Table of Contents

Advertisement

Quick Links

Instruction Manual

September 2013

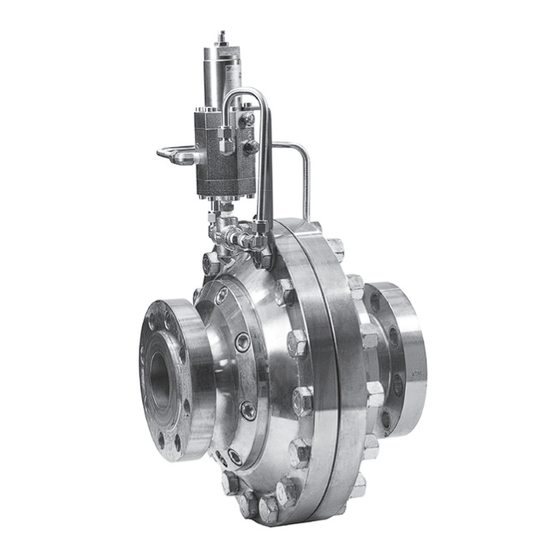

Type FL Relief Valve or Backpressure Regulator

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or fi re

causing property damage and personal injury

or death.

Tartarini™ regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies, Inc.

(Regulator Technologies) instructions.

If the product vents gas or a leak develops in

the system, service to the unit may be required.

Failure to correct trouble could result in a

hazardous condition.

Call a gas service person to service the

unit. Only a qualifi ed person must install or

service the product.

Introduction

Scope of the Manual

This manual provides instructions for installation,

adjustment, maintenance, and parts ordering information

for the Type FL relief valve or backpressure regulator

with a Type PRX/182 pilot sold in North America. Any

accessories used with this relief valve or backpressure

regulator are covered in their respective manuals.

Description

The Type FL relief valve or backpressure regulator are

accurate pilot-operated, relief valve or backpressure

regulators designed for high-pressure transmission/city gate,

large capacity distribution systems, and power plant feeds.

The Type FL relief provides smooth, reliable operation, tight

shutoff, and long life. The main valve actuator moves in

response to the pilot loading pressure to control upstream

system pressure.

Figure 1. Type FL Relief Valve or Backpressure Regulator

Principle of Operation

A pressure relief valve is a throttling pressure control

device that opens and closes to ensure the inlet pressure

does not rise above a predetermined pressure. Tartarini™

relief valves cannot be used as ASME safety relief valves.

A backpressure regulator is a device that controls and

responds to changes in the upstream pressure. It functions

the same as a relief valve in such a way that it opens on

increasing upstream pressure.

Relief Valve

As long as the inlet pressure is below the set pressure,

the pilot control spring keeps the pilot valve plug closed. Inlet

pressure passes through the restrictor and registers as loading

pressure on the main valve diaphragm chamber. Force from

www.tartarini-naturalgas.com

Type FL

with PRX Series Pilot

Advertisement

Table of Contents

Summary of Contents for Emerson Tartarini FL

- Page 1 Tartarini™ regulators must be installed, operated, and maintained in accordance with federal, state, and local codes, rules and regulations, and Emerson Process Management Regulator Technologies, Inc. (Regulator Technologies) instructions. If the product vents gas or a leak develops in the system, service to the unit may be required.

-

Page 2: Specifications

Type FL Specifications The Specifications section gives some general specifications for the Type FL relief valve or backpressure regulator. The nameplates give detailed information for a particular relief valve or backpressure regulator as it comes from the factory. Body Sizes Temperature Capabilities (1)(2) Nitrile (NBR) or Fluorocarbon (FKM) Disk:... - Page 3 Type FL SPRING PORT L CASE VENT SPRING PORT B PORT L CASE VENT PORT S EXHAUST PORT B PORT S EXHAUST PORT A PORT A M1205 INLET PRESSURE OUTLET PRESSURE ATMOSPHERIC PRESSURE LOADING PRESSURE Figure 2. Type FL Relief Valve or Backpressure Regulator Operational Schematic Table 2.

-

Page 4: Installation

Type FL the main spring, in addition to pilot loading pressure, provide or pressure-limiting devices to prevent service loading pressure to keep the main valve diaphragm and plug conditions from exceeding those limits. Also, assembly tightly shut off. be sure the installation is in compliance with all applicable codes and regulations. -

Page 5: Startup And Shutdown

Type FL 5. If the vent assembly (key 12, Figure 7) remains in the Backpressure Installation pilot body, then it must be pointed down if possible or otherwise protected. If the exhaust is to be piped to Startup the main valve exhaust or remotely vented, remove the vent assembly and install tubing or piping into 1. - Page 6 Type FL TOP VIEW TOP VIEW LEGACY TRAVEL INDICATOR DETAIL IMPROVED TRAVEL INDICATOR DETAIL P1764 APPLY LUBRICANT (L) / SEALANT (S) L1 = LITHIUM HYDROXYSTEGRATE NLGI 2 GRADE GREASE S1 = ANAEROBIC METHACRYLATE SEALANT FOR NUTS AND BOLTS 1. Lubricant and sealant must be selected such that they meet the temperature requirements. Figure 3.

- Page 7 Type FL Lower Diaphragm Maintenance Check sleeve (key 16) seating surface for damage. Check O-rings (keys 3 and 4) and anti-friction rings (key 2), 1. Disconnect pilot and remove it from the line. replace if necessary. 2. Remove machine screws (key 10) from lower cover 6.

-

Page 8: Parts Ordering

Type FL Remove orifice (key 19) and O-ring (key 17). Inspect Description Part Number the parts for damage or wear, and replace if necessary. Inlet Flange Lightly lubricate the O-ring and place in the body (key 16). CL300 RF Install the orifice. NPS 1 / DN 25 M0268280X12 NPS 2 / DN 50... - Page 9 Type FL Description Part Number Description Part Number Diaphragm, PVC Coated Nitrile (NBR) Disk (continued) Nitrile (NBR) (continued) NPS 1 / DN 25 GD19445X012 NPS 2 / DN 50 GD19463X012 NPS 6 / DN 150 M0250560X12 NPS 3 / DN 80 GD19209X012 NPS 8 / DN 200 M0296690X12...

- Page 10 Type FL Description Part Number Description Part Number Socket Head Screw (continued) Indicator Fitting Type FL (continued) NPS 1 / DN 25 ERSA01820A0 NPS 6 / DN 150 M5011003X12 NPS 2 / DN 50 ERSA01820A0 NPS 8 / DN 200 M5011005X12 NPS 3 / DN 80 ERSA01822A0...

- Page 11 Type FL PRX Series Pilots (Figure 7) Description Part Number Description Part Number Parts Kits Stem GD25343X012 Nameplate GD26808X012 Elastomer Parts Kits (includes keys: 4, 5, 14, Stem O-ring 17, 18, 25, and 28) Nitrile (NBR) GD01022X012 Type PRX/182 Fluorocarbon (FKM) GD01022X022 Nitrile (NBR) RPRX00X0N12...

- Page 12 Type FL SPACER DETAILS FOR SIZES SMALLER THAN NPS 6 / DN 150 SPACER DETAILS FOR NPS 6 TO 12 / DN 150 TO 300 E0831 OUTLET FLANGE (KEY 22) SOCKET HEAD SCREW (KEY 5 OUTLET SIDE) DISK-HOLDER (KEY 19) E0832 O-RING (KEY 4 OR 18 DEPENDING ON SIZE)

- Page 13 SPACER DETAILS SPACER DETAILS FOR SIZES SMALLER THAN FOR SIZES SMALLER THAN Type FL NPS 6 / DN 150 NPS 6 / DN 150 NPS 1 AND 2 / DN 25 AND 50 NPS 3, 4, 6, AND 8 / NPS 10 / DN 250 WITHOUT SILENCER DN 80, 100, 150, AND 200...

- Page 14 Type FL “S” PORT VENT “L” PORT “B” PORT (VENT) “A” PORT FLOW Figure 6. Type FL Single Pilot Mounting Assembly...

- Page 15 Type FL Figure 7. Types PRX/182 and PRX-AP/182 Pilots Table 6. Type FL Travel Indicator Assemblies Part Numbers DESCRIPTION MATERIAL NPS 1 / DN 25 NPS 2 / DN 50 NPS 3 / DN 80 NPS 4 / DN 100 NPS 6 / DN 150 NPS 8 / DN 200 NPS 10 / DN 250 Fluorocarbon Travel Indicator...

- Page 16 For further information visit www.emersonprocess.com/regulators The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Tartarini is a mark of O.M.T. Officina Meccanica Tartarini s.r.l., a business of Emerson Process Management.

Need help?

Do you have a question about the Tartarini FL and is the answer not in the manual?

Questions and answers