Table of Contents

Advertisement

Operating Instructions

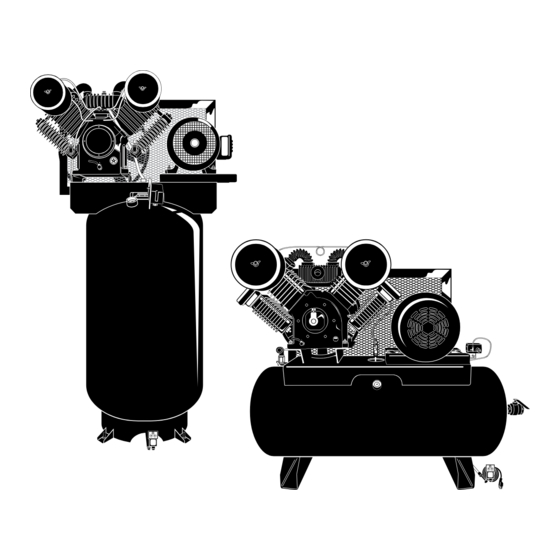

ELECTRIC OPERATED, PISTON COMPRESSORS

EMAX designs and manufactures products for safe operation. However, operators and maintenance persons are

responsibile for maintaining safety. All safety precautions are included to provide a guideline for minimizing the

possibility of accidents and property damage while equipment is in operation. Keep these instructions for reference.

EMNP000001 0810

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Emax EP05H080I1

- Page 1 Operating Instructions ELECTRIC OPERATED, PISTON COMPRESSORS EMAX designs and manufactures products for safe operation. However, operators and maintenance persons are responsibile for maintaining safety. All safety precautions are included to provide a guideline for minimizing the possibility of accidents and property damage while equipment is in operation. Keep these instructions for reference.

-

Page 2: Table Of Contents

Electrical Safety ....7 Wiring Installation ....7 EMAX Electric Operated, Two-Stage, 5-10 Hp Piston Air Compressors Model... -

Page 3: Description

Operating Instructions EMAX Electric Operated, Two-Stage, 15-25 Hp Piston Air Compressors Model EP15V120Y3 EP15H120Y3 EP20H120V3 EP25H120V3 15 Hp 15 Hp 20 Hp 25 Hp Description Three Phase Three Phase Three Phase Three Phase SCFM @ 175 psi 52.0 52.0 68.0 89.0... -

Page 4: Safety Information

4. NEVER modify the compressor and/or controls property damage could occur. in any way. A forklift may be necessary for unloading the EMAX 5. Keep a first aid kit in a convenient place. compressor. Use all forklift safety measures and Seek medical assistance promptly in case require a certified forklift operator. -

Page 5: Forklift Safety

Operating Instructions Forklift Safety Damage may result in bursting and cause injury or property damage. 1. Make sure lift operator stays aware while moving compressor. Installation 2. Be sure load is secure and well balanced Area before moving the compressor. 1. -

Page 6: Piping / Tank Installation

EMAX Electric Operated, Piston Compressors Piping / Tank Installation Minimum Pipe Size For Compressed Air Lines 1. Place tank feet on 1/4” thick rubber pads. (Pipe size shown in inches) Thicker padding will increase vibration and Length Of Piping System... -

Page 7: Electrical Safety

Power Supply 1. Follow all NEC and local codes for electrical wiring. 220 V Allow only authorized EMAX service person or cer- Power Power tified electrician to install electrical components. 2. Put unit on dedicated circuit and make sure no other electrical equipment is wired into it. -

Page 8: Operation

EMAX Electric Operated, Piston Compressors Breaker Breaker Power Supply Power Supply Wire connection Wire connection 220 V 220 V from coil to from coil to pressure switch pressure switch Common Common Power Power Power Power Power ground wire ground wire... -

Page 9: Start Up

Operating Instructions Keep all persons away from the discharge opening of hoses or tools or other points of compressed air discharge. If the machine is To pump installed in an enclosed area, be unloaders sure to vent the relief valve outside of the structure or to an unoccupied area. -

Page 10: Belt Adjustment

EMAX Electric Operated, Piston Compressors 5. Keep all body parts and any hand-held tools or other conductive objects away from exposed live parts of the electrical system. Pull ring on When making repairs or adjustments, stand safety valve before each use. -

Page 11: Maintenance Schedule

Operating Instructions Maintenance Schedule Daily Check oil level Check safety valve Check for unusual operation. Correct Drain tank and traps before damage occurs. Weekly Clean air filter General unit cleaning Check for unusual operation. Change oil (after first 50 hours) Correct before damage occurs. -

Page 12: Warranty

(at Purchaser’s expense) to have a redundant DRYER UNIT. Warranty repairs shall not include freight costs. Purchaser is responsible for returning unit to Emax, Inc. Each DRYER UNIT must have a coalescing filter attached to the intake of the dryer to remove any oil or dirt before air enters the dryer.

Need help?

Do you have a question about the EP05H080I1 and is the answer not in the manual?

Questions and answers