Summary of Contents for Metso Neles BW Series

- Page 1 Metal seated high performance disc valve Series BW Installation, Maintenance and Operating Instructions...

-

Page 2: Table Of Contents

If you require additional assistance, please contact the manufacturer or manufacturer’s representative. Addresses and phone numbers are printed on the back cover. See also www.metso.com/valves for the latest documentation. SAVE THESE INSTRUCTIONS! Subject to change without notice. All trademarks are property of their respective owners... -

Page 3: General

It can be measured or calcu- the sealing element has a long service life. lated using Metso Nelprof valve- sizing software. Observe the relevant work environment regulations on The sealing element, a metallic sealing, is located in the noise emissions. -

Page 4: Scope Of Delivery

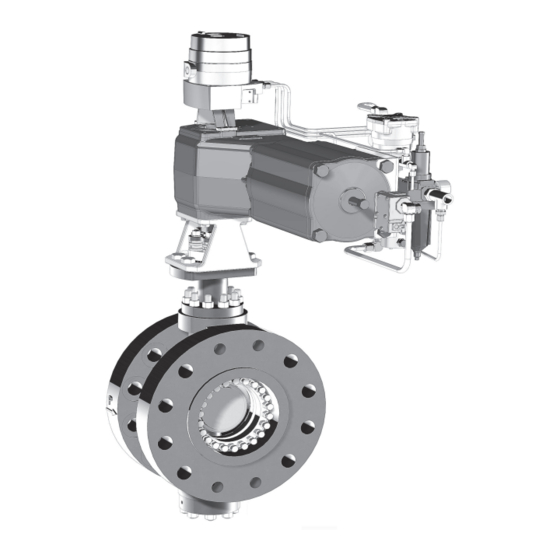

Metso assumes no liability for structural modifications car- ried out without explicit consent of the corporation. Use original spare parts only. Spare parts should be installed by Metso service personnel. Scope of delivery The series BW valve is available in four versions: lug (monof- lange), doubleflange, wafer, buttweld. -

Page 5: Marking And Identification

This is very important for installation of Contact valves in new plant sections. Also during this process, the Please contact your local Metso Partner on: medium must not carry any contaminant which may settle in www.metso.com/valves... -

Page 6: Installation

2 BW 70 en Advise caution when installing flaps with safety posi- tion “spring-to-open” . If the disc accommodates the total length of the valve, the disc shall be closed prior to the installation (pneumatic, hydraulic, etc.). Be sure that the energy supply is safely fas- tened and cannot be damaged or break off during installa- tion. - Page 7 2 BW 70 en BW3 (double-flanged) Table 2 Stud bolt dimensions Table 3 Stud bolt dimensions Table 1 Stud bolt dimensions BW3 - Class 1500 BW3 - Class 2500 BW3 - Class 900 thread K thread K thread K length length length 1 3/8"-8UN...

-

Page 8: Atex-Version

ATEX certified valves must only be serviced and maintained by Metso Service or authorized personnel. Metallic bright surface at the body, flange or bracket 1 … hex-head bolt 2 … grounding cable (min. 16 mm 3 …... -

Page 9: Cleaning And Maintenance Interval

Check the tightness of the valve at regularly intervals. switch to ensure that the package can be properly reas- sembled. Metso recommends to inspect the condition of the fol- The actuator must be mounted to be easily accessible, lowing parts after two years at the latest to change particularly for possible emergency manual override. -

Page 10: Detaching Preparation

2 BW 70 en Tools □ No special tools are needed for servicing the valve. Ordering spare parts When ordering spare parts, always include the following information: □ The unique number of the valve (on the type plate – see Figure 4 –... -

Page 11: Exploded View And Parts List

2 BW 70 en Exploded view and parts list (503) (501) (502) Flangetypes: -Doubleflange (as in the drawing) -Monoflange -Lug- or Wafertype PARTS LIST Part nr. Qty. Description Material Body ASTM A217 gr. WC6 Extension ASTM A217 gr. WC6 variable Stud ASTM A193 gr. -

Page 12: Troubleshooting

2 BW 70 en Troubleshooting If the energy supply is suddenly interrupted, the valve opens abruptly. This can lead to severe injury and dam- Valve leakage at the shut-off disc age to materials. □ Never close the valve by force: irreparable damage may occur. -

Page 13: Preliminary

2 BW 70 en 10.2 Preliminary 10.4 Reassembly In order to avoid longer shutdowns during the mainte- To re-install the disc valve please proceed as follows: nance work, suitable spare parts should be kept ready or □ Close the disc valve. procured in time. -

Page 14: Replacement Of The Metallic Seat Ring

2 BW 70 en 10.5 Replacement of the metallic seat ring 10. Demount the retaining ring (310) (see Figure 20). Please proceed as follows: 306 307 Fig. 17 Replacement of the metallic seat ring Demount the valve in its CLOSED position (see Figure 18). For further instructions, see Section 4.5 of this IMO. -

Page 15: Replacing Worn Parts

2 BW 70 en Fig. 23 Remove the sealing ring (304) Fig. 26 Lubricate the screws with Molykote 12. Now you can remove the metallic seat ring (321) (see 15. Check the high performance disc valve for its tightness Figure 24). before reinstallation. - Page 16 2 BW 70 en Fig. 31 Remove the gland and the packing ring (491, 451) Fig. 28 Disc backside Fig. 32 Remove the extension (102) Fig. 29 Remove the cover (430) Fig. 33 Remove the sealing ring and the actuator shaft Fig.

-

Page 17: Replacing The Gland Packing

2 BW 70 en □ Compress the gland packing by tightening the nuts Now the following parts can be changed with the recom- mended spare part sets: crosswise with a torque wrench until the disc springs have a value of compression (h1- h2) as in Table 5. Table 4 Spare part sets □... -

Page 18: Valve Screws - Clamping Torque

2 BW 70 en Table 5 Tightening of gland packing Shaft diameter at Spring outside Compression Height uncompressed Height compressed Body class Stud packing [mm] diameter d [mm] h1-h2 [mm] h1 [mm] h2 [mm] 900, 1500 35.6 35.1 2500 900, 1500 35.6 35.5 37.2... -

Page 19: Type Code

ASTM A494 CW-6M (Hastelloy C) HAST C Titanium Titanium Titanium NOTE: Check the recommend material combination from the Factory NOTE: The list of materials have been shortened due to space limitations. Please consult Metso to find the availability of other materials. - Page 20 ANSI B16.5 Large Tongue (Ra 3.2) Special, to be specified Metso Flow Control Inc. Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 VANTAA, Finland. Tel. +358 20 483 150. Fax +358 20 483 151 Von-Holzapfel-Str. 4, 86497 Horgau, Germany, Tel. +49 (0) 8294 8695-0, fax + 49 (0) 8294 8695-4681 North America, 44 Bowditch Drive, P.O.

Need help?

Do you have a question about the Neles BW Series and is the answer not in the manual?

Questions and answers