Danfoss 51 Series Repair Instructions

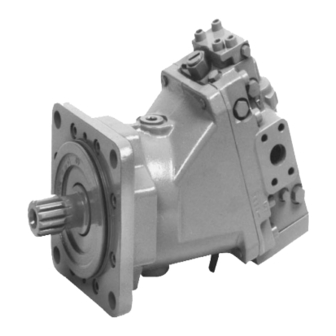

Bent axis motors

Hide thumbs

Also See for 51 Series:

- Service manual (64 pages) ,

- Service kit instructions (2 pages) ,

- Service manual (48 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Manual

Advertisement

Table of Contents

Summary of Contents for Danfoss 51 Series

- Page 1 MAKING MODERN LIVING POSSIBLE Repair Instructions Bent Axis Motors Series 51 and 51-1 Repair Instructions powersolutions.danfoss.com...

- Page 2 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Revision history Table of revisions Date Changed December 2014 Danfoss layout Jan 2008 First edition 11009449 • Rev BA • December 2014...

-

Page 3: Table Of Contents

Secure the unit..................................... 5 Safety precautions....................................5 Unintended machine movement............................5 Flammable cleaning solvents..............................5 Fluid under pressure.................................. 5 Personal safety..................................... 5 Symbols used in Danfoss literature............................6 Section diagram....................................7 Disassembly Endcap........................................8 Rotating components..................................9 Shaft removal (SAE or DIN)................................. 10 Shaft removal (Cartridge)................................11 Endcap disassembly..................................12... -

Page 4: Overview

Where rework of worn or damaged components is possible, specifications are given to ensure these parts meet factory tolerances. Only Danfoss Global Service Partners may perform major repairs. Danfoss trains Global Service Partners to perform major repairs and certifies their facilities on a regular basis. -

Page 5: Secure The Unit

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Introduction Secure the unit For major repair, place the unit in a stable position with the shaft pointing downward. Secure the pump while removing and torquing the endcap bolts. Safety precautions Always consider safety precautions before beginning a service procedure. -

Page 6: Symbols Used In Danfoss Literature

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Introduction Symbols used in Danfoss literature WARNING may result in injury Tip, helpful suggestion CAUTION may result in damage to product or Lubricate with hydraulic fluid property Reusable part... -

Page 7: Section Diagram

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Introduction Section diagram Series 51 bent axis variable motor Multi-function Minimum displacement Pressure compensator block limiter override Valve segment Control (hydraulic proportional) Motor output shaft Bearing plate Tapered roller bearings 4-way valve and sleeve Control... -

Page 8: Disassembly

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly Endcap Following procedures in the Series 51 and 51-1 Service Manual, 11008567: Remove the control and multi- function block (if installed). Remove the 4-way valve spool and sleeve (if installed). Remove the threshold springs and guides. -

Page 9: Rotating Components

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly Rotating components 1. Remove the valve segment (B05) and set aside. 2. Remove the bearing plate (C10) and alignment pins (C20). 3. Remove the cylinder block (C05) and set aside. Be careful not to scratch the running surface of the block. -

Page 10: Shaft Removal (Sae Or Din)

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly Shaft removal (SAE or DIN) Shaft assembly SAE or DIN flange version Shaft assembly P104 087 060 and 080: 6mm 110: 8mm 160: 10mm 250: 12mm 11009449 • Rev BA • December 2014... -

Page 11: Shaft Removal (Cartridge)

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly 1. Remove screws (L70) retaining the mounting flange (L35) to the main housing (B10). 2. Remove the mounting flange using a suitable puller. 3. Remove the O-ring (L50); discard. 4. -

Page 12: Endcap Disassembly

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly 10. Press shaft assembly out of bearing housing, taking care to not damage the shaft, piston sockets, and speed sensor ring (if installed). Shaft assembly, cartridge version Prior to N94-42 N94-42 thru... -

Page 13: 080 Frame

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly 5. Remove the setting lug (F24) from inside of end cap. End cap components 3 mm (060) 3 mm (060) (060) 060: 3/8 inch 080: 9/16 inch G80A (060) (080) End cap... -

Page 14: All Frame Sizes

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly 3. Remove feedback fork / setting lug (F24) from inside of end cap. Disassembling the end cap 5 mm (110, 160, 250) (110, 160, 250) P104 090 End cap (typical for 110, 160, and 250 frame sizes) side port style shown All frame sizes... - Page 15 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Disassembly 5. Inspect servo piston bore in end cap for damage or wear. Disassembling the end cap F12 Servo piston G10 End cap assembly P106 541E 11009449 • Rev BA • December 2014...

-

Page 16: Inspection

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Inspection Shaft assembly Caution The optional magnetic speed sensor ring is pressed onto a machined surface of the shaft. Take care not to damage the sensor ring. 1. Check the seal area of the shaft (L1) for damage or wear. 2. -

Page 17: Bearing Plate, Valve Segment, And Cylinder Block

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Inspection 2. Install new piston rings (L230). Ensure the spherical surface conforms to the shape of the piston. A radial identification mark appears on the outer side of the piston rings. Do not let the ends of each piston ring overlap each other. - Page 18 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Inspection 3. Inspect the spindle for wear. 4. Ensure the spindle is located correctly in the valve segment by measuring distance A. If this dimension is not within the range shown in the table, it indicates that the spindle has moved in the valve segment.

-

Page 19: Assembly

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly Endcap assembly All frame sizes 1. Carefully install a new O-ring (F11) and glide ring (F10) on the servo piston (F12). 2. Lubricate the glide ring. 3. Install the servo piston into the end cap (G10). The end of the servo piston with the glide ring is opposite the multi-function block/control mounting surface of the end cap. -

Page 20: 110-250 Frames

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 4. Using a 9/16 in. internal hex wrench torque the end cap plug (G80) to 40 N•m [29.5 lbf•ft]. Setting lugs 3 mm Lubricate with hydraulic fluid 3 mm (060) 5 N•m [44 lbf•in) (060) (060) 7 N•m [62 lbf•in) -

Page 21: All Frame Sizes

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 2. Install the cone-point set screw (F26) so that its point enters the groove in the feedback fork (F24) / setting lug. Do not tighten the set screw yet. See page 21 for final assembly instructions. Cone-point screw and feedback fork Lubricate with hydraulic fluid Multi-function... -

Page 22: Shaft And Mounting Flange Assembly

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly Cone-point set screws 3 mm 7 N•m [62 lbf•in] 3 mm 5 N•m [44 lbf•in] 060 frame size 6 mm 34 N•m [25.1 lbf•ft] P104 098 6 mm 25 N•m [18 lbf•ft] 080, 110, 160, 250, frame sizes Shaft and mounting flange assembly... -

Page 23: Cartridge Flange

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 7. Torque screws (L70) to value shown in the diagram. SAE/DIN Flange version bearing bore and housing 060 and 080: 6mm 060 & 080: 32 N•m [24 lbf•ft] 110: 63 N•m [46 lbf•ft] 110: 8mm 160: 110 N•m [81 lbf•ft]... - Page 24 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 6. Align ends of the retaining ring between the two bolt holes to allow clearance for speed sensor. Speed sensors speed sensor Notch Locking nut Spacer ring Sensor Axial notch on speed sensor Retaining-ring (L81) P104 100...

-

Page 25: Cylinder Block And Synchronizing Shaft

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly Cartridge version bearing bore and housing Before N94-42 N94-42 through N98-32 L750 N98-33 and beyond 060 and 080: 6mm 110: 8mm 160: 10mm 250: 12mm P104 101 Cylinder block and synchronizing shaft Synchronizing shaft and rollers 1. - Page 26 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 4. Position each roller with its outside edge flush with the end of the synchronizing shaft journal. Cylinder block and sync-shaft Cylinder block P104 102 5. Install the second C40 synchronizing shaft support pin into the motor shaft assembly. 6.

-

Page 27: Cylinder Block

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 7. Tip and rotate the synchronizing shaft in all directions to check for binding. The synchronizing shaft rollers must move freely in the races in the motor shaft. Cylinder block and sync-shaft Cylinder block... - Page 28 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 6. Install the cylinder block and its support pin (C40) on to the pistons and synchronizing shaft. Pistons Position the motor shaft as shown prior to installing the cylinder block P104 103 (Cylinder block not installed) The synchronizing shaft rollers (C50) enter their races in the block, while each piston enters its...

-

Page 29: Bearing Plate And Valve Segment

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly Cylinder block Lubricate the pistons and cylinder block bores with hydraulic oil Cylinder block Pistons P104 104 SAE flange version shown cartridge version similar Bearing plate and valve segment Bearing plate 1. -

Page 30: Endcap Installation

Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 6. Locate the cylinder block in the approximate center of the housing opening. Tip the housing until the endcap mounting surface is level to help keep the block centered. Do not allow pistons or synchronizing shaft rollers to fall out of position 7. - Page 31 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly 4. Tighten the screws by hand in a double-X pattern while rotating the motor shaft to ensure proper positioning of the synchronizing shaft rollers. 5. When the end cap is in position, torque the screws in a double-X pattern as shown in the table: Endcap screw torque Frame size Wrench size...

- Page 32 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions Assembly After assembly, test and adjust the motor as necessary before placing the unit back in service. Refer to Series 51 and 51-1 Service Manual, 11008567 for adjustment procedures. 11009449 •...

- Page 33 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions 11009449 • Rev BA • December 2014...

- Page 34 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions 11009449 • Rev BA • December 2014...

- Page 35 Repair Instructions Series 51 and 51-1 Bent Axis Motors Repair Instructions 11009449 • Rev BA • December 2014...

- Page 36 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

Need help?

Do you have a question about the 51 Series and is the answer not in the manual?

Questions and answers