusting, maintaining or repairing the machine, disengage the PTO drive, turn off the engine, remove ignition key and wait until all moving parts have come to a complete stop and apply park brake.

- Page 20 Merger Merge Maxx 900 Precautions for machine use After each use, check the seeding tools (shares, coulters) and their attachment hardware in accordance with the instructions given in the present manual. Check the guards regularly. Immediately replace any damaged or missing elements.

-

Page 21: Location And Description Of Safety Decals On The Machine

Merger Merge Maxx 900 3. Location and description of safety decals on the machine Location of safety decals Safety... - Page 22 Merger Merge Maxx 900 Description of safety decals Operating instructions (1) The operators' manual contains all the information necessary for using the machine safely. It is imperative to read and comply with all instructions. Working on the machine (2) Before...

- Page 23 Merger Merge Maxx 900 Body crushing (5) Stay a safe distance from the machine. Crushing hazard. Coupling device (6) Couple the machine to a tractor that is equipped with a system for locking the lift arms laterally and vertically. To drive on roads, respect the attachment height specified in the operator's manual and lock the lift linkage.

-

Page 24: Road Safety Equipment And Recommendations

4. Road safety equipment and recommendations The road safety equipment is mounted in the factory or by your authorized Kuhn dealer according to current safety regulations. Always keep to the legal speed limit for driving a tractor-machine assembly on public roads. - Page 25 Merger Merge Maxx 900 The side device comprises: - 3 amber reflectors (1) on each machine side. Tyre pressure (1) - Standard wheels: 2 bar (29 psi) - Wide wheels: 1.6 bar (23 psi). - Wheel nut torque: • 27 daN m (199 lbf ft)

- Page 26 Merger Merge Maxx 900 Instructions specific to France Coupling device (1) Couple the machine to a tractor that is equipped with a system for locking the lift arms laterally and vertically. To drive on roads, respect the attachment height specified in the operator's manual and lock the lift linkage.

-

Page 27: Machine Specifications

Merger Merge Maxx 900 $Machine specifications 1. Description and glossary Right pick-up Central pick-up Left pick-up Comb Hydraulic fluid reservoir Step up gearbox Parking stand Coupling device Three-point hitch coupler 10 : Drawbar 11 : Transport lock 12 : Folding cylinder... -

Page 28: Technical Specifications

Merger Merge Maxx 900 2. Technical specifications Merge Maxx 900 Coupling device 2 point linkage category 2 and 3 Working width (DIN11220) 9.10 m (29’10’’) - Central windrow delivery 10.50 m (34’5’’) (approximately) - Side windrow delivery Swath width from 1.40 to 1.80 m (4’7’’ - 5’11’’) (approximately) Width in working position 9.50 m (31’2’’) -

Page 29: Required Equipment

Merger Merge Maxx 900 3. Required equipment Wheels The machine is factory supplied with the following set of tires: - Standard wheels (400/55-22.5 14 ply) - Wide wheels (500/45-22.5 14 ply) Braking system This equipment is fitted on the machine transport wheels, in conformity with the legislation in force in the country concerned. -

Page 30: Sound Levels

Merger Merge Maxx 900 - Pneumatic braking system. 4. Sound levels Sound levels have been measured in accordance with the measuring methods as defined in: NF EN 1553 "Agricultural machinery - Self-propelled, mounted, semi-mounted and trailed - Common safety recommendations". -

Page 31: Putting Into Service

Merger Merge Maxx 900 $Putting into service 1. Description of control elements The machine is fitted with a control box to monitor all functions. - Model: T15M Description of the box Display Indicator light 7-pin CAN connector for the connection to the on board computer... - Page 32 Merger Merge Maxx 900 Description of the functions Transport mode Machine locking/unlocking function Machine unfolding/folding function Pick-up pivoting function Pick-up height adjustment function Function for setting the left pick-up in headland turn position Function for selecting the windrow delivery mode...

- Page 33 Merger Merge Maxx 900 The control box is made up of 2 areas (a) and (b): - The functions of area (a) are controlled by tractor valve I. - The functions of area (b) are controlled by tractor valve II.

- Page 34 Merger Merge Maxx 900 Description of the controls Key: On / Off The T15M control box displays the following messages when started: - Software version (T15M): v2.5. Then - The "ECU" message is displayed when the connection is activated to the on board computer.

- Page 35 Merger Merge Maxx 900 Particularity: In certain adjustment modes, the following keys have a different function: - Keys - (1) and + (2): • Enable modifying a mode or a value. - (3) key: • Enables validating an adjustment. - (4) key: •...

- Page 36 Merger Merge Maxx 900 Electrical power supply The box is energized by the tractor's 3-pin socket (DIN 9680, ISO 12369) or the battery power cable supplied. Number of contact Colour of cable Function (1) - 82 Brown +12V (2) - 15/30...

-

Page 37: Coupling And Uncoupling

Merger Merge Maxx 900 Harness connection: - Connect wire (1) to the battery + terminal. - Connect wire (2) to the battery + terminal. - Connect wire (3) to the battery - terminal. Do not connect the wiring harness to the starter connections. - Page 38 Merger Merge Maxx 900 Preparing the tractor The machine adapts to tractors fitted with a 3-point hitch coupler category 2 or 3. The tractor must be fitted with lower link stabilizers. The tractor nominal PTO speed must be 1000 min The tractor must be equipped with: - 1 double acting valve with float position.

- Page 39 Merger Merge Maxx 900 Coupling the machine - Lower the tractor three-point linkage. - Place the lower links as close as possible under the hitch pins. - Attach lower links to the hitch pins on the inside of the yokes.

- Page 40 Merger Merge Maxx 900 Hydraulic connections The tractor must be equipped with 2 double acting valves. Connect hydraulic hoses (a) and (b) of diameter 16 mm (0.6’’) on the same tractor double acting valve. Hoses (a) and (b) supply the following cylinders: - Transport lock cylinders.

- Page 41 Merger Merge Maxx 900 Connections for the hydraulic braking (depending upon specification) Connect hydraulic hose for braking system to the tractor "trailor brake" coupler. After connecting the hose, check that there is no risk of it getting caught during operation.

- Page 42 Merger Merge Maxx 900 Electrical connections Control box - Connect 7-pin plug (1) of module (3) to control box (2). - Connect the module M400 (3) wiring harness (4) to the tractor 3-pin plug (5). Lighting - Connect 7-pin plug to the tractor.

- Page 43 Merger Merge Maxx 900 Primary PTO shaft Make sure that the PTO shaft is correctly adjusted, to avoid premature wear and tear. The tractor PTO stub must rotate at a speed of 1000 min Separate the two half PTO shafts and connect them to the machine's input shaft and to the tractor PTO stub.

- Page 44 Merger Merge Maxx 900 To avoid serious accidents, the PTO drive shaft guards must be properly in place and fixed with the chains provided. Attach PTO shaft guard chain in hole (1) on machine side. Immediately replace any worn or damaged guard.

- Page 45 Merger Merge Maxx 900 Adjusting the machine Lateral adjustment of the lower linkage arms Balance the play on either sides of the lift linkage and lock lower link stabilizers. Frame height - Lower the tractor lift linkage so that hitch pins are at a distance H = 630 mm (2’1’’) from the ground.

- Page 46 Merger Merge Maxx 900 Uncoupling the machine Park the machine on an even fairly level ground. Preferably park the machine in transport position. - Block machine with wheel chocks (1). - Release and lower parking stand (2). - Secure parking stand using lock (1).

- Page 47 Merger Merge Maxx 900 - Disconnect and store brake system hydraulic hoses on holder. - Disconnect and store hydraulic hoses on holder (2). - Disconnect and store signalling electric plug on holder (2). - Disconnect and store module electric supply plug.

-

Page 48: Instructions For Transport

Merger Merge Maxx 900 $Instructions for transport Before placing the machine into transport position: - Wait until the rotating parts have come to a complete stop. - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. - Page 49 Merger Merge Maxx 900 - Press for approximately 1 second on the navigation key: • Indicator light (1) comes ON. • - - 2 - - is displayed on the screen. - Operate tractor hydraulic valve I: • The machine folds.

- Page 50 Merger Merge Maxx 900 - Press approximately 1 second on key (a): • Indicator light (1) flashes. • The hour counter is displayed. • all machine functions are deactivated. - Press on the button ON/OFF (b). The machine is in transport position.

-

Page 51: Conformity With The Road Regulations

Merger Merge Maxx 900 2. Conformity with the road regulations Before driving the machine on public roads, ensure that the machine complies with current highway code regulations. Check that the light boards are clean and that the lighting equipment functions before transporting the machine on public roads. - Page 52 Merger Merge Maxx 900 $Instructions for work Before placing the machine in working position: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. 1. Putting the machine into work...

- Page 53 Merger Merge Maxx 900 - Press for approximately 1 second on the navigation key: • Indicator light (1) comes ON. • - - 2- - is displayed on the screen. - Operate tractor hydraulic valve I: • The machine unfolds.

- Page 54 Merger Merge Maxx 900 - Press for approximately 1 second on the navigation key: • Indicator light (1) comes ON. • The hour counter is displayed. • The work functions are activated. - Activate tractor hydraulic valve II to lower the pick- ups.

-

Page 55: Adjustments In Working Position

Merger Merge Maxx 900 2. Adjustments in working position Before making any adjustment: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. Adjusting the pick-up working height - Select the "Pick-up height adjustment" function using navigation keys: •... - Page 56 Merger Merge Maxx 900 Adjusting the aggressiveness of the combs Various settings are possible: Adjustment 1: - Loosen screw (1). - Remove screw (2). - Place comb in the required position: • Position (a): More aggressive position. • Position (b): Intermediate position.

- Page 57 Merger Merge Maxx 900 Ground pressure adjustment of the side pick-ups The side pick-up ground pressure is obtained by 2 hydro- pneumatic accumulators. By modifying the accumulator pressure, the side pick-up ground pressure varies. The pressure must be adapted to the nature and moisture degree of the ground.

- Page 58 Merger Merge Maxx 900 Ground pressure reduction Increase pressure in the hydro-pneumatic accumulators to reduce the pick-up ground pressure: - Check that valves (1) and (2) are shut-off. - Operate and maintain hydraulic valve I control lever to pressurize the circuit.

- Page 59 Merger Merge Maxx 900 Ground pressure increase Reduce pressure in the hydro-pneumatic accumulators to increase pick-up ground pressure: - Check that valves (1) and (3) are shut-off. - Place hydraulic valve control lever I in floating position (or in the "oil returns to the tractor tank" position).

- Page 60 Merger Merge Maxx 900 Adjustment of the central pick-up ground pressure 2 springs enable adjusting the central pick-up ground pressure. Adjustment The pressure must be adapted to the nature and moisture degree of the ground. The springs are factory set to a minimum ground pressure (1).

- Page 61 Merger Merge Maxx 900 Adjustment of the balancing pressure of the side pick-ups During first adjustment, increase pressure to 175 bar (2538 psi) and then reduce pressure to (0 bar). Repeat procedure 5 times to bleed the circuit. - Check that valve (1) is shut-off.

- Page 62 Merger Merge Maxx 900 Adjusting the synchronisation of the side arm lift and the pick-up holding frame rotation The pick-up holding frame (2) rotation must be made after raising side arm (1): - a: Side arm lift. - b: Rotation of the pick-up holding frame.

- Page 63 Merger Merge Maxx 900 Synchronization of the lift of the side pick- ups with regards to the central pick-up lift pick-ups must occur approximately at the same moment. The sequencing valve is factory preset at (1). To delay the central pick-up raising: - Loosen counter nut (1).

- Page 64 Merger Merge Maxx 900 Adjustment of the time delay when inverting the conveyor belt direction of rotation (t2) To access the time delay adjustment: - Select transport mode: • Indicator light (1) flashes. - Simultaneously press keys + and - for approximately 5 seconds: •...

- Page 65 Merger Merge Maxx 900 Modification of the t2 or t3 value - Press key - (1) to reduce the time delay: • 2 seconds (minimum). - Press key + (2) to increase the time delay: • 10 seconds (max.). - Press on validation key (3) to save the modifications and return to the transport mode.

- Page 66 Merger Merge Maxx 900 Steering system adjustment Should the transport wheels hit an obstacle, check that the steering system is not damaged. Check the wheel toe-in (2.4°): - Measure distance A on the front edges of the wheel rims. - Measure distance B on the rear edge of the wheel rims.

- Page 67 Merger Merge Maxx 900 - Pivot areas S and S’ in an angle X of 90° in relation to beam (1). Adjusting the wheel alignment ( Perform the operation on each side of the machine ): - Loosen counter nut (1).

-

Page 68: Machine Use

Merger Merge Maxx 900 3. Machine use Before working: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. - The machine is fitted with a steering device to: •... - Page 69 Merger Merge Maxx 900 Selecting the windrow delivery mode Left windrow delivery - Press approximately 1 seconds on selection key: • The indicator light flashes for the whole period during which the conveyor belt direction of rotation is inverted and then stays on.

- Page 70 Merger Merge Maxx 900 Left and right windrow delivery - Press simultaneously selection keys approximately 1 second: • The indicator lights flash for the whole period during which the conveyor belt direction of rotation is inverted and then they stay on.

- Page 71 Merger Merge Maxx 900 Windrow delivery two thirds to the left and one third to the right - Press simultaneously selection keys approximately 1 second. - The indicator lights flash for the whole period during which the conveyor belt direction of rotation is inverted and then they stay on.

- Page 72 Merger Merge Maxx 900 By pressing and holding down key allows leaving the windrow delivery mode. Windrow delivery two thirds to the right and one third to the left - Press simultaneously selection keys approximately 1 second. - The indicator lights flash for the whole period during which the conveyor belt direction of rotation is inverted and then they stay on.

- Page 73 Merger Merge Maxx 900 - On headlands, press key activating the inversion of the conveyor direction of rotation. - The indicator lights flash for the whole period during which the conveyor belt direction of rotation is inverted and then they stay on.

- Page 74 Merger Merge Maxx 900 Putting the machine in headland turn position Right pick-up: Putting the machine in headland turn position: - Press selection key: • Indicator light (1) comes ON. - Operate tractor hydraulic valve II in the headland turn position direction: •...

- Page 75 Merger Merge Maxx 900 Left pick-up Putting the machine in headland turn position: - Press selection key: • Indicator light (1) comes ON. - Operate tractor hydraulic valve II in the headland turn position direction: • The left pick-up is raised.

- Page 76 Merger Merge Maxx 900 All pick-ups: Putting the machine in headland turn position: If one of the "putting the machine in headland turn position" function has been activated previously (Example: Right pick-up): - Press concerned pick-up selection key to deactivate the function.

- Page 77 Merger Merge Maxx 900 Viewing the position of the pick-ups During work, the pick-up position can be viewed on the screen. - Shortly press navigation key. • Symbols (1) and (2) indicate that the pick-ups are in lower position. • The symbol (3) indicates the pick-up is in raised position.

- Page 78 Merger Merge Maxx 900 Use in deteriorated mode This mode enables neutralizing the position sensors when one of the sensors is faulty. This allows continuing to work and to fold/unfold the machine. In deteriorated mode, the time delay for placing the central pick-up in headland turn position is neutralized.

- Page 79 Merge Maxx 900 Error messages If an error code is displayed on the screen, contact your Kuhn dealer. Note the sofware versions of the T15M and M400 before contacting your Kuhn dealer. Press "Esc" key to delete error code. Instructions for work...

-

Page 80: Optional Equipment

Merger Merge Maxx 900 $Optional equipment 1. Wide wheels Kit no. 1146870 Technical specifications When fitting this equipment, following technical specifications are modified Width in transport position 3.10 m (10’2’’) Tyres 500/45-22.5 (14 PLY) Tyre pressure 1.6 bar (23.20 psi) In certain countries the machine exceeds the maximum legal size to drive on public roads. -

Page 81: Maintenance And Storage

Merger Merge Maxx 900 $Maintenance and storage Before carrying out any maintenance or repairs on the machine, switch off the tractor engine, remove ignition key, wait until all moving parts have come to a standstill and remove PTO shaft. 1. Frequency chart Maintenance intervals are indicated for normal conditions of use. - Page 82 Merger Merge Maxx 900 - The undercarriage articulations Oil: - The coupling yokes - The parking stand Maintenance Check: - The belt tension - Step up gearbox oil level - Tank oil level - Braking system - Fixing elements - Check transport...

-

Page 83: Lubrication

Merger Merge Maxx 900 2. Lubrication The pictorials show the points to be greased (Part no. 09905400). Clean grease nipples before greasing. Lubricate with SHELL multi-purpose grease grade NLGI 2. Oil with SHELL SAE 90 gear oil. PTO shaft - Every 8 hours: •... - Page 84 Merger Merge Maxx 900 Oil change: Hydraulic tank Before draining oil, operate the machine for a few minutes so that the oil warms up. The oil tank contains 200 L (53 US gal) of SHELL TELLUS 46 oil. When draining and refilling, it is recommended to use either SHELL TELLUS 46 oil or a mineral base oil with viscosity grade conform with ISO 46 standard category HM.

- Page 85 Merger Merge Maxx 900 Step-up gearbox Before draining oil, operate the machine for a few minutes so that the oil warms up. The step-up gearbox is lubricated with 1.2 L (0.32 US gal) of SAE 80W90 oil. When draining and refilling, it is recommended to use either a mineral base oil with viscosity grade SAE 80W90 and API grade GL5, or a synthetic base oil, type PAO (Poly-Alpha-Olefins) with a viscosity grade equivalent to SAE 80W90.

- Page 86 Merger Merge Maxx 900 Grease: - The steering system. Maintenance and storage...

- Page 87 Merger Merge Maxx 900 - The left arm pivot points. Maintenance and storage...

- Page 88 Merger Merge Maxx 900 - The right arm pivot points. Maintenance and storage...

- Page 89 Merger Merge Maxx 900 - The undercarriage articulations. Maintenance and storage...

- Page 90 Merger Merge Maxx 900 Oil: - The coupling yokes. - The parking stand. - The transport locks. Maintenance and storage...

-

Page 91: Maintenance

Merger Merge Maxx 900 3. Maintenance Check: The belt tension Regularly check belt tension. The conveyor belts stretch during their first hours of use. Checking the central belt tension - Measure distance (L): If measure L is comprised between 1204 and 1208 mm (3’11.40’’... - Page 92 Merger Merge Maxx 900 Adjusting the tension: - Unscrew the 2 nuts (1). - Loosen the 2 screws (2). - Remove bolt (1) and nut (2). - Rotate pin (3) counterclockwise to tension the conveyor. - Rotate pin (3) clockwise to slacken the conveyor belt.

- Page 93 Merger Merge Maxx 900 Step up gearbox oil level Regurlarly check the step up gearbox oil level. From the working position: - Adjust the height of the lift linkage until the gearbox is horizontal. - Unscrew filler plug extension (2).

- Page 94 Merger Merge Maxx 900 Tank oil level - The oil level must reach the maximum mark on level indicator (1) (in particular when working on slopes). Fixing elements Check transport wheel nuts (1) for tightness: • Torque : 27 daN m (199 lbf ft).

- Page 95 - Activate brake system: • Measure dimension L1. Length L1 must not exceed measure L by more than 35 mm (1.38’’). If the travel is greater than 40mm, contact your Kuhn dealer to have the brake system re-configured. Maintenance and storage...

- Page 96 Merger Merge Maxx 900 Tyre pressure - Wide wheels (400/55 - 22.5 14 ply): 2 bar (29 psi). - Wide wheels (500/45 - 22.5 14 ply): 1.6 bar (23 psi). Emptying the air reservoir (depending upon specification) Before carrying out any maintenance or...

- Page 97 Merger Merge Maxx 900 Replace Hydraulic tank filter cartridge The "OIL FIL" message flashes when the hydraulic tank filter is clogged. Press "Esc" key (1) to delete message and to return to the hour counter. - Loosen the 4 self-locking screws (1).

-

Page 98: Storage

Merger Merge Maxx 900 4. Storage At the end of each season: - Clean the machine thoroughly. - Lubricate the whole machine. - Check tyre pressure: • Transport wheels: 2 bar (29 psi). - Touch up any areas of damaged paintwork. -

Page 99: Trouble Shooting Guide

No display when switching on by No display pressing M/A. Charge the battery. If the problem persists, call your Kuhn dealer. Short circuit on the M400 module E--0003 power supply when switching on the Contact your Kuhn authorized dealer. - Page 100 Check tractor electric circuit. Check functioning of the generator T15M control box voltage exceeds 16 E--0111 control unit. If the problem persists, call your Kuhn dealer. Check tractor electric circuit. Check functioning of the generator T15M control box voltage exceeds E--0112 control unit.

- Page 101 Remedy Check the state of the sensors, the cables and connections. Position sensor voltage of the lower E--1410 pick-ups is below 9 V. If the problem persists, call your Kuhn dealer. E--1411 Major fault. Contact your Kuhn authorized dealer. C--2401 Short circuit on B1 Contact your Kuhn authorized dealer.

- Page 102 Problem Cause Remedy Check that the coil is connected. E--2407 Circuit open on A11 If the problem persists, call your Kuhn dealer. Check that the coil is connected. E--2408 Circuit open on A12 If the problem persists, call your Kuhn dealer.

-

Page 103: Appendix

Merger Merge Maxx 900 $Appendix 1. Calculating the load on an axle When coupling a tool to the front and rear 3-point lift linkage, the maximum authorized payload must not be exceeded. The load on the tractor front axle must always represent 20 % of the tractor unladen weight. - Page 104 Merger Merge Maxx 900 Rear tool or front-rear combination: 1) Calculation of the minimum front ballast weight M1 minimum M2 x (c+d) - T1 x b + 0.2 x T x b minimum Write the minimal additional weight in the chart.

- Page 105 Merger Merge Maxx 900 Table: Actual value obtained Value authorized Double value of the by calculation according to authorized capacity operator's manual per tyre (2 tyres) Minimum front/rear ballasting kg ≤ Total weight kg ≤ kg ≤ Load on front axle kg ≤...

- Page 106 Merger Merge Maxx 900 Determining the machine weight (M2) and the position of its centre of gravity (d) If the data required to calculate the total weight, axle loads and minimum ballasting are not supplied, use the following method. Tractor only: - T1: Load on front axle.

- Page 107 Merger Merge Maxx 900 - T: Axle loads. • Tractor only. Appendix...

- Page 108 Merger Merge Maxx 900 Rear tool or front-rear combination: If the total unit weight exceeds the tractor Gross Combined Weight Rating in accordance with the countrie's legislation, empty the hopper to travel on public roads. In any case, we recommend to travel on public roads with empty hoppers and tanks.

-

Page 109: Limited Warranty

Merger Merge Maxx 900 $Limited warranty Limited warranty... - Page 110 Merger Merge Maxx 900 Limited warranty...

Need help?

Do you have a question about the Merge Maxx 900 and is the answer not in the manual?

Questions and answers