Table of Contents

Advertisement

Instruction Manual

D103658X012

January 2015 - Rev. 00

m Series Pressure regulators

Summary

Introduction ........................................................................

P.E.D. Categories and Fluid Group ...................................

Characteristics ...................................................................

Labelling ............................................................................

Overpressure Protection ...................................................

Transport and Handling .....................................................

Atex Requirements ............................................................

Slam-Shut Controller ..........................................................

Dimensions and Weights ...................................................

Operation ...........................................................................

Installation .........................................................................

Startup ...............................................................................

Adjustment .........................................................................

Shutdown ..........................................................................

Periodical Checks ..............................................................

Maintenance ......................................................................

Spare Parts ........................................................................

Troubleshooting .................................................................

Parts List ............................................................................

Schematic Assemblies .......................................................

INTrODuCTION

Scope of manual

This manual provides instructions for installation, startup,

maintenance and spare parts ordering for the M series

spring loaded regulators.

Product Description

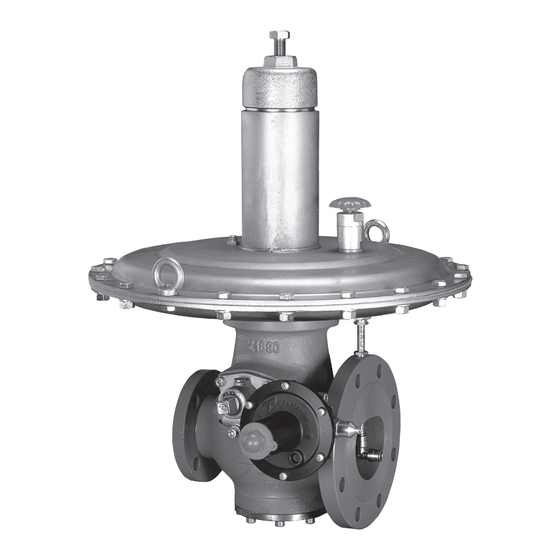

The M series regulators are fail open, differential strength, spring

loaded whit counterbalanced shutter. They can be provided with

slam-shut controller for minimum pressure, maximum pressure

or minimum and maximum downstream pressure.

The regulators of the M series due to their operating

specifications are mainly used in those system where

sudden capacity variations are required, or else, where the

cut-off of the gas distribution is controlled by solenoid valve,

such as for the feeding of burners.

TM

1

2

2

2

3

3

3

3

4

5

6

7

8

8

8

This product has been designed to be used with fuel gases of

1st and 2nd family according to EN 437, and with other non

8

aggressive and non fuel gases. For any other gases, other

9

than natural gas, please contact your local sales agent.

10

The following versions are available:

10

mN • mF: Regulator

11

mBN • mBF: Regulator with slam-shut

mBN-m • mBF-m: Monitor with slam-shut

MN, MF, MBN and MBF series with SR silencer are also

available.

The standard gas pressure devices (regulators and safety

shut-off devices) are those used in the assemblies dealt with

into EN 12186 and EN 12279 and their use has to be under

the provisions into ENs 12186 & 12279.

In the pressure regulators manufactured by Emerson

Process Management shall be used additional pressure

accessories (e.g. slam-shut controller) manufactured and

labeled by Emerson Process Management.

Emerson Process Management will be not responsible

for any possible inefficiency due to installation of not own

production additional pressure accessories (e.g. slam-shut

controller).

When pressure containing parts of possible built-in safety

shut-off device (SSD) valve and pilot have different

maximum allowable pressures, the SSD is differential

strength type.

Figure 1. Regulator Type MBN

(pressure accessories)

(safety accessories)

Type M

(safety accessories)

Advertisement

Table of Contents

Summary of Contents for Emerson Tartarini M Series

-

Page 1: Table Of Contents

M series the provisions into ENs 12186 & 12279. spring loaded regulators. In the pressure regulators manufactured by Emerson Process Management shall be used additional pressure Product Description accessories (e.g. slam-shut controller) manufactured and labeled by Emerson Process Management. -

Page 2: P.e.d. Categories And Fluid Group

Type M P.E.D. CaTEGOrIES aND FLuID GrOuP MF • MBF • MBF-M DN 80-100: 5 bar ** MN-PST • MBN-PST • MBN-M-PST: 19.6 bar * Fail open stand-alone M series regulators cannot be used MF-PST • MBF-PST • MBF-M-PST: 19.6 bar * as a safety accessory according PED 97/23/EC to protect downstream pressure equipment. -

Page 3: Overpressure Protection

Type M Note 1: See “Characteristics” In any case, Note 2: Year of manufacture • provisions of Directive 1999/92/EC and 89/655/EC shall Note 3: Class 1: -10/+60 °C be enforced by gas pressure regulating/measuring station/ Class 2: -20/+60 °C installation’s end user Note 4: PN 16 PS = 16 bar •... -

Page 4: Dimensions And Weights

Type M DImENSIONS aND WEIGhTS Table 3. Dimensions (mm) and Weights (kg) MN, MBN and MBN-M Regulators mN • mBN • mBN-m WEIGhT mONITOr mBN-m vErSION 25x65 40x80 50x100 65x100 80x150 620* 100x200 620* (*) BP Version (**) For models with internal impulse connection only (DN 25, 40, 50, 65) 180** Table 4. -

Page 5: Operation

Type M OPEraTION To downstream To downstream Figure 5. MBF-M Series Operational Schematic How the Regulator Works The range of position of control member depend from actuator assembly (spring-stem-diaphragm) movements. The Diaphragm divides the Regulator control head into two chambers. The lower chambers is connected to regulated pressure Pd, and the other, where the spring regulator is located, is connected to atmospheric pressure. -

Page 6: Installation

Type M INSTaLLaTION 1/4” Connection SS Pipe 4 x DN ø 6 mm 6 x DN rEGuLaTOr TyPE mBN DN 25 TO DN 65 WITh INTErNaL ImPuLSE CONNECTION SS Pipe ø 15 mm 1/2” Connection 1/4” Connection SS Pipe 4 x DN ø... -

Page 7: Startup

Type M • Ensure that the data found on the regulator plate are scrubbers to avoid any technical and compatible with usage requirements. reasonable hazard of erosion or abrasion for pressure containing parts. • Ensure that the regulator is mounted in accordance with the direction of flow indicated by the arrow. -

Page 8: Adjustment

Type M aDjuSTmENT The regulator and it’s pressure accessories are subject to normal wear and must be inspected periodically and To change the outlet pressure turn the adjusting screw replaced if necessary. (key. 1) clockwise to increase outlet pressure or counter clockwise to decrease pressure. -

Page 9: Spare Parts

Type M e. Reassemble the various parts by reversing the steps laid h. unscrew the screw (key 51), dismount the lower cover out above. (key 25) and the cup unit (key 44). reset unit maintenance CauTION a. Trip the slam-shut controller OS/66 and remove impulse For the versions with slam-shut keep connection. -

Page 10: Troubleshooting

Type M TrOuBLEShOOTING Table 5. M Series General Troubleshooting SymPTOmS CauSE aCTIONS Lack of incoming gas Check the station feeding The regulator does not open The slam-shut controller has not been reset Manually reset the slam-shut controller Insufficient upstream pressure Check the station feeding Flow requirements higher than the flow Check the regulator sizing... -

Page 11: Schematic Assemblies

Type M SChEmaTIC aSSEmBLIES MBN • MBF 48 49 50 51 52 14 15 16 17 18 19 80 84 85 MBN • MBF DN 25 DETAIL 32 31 LM/1392 Figure 7. M Series Regulator Assembly... - Page 12 Type M W.C.B. LM/1392 Figure 7. M Series Regulator Assembly (continued)

- Page 13 Type M EXTERNAL IMPULSE LINE MN • MBN DN 80 TO DN 100 DETAIL MBN-M DETAIL To downstream stainless steel pipe Ø 15 mm MN • MF DN 25 MN • MF DN 40 TO DN 100 DETAIL DETAIL DN 25 TO DN 100 AP, APA AND PST VERSION LM/1392 Figure 7.

- Page 14 Type M DN 25 DETAIL DN 100 DETAIL DN 100 AP VERSION DN 100 PST VERSION DN 25 TO DN 80 DN 100 APA VERSION APA VERSION LM/1392 Figure 7. M Series Regulator Assembly (continued)

- Page 15 Type M DN 25 MONITOR VERSION DN 40 TO DN 100 MONITOR VERSION To downstream stainless steel pipe Ø 10 mm To downstream stainless steel pipe Ø 10 mm AP AND APA MONITOR VERSION SR SILENCED VERSION DETAIL To downstream stainless steel pipe Ø...

- Page 16 For further information visit www.emersonprocess.com/regulators The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Tartarini is a mark of O.M.T. Officina Meccanica Tartarini s.r.l., a business of Emerson Process Management.

Need help?

Do you have a question about the Tartarini M Series and is the answer not in the manual?

Questions and answers