Table of Contents

Advertisement

Quick Links

Installation & Maintenance Instructions

IMPORTANT: See separate solenoid installation

and maintenance instructions for information on:

Wiring, Solenoid Temperature, Causes of Improp

er Operation, Coil, or Solenoid Replacement.

DESCRIPTION

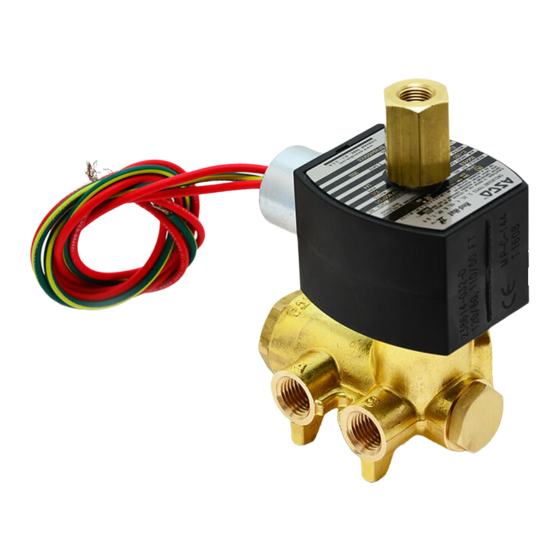

Series 8345 valves are 2- position 4-way solenoid

valves designed for air or inert gas service. Valve

bodies are made of rugged brass. The valves may

be provided with a low power or intrinsically safe

solenoid.

OPERATION

Solenoid De-energized: Flow is from Pressure P

to Cylinder A and from Cylinder B to Exhaust EB.

Exhaust EA is closed.

Solenoid Energized: Flow is from Pressure P to

Cylinder B and from Cylinder A to Exhaust EA.

Exhaust EB is closed.

IMPORTANT:

Minimum operating pressure

differential is 10 psi.

Flow Diagrams

De-energized

EB

P

B EA A

INSTALLATION

Check nameplate for correct catalog number,

pressure, voltage, frequency, and service. Never

apply incompatible fluids or exceed pressure

rating of the valve.

Maintenance to be performed by qualified

personnel.

e

ASCO Valves

2 - POSITION 4-WAY SOLENOID VALVES

BRASS CONSTRUCTION

1/4I NPT - AIR OR INERT GAS SERVICE

Energized

EB

B EA A

Installation and valve

MCMXCIII All Rights Reserved.

Temperature Limitations

Fluid and ambient temperature range: -4_F to

+140_F.

Future Service Considerations

Provision should be made for performing seat

leakage, external leakage, and operational tests on

the valve with a nonhazardous, noncombustible

fluid after disassembly and reassembly.

Positioning

Valve may be mounted in any position.

Mounting

For mounting valve body refer to Figure 1.

[41,3]

1 5/8

Figure 1. Dimensions for mounting valve body.

Piping

There are two exhaust ports EA and EB. Exhaust

P

ports EA and EB may be connected to a common

exhaust if the air or inert gas cannot be exhausted

directly to the atmosphere. Connect piping or

tubing to valve according to markings on valve

body. Refer to flow diagrams in OPERATION

section.

CAUTION: To avoid damage or accidental

disengagement of cartridge assembly from valve

body, hold cartridge assembly securely by

wrenching flats when installing or removing

piping at Port EB.

Printed in U.S.A.

50-60 Hanover Road, Florham Park, New Jersey 07932

SERIES

8345

Form No.V6865R1

[7,9]

5/16

[5,6]

7/32

2 slots for mounting

Page 1 of 4

Advertisement

Table of Contents

Summary of Contents for Asco 8345 Series

- Page 1 Installation and valve wrenching flats when installing or removing maintenance to be performed by qualified piping at Port EB. personnel. Page 1 of 4 MCMXCIII All Rights Reserved. Printed in U.S.A. ASCO Valves 50-60 Hanover Road, Florham Park, New Jersey 07932...

- Page 2 In the extreme case, valve malfunction. faulty valve operation will occur and the valve may fail to shift. Clean filter when cleaning the valve. Page 2 of 4 Form No.V6865R1 ASCO Valves 50-60 Hanover Road, Florham Park, New Jersey 07932...

- Page 3 Parts marked with an asterisk (*) in the exploded view are supplied in Rebuild Kits. When Ordering 7. Clean valve and install a complete ASCO Rebuild Kit. Rebuild Kits for ASCO valves, order the Rebuild Kit number stamped on the valve nameplate. If the...

- Page 4 (mouth or open end to face end plug) Indicates parts supplied in Rebuild Kit end plug gasket end plug Figure 3. Series 8345 without solenoid. Page 4 of 4 Form No.V6865R1 ASCO Valves 50-60 Hanover Road, Florham Park, New Jersey 07932...

Need help?

Do you have a question about the 8345 Series and is the answer not in the manual?

Questions and answers