Summary of Contents for dynasonics DXN Series

- Page 1 Operator’s Manual DXN™ Portable Ultrasonic Measurement System 8635 Washington Avenue Racine, WI 53406-3738 USA Tel: 262-639-6770 Toll Free: 800-535-3569...

- Page 2 DTTL Transducers Order No.: GS40A15-P1J MEAN WELL AC/DC SWITCHING ADAPTOR MODEL NO.: GS40A15 INPUT: 100-240 VAC, 50/60 Hz, 1.0 A OUTPUT: 15 V 2.67 A, 40 W MAX. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions (1) this device may not cause harmful interference.

-

Page 3: Transducer Location

QUICK-START OPERATING INSTRUCTIONS This manual contains detailed operating instructions for all aspects of the DXN instrument. The follow- ing condensed instructions are provided to assist the operator in getting the instrument started up and running as quickly as possible. This pertains to basic operation only. If specific instrument features are to be used or if the installer is unfamiliar with this type of instrument, refer to the appropriate section in the manual for complete details. - Page 4 Piping Configuration Upstream Downstream Pipe Pipe and Transducer Positioning Diameters Diameters Flow Flow Flow Flow Flow Flow TABLE Q.1 - PIPING CONFIGURATION AND TRANSDUCER POSITIONING Form 06-HYB-UM-00010 1/12...

-

Page 5: Pipe Preparation And Transducer Mounting

PIPE PREPARATION AND TRANSDUCER MOUNTING DTTN and DTTL Transit Time Transducers 1) During this procedure the flow meter’s signal quality value should be observed. This value is avail- able on the DXN Display Tab ► Meters Page where “TT Signal Quality” is one of the parameters that can be shown. -

Page 6: Top View

3) Apply a single ½” (12 mm) wide by approximately 1/8” thick bead of acoustic couplant grease to both transducers and secure them to the pipe 180° apart using a mounting strap. Ensure that the transducer cable is pointing in the downstream direction. Wires Pointing in Direction of Flow FLOW Top View... -

Page 7: Transducer Connections

TRANSDUCER CONNECTIONS 1) Route the transducer cables from the transducer mounting location back to the DXN enclosure, avoiding locations near high voltage supply wires. 2) Connect the transit time transducer wires to the appropriate BNC or connect the Doppler trans- ducers to the 4-pin Doppler transducer plug. -

Page 8: Initial Settings And Power Up

FIGURE Q.5 -THICKNESS GAGE (AUXILIARY) CONNECTION STARTUP INITIAL SETTINGS AND POWER UP 1) Apply power to the transmitter by pressing the “Power On” button. 2) Verify that Signal Quality is greater than 5.0 %. Form 06-HYB-UM-00010 1/12... -

Page 9: Application Versatility

1 - INTRODUCTION GENERAL The DXN portable ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non-fouling operation and ease of installation. In transit time mode the flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. -

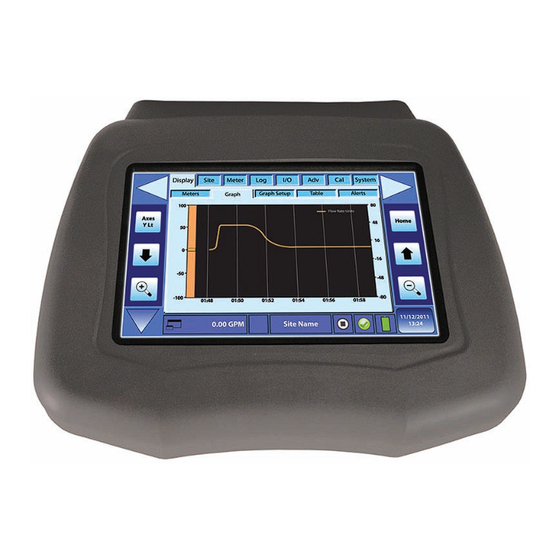

Page 10: User Interface Features

User Interface Features 2-Level Tabbed Menu: • Group Tabs contain a group of Page Tabs and Interface Pages • The user can navigate to Page Tabs sequentially by the Navigate Left or Navigate Right buttons • The user can activate any Group Tab or Page Tab by single finger press. • Certain Page Tabs can be pressed or double pressed for additional functionality. • Interface Page can contain meters, user entry controls, graphs, etc. Smart Status Bars: • Status Bars contain Status Items that show and control helpful transmitter functions such as show- ing flow or controlling data logging. • The user can navigate Status Bars sequentially only with the Status Bar Navigation Button • Certain Status Items can be double clicked for addition functionality. Often times they can auto- matically navigate to a Page Tab. • Status Bars include Quickview, Power Status, Shutdown, Sensor Positioning, etc... CE COMPLIANCE The DXN transmitter conforms to CISPR 11 (EN 55011) standards. -

Page 11: Software Conventions

2 - SOFTWARE CONVENTIONS The DXN uses a sophisticated touch screen user interface to control all functions. The tabbed menu tree provides access to all controls and settings within two layers of menus. Large easy to read touchscreen buttons allow for gloved operation in inclement weather. CONVENTIONS AND CONTROLS When navigating the DXN menus this manual will specify first the Group Tab name and then the Page as shown below. -

Page 12: Create New Site

DXN Data and Controls Layout Group & Page Tabs Display Site Meter System Navigate Navigate Menu Left Menu Right Graph Graph Setup Table Alerts Meters Meter Flow Rate 0.00 Left Context Right Context Sensitive Sensitive Area Area Total Net TT Signal Quality Data &... - Page 13 Enter New Site Name: <name> Create Site Cancel “ ‘ Enter Enter < > Shift Abc Shift <- <- Space Space -> -> Backspace Backspace FIGURE 2.5 - ALPHA NUMERIC KEYPAD On/Off Check Box This control allows the user to turn on or off a function. A box with a check mark in it indicates the func- tion is on and the function is off when the check mark is absent.

- Page 14 Buttons Button controls work in a similar manner to a push-button switch and generally starts or stops some function. 0.00 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 2.8 - PUSH BUTTON CONTROL Shut Down Slider The shutdown slider allows the DXN to be turned off without having to press and hold the physical On/ Off button.

-

Page 15: Water-Distilled

Parameter Pipe OD Currently 2.375 0.25 200.00 Clear Cancel FIGURE 2.11 - NUMERIC INPUT CONTROL Min, Max, parameters are all shown. Clear starts over and cancel closes without changes. Click “OK” to store. Keypad will disappear. Combo Box Combo boxes function as a list of alternate items that can be chosen during setup. The combo box pres- ents as a bar with text and a downward pointing arrow directly to the left indicating the control has a selection list. - Page 16 Water-Distilled Water-Tap Make Water-Sewage Selection Water-Sea Acetone Scroll Alcohol Ammonia Parameter Benzine Choices Brine Ethanol Ethelene Glycol Gasoline Glycerin Move × Selection Isopropanol Indicator Cancel FIGURE 2.13 - COMBO BOX WITH SCROLL BAR plus button moves the blue highlights area up or down depending on the original position of the highlight.

-

Page 17: General Guidelines

3 - TRANSDUCER INSTALLATION GENERAL GUIDELINES At its simplest setting up the DXN portable ultrasonic measurement system consists of two steps. The first step should be configuring the electronics because the second step, mounting the transducers, requires information obtained when the electronics are configured. Transmission Mode The first decision to be made is what mode of ultrasonic transmission should be used. Generally the tran- sit time mode is used with fluids that have little to no particulates or entrained air. -

Page 18: Pipe Preparation

An optimum transducer mounting location is defined as: ~ A piping system that is completely full of liquid when measurements are being taken. The pipe may become empty during a process cycle – causing an error to be displayed on the flow meter while the pipe is empty. - Page 19 TRANSIT TIME TRANSDUCER INSTALLATION In transit time mode the flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. The transducers can be mounted in V-Mount where the sound transverses the pipe two times, W-Mount where the sound transverses the pipe four times, or in Z-Mount where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once.

- Page 20 Transducer Mount Mode Pipe Material Pipe Size Liquid Composition Plastic (all types) Carbon Steel 2-4 in. (50-100 mm) Stainless Steel W-Mount Copper Ductile Iron Not recommended Cast Iron Plastic (all types) Carbon Steel 4-12 in. (100-300 mm) Stainless Steel V-Mount Low TSS;...

-

Page 21: Alignment Marks

NOTE: Transducer spacing is calculated on “ideal” pipe. Ideal pipe is almost never found so the transducer spacing distances may need to be altered. An effective way to maximize signal strength is to configure the display to show signal strength, fix one trans- ducer on the pipe and then starting at the calculated spacing, move the remaining transducer small distances forward and back to find the maximum signal strength point. -

Page 22: Transducer Positioning

V-MOUNT AND W-MOUNT INSTALLATION Application of Couplant For DTTN, DTTH and DTTL transducers, place a single bead of couplant, approximately ½ inch (12 mm) wide, on the flat face of the transducer. See Figure 3.4. Generally, a silicone-based grease is used as an acoustic couplant, but any grease-like substance that is rated not to “flow” at the temperature that the pipe may operate at will be acceptable. - Page 23 3) If after adjustment of the transducers the signal strength does not rise to above 5, then an alter- nate transducer mounting method should be selected. If the mounting method was W-Mount, then re-configure the transmitter for V-Mount, move the downstream transducer to the new spacing distance.

- Page 24 The transducer spacing is the same as found in the Transducer Positioning section. Mark opposite corners of the paper on the pipe. Edge of Apply transducers to these two marks. Paper 5) For DTTN, DTTH and DTTL transducers, place a single bead of couplant, approximately ½...

-

Page 25: Dttsu Small Pipe Transducer Installation

MOUNTING TRACK INSTALLATION 1) A convenient transducer mounting track can be used for pipes that have outside diameters between 2 and 10 inches (50 and 250 mm). If the pipe is outside of that range, select a V-Mount or Z-Mount mounting method. 2) Install the single mounting rail on the side of the pipe with the stainless steel bands provided. - Page 26 DTTSU installation consists of the following steps: 1) Determine the transducer spacing required using the DXN and using the scale on the side of the DTTSU transducers, set the spacing. See Figure 3.11. 2) On horizontal pipes, mount the transducer in an orientation such that the cable exits at ±45 de- grees from the side of the pipe.

-

Page 27: Doppler Transducer Installation

DOPPLER TRANSDUCER INSTALLATION For Doppler installation the only pipe information needed is the Pipe ID (Inside Diameter) Sonic Reflectors for Doppler Mode Flow meters based on Doppler shift principals operate by transmitting an ultrasonic sound from its transmitting transducer through the pipe wall into the flowing liquid. -

Page 28: Mounting Straps

Individual straps in both 36” (915 mm) and 72” (1830 mm) are available from Dynasonics. See Figure 5.12. The straps can be connected together to make a continuous length. Small pipe transducer installations do not utilize straps, but use an integral clamping mechanism built into the transducer. - Page 29 Pipe Size 36” Straps Required* 1” to 9” (25 mm to 225 mm) 10” to 19” (250 mm to 480 mm) 20” to 29” (500 mm to 740 mm) 30” to 39” (760 mm to 1000 mm) * The above table indicates the number of straps required to mount one transducer.

-

Page 30: Software Configuration

> > > Slide To Shut Down > > > Power and Activity Status Bar PC CPU: 12% 138MB 54C Battery: 35%, -1.0A, 42.0C Copyright 2010 Dynasonics Version 1.0 About Status Bar FIGURE 4.1 - STATUS BARS Form 06-HYB-UM-00010 1/12... - Page 31 The Flow Meter Quick Status Bar and the Transit Time Setup Status Bar also have segments that do double duty as buttons. 0.00 GPM Full Screen On/O Transit Time Zero Null 0.000 ns FIGURE 4.2 -STATUS BAR BUTTONS The left most segment of the Flow Meter Quick Status Bar turns on/off Full Screen mode when pressed. The left most segment of the Transit Time Setup Status Bar zeros (removes the “No Flow”...

-

Page 32: Display Group

DISPLAY GROUP Site Display Meter System Meters Meters Graph Graph Graph Setup Graph Setup Table Table Alerts Alerts FIGURE 4.4 -DISPLAY PAGE GROUP Meters Page The “Home” display is to show meters that can indicated almost any of the system data. Meters On Screen Button Display... -

Page 33: Graph Page

Metering Parameter displayed can be changed by clicking on the combo box in the upper left corner of each screen or sub screen. When the down arrow key is pressed a drop down menu becomes avail- able allowing the choice of parameter to be displayed on that screen or sub screen. Figure 4.6 shows an example of the drop down menu. - Page 34 Axes Scaling Button Control of the axis scaling is performed with the axes scaling buttons. Pressing the Axes button succes- sively will move through the three axis configuration choices. Axes Axes Axes Axes Y Lt Y Rt Home Home The X axis is always time based. Use the + or - buttons to either expand or contract the time line shown on the X axis.

- Page 35 Graph Setup Page Site Display Meter System Meters Graph Graph Setup Table Alerts Meter Flowrate Left Axis Data Meter Total Net Right Axis Data 10 Seconds Time Range 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.8 - GRAPH SETUP PAGE Left and Right Axis Data - (Choices) The Left and Right Axis Data controls allows for the choice of parameters to be shown on the respective axis.

- Page 36 10 Seconds 30 Minutes 1 Day 14 Days 30 Seconds 1 Hour 5 Days 1 Month 1 Minute 5 Hours 7 Days 6 Months 10 Minutes 10 Hours 10 Days 1 Year TABLE 4.2 - TIME AXIS CHOICES Table Page Site Display Meter...

-

Page 37: Alerts Page

Alerts Page Site Display Meter System Meters Graph Graph Setup Table Alerts Description Time Level 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.10 - ALERTS PAGE The Alerts page keeps track of any abnormal conditions encountered by the meter. Such things as bat- tery condition, unit temperature issues, low signal strength episodes and fluid sound speed problems are shown in the alerts page until they are resolved. - Page 38 SITE GROUP Display Site Meter System Create Create Fluid Fluid Lookup Lookup Pipe Pipe Liner Liner Transit Transit Doppler Doppler FIGURE 4.11 - SITE GROUP Create Page Display Site Meter System Create Fluid Lookup Pipe Liner Transit Doppler Load Factory Defaults Create New Site <Default>...

- Page 39 3) Use any of the meter’s setup functions to configure the meter for the named site. The parameters will update about 1 second after a value is entered so there is no need to do a save to attach the parameters to the site name.

- Page 40 Navigation in the fluid page is accomplished using either the Up/Down arrow keys located on the left hand side of the screen or the scroll bar to the right of the decrement (-) buttons on the right. Fluid Material - (Choice) Choose the fluid material from the combo box dropdown.

- Page 41 Custom Fluid Sound Speed - (Numeric Value) If a “Custom Fluid Name” was entered, the sound speed of the custom fluid here. If “English” was cho- sen for the “Entry Units” enter the sound speed in FPS. If “Metric” was chosen the sound speed is entered in MPS.

- Page 42 If a custom fluid is setup, then a “Fluid Viscosity” must also be entered. Custom Fluid Specific Gravity - (Numeric Value) Allows adjustments to be made to the specific gravity (density relative to water) of the liquid. As stated previously specific gravity is utilized in the Reynolds correction algorithm. It is also utilized if mass flow measurement units are selected for rate or total.

- Page 43 Pipe Page Display Site Meter System Pipe Create Fluid Lookup Liner Transit Doppler Pipe Material 2.375 Pipe OD (Inch) 0.154 Pipe Wall (Inch) 0.005 Pipe Roughness (e/D) 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.16 - PIPE PAGE The first parameter is the Pipe Material. The combo box associated with the pipe material has a selection of the most common pipe materials in use.

- Page 44 If a pipe material was chosen from the “Pipe Material” list, a nominal value for speed of sound in that material and the pipe roughness will be automatically loaded. If the actual sound speed is known for the application piping system and that value varies from the automatically loaded value, the value can be revised.

-

Page 45: Liner Page

Liner Page Display Site Meter System Liner Create Fluid Lookup Pipe Transit Doppler None Liner Material 0.000 Liner Wall (Inch) 0.000 Liner Roughness 0.000 Liner Sound Speed 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.17 - LINER PAGE Liner Material - (Choice) Choose the pipe liner material from the combo box dropdown. -

Page 46: Transit Page

Liner Roughness - (Numeric Value in µ Feet) The DXN provides flow profile compensation in its flow measurement calculation. The ratio of average surface imperfection as it relates to the liners internal diameter is used in this compensation and is found by using the following formula: RMS Measurement of the Liners Internal Wall Surface Liner R... - Page 47 Transducer [Transducer Type and Frequency] - (Choice) DTTN 1 MHz Standard Transducers DTTN 0.5 MHz Large Pipe Transducers DTTH 1 MHz High Temperature Transducers DTTSU 2 MHz Small Pipe Transducers TABLE 4.4 TRANSDUCER TYPES AND FREQUENCIES Transducer transmission frequencies are specific to the type of transducer. In general the DTTL 500 KHz (0.5 M Hz) transducers are used for pipes greater than 24 inches (600 mm).

-

Page 48: Doppler Page

Doppler Page Display Site Meter System Doppler Create Fluid Lookup Pipe Liner Transit DT9 - Std Doppler Transducer 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.19 - DOPPLER TRANSDUCER SELECTION If the Doppler measuring mode is to be used, the proper Doppler transducers must be chosen. At this time the DT94 series transducers are the only Doppler transducers supported. - Page 49 METER GROUP Site Display Meter System Flow Flow Totalizer Totalizer Limit Limit Filter Filter Energy Energy FIGURE 4.20 - METER GROUP Select the “Meter Group Tab” from the Group bar at the top of the screen. When the Meter pages appear select the flow page to enter information about the flow units to be used. Flow Page Display Site...

-

Page 50: Totalizer Page

Select a desired engineering unit for flow rate measurements. Flow Units Rate - Time Interval for Flow Rate (Choice) The flow interval can be any of the following: Seconds Minutes Hours Days Select a desired time unit for flow rate measurements. Transmission Mode [The Type of Ultrasonic Signal The Transmitter Generates] - (Choice) The Transmission Mode can be any of the following: Hybrid - The DXN monitors the fluid conditions and determines automatically when to switch... - Page 51 Total Units -- Totalizer Units Gallons Pounds Liters Kilograms Millions of Gallons British Thermal Units Cubic Feet Thousands of BTUs Cubic Meters Millions of BTUs Acre Feet Tons Oil Barrels Kilojoule Liquid Barrels Kilowatt Feet Megawatt Meters TABLE 4.5 - TOTALIZER UNITS Select a desired engineering unit for flow accumulator (totalizer) measurements.

- Page 52 Limit Page Site Display Meter System Limit Flow Totalizer Filter Energy Min Flow Limit (FPM) Max Flow Limit (FPM) Low Flow Limit (FPM) Limits in GPM: Min = -53.16; Max = 53.16; Low = 1.33 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.23 - LIMIT VALUE SETTINGS Min Flow Limit [Minimum Flow Rate Settings] - (Value)

-

Page 53: Filter Page

off and valves are closed) to be displayed as zero flow. Typical values that should be entered are between 1.0% and 5.0% of the flow range between “Min Flow Limit” and “Max Flow Limit”. The Low Flow Limit can also be thought of as the minimum flow rate that the meter will give reliable readings. - Page 54 Energy Page Site Display Meter System Energy Flow Totalizer Limit Filter Watts Power (Flow) Units Watt-Hours Energy (Total) Units 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.25 - ENERGY UNITS SELECTION Form 06-HYB-UM-00010 1/12...

- Page 55 DATA LOGGING (LOG) GROUP Site Display Meter System Setup Setup Select Data Select Data FIGURE 4.26 - LOG GROUP Setup Site Display Meter System Setup Select Data Stopped Data Log Status 10 Sec Logging Rate 65500 Lines Max Per File 10/12/2011 0.00 GPM Site Name...

- Page 56 Site Display Meter System Select Data Setup YYYY/MM/DD Column 0: Time HH:MM:SS.SSS Flow Rate (User Units) Column 1: Flow None Column 2: User None Colum 3: User 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.28 - DATA SELECTION (PAGE 1) Display Site Meter...

-

Page 57: Meter Log

INPUT / OUTPUT (I/O) GROUP Site Display Meter System Set Out Set Out Test Out Test Out FIGURE 4.30 - DATA OUTPUTS SETUP Setup Outputs (Set Out) Display Site Meter System Set Out Test Out Enable Enable Enable 4-20 mA Out 0 - 5V Out Digital Out -2000... - Page 58 Setup Test Outputs (Test Out) Site Display Meter System Test Out Set Out Enter Output Test Mode 4.000 Test 4-20 mA Out (mA) Test Frequency Out (Hz) 0.000 Test 0 - 10V Out (V) 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.32 - TEST OUTPUTS SETUP Form 06-HYB-UM-00010 1/12...

- Page 59 ADVANCED (ADV) GROUP Site Display Meter System Signals Signals Transit Transit Waveform Waveform Doppler Doppler Monitor Monitor FIGURE 4.33 - ADVANCED GROUP Display Site Meter System Transit Waveform Doppler Monitor Signals Transit RX Signals Monitor Signal Axes Home -35000 Y Lt -25000 -15000 -5000...

- Page 60 Display Site Meter System Transit Signals Waveform Doppler Monitor Auto Tx or 1/Amp Transit AGC or Gain Correlation NoPH 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.35 - ADVANCED TRANSIT TIME SETUP Display Site Meter System Waveform Signals Transit Doppler Monitor Automatic Waveform Duration (%)

- Page 61 Display Site Meter System Doppler Signals Transit Waveform Monitor Doppler Tx Freq (kHz) Custom Transducer Angle 30.0 (deg) Doppler Sample Rate Automatic Control Doppler AGC Gain 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.37 - ADVANCED DOPPLER SETUP Display Site Meter System Monitor...

- Page 62 CALIBRATION (CAL) GROUP Site Display Meter System Transit Transit Doppler Doppler Factory Factory FIGURE 4.39 - ADVANCED GROUP Site Display Meter System Transit Doppler Factory 0.000 Delta Time Null (ns) 1.000 User Adjustment Positive Reynolds Flow Correcting Comp 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.40 - ADVANCED TRANSIT TIME...

-

Page 63: User Adjustment

Site Display Meter System Doppler Transit Factory 1.000 User Adjustment Positive Flow 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.41 - ADVANCED DOPPLER Display Site Meter System Factory Transit Doppler Click To Update Transducer Master Cal Factor Factor DTTL 200.00 1.000 1.000 DTTN... - Page 64 Site Display Meter System Factory Transit Doppler RTD B Hi 1.000 1.000 Serial Number 0611120009 11110001 Store Cal Table Re-Load Table Store Cal Table To USB Reset Cal Values 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.43 - FACTORY CALIBRATION (PAGE 2) Form 06-HYB-UM-00010 1/12...

-

Page 65: System Group

SYSTEM GROUP Display Site Meter System Misc Misc Power Power Disk Disk Storage Storage ENet ENet Time Time Update Update Comm Comm FIGURE 4.44 - FACTORY CALIBRATION (PAGE 2) Display Site Meter System Misc Power Disk Storage ENet Time Update Comm English Language... - Page 66 Display Site Meter System Misc Power Disk Storage ENet Time Update Comm Battery Status Battery Not Being Discharged 46.1C Not Charging External DC Cycles = 28 Degrees C %Charge 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.46 - SYSTEM POWER Display Site Meter...

-

Page 67: Backlight Control

Display Site Meter System Misc Power Disk Storage ENet Time Update Comm Backlight Control PC CPU Status Brightness 56.0C 52.0C Timed Power O Display O Minutes Board CPU %CPU %RA 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.48 - SYSTEM PC Display Site Meter... - Page 68 Display Site Meter System Misc Power Disk Storage ENet Time Update Comm IP Address 00.00.00.00 Edit Subnet Mask 00.00.00.00 Edit Default Gateway 00.00.00.00 Edit Editing New IP Address 222.222.222.222 Accept New Value Cancel New Value 10/12/2011 0.00 GPM Site Name 13:24 FIGURE 4.50 - SYSTEM ETHERNET (ENET) Display...

- Page 69 Display Site Meter System Misc Power Disk Storage ENet Time Update Comm Quit Meter to Manage / Update -> Rev A = 001.1 20111116.0 -> Rev A = 001.1 20111116.0 DASH -> Rev A = 001.0 20111112.0 BIOS -> Rev A = 001.0 20111112.0 ->...

-

Page 70: Specifications

APPENDIX SPECIFICATIONS System Flow: Ultrasonic transit time and Doppler (reflection of acoustic signals); Hybrid operation. Measurement Type Pipe wall thickness: Ultrasonic transit time of acoustic signals. Liquid thermal energy. Liquid Types Liquid dominant fluids Transit Time: Bi-directional to 40 FPS (12 MPS) Velocity Range Doppler: Unidirectional to 40 FPS (12 MPS) -

Page 71: Digital Output

Transducers Pipe Sizes ½” and larger; standard pipe tables built into user Interface DTTSU: CPVC, Ultem®, and anodized aluminum track system; Connector: Nickel-plated brass with Teflon® insulation Housing Materials DTTN/DTTL/DT94 Doppler: CPVC, Ultem®; Connector: Nickel-plated brass with Teflon® insulation DTTSU/DTTN/DTTL: -40 ºF to +250 ºF (-40 ºC to +121 ºC) Pipe Surface Temperature DT94 Doppler:... -

Page 72: Upgrading Software

UPGRADING SOFTWARE The upgrade is supplied as a self extracting zip file and must be expanded on a PC before it can be loaded into the DXN. 1) Save the supplied zip file to a convenient place on the computers hard drive. 2) Double-click on the DXN_Updater_R_x.zip file to start the extraction process. - Page 73 Display Site Meter System System Update Update Misc Power Disk Storage ENet Time Comm Quit Meter to Manage / Update -> Rev A = 001.1 20111116.0 -> Rev A = 001.1 20111116.0 DASH -> Rev A = 001.0 20111112.0 BIOS ->...

- Page 74 Series DXN Launch Updater Start Flowmeter Start Updater Flowmeter Administration Tools dynasonics.com 800-535-3569 ©2011 Racine Federated Inc., all rights reserved 10) Press the “Unlock” button (Step 1: Unlock System (reboot) COM1 Test Disconnect Check Update Status >> COM2 C:\Documents and Settings\FlowMeterUser>...

- Page 75 Series DXN Start Flowmeter Insert USB Update Drive Flowmeter Administration Tools dynasonics.com 800-535-3569 ©2011 Racine Federated Inc., all rights reserved 13) The meter should now be back on the update screen. Press “Copy” (Step 2: Copy Up- dated Files). When the copy process is complete the green “Copy” light will be illuminated.

- Page 76 Quit Update Force Copy All Files System Utility dynasonics.com 800-535-3569 ©2011 Racine Federated Inc., all rights reserved NOTE: If the process “hangs-up” press the “Update DSP” button a second time which should clear the hang. NOTE: The process may take a few minutes to complete. When the process is complete the scroll bars in the message area should be used to verify that the updating process has terminated with the “! Successful Update ! Exiting Reprogramming Mode”.

- Page 77 Quit Update Force Copy All Files System Utility dynasonics.com 800-535-3569 ©2011 Racine Federated Inc., all rights reserved 16) At the conclusion of the process the “OK” to reboot will appear on the screen. At this point remove the thumb drive and then press “OK”...

- Page 78 When the thumb drive is removed the device may continue on to a system reboot but hang at the “Dynasonics” splash screen. This condition will require a “Hard” reboot by pressing and holding the main power button until the unit turns off.

- Page 79 MICROSOFT SOFTWARE LICENSE TERMS FOR: WINDOWS XP EMBEDDED AND WINDOWS EMBEDDED STANDARD RUNTIME These license terms are an agreement between you and Racine Federated. Please read them. They ap- ply to the software included on this device. The software also includes any separate media on which you received the software.

- Page 80 Software that provides consumer or business tasks or processes may not be run on the device. This includes e-mail, word processing, spreadsheet, database, scheduling and personal finance soft- ware. The device may use terminal services protocols to access such software running on a server. Device Connections.

- Page 81 You may use remote access technologies in the software such as Remote Desktop to access the software remotely from another device. You are responsible for obtaining any licenses required for use of these pro- tocols to access other software. • Remote Boot Feature. If the Racine Federated enabled the device Remote Boot feature of the soft- ware, you may (i) use the Remote Boot Installation Service (RBIS) tool only to install one copy of the software on your server and to deploy the software on licensed devices as part of the Remote Boot process;...

- Page 82 • Auto Root Update. The Auto Root Update feature updates the list of trusted certificate authorities. You can switch off the Auto Root Update feature. • Windows Media Player. When you use Windows Media Player, it checks with Microsoft for • Compatible online music services in your region; • New versions of the player; and • Codecs if your device does not have the correct ones for playing content. You can switch off this feature. For more information, go to: http://microsoft.com/windows/windowsmedia/mp10/privacy.aspx.

- Page 83 8. Transfer to a Third Party. You may transfer the software only with the device, the Certificate of Authenticity label, and these license terms directly to a third party. Before the transfer, that party must agree that these license terms apply to the transfer and use of the software. You may not retain any copies of the software including the backup copy.

-

Page 84: Electrical Symbols

ELECTRICAL SYMBOLS Direct Alternating Earth Protective Chassis Function Current Current (Ground) Ground Ground Symbol BATTERY CONSIDERATIONS The 24 volt DC power converter and 12 volt auto-style power cord connect to the 3-pin socket connec- tion located on the back of the enclosure. A fully charged battery will provide up to 9 hours of continu- ous operation before recharging will be necessary. -

Page 85: Safety Instructions

40 watts – observe proper polarity. Note that extended operation on an automotive supply could substantially reduce the automotive battery. SAFETY INSTRUCTIONS Warning - The Internal battery pack should only be replaced by an authorized Dynasonics service representative. Please contact your product and/or service provider for internal bat- tery replacement service. -

Page 86: Waste Electrical And Electronic Equipment (Weee) Directive

16) If one of the following situations arises, get the equipment checked by service personnel: a. The power cord or plug is damaged. b. Liquid has penetrated into the equipment. c. The equipment does not work properly, or you cannot get it to work according to the user’s manual. -

Page 87: K-Factors Explained

K-FACTORS EXPLAINED The K-factor (with regards to flow) is the number of pulses that must be accumulated to equal a particu- lar volume of fluid. You can think of each pulse as representing a small fraction of the totalizing unit. An example might be a K-factor of 1000 (pulses per gallon). - Page 88 Known values are: Full Scale Flow Rate 85 GPM Full Scale Output Frequency 650 Hz 1) 650 Hz x 60 sec = 39,000 pulses per min 39,000 pulses per − K factor 458.82 pulses per gallon The calculation is a little more complex if velocity is used because you first must convert the velocity into a volumetric flow rate to be able to compute a K-factor.

- Page 89 0.384 gallons × 4.3 FPS × 60 sec (1 min) = 99.1 GPM Now that the volumetric flow rate is known, all that is needed is an output frequency to determine the K-factor. Known values are: Frequency 700 Hz (By measurement) Flow Rate 99.1 GPM (By calculation) 1) 700 Hz ×...

- Page 90 Tel: 262-639-6770 · Fax: 262-639-2267 www.dynasonics.com · info@dynasonics.com DYNASONICS is a registered trademark of Racine Federated Inc. BELDEN is a registered trademark of Belden Technologies, Inc. BACNET is a registered trademark of American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

Need help?

Do you have a question about the DXN Series and is the answer not in the manual?

Questions and answers