Summary of Contents for Alfa Laval Unique Mixproof LP

- Page 1 Instruction Manual Unique Sanitary Mixproof LP and LP-F Valve 2314-0005 ESE02021-EN2 2016-07 Original manual...

-

Page 3: Table Of Contents

7.3. Unique Mixproof LP Valve - parts - 6” ............7.4. Unique Mixproof LP Valve - service kits - 4" and 6" ........... 7.5. Unique Mixproof LP-F Valve - wear parts 4" and 6" ........... 7.6. Unique Mixproof LP-F Valve - parts - 4” ............ -

Page 4: Ec Declaration Of Conformity

1 EC Declaration of Conformity The Designated Company Alfa Laval Kolding A/S Company Name Albuen 31, DK-6000 Kolding, Denmark Address +45 79 32 22 00 Phone No. hereby declare that Valve Designation Unique LP, Unique LP-F Type From serial number 1181354 - 9999999... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. 2.1 Important information Always read the manual before using the valve! WARNING Indicates that special procedures must be followed to avoid serious personal injury. CAUTION Indicates that special procedures must be followed to avoid damage to the valve. -

Page 6: Safety Precautions

2 Safety All warnings in the manual are summarised on this page. Pay special attention to the instructions below so that serious personal injury and/or damage to the valve are avoided. 2.3 Safety precautions Installation Always read the technical data thoroughly. Always release compressed air after use. -

Page 7: Installation

Fit the warning label supplied on the valve after installation so that it is clearly visible. 3.1 Unpacking/intermediate storage Step 1 CAUTION Alfa Laval cannot be held responsible for incorrect unpacking. Check the delivery for: 1. Complete valve. 2. Delivery note. - Page 8 3 Installation The instruction manual is part of the delivery. Study the instructions carefully. Fit the warning label supplied on the valve after installation so that it is clearly visible. Step 4 Remove possible packing materials from the valve ports. Step 5 Inspect the valve for visible transport damage.

- Page 9 3 Installation The instruction manual is part of the delivery. Study the instructions carefully. Fit the warning label supplied on the valve after installation so that it is clearly visible. Step 7 on / off Disassemble according to illustrations 1 to 6 (please also see 5.2 Dismantling of valve).

- Page 10 3 Installation The instruction manual is part of the delivery. Study the instructions carefully. Fit the warning label supplied on the valve after installation so that it is clearly visible. Step 8 Mount sealing element on valve. 2314-0011 Step 9 1.

-

Page 11: General Information

Fit the supplied warning label on the valve so that it is clearly visible. Always read the technical data thoroughly. CAUTION Alfa Laval cannot be held responsible for incorrect Always release compressed air after use. installation. NOTE Always install the valve vertically. -

Page 12: Welding

- please see later on in this section! If there is a risk of foot damage, Alfa Laval recommends to leaving a distance of 120 mm below the valve (look at the specific built-in conditions). - Page 13 3 Installation Study the instructions carefully and pay special attention to the warnings! The valve has ends for welding as standard. Weld carefully/aim for stressless welding to avoid deformation on sealing areas. Check the valve for smooth operation after welding. Step 4 WARNING Make sure to turn the valve body correctly - conical valve seat...

- Page 14 3 Installation Study the instructions carefully and pay special attention to the warnings! The valve has ends for welding as standard. Weld carefully/aim for stressless welding to avoid deformation on sealing areas. Check the valve for smooth operation after welding. NOTE! If ThinkTop®...

-

Page 15: Operation

Never pressurise air connections (AC1, AC3) simultaneously as both valve plugs can be lifted (can cause mixing). CAUTION Alfa Laval cannot be held responsible for incorrect operation. Step 2 Never touch the valve or the pipelines when processing hot liquids Burning danger! or when sterilising. -

Page 16: Troubleshooting And Repair

4 Operation The valve is adjusted and tested before delivery. Study the instructions carefully and pay special attention to the warnings! Pay attention to possible faults. The items refer to the parts list and service kits section. 4.2 Troubleshooting and repair NOTE Study the maintenance instructions carefully before replacing worn parts. -

Page 17: Recommended Cleaning

4 Operation The valve is designed for cleaning in place (CIP). Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. HNO = Nitric acid. Internal leakage in the valve is externally visible by means of the leakage outlet. 4.3 Recommended cleaning Step 1 Caustic danger! - Page 18 4 Operation The valve is designed for cleaning in place (CIP). Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. HNO = Nitric acid. Internal leakage in the valve is externally visible by means of the leakage outlet. Step 3 Never throttle the leakage outlet.

- Page 19 4 Operation The valve is designed for cleaning in place (CIP). Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. HNO = Nitric acid. Internal leakage in the valve is externally visible by means of the leakage outlet. Step 7 Always rinse! Always rinse well with clean water after cleaning.

- Page 20 4 Operation The valve is designed for cleaning in place (CIP). Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. HNO = Nitric acid. Internal leakage in the valve is externally visible by means of the leakage outlet. Seat-cleaning cycles: Pay special attention to the warnings! 1.

-

Page 21: Maintenance

5 Maintenance Maintain the valve/actuator regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and guide rings in stock. The items refer to the parts list and service kits section. The valve is designed so that internal leakages do not result in the products becoming mixed. Internal leakage in the valve is externally visible. - Page 22 5 Maintenance Maintain the valve/actuator regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and guide rings in stock. The items refer to the parts list and service kits section. The valve is designed so that internal leakages do not result in the products becoming mixed. Internal leakage in the valve is externally visible.

- Page 23 - If repair is required, replacing all actuator rubber seals is recommended. - Lubricate seals with Klüberplex BE31. - To avoid possible black marks on pos. 1 and 29, Alfa Laval recommends Klüber Paraliq GTE703 (white) for these two positions.

- Page 24 5 Maintenance Maintain the valve/actuator regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and guide rings in stock. The items refer to the parts list and service kits section. The valve is designed so that internal leakages do not result in the products becoming mixed. Internal leakage in the valve is externally visible.

-

Page 25: Dismantling Of Valve

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. 5.2 Dismantling of valve (NOTE: LP-F IS SHOWN!) Step 1 Disassemble valve acc. to illustrations (1 to 6). 1. - Page 26 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 2 Unique LP Dismantling of lower sealing element: 1. Pull out O-ring (76) and lip seal (77). Unique LP-F 1.

- Page 27 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 4 Remove coupling system and upper plug according to illustrations (1 to 4). 1. Unscrew plug (15) 2.

- Page 28 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 5 1. Remove upper sealing element (48) from upper plug (55). 2. Pull out O-ring (47) and lip seal (49) from upper sealing element. 2314-0031 Step 6 Remove lip seal (57) and guide ring (54).

-

Page 29: Lower Plug, Replacement Of Radial Seal

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. 5.3 Lower plug, replacement of radial seal Step 1 Cut and remove old seal ring (74) using a knife, screwdriver or similar. - Page 30 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Step 3 Item No. Seat ø143.9 Seat ø206.1 Tool for radial sealing, lower plug 9613-4260-09 9613-4260-10 2314-0035 Step 4 Place lower tool part. 2314-0036 Step 5 1.

-

Page 31: Upper Plug, Replacement Of Axial Seal

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly 5.4 Upper plug, replacement of axial seal Step 1 Remove old seal ring (56) using a knife, screwdriver or similar. Be careful not to scratch the plug. - Page 32 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly Step 6 1. Supply compressed air. 2. Release compressed air. 3. Rotate the tool 45° in relation to the plug. 4.

-

Page 33: Valve Assembly

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. 5.5 Valve assembly Step 1 1. Fit O-ring (47) (do not twist), and lip seal (49) in upper sealing element (48) (Lubricate with Klüber Paralique GT 703). - Page 34 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 3 Place coupling system and upper plug according to illustrations. 1. Push lock (44) up over piston rod (29). 2.

- Page 35 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 4 1. Supply compressed air for air connection AC1 2. Insert lower plug (75) and tighten 3.

- Page 36 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 6 - Never stick your fingers through the valve ports if the actuator is supplied with compressed air. - Always supply compressed air, before demounting the valve.

-

Page 37: Dismantling Of Actuator - 4

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. 5.6 Dismantling of actuator - 4” 83/83.1 TD 481-015_2... - Page 38 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 1 1. Dismantle the valve in accordance with instructions in section 5.2 Dismantling of valve Pay special attention to the warnings! 2.

-

Page 39: Assembly Of Actuator - 4

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Replace seals if necessary. Lubricate the rubber seals before fitting them. 5.7 Assembly of actuator - 4” 83/83.1 TD 481-015_2... - Page 40 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Replace seals if necessary. Lubricate the rubber seals before fitting them. Step 1 Please see drawing when reassembling according to steps 2 to 5 on this page. Note! The actuator is maintenance-free but repairable.

-

Page 41: Dismantling Of Actuator - 6

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. 5.8 Dismantling of actuator - 6” 2314-0004_1... - Page 42 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. Replace seals if necessary. Step 1 1. Dismantle the valve in accordance with instructions in section 4.2 Pay special attention to the warnings! 2.

-

Page 43: Assembly Of Actuator - 6

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Replace seals if necessary. Lubricate the rubber seals before fitting them. 5.9 Assembly of actuator - 6” 2314-0004_1... - Page 44 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Replace seals if necessary. Lubricate the rubber seals before fitting them. Step 1 Please see drawing when reassembling according to steps 2 to 5 on this page. Note! The actuator is maintenance-free but repairable.

-

Page 45: Technical Data

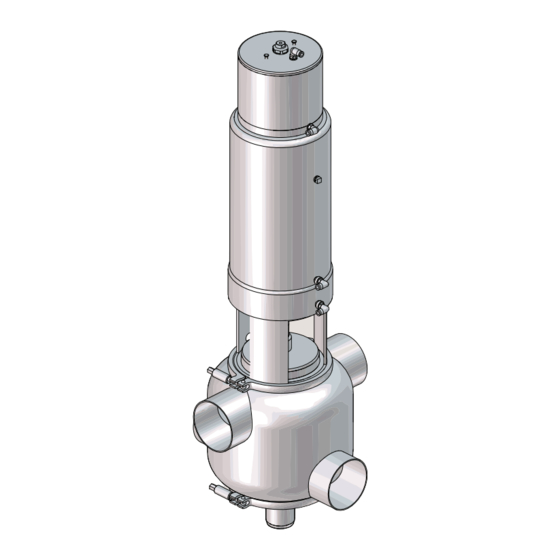

Inform personnel about the technical data. 6.1 Technical data Unique Mixproof LP-F is remote-controlled by means of compressed air. The valve is a normally closed (NC) valve. It is as standard supplied seat lift, which enables handling of two different products at the same time, or safe handling of one product while seat-lift cleaning operations are being conducted in the other portion of the valve –... - Page 46 6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Materials Product wetted steel parts: Acid-resistant steel AISI 316L. Other steel parts: Stainless steel AISI 304 Product wetted parts: EPDM, HNBR, NBR or FPM.

-

Page 47: Parts List And Service Kits

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.1 Unique Mixproof LP Valve - wear parts 4" and 6" 1 6 7 4 83 83.1... - Page 48 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. = Sensor kit = Wear parts...

- Page 49 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination O-ring O-ring Lip seal Seal ring Lip seal Seal ring O-ring Lip seal...

-

Page 50: Unique Mixproof Lp Valve - Parts - 4

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.2 Unique Mixproof LP Valve - parts - 4” 2314-0003_1 = Wear parts... - Page 51 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Parts list Pos. Denomination Pos. Denomination Guide ring, Turcite Cpl. Actuator O-ring, NBR Upper stem Bolt Screw...

-

Page 52: Unique Mixproof Lp Valve - Parts - 6

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.3 Unique Mixproof LP Valve - parts - 6” 2314-0004_2 = Wear parts... - Page 53 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination Cpl. Actuator Upper stem Screw Air fitting Air fitting Air fitting Stop for upper piston O-ring, NBR Guide ring, Turcite...

-

Page 54: Unique Mixproof Lp Valve - Service Kits - 4" And

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.4 Unique Mixproof LP Valve - service kits - 4" and 6" TYPE 11-00 TYPE 11-90... - Page 55 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination Intermediate piece Valve body Service kits Denomination 4” 6” Service kit, NBR .

-

Page 56: Unique Mixproof Lp-F Valve - Wear Parts 4" And

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.5 Unique Mixproof LP-F Valve - wear parts 4" and 6" 83 83.1 42,43,44 60,64 42,43,44 83 83.1... - Page 57 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination O-ring O-ring Lip seal, Seal ring Lip seal Seal ring O-ring Special lip seal...

-

Page 58: Unique Mixproof Lp-F Valve - Parts

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.6 Unique Mixproof LP-F Valve - parts - 4” 2315-0004_1 = Wear parts... - Page 59 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Parts list Pos. Denomination Pos. Denomination Guide ring, Turcite Cpl. Actuator O-ring, NBR Upper stem Screw Bolt...

-

Page 60: Unique Mixproof Lp-F Valve - Parts

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.7 Unique Mixproof LP-F Valve - parts - 6” 2315-0005_1 = Wear parts... - Page 61 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination Cpl. Actuator Upper stem Screw Air fitting Air fitting Air fitting Stop for upper piston O-ring, NBR Guide ring, Turcite...

-

Page 62: Unique Mixproof Lp-F Valve - Service Kits - 4" And

7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.8 Unique Mixproof LP-F Valve - service kits - 4" and 6" TYPE 11-00 TYPE 11-90... - Page 63 7 Parts list and service kits It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Parts list Pos. Denomination Intermediate piece Valve body Service kits Denomination 4” Service kit, NBR .

- Page 64 © Alfa Laval Corporate AB This document and its contents is owned by Alfa Laval Corporate AB and protected by laws governing intellectual property and thereto related rights. It is the responsibility of the user of this document to comply with all applicable intellectual property laws. Without limiting any rights related to this document, no part of this document may be copied, reproduced or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), or for any purpose, without the expressed permission of Alfa Laval Corporate AB.

Need help?

Do you have a question about the Unique Mixproof LP and is the answer not in the manual?

Questions and answers