Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for McQuay WHR 017EW

- Page 1 PM WHR-2 Group: Chiller Effective: May 2000 Supersedes: PM WHR-1 Reciprocating Chillers WHR 017EW To WHR 210EW, Packaged Water-Cooled WHR 017EA To WHR 210EA, Remote Condenser 17 to 210 Tons, 60 to 740 kW R-22, R134a 60 Hz © 1997 McQuay International...

-

Page 2: Table Of Contents

"McQuay" is a registered trademark of McQuay International © 1997 McQuay International "Illustrations cover the general appearance of McQuay International products at the time of publication and we reserve the right to make changes in design and construction at anytime without notice" WHR 017E - 210E... -

Page 3: Introduction

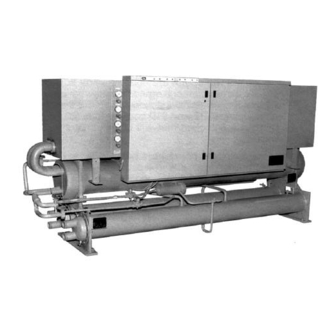

Introduction McQuay International offers a complete line of water-cooled chillers from 17 to 2500 tons (60 to 8800 kW) utilizing reciprocating and centrifugal compressors. The WHR packaged reciprocating compressor chillers are a product of the McQuay commitment to offer energy efficient equipment design. A design approach carefully combining high quality compressors, efficient shell-and-tube heat exchangers, and state-of- the-art controls into a unit of uncompromised operating efficiency and reliability. -

Page 4: Features And Benefits

Optional steps of capacity reduction are accomplished by the most efficient method of cylinder unloading in the industry today. To McQuay, operating economy means more than just energy efficiency. The WHR chillers reduce operating costs not only through energy efficiency, but by offering high unit reliability, easy serviceability, full factory testing and the backing of a factory trained sales, service and parts organization. - Page 5 Serviceability Semi-hermetic, 1750 rpm induction type motors are employed. The motors are refrigerant gas cooled. A finned motor housing helps dissipate motor heat. Solid-state modules in the motor terminal box respond to temperature sensors imbedded in all three motor windings to provide inherent thermal overload protection for all run and start conditions.

-

Page 6: Design Advantages

Design Advantages Unit Arrangements The McQuay water chillers are completely factory assembled, piped, wired and shipped in one piece, ready for field connection of refrigerant (EA models) and water piping. Each unit consists of motor compressors, insulated DX cooler and centralized electrical control panel containing all necessary safety and operating controls, and compressor starting controls. - Page 7 IPLV is an excellent method for comparing chillers' efficiencies. Noise All McQuay WHR chillers are equipped with hot gas discharge line mufflers in each refrigerant circuit to reduce the overall sound levels. An optional insulated acoustical compressor enclosure to further reduce sound levels is also available for most units.

- Page 8 Air-Cooled Condensers The WHR-EA chillers are designed for use with properly sized and configured remote air-cooled or evaporative condensers. The McQuay AC/AQ line of air-cooled condensers are designed for use with these chillers. The AC/AQ condensers are available with single or double row vertical discharge fans and are fully described and rated in Product Manual PM ACAQ.

-

Page 9: Temperature Control

Temperature Control The McQuay WHR-040EW through 210EW water chillers are available with any one of three different temperature controls to satisfy your requirements: 1) the standard microprocessor leaving water controller, 1a) the same controller but with an indicator light package, and 2) the MicroTech Controller. - Page 10 Figure 1, Zone Terminal Configuration Display Item List Warning Signal Display Indicator Dot On/Off Status M cQuay AGZ/AGR Global Chiller INSERT 10 Display Area Occupied Lvg Water Temp Flow Failure Evap Pres #1 Display OA Lockout Evap Pres #2 Button 1 Cir#2Lead=On OA/AI3 Input Pmp/Stp #1=0...

- Page 11 Operator-friendly The 12-key, touch-sensitive, membrane keypad and 32-character display makes the MicroTech system especially user-friendly. Inch-pound or SI units are optionally available. The MicroTech menu structure is separated into three distinct categories, which provide the operator or service technician with a full description of current unit status, control parameters, and alarms.

-

Page 12: Optional Network Master Panel

Automatic circuit lead-lag With the keypad, the operator can manually select either refrigerant circuit for the lead position or the controller will automatically select the lead circuit based on the circuit with the fewest operating hours. Time clock, daily and holiday start/stop control The operator can program daily start/stop schedules including weekends and up to fourteen separate holidays without the need of an external time clock or EMS interface. -

Page 13: Monitor Software

(BAS). A protocol is a set of rules governing data exchange between microprocessors, thereby permitting communications between unlike controllers. As a result, building designers, owners and operators can obtain the advantages of McQuay equipment, and the control versatility MicroTech has to offer. A low cost site license covering any and all McQuay product is required. -

Page 14: Selection Procedure

Selection Procedure EW Water-Cooled, R-22 Ratings are based and certified in accordance with ARI Standard 550/590-98. Ratings in Table 5 through Table 10 may be interpolated for any chiller water temperature between 40°F and 50°F (4.4°C and 10.0°C) but cannot be extrapolated. Chilled water quantities - Ratings are based on a 10 degree F (5.6 degree C) chilled water range (2.4 gpm/ton) and can be used for a delta-T range of 6 to 16 degrees F (3.3 to 8.8 degrees C) by adjustments from Table 3. -

Page 15: Ew Water-Cooled, R-134A

The performance of the WHR chillers is listed by LWT (leaving chilled water temperature) and by Condensing Temperature. Tons, Power, and THR (Total Heat Rejection) are given. This data can then be used to select any condenser from its own capacity data. For a McQuay AC/AQ air-cooled condenser, use product manual PM ACAQ. - Page 16 Progressing from a) to c) above will require smaller condensers, offset by larger, more expensive chillers and lessening efficiency. 2) A condenser can be selected with the above information. For this example, a McQuay Model ACAQ air-cooled condenser will be selected using selection procedures and data contained in Product Manual PM ACAQ.

-

Page 17: Ea Remote Condenser, R-134A

The reduction in performance depends upon the glycol concentration. This should be taken into consideration during initial system design. McQuay encourages a minimum concentration of 25% be provided on all glycol applications. Glycol concentrations below 25% are too diluted for long-term corrosion protection of ferrous metals and corrosion inhibitors may need to be recalculated. -

Page 18: Evaporator And Condenser Delta-T Factors

Water treatment should be based on characteristics of the area’s water. Improper or untreated water may lead to scale build up, erosion and corrosion in both the condenser and evaporator. McQuay will not accept responsibility for poorly or improperly treated water. -

Page 19: Performance Data

Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 40°F and below please refer to Application Adjustment Factors section. - Page 20 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 40°F and below please refer to Application Adjustment Factors section.

- Page 21 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 40°F and below please refer to Application Adjustment Factors section.

- Page 22 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 5°C and below please refer to Application Adjustment Factors section.

- Page 23 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 5°C and below please refer to Application Adjustment Factors section.

- Page 24 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown. For LWT of 5°C and below please refer to Application Adjustment Factors section.

-

Page 25: Part Load Data (Ew Only)

Part Load Data (EW Only) Table 11, Part Load Performance 60 Hz 60 Hz Capacity Capacity Unit Size % Load Power IPLV Unit Size % Load Power IPLV Tons Tons Unit kW Unit kW 100.00 17.7 14.7 14.4 100.00 96.0 82.0 14.0 75.00... -

Page 26: Ea Remote Condenser

Remote condenser units are not covered in the ARI Certification Program. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings. For LWT of 41°F and below please refer to application considerations for reciprocating chillers. - Page 27 Remote condenser units are not included in the ARI Certification Program. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings. For LWT of 41°F and below please refer to application considerations for reciprocating chillers.

- Page 28 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings. For LWT of 5°C and below please refer to application considerations for reciprocating chillers.

- Page 29 Ratings are based on circuit #1 in lead position and circuit #2 in lag position. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings. kWi input is for compressors only. COP is for the entire unit, including compressors and control power.

-

Page 30: Pressure Drop Curves

Pressure Drop Curves Figure 2, Evaporator Pressure Drop WHR 017 – WHR 210 Product Manual WHR-2... - Page 31 Figure 3, Condenser Pressure Drop WHR 017EW – WHR 090EW Product Manual WHR-2...

- Page 32 Figure 4, Condenser Pressure Drop WHR 095EW – WHR 210EW Product Manual WHR-2...

-

Page 33: Electrical Data

Electrical Data Table 16, Compressor Amp Draw, WHR 017E - WHR 060E Rated Load Amps (1) Locked Rotor Amps (2) w/o Supplemental w/ Supplemental Across-The-Line Part Winding Unit Voltage Freq Overloads Overloads Start Start Size 3-Phase (Hz) Circuit Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1 Circuit 1 Circuit 2 NOTES: Compressor RLA values are for wire sizing purposes only and do not reflect normal operating current draw. - Page 34 Table 17, Compressor Amp Draw, WHR 070E - WHR 120E Rated Load Amps (1) Locked Rotor Amps (2) Unit Voltage Freq. w/o Supplemental w/ Supplemental Across-The-Line Part Winding Size 3-Phase (Hz) Overloads Overloads Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1...

- Page 35 Table 18, Compressor Amp Draw, WHR 130E - WHR 210E Rated Load Amps (1) Locked Rotor Amps (2) Unit Voltage Freq. w/o Supplemental w/ Supplemental Across-The-Line Part Winding Size 3-Phase (Hz) Overloads Overloads Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1...

- Page 36 Table 19, Wire Sizing Amps, WHR 017E - WHR 080E w/o Supplemental Overloads (1) w/ Supplemental Overloads (1) Minimum Circuit Ampacity (MCA) Minimum Circuit Ampacity (MCA) Unit Voltage Freq. Multiple Point Power Single Multiple Point Power Single Point Size 3-Phase (Hz) Supply(3) Point...

- Page 37 Table 20,Wire Sizing, WHR 085E - WHR 130E w/o Supplemental Overloads (1) w/ Supplemental Overloads (1) Minimum Circuit Ampacity (MCA) Minimum Circuit Ampacity (MCA) Unit Voltage Freq Single Multiple Point Power Multiple Point Power Single Point Size 3-Phase (Hz) Point Supply(3) Supply(3) Power...

- Page 38 Table 21, Wire Sizing Amps, WHR 145E - WHR 210E w/o Supplemental Overloads (1) w/ Supplemental Overloads (1) Minimum Circuit Ampacity (MCA) Minimum Circuit Ampacity (MCA) Unit Voltage Freq. Multiple Point Power Multiple Point Power Single Point Single Point Size 3-Phase (Hz) Supply(3)

- Page 39 Table 22, Single Point Fuse Sizing, WHR 017E - WHR 080E Recommended Fuse Size(1) Maximum Fuse Size(2) Single Point Power Single Point Power Unit Voltage Freq. Size 3-Phase (Hz) w/o Supplemental w/ Supplemental w/o Supplemental Supplemental Overloads Overloads Overloads Overloads NOTES: "Recommended Fuse Size"...

- Page 40 Table 23, Single Point Fuse Sizing, WHR 085E - WHR 145E Recommended Fuse Size(1) Maximum Fuse Size(2) Single Point Power Single Point Power Unit Voltage Freq. Size 3-Phase (Hz) w/o Supplemental w/ Supplemental w/o Supplemental Supplemental Overloads Overloads Overloads Overloads NOTES: "Recommended Fuse Size"...

- Page 41 Table 24, Single Point Fuse Size, WHR 155E - WHR 210E Recommended Fuse Size(1) Maximum Fuse Size(2) Single Point Power Single Point Power Unit Voltage Freq. Size 3-Phase (Hz) w/o Supplemental w/ Supplemental w/o Supplemental Supplemental Overloads Overloads Overloads Overloads 1000 1000 1000...

- Page 42 Table 25, Multiple-Point Fuse Sizing, WHR 040E - WHR 145E Recommended Fuse Size(1) Maximum Fuse Size(2) Multiple Point Power Multiple Point Power Unit Voltage Freq. Circuit 1 Circuit 2 Circuit 1 Circuit 2 Size 3-Phase (Hz) Supplemental Supplemental Supplemental Supplemental Supplemental Supplemental Supplemental...

- Page 43 Supplemental overloads are used in conjunction with standard inherent overload protection. The supplemental overloads: • Reduce wire sizing amps • Add additional protection • Lower compressor amperage Table 26, Multiple Point Fuse Size, WHR 155E - WHR 210E Recommended Fuse Size(1) Multiple Point Power Maximum Fuse Size(2) Multiple Point Power Circuit 1 Circuit 2...

-

Page 44: Field Wiring Diagram

Field Wiring Diagram Figure 5, Field Wiring Diagram WHR 017EW - 030EW only WHR 040EW - 220EW only Field connection terminal Field wiring Product Manual WHR-2... -

Page 45: Physical Data

Physical Data EW Water-Cooled Table 27, WHR-017EW - WHR-030EW WHR UNIT SIZE 017EW 020EW 025EW 030EW Unit capacity @ ARI conditions tons, (kW) (1) 17.7 (62.3) 21.7 (76.4) 27.0 (95.0) 30.2 (106.3) No. Circuits COMPRESSORS Nominal Horsepower Number Speed RPM 1750 1750 1750... - Page 46 Table 28, WHR-040EW - WHR-070EW WHR UNIT SIZE 040EW 045EW 050EW 060EW 070EW Capacity @ ARI conditions tons, (kW) 38.0 (133.8) 44.0 (154.9) 51.5 (181.3) 58.5 (205.9) 70.5 (248.2) No. Circuits COMPRESSORS Nominal Horsepower Number Speed RPM 1750 1750 1750 1750 1750 No.

- Page 47 Table 29, WHR-080EW - WHR-110EW WHR UNIT SIZE 080EW 085EW 090EW 095EW 100EW 110W Unit capacity @ ARI conditions tons, (kW) (1) 76.5 (269.3) 85.0 (299.2) 91.5 (322.1) 96.0 (337.9) 102.0 (359.0) 111.5 (392.5) No. Circuits COMPRESSORS Nominal Horsepower 30/25 30/25 30/25 30/25...

- Page 48 Table 30, WHR-115EW - WHR-165EW WHR UNIT SIZE 115EW 120EW 130EW 145EW 155EW 165EW Unit capacity @ ARI conditions tons, (kW) (1) 113.5 (399.5) 122.0 (429.4) 132.0 (464.6) 144.0 (506.9) 150.5 (529.8) 163.8 (576.6) No. Circuits COMPRESSORS Nominal Horsepower 35/25 35/25 35/25 35/35...

- Page 49 Table 31, WHR-175EW - WHR-210EW WHR UNIT SIZE 175EW 185EW 195EW 210EW Unit capacity @ ARI 177.0 (623.0) 185.0 (651.2) 197.0 (693.4) 211.9 (742.7) conditions tons, (kW) (1) No. Circuits COMPRESSORS Nominal Horsepower 40/60 40/60 50/50 50/50 50/60 50/60 60/60 60/60 Number (2) Speed RPM...

-

Page 50: Ea Remote Condenser

EA Remote Condenser Table 32, WHR-017EA - WHR-030EA WHR UNIT SIZE 017EA 020EA 025EA 030EA Capacity @ 44 °F LWT, 120°F CT; tons, (kW) 15.9 (56.06) 19.6 (68.8) 23.3 (81.8)) 26.7 (93.7) No. Circuits COMPRESSORS Nominal Horsepower Number Speed RPM 1750 1750 1750... - Page 51 Table 34, WHR-080EA - WHR-110EA WHR UNIT SIZE 080EA 085EA 090EA 095EA 100EA 110EA Cap. @ ARI conditions, tons, (kW) 76.7 (269.7) 83.8 (294.6) 90.8 (319.3) 94.9 (333.7) 100.7 (354.1) 110.1 (387.1) No. Circuits COMPRESSORS Nominal Horsepower 30/25 30/25 30/25 30/25 35/25 35/25...

- Page 52 Notes: Condenser and field piping not included. Victaulic connections, WHR080 - 110. Unit sizes WHR095 thru 165 have two compressors per circuit in parallel. Table 36, WHR-175EA - WHR-210EA WHR UNIT SIZE 175EA 185EA 195EA 210EA Unit capacity @ ARI conditions tons, (kW) (1) 176.1 (619.2) 182.0 (639.9)

-

Page 53: Dimensional Data

Dimensional Data EW Water-Cooled Figure 6, WHR 017EW through WHR 030EW Maximum Overall Chilled Water Condenser Water Model Dimensions Connections Connections Number SIZE SIZE 104 1/4 26-1/4 46-1/2 2 NPT (EXT) 13-1/2 17-3/4 2 NPT (INT) 1-1/2 017EW (2648) (667) - Page 54 Figure 7, WHR 040EW through WHR 090EW Maximum Overall Condenser Water MODEL Dimensions Connections (NPT) NUMBER 040EW 116-7/8 (2969) 34 (864) 62-1/4 (1581) 6-5/8 (168) 11-3/8 (289) 4-3/4 (121) 4-3/4 (121) 2-1/2 (64) 045EW 116-7/8 (2969) 34 (864) 62-1/4 (1581) 6-5/8 (168) 11-3/8 (289) 4-3/4 (121)

- Page 55 Figure 8, WHR 095EW through WHR 175EW Maximum Overall Center of MODEL Dimensions Gravity NUMBER 095EW 142-3/4 (3626) 34 (864) 77 (1956) 55-1/4 (1403) 32-5/8 (829) 13-5/8 (346) 100EW 142-3/4 (3626) 34 (864) 77 (1956) 55-1/4 (1403) 32-5/8 (829) 13-5/8 (346) 110EW 142-3/4 (3626 34 (864)

- Page 56 Figure 9, WHR-185EW through WHR-210EW Maximum Overall Center of Dimensions Gravity MODEL NUMBER 185EW 145-7/8 (3705) 35 (889) 79 (2007) 55 (1397) 36 (914) 13-1/2 (343) 195EW 145-7/8 (3705) 35 (889) 79 (2007) 55 (1397) 36 (914) 13-1/2 (343) 210EW 145-7/8 (3705) 35 (889) 79 (2007)

-

Page 57: Ea Remote Condenser

EA Remote Condenser Figure 10 Dimensions, WHR 017EA– WHR 030EA Maximum Overall Chilled Water Inlet Liquid Discharge Dimensions, in. (mm) Connections, in. (mm) Conn. Size Conn. size MODEL Size In. (mm) In. (mm) 97 1/2 25 1/2 46 1/2 2 NPT (EXT) 13 1/2 17 3/4 7/8 O.D. - Page 58 Figure 11, Dimensions WHR 040EA – WHR 090EA Refrig. Connections Maximum Overall Evaporator Water Center of Gravity Dimensions Connections (Victualic) Model Liquid Discharge Number 115 3/4 52 1/8 2 3/4 13 1/4 7/8 O.D. 1 3/8 O.D. 19 5/8 41 3/4 18 7/8 14 1/8 040EA...

- Page 59 Figure 12, Dimensions, WHR 120EA – WHR 175EA Maximum Overall Evap. Water Conn. Center of Gravity Refrigerant Connections MODEL Dimensions (Victaulic) Liquid Disc. 095EA 142 3/4 64 3/4 5 1/2 20 5/8 54 1/2 28 3/4 13 1/8 1 1/8 O.D. 1 5/8 O.D.

- Page 60 Figure 13, Dimensions WHR 185EA, 195EA, 210EA Maximum Overall Evap. Water Conn. Center of Gravity Refrigerant Connections Dimensions (Victaulic) MODEL Liquid Disc. 185EA 145 7/8 64 3/4 4 1/8 21 3/8 32 1/2 1 3/8 O.D 1 5/8 O.D. 195EA 145 7/8 64 3/4 4 1/8...

-

Page 61: Sound Data

Sound Data WHR Sound Pressure Charts Table 37 WHR "E" Octave Band Sound Pressure Levels Per ARI Standard 575 (dB) Overall "A" Unit Size Weighted 63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz Notes: Sound Pressure per ARI Standard 575. - Page 62 WHR with Acoustical Enclosure Sound Pressure Chart Table 39 WHR "E" Octave Band Sound Pressure Levels Per ARI Standard 575 (dB) Overall "A" Unit Size Weighted 63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz Notes: Sound Pressure per ARI Standard 575.

- Page 63 WHR Sound Power Table 41 WHR "E" Octave Band Sound Power Levels Per ARI Standard 575 (dB) Overall "A" Unit Size Weighted 63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz Notes: Sound Power per ARI Standard 575. Sound values taken with units fully loaded with hot gas mufflers.

- Page 64 WHR with Acoustical Enclosure Sound Power Chart Table 43 WHR "E" Octave Band Sound Power Levels Per ARI Standard 575 (dB) Overall "A" Unit Size Weighted 63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz Notes Sound Power per ARI Standard 575.

-

Page 65: Application Data

Application Data Location and Space Requirements The units are designed for indoor application and must be located in a space where the temperature is 40°F (4.4°C) or above. Provide clearance of 2 to 3 ft. (609 to 914 mm) on each side and ends for piping and to help when servicing unit. - Page 66 Figure 14, Typical chilled water piping Condenser Water (EW Units) Be certain the condenser water enters the bottom connection of the condenser. The condenser water will exit the condenser from the top connection. Head pressure control must be provided if the entering condenser water can fall below 60°F.

- Page 67 Series or Parallel Operation Consider system pressure drop when designing the water piping. Parallel piped systems have half of the total system flow going through the evaporator of each chiller, reducing the individual unit and total system pressure drop. Series piped evaporators require that the total system water flows through both evaporators. Not only is the pressure drop through each evaporator increased but the pressure drops must be added together to obtain the total evaporator pressure drop.

- Page 68 Minimum design leaving water temperature from the evaporator without freeze protection is 42°F (6°C). Contact your McQuay representative for operation with tower condenser water entering the chiller below 70°F (21.1°C). Compressor unloading is not allowed with leaving chilled fluid temperatures 35°F or less.

-

Page 69: Optional Features

Optional Features Hot Gas Bypass Factory mounted hot gas bypass permits unit operation down to 10% of full load capacity and includes a hot gas bypass valve, solenoid valve and manual shutoff valve. Hot gas bypass is provided both refrigerant circuits. Vibration Isolators Spring or rubber-in-shear vibration isolators are available as a kit for field installation to reduce vibration transmission through the unit base. - Page 70 Through-the-Door Handle Kits Kits are available for 225, 250, 400, 600, 800 and 1200 amps. To select the proper kit, refer the maximum fuse data in the catalog for the desired chiller and voltage. Select the kit size that is equal to the maximum fuse size.

-

Page 71: Product Specifications

Product Specifications Water-Cooled, WHR 017 through 030 PART 1 - GENERAL 1.01 SUMMARY Section includes design, performance criteria, refrigerants, controls, and installation requirements for water-cooled reciprocating compressor packaged chillers. 1.02 REFERENCES Comply with applicable Standards/Codes of ARI 550/590-98, ANSI/ASHRAE 15, ASHRAE 90.1, ASME Section VIII, NEC, and OSHA as adopted by the State. - Page 72 PART 2--PRODUCTS 2.01 ACCEPTABLE MANUFACTURERS McQuay International (Approved Equal) 2.02 UNIT DESCRIPTION Provide and install as shown on the plans factory assembled, factory charged, and factory run tested, water-cooled reciprocating compressor packaged chillers in the quantity specified.

- Page 73 2.04 CHILLER COMPONENTS Compressor: The compressor shall be of the accessible hermetic reciprocating type with suction and discharge service valves, crankcase oil heater and suction strainer. Compressor shall have a forced feed lubrication system with a reversible oil pump, oil sight glass, and oil charge. The compressor motor shall be refrigerant gas cooled, high torque, hermetic induction type, four-pole, with inherent thermal protection on all three phases and shall be mounted on rubber vibration isolators.

- Page 74 PART 3 - EXECUTION 3.01 INSTALLATION Install in strict accordance with manufacturer’s requirements, shop drawings, and Contract Documents. Adjust and level chiller in alignment on supports. Coordinate electrical installation with electrical contractor. Coordinate controls with control contractor. Provide all appurtenances required to insure a fully operational and functional chiller.

-

Page 75: Water-Cooled, Whr 040E Through Whr 210E

Water-Cooled, WHR 040E through WHR 210E PART 1 - GENERAL 1.01 SUMMARY Section includes design, performance criteria, refrigerants, controls, and installation requirements for water-cooled reciprocating compressor packaged chillers. 1.02 REFERENCES Comply with applicable Standards/Codes of ARI 550/590-98, ANSI/ASHRAE 15, ASHRAE Standard 90.1, ASME Section VIII, NEC, and OSHA as adopted by the State. - Page 76 18 months from shipment. The warranty shall cover defective material and workmanship within the above period, excluding refrigerant. PART 2--PRODUCTS 2.01 ACCEPTABLE MANUFACTURERS McQuay International (Approved Equal) 2.02 UNIT DESCRIPTION Provide and install as shown on the plans factory assembled, factory charged, and factory run tested water-cooled reciprocating compressor packaged chillers in the quantity specified.

- Page 77 2.04 CHILLER COMPONENTS Compressors: The compressors shall be accessible hermetic reciprocating type with suction and discharge service valves, crankcase oil heaters and suction strainers. The compressors shall have a forced feed lubrication system with a reversible oil pump, oil sight glass, and oil charge. The compressor motors shall be refrigerant gas cooled, high torque, hermetic induction type, four-pole, with inherent thermal protection on all three phases and shall be mounted on rubber vibration isolators.

- Page 78 The system shall stage the unit based on the leaving water temperature. Safeties controlled by the microprocessor include oil differential pressure, motor protection, high pressure, loss of refrigerant, loss of water flow, freeze protection, and low refrigerant pressure. Controls shall include auto/stop switch, chilled water setpoint adjustment, anti-recycle timer, and digital display with water temperature and setpoint, operating temperatures and pressures, and diagnostic messages.

- Page 79 PART 3 - EXECUTION 3.01 INSTALLATION Install in strict accordance with manufacturer’s requirements, shop drawings, and Contract Documents. Adjust and level chiller in alignment on supports. Coordinate electrical installation with electrical contractor. Coordinate controls with control contractor. Provide all appurtenances required to insure a fully operational and functional chiller.

-

Page 80: Remote Condenser Chiller, Whr 017 Through 030

Remote Condenser Chiller, WHR 017 through 030 PART 1 - GENERAL 1.01 SUMMARY Section includes design, performance criteria, refrigerants, controls, and installation requirements for water-cooled reciprocating compressor packaged chillers. 1.02 REFERENCES Comply with applicable Standards/Codes of ANSI/ASHRAE 15, ASHRAE 90.1, ASME Section VIII, NEC, and OSHA as adopted by the State. - Page 81 PART 2--PRODUCTS 2.01 ACCEPTABLE MANUFACTURERS McQuay International (Approved Equal) 2.02 UNIT DESCRIPTION Provide and install as shown on the plans factory assembled, and factory run tested, reciprocating compressor chiller(s) in the quantity specified. Each chiller shall consist of hermetic reciprocating compressor, direct expansion evaporator, control system and be arranged for connection to a remote single circuit condenser specified elsewhere.

- Page 82 2.04 CHILLER COMPONENTS Compressor: The compressor shall be of the accessible hermetic reciprocating type with suction and discharge service valves, crankcase oil heater and suction strainer. Compressor shall have a forced feed lubrication system with a reversible oil pump, oil sight glass, and oil charge. The compressor motor shall be refrigerant gas cooled, high torque, hermetic induction type, four-pole, with inherent thermal protection on all three phases and shall be mounted on rubber vibration isolators.

- Page 83 Coordinate electrical installation with electrical contractor. Coordinate controls with control contractor. Provide all appurtenances required to insure a fully operational and functional chiller. 3.02 START-UP Insure proper charge of refrigerant and oil. Provide testing, and starting of machine, and instruct the Owner in its proper operation and maintenance.

-

Page 84: Remote Condenser Chiller, Whr 040E - Whr 210E

Remote Condenser Chiller, WHR 040E - WHR 210E PART 1 - GENERAL 1.01 SUMMARY Section includes design, performance criteria, refrigerants, controls, and installation requirements for water-cooled reciprocating compressor packaged chillers. 1.02 REFERENCES Comply with applicable Standards/Codes of ANSI/ASHRAE 15, ASHRAE Standard 90.1, ASME Section VIII, NEC, and OSHA as adopted by the State. - Page 85 18 months from shipment. The warranty shall cover defective material and workmanship within the above period, excluding refrigerant. PART 2--PRODUCTS 2.01 ACCEPTABLE MANUFACTURERS McQuay International (Approved Equal) 2.02 UNIT DESCRIPTION Provide and install as shown on the plans factory assembled, and factory run tested remote condenser reciprocating compressor packaged chiller(s) in the quantity specified.

- Page 86 2.04 CHILLER COMPONENTS Compressors: The compressors shall be accessible hermetic reciprocating type with suction and discharge service valves, crankcase oil heaters and suction strainers. The compressors shall have a forced feed lubrication system with a reversible oil pump, oil sight glass, and oil charge. The compressor motors shall be refrigerant gas cooled, high torque, hermetic induction type, four-pole, with inherent thermal protection on all three phases and shall be mounted on rubber vibration isolators.

- Page 87 The system shall stage the unit based on the leaving water temperature. Safeties controlled by the microprocessor include oil differential pressure, motor protection, high pressure, loss of refrigerant, loss of water flow, freeze protection, and low refrigerant pressure. Controls shall include auto/stop switch, chilled water setpoint adjustment, anti-recycle timer, and digital display with water temperature and setpoint, operating temperatures and pressures, and diagnostic messages.

- Page 88 PART 3 - EXECUTION 3.01 INSTALLATION Install chiller and remote condenser with interconnecting piping in strict accordance with manufacturer’s requirements, shop drawings, and Contract Documents. Chiller manufacturer must approve the refrigerant piping design. Adjust and level chiller in alignment on supports. Coordinate electrical installation with electrical contractor.

- Page 89 Product Manual WHR-2...

- Page 90 Post Office Box 2510 Staunton, Virginia 24402 USA • (800) 432-1342 • www.mcquay.com...

Need help?

Do you have a question about the WHR 017EW and is the answer not in the manual?

Questions and answers