Summary of Contents for Classeq CST

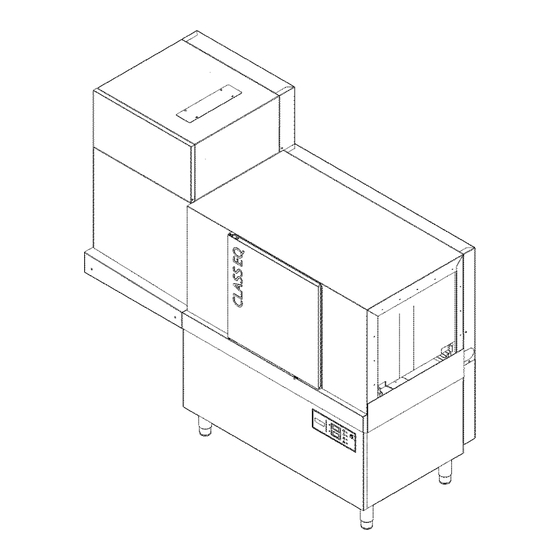

- Page 1 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT CST Machines Drawn up: 05/10/2018 Document number : 30008893 Page 1 of 48 Revision: C...

- Page 2 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Drawn up: 05/10/2018 Document number : 30008893 Page 2 of 48 Revision: C...

-

Page 3: Table Of Contents

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Contents Introduction ..........................4 Recommended Tool Kit ......................5 Machine Specifications ....................... 6 Installation Instructions ....................... 7 Know your unit ..........................7 Warning and safety information ....................9 Site requirements ........................10 Commissioning Instructions ...................... 14 Water Systems ......................... -

Page 4: Introduction

The appliance must only be repaired by a Classeq approved technician, using genuine Classeq spare parts, failure to do so could invalidate any warranty and relieve the manufacture of all liability. Modification: Classeq reserves the right to modify either the appliance or the contents of these instructions without notice. Drawn up: 05/10/2018... -

Page 5: Recommended Tool Kit

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 2. Recommended Tool Kit Recommended hand tools Specification 5.5mm - Spanner / nut runner / socket 7.0mm - Spanner / nut runner / socket 8.0mm - Spanner / nut runner / socket 10.0mm - Spanner / nut runner / socket 13.0mm –... -

Page 6: Machine Specifications

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 3. Machine Specifications Door opening angle 180° Maximum clear entry height 492mm Operating noise level* <70dB Net weight 180kg Gross weight 268kg Built in air gap (WRAS Approved) Rinse booster pump Built in Detergent dispenser... -

Page 7: Installation Instructions

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 4. Installation Instructions The site: Ensure that there is sufficient space for the installation, servicing and easy access to all mains isolator switches / valves (i.e. electricity and water). Ensure that the surface the appliance is going to be installed onto is adequately stable and capable of supporting the appliance during normal operation (see site requirements). - Page 8 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Dryer unit layout Dryer element* Dryer thermostat Blower unit Blower terminal block (TB4) Dryer cassette Drawn up: 05/10/2018 Document number : 30008893 Page 8 of 48 Revision: C...

-

Page 9: Warning And Safety Information

When disconnecting your machine from the mains electrical supply: Machines hard wired (i.e. no plug), this must be disconnected in accordance with local and national regulations; Classeq recommends this is performed by a qualified electrician. Always remove excess food from the dishes before loading. -

Page 10: Site Requirements

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 7. Site requirements Machine dimensions: Dishwashers With dyer A = width (mm) 1300 2000 Closed (mm) B = depth Open (mm) 1490 C = height (mm) 1380-1440 1730-1790 Basket size (mm) (square basket) - Page 11 Electrical connections MUST be carried out by an authorized technician and in accordance with local and national regulations. As a minimum Classeq recommends the following standards are maintained: All appliances are connected via a residual current device (R.C.D.) or earth leakage protection device.

- Page 12 , or your Classeq appliance is connected to an appropriate water softener. Note: Water supply can be either side of the machine...

- Page 13 Waste hose must flow down from the waste outlet to the drain. Joint between standpipe and waste hose must be water tight. If you have any doubts about the drainage system on the machine, please contact either Classeq or your dealer/agent.

-

Page 14: Commissioning Instructions

8. Commissioning Instructions Rinse aid & Detergent: The CST is not fitted with internal chemical dosing pumps, these will need to be fitted during the installation. A terminal block is provided on right hand side of the wash tank for connecting the electrics of the chemical pumps. - Page 15 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine temperature settings: The water temperatures on ’Classeq’ range of machines are adjustable, but have been pre-set to: Thermostat positions Rinse thermostat – Rinse thermostat – Wash thermostat standby (ST1) Running (ST2) (ST3) 55ºC –...

- Page 16 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Cable gland Terminal block Min. 50mm Adjustable 20-70mm This switch will stop the machine when activated allowing the operator time to remove the clean baskets before more baskets are pushed through the machine.

- Page 17 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Electrical supply setup If the machine is fitted to a hot water supply (maximum temperature of 55°C) then the electrical supply to the machine can be changed (►7). This is done by turning off CB2, this turns off one of the banks of elements used in the rinse boiler and reduces the current required.

-

Page 18: Water Systems

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 9. Water Systems Rinse system (Also used for filling the wash tank): Wash system: Drawn up: 05/10/2018 Document number : 30008893 Page 18 of 48 Revision: C... -

Page 19: Electrical Component Data

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Electrical Component Data Voltage Frequancy Current Power Resistance Component (Ω) (Hz) Inlet solenoid 220 ~ 240 50 ~ 60 valve Rinse elements 4 x (3x2kW) 50 ~ 60 8.7 / leg 2000 / leg 26.42 / leg... -

Page 20: Changing Orientation

Remove rear top and rear bottom panels in order to get access to wash and rinse hoses. When changing the direction of the CST care must be taken not to misplace or damage the sealing O- rings. - Page 21 CST MACHINES AND DRYER UNIT Tighten jubilee clips Replace wash top wash hose with the hose required for the direction of travel. A= Right hand CST Top wash hose (PN) B= Left hand CST Top wash hose (PN) ...

- Page 22 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT 11.2 Setting orientation of the wash arms Note the orientation of the locating ring for the wash arms. These are fitted in different orientations in the machine as show below Orientation 1: Pointing directly down...

- Page 23 Bottom wash arms shown with entrance to the right: 11.3 Changing cassette assembly setting. Once CST’s hoses have been changed, the cassette assembly needs to be rotated to move the baskets in the required direction. Remove the nuts holding centre plate.

-

Page 24: Speed Setting

F = 1 x Centre plate G = 2 x Speed variable plate The CST is available at two speed settings of 100 or 130 baskets per hour. In order to change the setting, remove cassette assembly from the machine and follow the steps below: Step 1: Remove 4x M5 nuts holding centre plate (F) then re-locate centre plate (F) to the correlating stud and tighten it back with the 4 x M5 nuts. - Page 25 It is very important to follow the steps; failure to it will lead to potential damage to the cassette Caution assembly. If in doubt then contact Classeq or your local dealer. Drawn up: 05/10/2018 Document number : 30008893 Page 25 of 48 Revision: C...

-

Page 26: Setting Basket Arm

CST MACHINES AND DRYER UNIT Setting basket arm The basket arm is factory set to work with all Classeq baskets and should not need to be adjusted. However should baskets from a different manufacturer be used that is not being picked up by the machine or are causing the machine to stop in the cylce then the arm can be adjusted to suite these. -

Page 27: Machine Wiring And Layout

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine wiring and layout Machine control panel layout Timer (TM3) Basket present relay (RL5) On/Off relay (RL1) Drive motor relay (RL6) Door relay (RL2) Wash heater relay (RL7) Wash pump relay (RL3) Control Panel... - Page 28 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Front panel Wash temperature Pump running lamp (L2) On/Off lamp (L1) Double Orange Double Double Double Double Blue Blue Blue Heating lamp (L3) On/Off switch Error lamp (L4) Rinse temperature Brown Double Brown...

- Page 29 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine breakers and timer wiring Breaker Breaker Type Wire colour / Connection configuration size number Incoming wire from Filter 4A (P1) Circuit breaker 5 Out going wire to On/Off switch Incoming wire from Terminal block (TB1)

- Page 30 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Neutral from Terminal block (TB1) From timer (TM2) Incoming wire from Door relay (RL2) Motor timer (TM1) To Drive motor (DM1) Incoming wire from Door relay (RL2) Select time Default: Time segment segment to...

- Page 31 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Neutral from Terminal block (TB1) From CB5 From on/off switch Delay timer (TM3) To Basket pressent relay (RL5) To Control circuit From timer (TM2) Select time Default: Time segment segment to 20s (20 seconds)

- Page 32 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine contactors Rinse heating contactor (CT1) Rinse heating contactor (CT2) Wash heating contactor (CT3) Blue Blue Blue Brown Black Grey Brown Black Grey Brown Black Grey Brown Black Grey Brown Black Grey Brown...

- Page 33 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine contactors Rinse heating contactor (CT4) Rinse heating contactor (CT5) Wash heating contactor (CT6) Grey Blue Grey Purple Brown Black Grey Brown Brown Black Grey Brown Brown Black Grey Brown Brown Black Grey...

- Page 34 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine relays Wash heater Relay (RL7) Door Relay (RL2) Wash pump Relay (RL3) Red cover Black cover White cover Green cover Purple Purple Red cover Purple Black cover Orange Purple Grey Black Purple...

- Page 35 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine relays Machine full Relay (RL4) Basket present Relay (RL5) Drive motor Relay (RL6) Red cover Black cover White cover Green cover Red cover Black Black cover White Purple Purple Black Orange Brown...

- Page 36 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine Filters 1) Suppression filter (4 Amp) From TB1 Yellow - From TB1 From TB1 Earth Brown Blue Blue Black To CB5 2) RC Filters CT4 & CT5 Rinse heating Blue Grey contactor...

- Page 37 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine thermostat wiring Rinse standby thermostat (ST1) Rinse run thermostat (ST2) Red cover Black cover White cover Red cover / Normally Closed Grey Grey Black cover / Normally Open White cover / Common...

- Page 38 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Machine options / Selection Air break Purple Brown Purple Brown Black Grey Grey Common White Pressurised Table end switch (CC4 and CC5) connector plug Blue Brown Brown Basket present switch (SW4) connector plug...

- Page 39 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Components wiring Part number & Component Wiring configuration Description Inlet Solenoid Valve Blue Wire Grey wire White Crimp White Crimp Rinse safety Thermostat (95°C) Blue Wire Double blue Wire White Crimp White Crimp...

- Page 40 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Element wiring 6kW Rinse elements, using LM-CST-HEATING Element 1, 2, 3 & 4: Brown wire (Thick) Black wire (Thick) Grey wire (Thick) 6kW Wash elements, using LM-CST-HEATING Element 5 & 6: Brown wire (Thick)

-

Page 41: Dryer Unit Wiring And Layout

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Dryer unit wiring and layout Dryer control panel layout Tempraure rdfd Dryer breaker (CB6) Blower relay (RL10) Heater safety relay (RL9) Air heater relay (RL8) Drawn up: 05/10/2018 Document number : 30008893 Page 41 of 48... - Page 42 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Dryer terminal block (TB3) Earth 1.5mm Black 0.5mm Orange 0.5mm White 0.5mm Grey 0.75mm Black 0.75mm Brown 0.75mm White 1.5mm Purple 1.5mm Brown 1.5mm Drawn up: 05/10/2018 Document number : 30008893 Page 42 of 48...

- Page 43 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Blower terminal block From TB3 To blower motor Dryer breakers Breaker Breaker Type Wire colour / Connection configuration size number Incoming wire from Terminal block (TB3) Out going wire to Drive motor relay (RL8)

- Page 44 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Dryer relays Air heater relay (RL8) Heater safety relay (RL9) Blower relay (RL10) Red cover Black cover White cover Green cover Red cover Brown Purple White Brown Black cover White Brown Purple Grey...

- Page 45 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Dryer safety thermostat Rinse safety Thermostat (100°C) Red Wire Black Wire White Crimp White Crimp Dryer elements 6kW Delta connection Grey wire White wire from TB3 Dryer Element 2 (E8) Purple wire from TB3...

-

Page 46: Trouble Shooting

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Trouble shooting Machine does not fill: Check water supply is turned ON. Check water supply hose is not trapped or kinked. Check that the machine is switched ON. Check that door is closed. - Page 47 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT VII. Overfilling: Drain machine fully, then try again to fill the machine. Check and clean all filters within the machine. Check drain height is configured correctly. Check that drain is not clogged / blocked / kinked.

- Page 48 ENGINEERS MANUAL CST MACHINES AND DRYER UNIT Classeq Ltd Winterhalter House Roebuck Way Knowlhill Milton Keynes MK5 8WH Classeq Ltd Spares department 0844 225 9252 spares@classeq.co.uk Service department 0844 225 9245 service@classeq.co.uk Drawn up: 05/10/2018 Document number : 30008893...

Need help?

Do you have a question about the CST and is the answer not in the manual?

Questions and answers