Advertisement

Quick Links

Installation & Maintenance Instructions

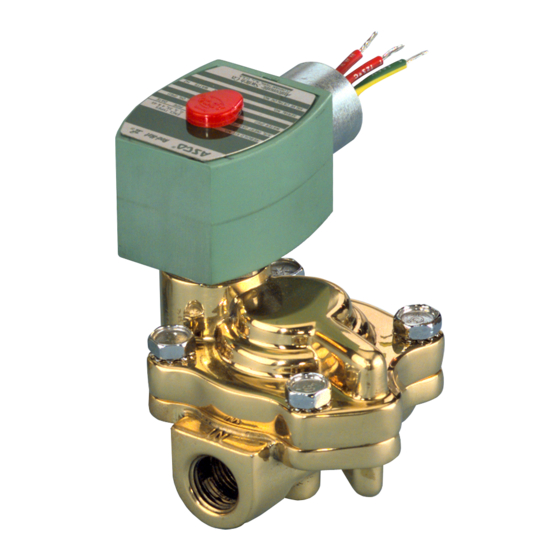

2-WAY INTERNAL PILOT-OPERATED SOLENOID VALVES

NORMALLY CLOSED OPERATION

3/8I, 1/2I, OR 3/4I NPT

IMPORTANT:

See separate solenoid installation and

maintenance instructions for information on:

Solenoid Temperature, Causes of Improper Operation, Coil

or Solenoid Replacement.

DESCRIPTION

Series 8221 valves are 2-way normally closed, internal

pilot-operated solenoid valves designed for soft closing.

Valves are made of forged brass with internal parts of brass

or stainless steel and elastomers of Buna N or ethylene

propylene depending upon service requirements. Valves

may

be

provided

with

explosionproof/watertight solenoid enclosure.

OPERATION

Normally Closed:

Valve is closed when solenoid is

de-energized; open when energized.

IMPORTANT: Minimum operating pressure differential

required is 5 psi. Valve will remain open down to 3 psi

differential.

INSTALLATION

Check nameplate for correct catalog number, pressure,

voltage, frequency, and service. Never apply incompatible

fluids or exceed pressure rating of the valve. Installation and

valve maintenance to be performed by qualified personnel.

Future Service Considerations

Provision should be made for performing seat leakage,

external leakage, and operational tests on the valve with a

nonhazardous, noncombustible fluid after disassembly and

reassembly.

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer

to chart.

Check catalog number prefix and suffix on

nameplate to determine the maximum temperatures. See

example following chart.

Catalog

Construction

Number

Number

AC or DC

AC or DC

Prefix

None

HT

AC

AC

None

HT

None,

DC

or HT

e

ASCO Valves

9/16I OR 3/4I ORIFICE

Wiring,

a

general

purpose

Maximum

Catalog

Temperature _F

Number

Number

Suffix

Ambient

Fluid

None

125

180

None

140

180

HW

125

210

HW

140

210

None

104

150

MCMXCIV All Rights Reserved.

SOFT CLOSING

EXAMPLES: For Catalog No. HT8221G3, AC construction

the maximum ambient temperature is 140_ F with a

maximum fluid temperature of 180_F. For Catalog No.

8221G1HW, AC construction the maximum ambient

temperature is 125_ F with a maximum fluid temperature of

210_F.

Positioning

This valve is designed to perform properly when mounted in

any position. However, for optimum life and performance,

the solenoid should be mounted vertically and upright to

reduce the possibility of foreign matter accumulating in the

solenoid base sub-assembly area.

Piping

or

Connect piping to valve according to markings on valve

body.

CAUTION: Valves with suffix HW" in the catalog

number are equipped with ethylene propylene

elastomers which can be attacked by oils and

greases. Wipe the pipe threads clean of cutting oils.

Apply pipe compound sparingly to male pipe threads only.

If applied to valve threads, the compound may enter the

valve and cause operational difficulty. Avoid pipe strain by

properly supporting and aligning piping. When tightening

the pipe, do not use valve or solenoid as a lever. Locate

wrenches applied to valve body or piping as close as possible

to connection point.

IMPORTANT: To protect the solenoid valve, install a

strainer or filter suitable for the service involved, in the inlet

side as close to the valve as possible. Clean periodically

depending on service conditions. See ASCO Series 8600,

8601 and 8602 for strainers.

Note: It is not necessary to remove the valve from the

pipeline for repairs.

WARNING: To prevent the possibility of

personal injury or property damage, turn off

electrical power, depressurize valve, and

vent fluid to a safe area before servicing the

valve.

Cleaning

All solenoid valves should be cleaned periodically. The time

between cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage

will indicate that cleaning is required. In the extreme case,

faulty valve operation will occur and the valve may fail to

open or close. Clean strainer or filter when cleaning the

valve.

Printed in U.S.A.

50-60 Hanover Road, Florham Park, New Jersey 07932

SERIES

8221

Form No.V6489R1

MAINTENANCE

Page 1 of 4

Advertisement

Summary of Contents for Asco 8221 Series

- Page 1 Clean periodically Provision should be made for performing seat leakage, depending on service conditions. See ASCO Series 8600, external leakage, and operational tests on the valve with a 8601 and 8602 for strainers.

- Page 2 S Excessive Leakage: Disassemble valve and clean all parts. 7. Replace piston spring, valve bonnet, and bonnet If parts are worn or damaged, install a complete ASCO screws. Torque bonnet screws in a crisscross manner to Rebuild Kit. 95 ± 10 in-lbs [10,7 ± 1,1 Nm].

- Page 3 (see note 2) pilot gasket valve body Indicates Parts Supplied In ASCO Rebuild Kits Notes: 1. Wide end of core spring in core first closed end protrudes from top of core. 2. Concave end of flow control to face valve bonnet.

- Page 4 (see note) pilot gasket valve body Indicates Parts Supplied In ASCO Rebuild Kits Note: Concave end of flow control to face valve bonnet. Figure 2. Series 8221 valve without solenoid, DC construction shown. Page 4 of 4 Form No.V6489R1...

Need help?

Do you have a question about the 8221 Series and is the answer not in the manual?

Questions and answers