Subscribe to Our Youtube Channel

Summary of Contents for HEROSE 06602

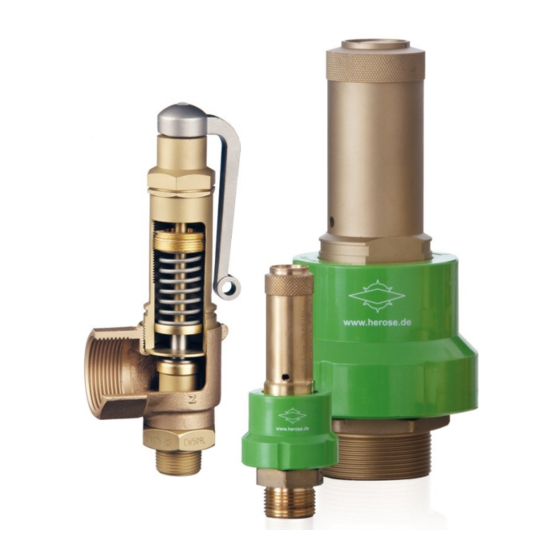

- Page 1 HEROSE GMBH ARMATUREN UND METALLE Operating instructions Safety valve for industrial applications...

- Page 3 Operating instructions IMPORTANT Read carefully before use. Keep for future reference. © 2020 HEROSE GMBH ARMATUREN UND METALLE Elly-Heuss-Knapp-Straße 12 23843 Bad Oldesloe Germany Phone: +49 4531 509 – 0 Fax: +49 4531 509 – 120 E-mail: info@herose.com Web: www.herose.com...

-

Page 4: Table Of Contents

Operating instructions Table of contents About these instructions ....................1 Safety ..........................1 Transport and storage ....................3 Description of the safety valve ..................4 Assembly ........................7 Operation ........................9 Maintenance and service ..................... 10 Disassembly and disposal ................... 12 Phone +49 4531 509-0... -

Page 5: About These Instructions

Follow all safety instructions and operating procedures in these operating instructions. Warranty claims against HEROSE GMBH will be rejected if the HEROSE seal is broken by unauthorised companies. Meaning of the operating instructions The operating instructions are to be read and followed by the responsible technical personnel before mounting and start-up. - Page 6 Operating instructions Requirements for persons who work with the safety valve Persons could be seriously injured or killed if the safety valve is used improperly. In order to avoid accidents, all persons who work on the valve must meet the following minimum requirements: ...

-

Page 7: Transport And Storage

Inspection of condition on delivery Inspect the safety valve for damage upon receipt. In case of transport damage, determine and document the precise extent of the damage, and report it immediately to the supplying dealer/carrier and the insurer. herose.com... -

Page 8: Description Of The Safety Valve

The safety valves are provided with an individual marking for identification. Symbol Explanation e.g. G1/2 Connection size PN….. Rated working pressure (max. permissible operating pressure) Manufacturer’s mark “HEROSE” e.g. 1.4301 Material no. CE-mark, ID of notified body e.g. 0045 e.g. 06205 Type e.g. - Page 9 +150°C 28.0 0.5 to 12.0 +185°C 06500 28.0 1.5 to 2.5 24.0 0.5 to 6.0 28.0 0.5 to 4.5 06505 31.0 0.5 to 6.0 -40 °C to +200 °C 48.0 0.5 to 3.5 24.0 06506 0.5 to 6.0 31.0 herose.com...

- Page 10 See catalogue page. Lifetime The user is obligated to use Herose products for their intended purpose. In this case, a technical service life may be assumed in accordance with the underlying product standards (e.g. EN1626 for shut-off valves and EN ISO 4126-1 for safety valves).

-

Page 11: Assembly

With the narrowest flow diameter of 24 mm, 28 mm and 06505/06506 31 mm the valve may also be installed in a horizontal position. The safety valves can be installed vertically or in a 06602/06603 horizontal installation position with the outlet facing downwards. 50051.0004 Vertical The safety valve can be installed vertically or in a 50051.0011... - Page 12 Operating instructions Tightening torques max. tightening torque [Nm] Male thread Female thread Type Material Thread R; Rc R; Rc 1/4'' 3/8'' 1/2'' CW614N 3/4'' 06205 11/4'' 11/2'' 1/4'' 1.4571 3/8'' 1/2'' 3/4'' 06216/06217 CW617N 06218/06219 11/4'' 11/2'' 1100 1300 1/2'' 3/4'' CC491K 11/4''...

-

Page 13: Operation

Thread R; Rc R; Rc 11/4'' CW614N 11/2'' 06505 06506 11/4'' 1.4408 11/2'' 1400 1400 1.4571 CW614N 1/2'' 06602 1.4301 1/2'' 06603 CC491K 1.4301 1/2'' 50051.0004 CC491K 1/2'' 1/4'' 50051.0011 CW614N 3/8'' Operation The maximum permissible pressure drop in the inlet lines to the safety valves may not exceed the 3% pressure difference between the response pressure and superimposed back pressure on the safety valve. -

Page 14: Maintenance And Service

Operating instructions Maintenance and service Safety during cleaning Take note of the specifications in the safety data sheet and the general occupational health and safety rules if degreasers are used for process-related reasons for the cleaning of bearing parts, unions and other precision parts. - Page 15 Safety valves dimensioned Inadequate Re-dimension and replace the safety incorrectly for the plant capacity valve. conditions; Safety valves not being used in accordance with the applicable Change conditions. regulations; herose.com...

-

Page 16: Disassembly And Disposal

Operating instructions Repairs Repairs to the safety valves may be carried out only by HEROSE or by specialist workshops authorised by HEROSE and monitored by the regulatory authorities, using only original spare parts. Returns / complaints Use the Service form in case of returns/complaints.

Need help?

Do you have a question about the 06602 and is the answer not in the manual?

Questions and answers