Summary of Contents for Alfa Laval Unique RV-P

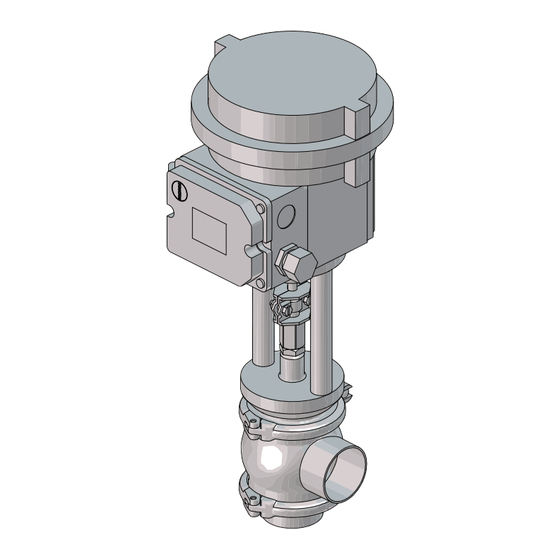

- Page 1 Instruction Manual Unique RV-P, pneumatic regulating valve 2405-0001 ESE02801-EN2 2016-10 Original manual...

-

Page 3: Table Of Contents

Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 1. EC Declaration of Conformity ............... 2. Safety ....................2.1. Important information ................2.2. Warning signs ..................2.3. Safety precautions ................3. -

Page 4: Ec Declaration Of Conformity

+45 79 32 22 00 Phone No. hereby declares that Valve Designation Unique RV-P, Unique RV-P-A Type is in conformity with the following directive with amendments: - Machinery Directive 2006/42/EC The person authorised to compile the technical file is the signer of this document... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. 2.1 Important information Always read the manual before using the valve! WARNING Indicates that special procedures must be followed to avoid serious personal injury. CAUTION Indicates that special procedures must be followed to avoid damage to the valve. -

Page 6: Safety Precautions

Never stick your fingers through the valve ports if the actuator is supplied with compressed air Never touch moving parts if the actuator is supplied with compressed air Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. -

Page 7: Installation

3.1 Unpacking/delivery Step 1 Check the delivery for: CAUTION 1. Complete valve 2. Delivery note Alfa Laval cannot be held responsible for incorrect unpacking. 3. Instruction manual Step 2 Remove possible packing materials from the valve/valve parts. 2405-0002 Step 3 Inspect the valve for visible transport damage. -

Page 8: General Installation

Avoid damaging the air connection, the electrical connection and the valve ports. 2405-0004 3.2 General installation Step 1 CAUTION Alfa Laval cannot be held responsible for incorrect Always read the technical data thoroughly. installation. See chapter 6 Technical data. Always release compressed air after use. Step 2 Never touch moving parts if the actuator is supplied with compressed air. - Page 9 3 Installation Study the instructions carefully and pay special attention to the warnings! The valve has welding ends as standard but can also be supplied with fittings. Step 3 To avoid water hammer, it is recommended to install the valve so that the flow is against the closing direction.

-

Page 10: Welding

3 Installation Study the instructions carefully. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. 3.3 Welding Step 1 Always weld the valve body into the system when it is disassembled from the valve. - Page 11 3 Installation Study the instructions carefully. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. Step 2 Assemble the valve in accordance with the steps on page 22. Pay special attention to the warnings! Standard model 1.

- Page 12 3 Installation Study the instructions carefully. The items refer to the parts list and service kits section. Check the valve for smooth operation after welding. Aseptic model 1. Lubricate O-ring (21) with Klüber Paraliq GTE 703. 2. Fit seat (63) and O-ring (21) in the valve body (26). 3.

-

Page 13: Recycling Information

- At end of use, the equipment must be recycled according to the relevant local regulations. Besides the equipment itself, any hazardous residues from the process liquid must be considered and dealt with in a proper manner. When in doubt, or in the absence of local regulations, please contact your local Alfa Laval sales company... -

Page 14: Operation

The items refer to the parts list and service kits section. 4.1 Operation Step 1 CAUTION Alfa Laval cannot be held responsible for incorrect Always read the technical data thoroughly. operation. See chapter 6 Technical data. Always release compressed air after use. - Page 15 4 Operation Study the instructions carefully and pay special attention to the warnings! Ensure that the valve operates smoothly. The items refer to the parts list and service kits section. Step 4 Lubrication of valves: 1. Ensure smooth movement between lip seal (25) and plug stem (23).

-

Page 16: Troubleshooting

4 Operation Pay attention to possible faults. Study the instructions carefully. The items refer to the parts list and service kits section. 4.2 Troubleshooting NOTE! Study the maintenance instructions carefully before replacing worn parts - section 5.1 General maintenance. Repair Problem Cause/result External product leakage... - Page 17 4 Operation The valve is designed for cleaning in place (CIP). Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic soda. = Nitric acid. Step 3 Clean the plug and the seats correctly. Pay special attention to the warnings Lift and lower valve plug momentarily! 2405-0014 Step 4...

-

Page 18: Maintenance

Maintain the valve regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and lip seals in stock. Always use Alfa Laval genuine spare parts. Check the valve for smooth operation after service. - Page 19 Maintain the valve regularly. Study the instructions carefully and pay special attention to the warnings! Always keep spare rubber seals and lip seals in stock. Always use Alfa Laval genuine spare parts. Check the valve for smooth operation after service.

-

Page 20: Dismantling The Valve

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. 5.2 Dismantling the valve Step 1 Standard model 1. Loosen and remove upper clamp (19). 2. - Page 21 5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. NC = Normally closed. NO = Normally open. Aseptic model 1. Loosen and remove upper clamp (19). 2. Unscrew the clamp fitting (111). 3.

-

Page 22: Plug Seal Replacement

Lubricate O-ring (21) and lip seal (25) with Klüber Paraliq GTE 703. Remember to tighten spindle and plug to a torque of 30 Nm (using two 17 mm spanners). If there are vibrations in the pipeline, Alfa Laval recommends the use of Loctite no. 243. -

Page 23: Technical Data

6 Technical data Technical data must be observed during installation, operation and maintenance. All personnel should be informed about the technical data 6.1 Technical data Working principles The Product is remote-controlled by an electrical signal and compressed air. The IP-converter, which is an integrated part of the actuator, converts the electrical signal to a pneumatic signal. - Page 24 6 Technical data Technical data must be observed during installation, operation and maintenance. All personnel should be informed about the technical data Weights 101.6 mm/4” 101.6 mm/4” Size 38 mm/1½” 51 mm/2” 63.5 mm/2½” 76.1 mm/3” 11.2 15.4 24.9 Noise One metre away from and 1.6 metres above the exhaust the noise level of a valve actuator will be approximately 77 db(A) without noise damper and approximately 72 db(A) with damper - measured at 7 bar air pressure.

-

Page 25: Parts List And Service Kits

7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. 7.1 Standard model 2405-0019_1... - Page 26 7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. 2405-0000...

- Page 27 7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. Parts list Pos. Denomination Clamp O-ring Plug Bushing ...

-

Page 28: Aseptic Model

7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. 7.2 Aseptic model 2405-0023_1... - Page 29 7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts.

- Page 30 7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. 23.1 2405-0020...

- Page 31 7 Parts list and service kits Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on the use of Alfa Laval genuine spare parts. Parts list Pos. Denomination Clamp O-ring Plug, complete 23.1...

- Page 32 © Alfa Laval Corporate AB This document and its contents is owned by Alfa Laval Corporate AB and protected by laws governing intellectual property and thereto related rights. It is the responsibility of the user of this document to comply with all applicable intellectual property laws. Without limiting any rights related to this document, no part of this document may be copied, reproduced or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), or for any purpose, without the expressed permission of Alfa Laval Corporate AB.

Need help?

Do you have a question about the Unique RV-P and is the answer not in the manual?

Questions and answers