SystemAir Multibox MUB/T Series Installation And Operating Instructions Manual

Hide thumbs

Also See for Multibox MUB/T Series:

Summary of Contents for SystemAir Multibox MUB/T Series

- Page 1 Multibox MUB, MUB/T, MUB/T-S, MUB-CAV/VAV, MUB/F Installation and Operating Instructions Document in original language | · 007...

- Page 2 © Copyright Systemair AB All rights reserved E&OE Systemair AB reserves the rights to alter their products without notice. This also applies to products already ordered, as long as it does not affect the previously agreed specifications. | 007...

-

Page 3: Table Of Contents

Contents General information .........1 Safety information........ 17 Preconditions ........17 Notice symbols ........1 Connection ......... 17 1.1.1 Instruction symbols.....1 Cable bushing panel ......17 Important safety information ......1 Protective grounding wire ...... 17 Personnel ..........1 Residual current circuit breaker....18 Personal protective equipment....2 Protecting the motor...... -

Page 5: General Information

General information | General information Notice symbols Danger Caution Hazard with a low risk Direct hazard Failure to comply with this warning may lead to Failure to comply with this warning will lead moderate injuries. directly to death or to serious injury. Important Warning Hazard with risk of damage to objects... -

Page 6: Personal Protective Equipment

Further prerequisites are a completed maintenance plan with no gaps and a commissioning re- port. Systemair will require these in the case of a warranty claim. The commissioning report is a component of this document. The maintenance plan must be created by the operator, see section 12.3 Maintenance, page 22. -

Page 7: Transport

Delivery, transport, storage | Warning When opening the transport packaging, there is a risk of damage from sharp edges, nails, staples, splinters etc. ♦ Unpack the fan carefully. ♦ Check the fan for obvious transport damage. ♦ Only remove the packaging shortly before assembly. ♦... -

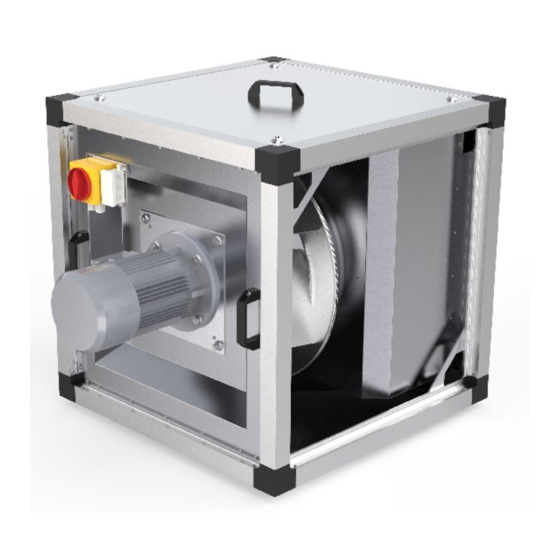

Page 8: Description

| Description Description MUB equipped with an EC motor The fans are driven by EC motors. These motors are delivered with a pre-wired potentiometer (0–10 V) that allows you to easily find the required working point of the fan. All motors are suitable for 50/60 Hz. The input voltage for single- phase units can vary between 200 and 277 V for three phase units between 380 and 480 V. -

Page 9: Description Mub-Cav/Vav

Description | Table 4 Dimensions MUB/T-S [mm] MUB/T-S 025 315... MUB/T-S 042 355... MUB/T-S 042 400... MUB/T-S 042 450... MUB/T-S 062 500... MUB/T-S 062 560... 1 '' 1000 1000 MUB/T-S 100 630... Table 5 MUB/T-S Dimensions l D4: 1023 mm MUB/T-S 025 315... -

Page 10: Sensor Control Module For Differential Pressure And Volume Pca1000/6000D2

| Description 5.5.1 Sensor control module for differential pressure and volume PCA1000/6000D2 The factory setting of the controller is CAV (constant air volume). The measured value is compared with the setpoint value. The controller adjusts the 0-10 V controlled output for the EC motor to keep the air volume constant. The specific characteristics of the inlet cone size are considered in the k-factor. -

Page 11: Fan Data

Description | Fan data • Max. temperature of transported air, max. ambient temperature, sound pressure –> see data sheet, available in our online catalogue. • Voltage, current, enclosure class, weight –> see name plate Motor data The motor data can be found on the name plate of the motor, or in the technical documents of the motor manufacturer. -

Page 12: Name Plate And Type Key

| Name plate and type key Name plate and type key 1 Type designation 2 Voltage/current/frequency 3 Input power Max. temperature of transported air Enclosure class/fan impeller speed/weight 6 Insulation class 7 Article number/production number/manufacturing date 8 Certifications Table 9 Type key MUB/T Motor type Electronically commutated/1 phased or 3 phased... -

Page 13: Accessories

Accessories | Accessories Note: For details of the accessories, please check our online catalog or contact Systemair. Table 10 Accessories MUB, MUB/T, MUB/T-S, MUB-CAV/VAV Flexible connection Weather protection grille WSG* Transition connections, square to round Tune- Damper Weather protection roof... -

Page 14: Installation

| Installation Installation Safety information Danger: Risk that MUB/F does not work in case of fire. ♦ Use installation material with fire resistance classes that meet temperature requirements. Warning: Danger from falling fan or fan parts. ♦ Check the surface before installation for load bearing capacity. ♦... -

Page 15: Installation Variations

Installation | Important Damage to the bearings or other parts of the fan can occur. ♦ Do not place a duct bend directly before or after the fan! ♦ Ensure a smooth and constant air flow to the device. Ensure a free exhaust. See Fig. 1 Straight ducts, page 11. -

Page 16: Changing The Discharge Direction

| Installation Changing the discharge direction MUB/T Important An inline airflow direction is not possible with a MUB/T. This application can be implemented with a MUB/T-S Legend 1. MUB/T with airflow direction 90° upwards (factory assembly) 2. MUB/T with airflow direction 90° sideways 3. -

Page 17: Weather Protection Roof (Wsd)

Installation | Weather protection roof (WSD) Important Damage to the motor due to moisture. ♦ Only install outdoors with the weather protection roof from our accessory range, see chapter Accessories. ♦ Install the weather protection roof as described below. Weather protection roof (WSD) Cap nut Double facets ring... -

Page 18: Weather Protection Grille (Wsg)

Weather protection grille (WSG) Note: For reasons of space there are two versions of Weather protection grille (WSG) existing, a standard version and a “turned” version. Please chose the correct WSG for your Multibox from the Systemair online catalogue. Standard version... -

Page 19: Assembly/Disassembly Impeller - Internal Rotor Motor

The ball bearing of the motor and the balanced impeller may be damaged by forceful impacts. ♦ Attach the impeller and/or the shaft extension to the shaft or the rotor without forceful impacts. ♦ Do not separate the impeller and the hub. They were balanced as one unit by Systemair. Note: The hub can be heated for easier assembly and disassembly, for example with a hot-air blower. - Page 20 | Installation The hub is shown without impeller due to better lucidity. Disassembly 1. Aluminium hub 1. Steel hub Assembly 5. Aluminium hub Use screw locking Use screw locking The set screw must push on the wedge of the shaft. 5.

-

Page 21: Electrical Connection

20 mm cable. ♦ We recommend using stepped rubber to avoid damaging the cable (available at Systemair, article no. 313521). Protective grounding wire The protective grounding must have a cross-section equal to or greater than that of the phase conductor. -

Page 22: Residual Current Circuit Breaker

| Electrical connection Residual current circuit breaker All-current-sensitive residual current circuit breakers are required for use in alternating-current systems with 50/60 Hz, in combination with electronic devices such as EC motors, frequency converters or uninterruptible power supplies (UPS). Protecting the motor Note: In fans equipped with an EC motor, there is no additional motor protection needed. -

Page 23: Commissioning

Commissioning | Commissioning Warranty claims can only be made if commissioning work is carried out correctly and written evidence thereof is provided. It is recommended to fill out the commissioning report 19 Commissioning Report, page 25. 10.1 Safety information ♦ Commissioning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 1. ♦... -

Page 24: Operation

12.2 Troubleshooting Table 13 Troubleshooting Remedy Problem Possible causes Rebalancing by a specialist company if possible, Impeller imbalance otherwise contact Systemair. Soiling on the impeller Clean carefully, rebalance Material decomposition on the impeller due to aggressive Contact Systemair material conveyed. - Page 25 Overloaded motor overheated Ambient temperature too high Check if the correct fan is used for your application. Note: For all other damage/defects, please contact Systemair. Defective safety-relevant fans (for Ex and smoke extraction applications) must be replaced completely. | 007...

-

Page 26: Maintenance

Check the flexible connectors for damage. See normal operating conditions Note: For all other damage/defects, please contact Systemair. Defective safety-relevant fans (for Ex and smoke extraction applications) must be replaced completely. 12.4 Spare parts ♦ Use original spare parts from Systemair only. -

Page 27: Cleaning

Cleaning | Cleaning 13.1 Safety information ♦ Cleaning may only be carried out by adequately qualified persons, details see Table 1 Qualifications, page 1. ♦ Wear protective equipment during all work in the vicinity of the fan, details see 2.2 Personal protective equipment, page 2. -

Page 28: Eu Declaration Of Conformity - Multibox

| EU Declaration of conformity — Multibox EU Declaration of conformity — Multibox The manufacturer: Systemair GmbH Seehöfer Straße 45 97944 Boxberg Germany Product designation: Multibox Type designation: MUB, MUB EC, MUB—CAV/VAV 2016 Since year of manufacture: The manufacturer declares that the above mentioned products in their design and construction and the version... -

Page 29: Commissioning Report

Commissioning Report | Commissioning Report Warranty claims can only be made if commissioning work is carried out correctly and written evidence thereof is provided. Description: Article no.: Manufacturing order no.: Installer Company: Contact person: Company address: Tel. no.: Email: Operator (Place of installation) Company: Contact person: Company address:... - Page 30 | Commissioning Report Current L2 [A]: Air volume [m3/s]: Current L3 [A]: Differential pressure [Pa]*: *For single-phase fans, fill in line “Current L1 [A]” *Δ- Pressure between suction-side and discharge of the fan If an air flow measurement is not possible, this value can be calculated using the following formula: Flow speed [m/s] Duct cross-section [m²] Air volume [m³/s]:...

- Page 31 | 007...

- Page 32 Systemair GmbH Seehöfer Str. 45 97944 Boxberg Germany Tel.: +49 (0)7930/9272-0 Fax: +49 (0)7930/9273-92 info@systemair.de www.systemair.de...

Need help?

Do you have a question about the Multibox MUB/T Series and is the answer not in the manual?

Questions and answers