Table of Contents

Advertisement

No. CP-SP-1204E

™

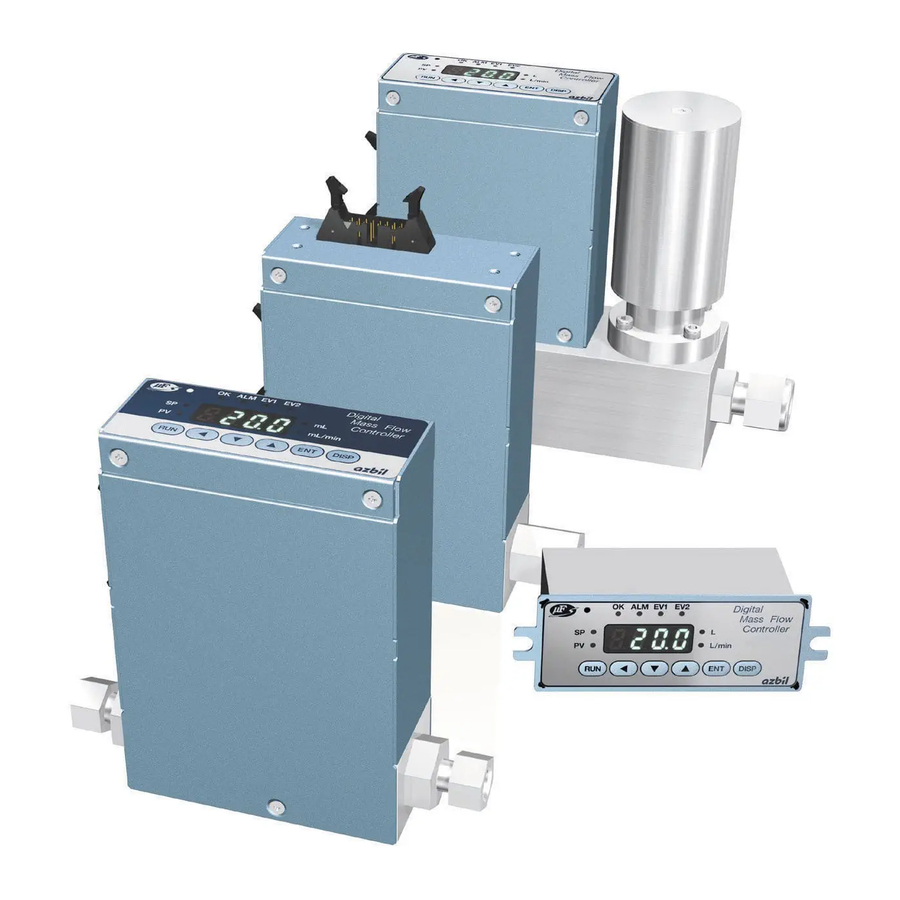

Digital Mass Flow Controller

Standard Gas Model

MQV9005/9020/9200/9500

0002/0005/0020/0050/0200/0500

User's Manual

Thank you for purchasing an Azbil

Corporation product.

This manual contains information for

ensuring the correct use of this product.

It also provides necessary information

for installation, maintenance, and

troubleshooting.

This manual should be read by those who

design and maintain equipment that uses

this product. Be sure to keep this manual

nearby for handy reference.

Advertisement

Table of Contents

Need help?

Do you have a question about the Micro Flow MQV9005 and is the answer not in the manual?

Questions and answers