Danfoss 51 Series Service Kit Instructions

Pressure compensator over-ride

Hide thumbs

Also See for 51 Series:

- Service manual (64 pages) ,

- Repair instructions (36 pages) ,

- Service manual (46 pages)

Advertisement

Quick Links

Service Kit Instructions

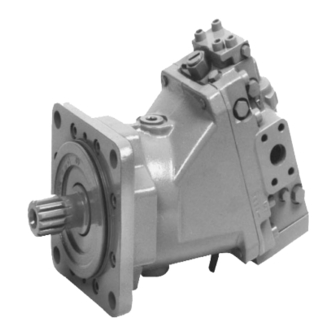

Series 51

Pressure compensator over-ride

PROCEDURE:

1. Install new O-rings on the pressure compensator

over-ride valve block and retain with petroleum jelly.

2. Install the PCOR valve block on the multi-function

block and install the screws.

3. Torque the screws to 11 Nm (8 ft•lbf).

4. Perform the PCOR pressure adjustments as de-

scribed below.

ADJUSTMENT:

The following procedure will require the vehicle/

machine to be disabled (wheels raised off the ground,

work function disconnected, etc.) while performing

the adjustments to prevent injury to the technician

and/or bystanders.

The PCOR may be adjusted with the screw on the PCOR

valve block attached to the multifunction block. The setting

pressure is that system gauge pressure at which the PCOR

causes the motor displacement to start to increase. On a

test stand this point is when system flow begins to increase.

On a machine, with the motor shaft locked from turning, this

point is when maximum servo pressure becomes higher

than minimum servo pressure.

In order to measure the PCOR setting pressure on a test

stand, monitor system gauge pressure and system flow.

Provide a signal to the motor control to maintain the motor

at minimum displacement. Increase the system pressure

until system flow just starts to increase. The system pres-

sure at this point is the PCOR setting pressure. To adjust the

setting, loosen the lock nut with a 1

Turn the adjusting screw, with a large screw driver or a

inch hex wrench until the desired setting is established.

Clockwise rotation of the adjustment screw will increase the

pressure setting approximately 1200 psi (83 bar) per turn.

While holding the adjusting screw from turning, torque the

locknut to 52 Nm (38 ft•lbf).

© Danfoss, 2013

WARNING

/

inch hex wrench.

1

16

BLN-10118 • Rev AA • September 2013

In order to measure the PCOR setting pressure on a

machine, monitor the system gauge pressure (M1 or M2

gauge port), minimum servo pressure (M3 gauge port), and

maximum servo pressure (M4 gauge port). Apply the park-

ing brake, block the load, etc. to keep the motor shaft from

turning during this test. CAUTION: Take necessary precau-

tions to prevent personal injury if machine or load should

move during this test. While watching the gauges, very

slowly increase the pump displacement, thereby increasing

system pressure gradually (or use the pressure limiter

adjustment screw on the pump to increase the system

pressure gradually). Minimum servo pressure will increase

with the system pressure. At about 50 psi below the PCOR

set point the minimum servo pressure will stop increasing

with system pressure and the maximum servo pressure will

begin to increase. As system pressure is increased farther,

minimum servo pressure will begin to decrease and maxi-

mum servo pressure will begin to increase. When maximum

servo pressure becomes 50 to 100 psi higher than minimum

servo pressure the motor servo piston will begin to move

toward maximum displacement. The system pressure at

this point is the PCOR setting pressure. To adjust the

/

1

2

setting, loosen the lock nut with a 1

turn adjusting screw until the desired setting is established.

Clockwise rotation of the adjustment screw will increase the

pressure setting approximately 1200 psi (83 bar) per turn.

While holding the adjusting screw from turning, torque the

lock nut to 52 Nm (38 ft•lbf).

/

inch hex wrench and

1

16

1

Advertisement

Summary of Contents for Danfoss 51 Series

- Page 1 While holding the adjusting screw from turning, torque the While holding the adjusting screw from turning, torque the locknut to 52 Nm (38 ft•lbf). lock nut to 52 Nm (38 ft•lbf). BLN-10118 • Rev AA • September 2013 © Danfoss, 2013...

- Page 2 Note: Some motor controls may be configured for the PCOR to function on only one side of the closed loop. Refer to the nomenclature on the motor nameplate. BLN-10118 • Rev AA • September 2013 © Danfoss, 2013...

Need help?

Do you have a question about the 51 Series and is the answer not in the manual?

Questions and answers