Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for KUHN SpeedRake SR108

- Page 1 OPERATOR'S MANUAL 7N001EUS D SpeedRake - English (USA) - 10-2013 7N001EUS D...

-

Page 3: Dear Owner

SR108 SR110 SR112 $Dear Owner In buying a Kuhn machine you have chosen wisely. Into it have gone years of thought, research and improvement. You will find, as have thousands of owners all over the world, that you have the best that engineering skill and actual field testing can produce. -

Page 4: Table Of Contents

SpeedRake SR108 SR110 SR112 $Contents Dear Owner ........................1 Contents..........................2 Identification of the machine..................4 Front view............................4 Rear view............................4 Model identification plate ........................5 Optional equipment..........................5 Safety..........................6 Description of symbols used in this document................6 Safety instructions ...........................7 Location and description of safety decals on the machine ............14 Road safety equipment and recommendations................16 ... - Page 5 SpeedRake SR108 SR110 SR112 Instructions for work ....................25 Place the machine in working position ..................25 Adjustments in working position....................26 Setting the machine to windrow turning position............... 29 Adjusting rake wheel ground pressure..................30 Adjusting hydraulic hose length....................31 ...

-

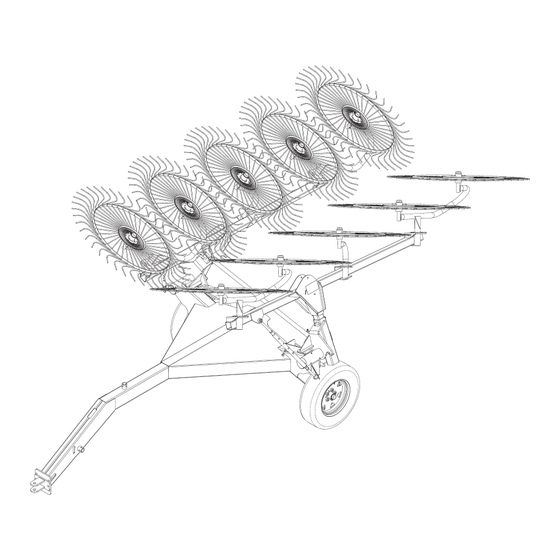

Page 6: Identification Of The Machine

SpeedRake SR108 SR110 SR112 $Identification of the machine 1. Front view 2. Rear view Identification of the machine... -

Page 7: Model Identification Plate

SpeedRake SR108 SR110 SR112 3. Model identification plate Please write below the type and serial number of the machine. This information is to be given to the Kuhn authorized dealer for any spare parts order or warranty claim. SR108-SR110-SR112 Type: Serial no.:... -

Page 8: Safety

SpeedRake SR108 SR110 SR112 $Safety 1. Description of symbols used in this document This symbol indicates a potentially hazardous situation that if not avoided, could result in serious bodily injury. This symbol is used to identify special instructions or procedures which, if not followed strictly, could result in machinery damage. -

Page 9: Safety Instructions

It is too late to learn once work has been started! Never let anyone operate the machine who is not trained to do so. Should you have any difficulties in understanding any parts of this manual, please contact your KUHN dealer. Safety shutdown procedure Before leaving... - Page 10 SpeedRake SR108 SR110 SR112 Precautions to take before using the machine Do not wear loose clothing which could become caught up in moving parts. Wear appropriate protective clothing (gloves, shoes, goggles, helmet, ear defenders, etc.). Ensure that all operating controls (ropes, cables, rods, etc) are placed so as they cannot be operated unintentionally and cause damage or injury.

- Page 11 SpeedRake SR108 SR110 SR112 Precautions when driving on public roads Dimensions Depending on the dimensions of the machine, contact the relevant authorities to ensure that it can be legally transported on public roads. If the machine is over the maximum legal size, follow the local regulations for special transportation of oversize equipment.

- Page 12 SpeedRake SR108 SR110 SR112 Precautions when coupling Before attaching the machine, make sure that it cannot accidentally start moving (chock the wheels) and that the parking stand is in the right position. The machine must only be attached to the hitch points provided for this purpose.

- Page 13 SpeedRake SR108 SR110 SR112 Precautions when moving rake arms When moving the machine from the transport position to the working position and vice versa, make sure that nobody is within the machine pivoting area. Remote controlled components Danger of crushing and shearing can exist when components are operated by hydraulic or pneumatic controls.

- Page 14 SpeedRake SR108 SR110 SR112 Precautions for maintenance and repair work Before leaving tractor before adjusting, maintaining or repairing the machine, always perform the safety shutdown procedure. Rest the machine on the ground, release the pressure from the hydraulic circuit and leave the machine to cool down.

- Page 15 SpeedRake SR108 SR110 SR112 Precautions for machine use Before using the machine, check the wheel tines and their attachment hardware per the instructions in this manual. Stay a safe distance from the Wheel Rake when the wheels are moving. Never work in reverse.

-

Page 16: Location And Description Of Safety Decals On The Machine

SpeedRake SR108 SR110 SR112 3. Location and description of safety decals on the machine Location of safety decals Safety... - Page 17 SpeedRake SR108 SR110 SR112 Description of safety decals Operating instructions (1) The operators' manual contains all the information necessary for using the machine safely. It is imperative to read and comply with all instructions. Body crushing (2) Hand crushing (3) Red reflector (4) Amber reflector (5) Safety...

-

Page 18: Road Safety Equipment And Recommendations

4. Road safety equipment and recommendations The road safety equipment is mounted in the factory or by your authorized Kuhn dealer according to current safety regulations. Always keep to the legal speed limit for driving a tractor-machine assembly on public roads. - Page 19 SpeedRake SR108 SR110 SR112 Transport lock When transporting the rake on public roads, always lock the rake arms in the transport position with the link bar (1). Always lock rake arms and wheels up before driving on roads. To lock rake arms and wheels for transport, follow the specific procedure in section, "Instructions for Transport".

-

Page 20: Machine Specifications

SpeedRake SR108 SR110 SR112 $Machine specifications 1. Description and glossary Clevis Right finger wheel 15 Transport wheel Jack Left finger wheel 16 Right and left twin wheel mount Main frame 10 Primary pivot assembly 17 Finger wheel hub Stop pad 11 Lift cylinders 18 Mount retainer Turnbuckle... -

Page 21: Technical Specifications

SpeedRake SR108 SR110 SR112 2. Technical specifications SR108 SR110 SR112 Minimum tractor power 20hp/14.9kW 20hp/14.9kW 30hp/22.3kW Number of rake wheels Rake wheel diameter 55"(1.4m) 55"(1.4m) 55"(1.4m) Tine diameter 9/32" (7mm) 9/32" (7mm) 9/32" (7mm) Width in transport position (with single axle) 8’10"... -

Page 22: Putting Into Service

SpeedRake SR108 SR110 SR112 $Putting into service 1. Coupling and uncoupling Drawbar height adjustment Dimension A Top of drawbar to ground - 13" (33.0cm) to 18" (45.7cm). Make sure the hitch pin is installed and secured to prevent unexpected detaching. ... - Page 23 10,100 lbs (45kN). The safety chain must be tied around a tractor attachment point other than the attachment bar. Safety chains are sold separately. Contact your Kuhn dealer to purchase a safety chain for your specific rake. Hydraulic connection Remove connector dust caps and connect hydraulic hoses to tractor.

- Page 24 SpeedRake SR108 SR110 SR112 Uncoupling the machine Park the machine on fairly level ground. Preferably park the machine in the transport position with the transport lock installed. - Position chocks underneath the machine wheels. - Disconnect and store hydraulic hoses in holder 4 - Disconnect safety chain from tractor (if so equipped).

-

Page 25: Instructions For Transport

SpeedRake SR108 SR110 SR112 $Instructions for transport 1. Place the machine in transport position Before placing the machine into transport position: - Wait until the rotating parts have come to a complete stop. - Check that nobody is located in the machine pivoting area. -

Page 26: Conformity With The Road Regulations

SpeedRake SR108 SR110 SR112 2. Conformity with the road regulations Before driving the machine on public roads, ensure that the machine complies with current highway code regulations. Check that the reflectors are clean and that the lighting equipment is working properly before transporting on public roads. -

Page 27: Instructions For Work

SpeedRake SR108 SR110 SR112 $Instructions for work 1. Place the machine in working position Before placing the machine in working position: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. -

Page 28: Adjustments In Working Position

SpeedRake SR108 SR110 SR112 2. Adjustments in working position Minimum and maximum width and windrow specifications (See Note A). Model Windrow width (1) SR108/110/112 3’0" (1m) 7’0" (2.1m) Model Working width (2) Minimum Maximum SR108 15’10" (4.7m) 18’10" (2.1m) SR110 16’11"... - Page 29 SpeedRake SR108 SR110 SR112 Turning at headlands 180° To prevent damage to the rake, DO NOT make a sharp turn around at the headlands with the rake in the work position. At a headland, use the tractor hydraulics to lift the rake wheels from the ground (A), turn around, and then lower the rake wheels back to the ground (B).

- Page 30 SpeedRake SR108 SR110 SR112 Changing the working width The working width can be adjusted by sliding the telescopic arm (1) and turnbuckle (4) inward or outward. This will change the windrow width but not affect the rake arm angle. To change working width: - Stop the tractor engine and remove ignition key.

-

Page 31: Setting The Machine To Windrow Turning Position

SpeedRake SR108 SR110 SR112 3. Setting the machine to windrow turning position Before placing the machine in windrow turning position: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. From the transport position: - Stop the tractor engine and remove ignition key. -

Page 32: Adjusting Rake Wheel Ground Pressure

SpeedRake SR108 SR110 SR112 4. Adjusting rake wheel ground pressure Before leaving tractor before adjusting, maintaining or repairing the machine, always perform safety shutdown procedure. - Activate the tractor hydraulics and lower the rake arms to the working position. - Adjust the rake wheel's ground pressure by turning the adjusting nut (1). -

Page 33: Adjusting Hydraulic Hose Length

SpeedRake SR108 SR110 SR112 5. Adjusting hydraulic hose length - Loosen clamp nut (1) until hydraulic hoses (2) move freely. - Slide hoses in or out of the tongue tube until they are the desired length. - Retighten clamp nut (1) to secure hoses. Instructions for work... -

Page 34: Optional Equipment

SpeedRake SR108 SR110 SR112 $Optional equipment 1. Center kicker wheel The center kicker wheel (1) is used to fluff the center part of the windrow. It can be used when raking 3 windrows together or after mowers or tedders have been used. ... - Page 35 SpeedRake SR108 SR110 SR112 Locking center kicker wheel in the transport position Before leaving tractor before adjusting, maintaining repairing machine, always perform safety shutdown procedure. The center kicker wheel can be locked to prevent it from rotating to the working position during operation or transportation.

-

Page 36: Helper Springs

SpeedRake SR108 SR110 SR112 Adjusting center kicker wheel ground pressure Before leaving tractor before adjusting, maintaining or repairing the machine, always perform safety shutdown procedure. Ground pressure adjustments can be made by tightening or loosening the adjustment nut (1). To adjust center kicker wheel ground pressure: - Stop the tractor engine and remove ignition key. -

Page 37: Hydraulic Flow Restrictor

SpeedRake SR108 SR110 SR112 3. Hydraulic flow restrictor Excessive hydraulic flow to the rake arm cylinders may cause them to lower or raise too quickly. If the tractor hydraulic flow cannot be adjusted, an optional restrictor (1) can be installed in place of the straight adapter behind the quick coupler to allow the rake arms to move more slowly. -

Page 38: Maintenance And Storage

SpeedRake SR108 SR110 SR112 $Maintenance and storage 1. Lubrication Before leaving tractor before adjusting, maintaining or repairing the machine, always perform safety shutdown procedure. The pictorials show the points to be greased. Clean grease zerks before greasing. Every 25 hours - Primary pivot (1) - Twin rake wheel mount pivot (2) - Rake wheel hubs (3) - Page 39 SpeedRake SR108 SR110 SR112 Every 50 hours - Secondary pivot (1) - Telescopic tube (2) Every year - Transport wheel bearing (3) repack Maintenance and storage...

-

Page 40: Maintenance

SpeedRake SR108 SR110 SR112 2. Maintenance After the first 10 hours of use and periodically thereafter - Check tightness of all bolts and nuts on rake assembly, particularly on rake wheels and on clevis. - Check the center retaining clips on the rake wheels for tightness and adjust as necessary. -

Page 41: Storage

- Retract all hydraulic cylinders and coat the exposed parts of ram rods with lubricant. - Replace any damaged or missing safety decals. - Replace all parts that are worn or damaged with KUHN original parts. At the start of each season - Re-read the operators' manual. -

Page 42: Limited Warranty

WARRANTY LIMITATIONS AND EXCLUSIONS This warranty shall not apply to any machine or machine part which, in the judgment of KUHN, has been altered or tampered with in any way, has been subjected to misuse, neglect or accident, has been used for an application not designed for or pre-authorized by KUHN in writing, has had the serial numbers altered, effaced or removed, or has been scrapped, junked, or totaled. - Page 44 Société Anonyme au Capital de 2 530 000 Euros KUHN-BLANCHARD SAS - 24, route de Nantes - F - 44680 CHEMERE (FRANCE) Tél. : + 33 (0) 2 40 21 30 24 - Fax : + 33 (0) 2 40 64 80 11 Société...

Need help?

Do you have a question about the SpeedRake SR108 and is the answer not in the manual?

Questions and answers