Advertisement

Quick Links

Installation & Maintenance Instructions

IMPORTANT:

See separate solenoid installation and

maintenance instructions for information on: Wiring, Sole

noid Temperature, Causes of Improper Operation, and Coil

or Solenoid Replacement.

DESCRIPTION

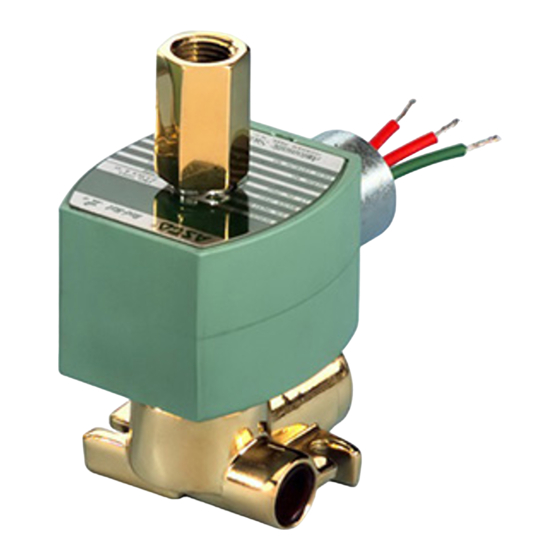

Series 8317 V alves are direct acting, packless, 3-way solenoid valves.

Valve bodies are either brass or stainless steel with integral seats. A

core, disc, spring assembly and diaphragm are the only moving parts.

Valves may be provided with a general purpose/watertight, open-

frame or watertight/explosionproof solenoids.

OPERATION

The solenoid pilots the quick exhaust" diaphragm by using the un

balanced pressure principle. When the pressure orifice is open, the

main and pilot exhaust orifices are closed. When the pressure orifice

is closed, the main and pilot exhaust orifices are open.

Normally Closed:

Solenoid De-energized: Flow is from Cylinder 1" to Main Exhaust

4". Pilot Exhaust is open. Pressure 2" is closed.

Solenoid Energized: Flow is from Pressure 2" to Cylinder 1", Main

Exhaust 4" and Pilot Exhaust 3"are closed.

Universal:

Pressure at 2": Refer to Normally Closed above.

Pressure at 3": Refer to Normally Open above.

Universal construction is interchangeable with Normally Closed in

the field by merely changing pipe connections.

IMPORTANT: A minimum operating pressure differential

of 5 psi on Air, Gas and Water and 10 psi on Hydraulic oil

(300 S.S.U.) is required.

NORMALLY CLOSED

DE-ENERGIZED

PILOT

3

EXH

2

4

PRESS

MAIN EXH

UNIVERSAL (PRESSURE AT 2")

DE-ENERGIZED

ENERGIZED

3

PILOT

PILOT

3

EXH

EXH

1

CYL

2

2

4

4

PRESS

PRESS

MAIN EXH

MAIN EXH

NOTE: Port markings 1, 2, 3 and 4 correspond directly to A, B, C and

C2.

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

3-WAY QUICK EXHAUST SOLENOID VALVES

NORMALLY CLOSED AND UNIVERSAL OPERATION

ENERGIZED

PILOT

3

EXH

1

1

CYL

CYL

2

4

PRESS

MAIN EXH

UNIVERSAL

(PRESSURE AT 3")

DE-ENERGIZED

ENERGIZED

3

PRESS

PRESS

3

1

1

CYL

CYL

2

2

PILOT

4

PILOT

EXH

EXH

MAIN EXH

MAIN EXH

1/4I NPT

Check nameplate and solenoid marking for correct catalog number,

pressure, voltage, frequency, and service. Never apply incompatible

fluids or exceed pressure rating of the valve. Installation and valve

maintenance to be performed by qualified personnel.

Future Service Considerations.

Provision should be made for performing seat leakage, external leak

age, and operational tests on the valve with a nonhazardous,noncom

bustible fluid after disassembly and reassembly.

Temperature Limitations

Valves with design change letter K" or P" within the catalog num

ber (example: 8317K007) have a maximum fluid temperature of

180_F. Refer to separate solenoid Installation and Maintenance In

structions for maximum ambient temperature.

Positioning

This valve is designed to perform properly when mounted in any posi

tion. However, for optimum life and performance, the solenoid

should be mounted vertically and upright to reduce the possibility of

foreign matter accumulating in the solenoid base sub-assembly area.

Piping

The pressure and exhaust lines must be connected as indicated in the

flow diagram for the particular application. Full size piping must be

used.

On Normally Closed Valves, the 3" connection is a Pilot Exhaust and

may be connected to a Common Exhaust with the 4" connection.

IMPORTANT: Pilot Exhaust 3" on Normally Closed form

must be connected at the installation into the piping to the

Main Exhaust 4" when controlling fluids such as liquids or

flammable gases that are not permissible to exhaust to at

mosphere.

Connect piping to valve according to markings on valve body. Apply pipe

compound sparingly to male pipe threads only. If applied to valve

threads, the compound may enter the valve and cause operational diffi

culty. Avoid pipe strain by properly supporting and aligning piping.

When tightening the pipe, do not use valve or solenoid as a lever, Locate

wrenches applied to valve body or piping as close as possible to con

nection point.

IMPORTANT: To protect the solenoid valve, install a strain

er or filter suitable for the service involved, in the inlet side

as close to the valve as possible. Clean periodically depend

ing on service conditions. See ASCO Series 8600, 8601 and

1

8602 for strainers.

CYL

4

SERIES

8317

I&M No.V7536

INSTALLATION

Page 1 of 3

All Rights Reserved.

E176965

Advertisement

Summary of Contents for Asco RedHat 8317 Series

- Page 1 PRESS PRESS er or filter suitable for the service involved, in the inlet side as close to the valve as possible. Clean periodically depend ing on service conditions. See ASCO Series 8600, 8601 and 8602 for strainers. PILOT PILOT PRESS...

- Page 2 All solenoid valves should be cleaned periodically. The time between Replace worn or damaged parts with a complete ASCO Re build Kit for best results. cleanings will vary depending on the medium and service conditions.

- Page 3 175 ± 25 19,8 ± 2,8 seat/end plug 125 ± 20 14,1 ± 2,3 Indicates Parts Supplied solenoid base In ASCO Rebuild Kits sub-assembly core assembly core spring bonnet gasket valve body diaphragm end plug gasket seat/end plug Figure 1.

Need help?

Do you have a question about the RedHat 8317 Series and is the answer not in the manual?

Questions and answers