SCHUNK SVP-4 Assembly And Operating Manual

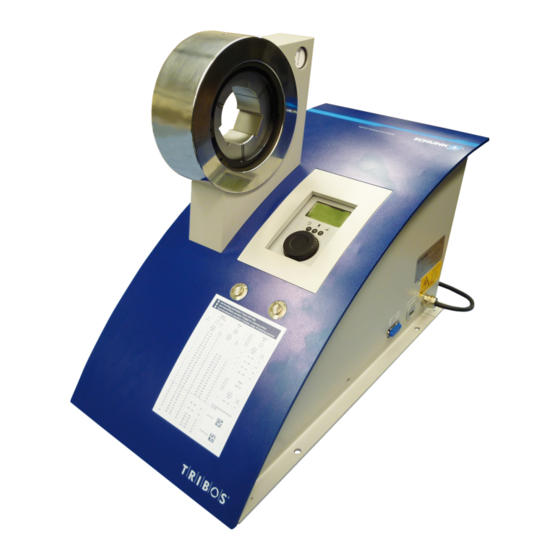

Polygonal clamping system, clamping device

Hide thumbs

Also See for SVP-4:

- Assembly and operating manual (24 pages) ,

- Assembly and operating manual (48 pages) ,

- Assembly and operating manual (24 pages)

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK SVP-4

- Page 1 Translation of the original manual Polygonal Clamping System Clamping Device SVP-4 Assembly and Operating manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights re- served. Any reproduction, processing, distribution (making available to third parties), transla- tion or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

4.2 Software installation instructions ................... 18 4.2.1 System requirements ..................18 4.2.2 Program installation .................... 18 4.3 Assembly of the length adjustment for TRIBOS SVP-4 ..........24 5 Operation ........................25 5.1 Reduction insert and Toolholder ..................25 5.2 Operating the module for stationary use and the pressure regulator ......27 5.2.1 Tab "Initial Page"... - Page 4 6.5 Tool shank can yet not be inserted at maximum pressure .......... 42 6.6 Torque / clamping force / holding force too low ............43 6.7 Concentricity errors on the clamped tool ..............44 7 Maintenance ........................45 8 Short manual ........................46 9 Declaration of conformity....................47 05.00|Clamping Device SVP-4|en...

-

Page 5: General

Non-observance will inevitably cause irreversible injury or death. WARNING Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. NOTICE Material damage! Information about avoiding material damage. 05.00|Clamping Device SVP-4|en... -

Page 6: Applicable Documents

Basically tool and machine contacting components, and wear parts (actuation screw and seal) are not part of the warranty. Scope of delivery The scope of delivery includes: • TRIBOS clamping device SVP-4 in the ordered model (230V or 110V). • Operating manual SVP-4 • USB-A cable Accessories •... -

Page 7: Power Adapter

• England - ID no.: 9958141 • USA / Canada - ID no.: 9958142 • Switzerland - ID no.: 9958143 • South Africa - ID no.: 9961009 • France - ID no.: 9900076 Note: Product pictures see catalog Tool holder systems "Accessories" 05.00|Clamping Device SVP-4|en... -

Page 8: Basic Safety Notes

• Structural changes should only be made with the written approval of SCHUNK. Spare parts Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 05.00|Clamping Device SVP-4|en... -

Page 9: Environmental And Operating Conditions

"Basic safety notes" ( 2, Page This applies particularly to personnel only used occasionally at the TRIBOS clamping device. 05.00|Clamping Device SVP-4|en... -

Page 10: Transport

Basic safety notes Transport Use the original SCHUNK packaging for transport. Transport the clamping device only horizontally. CAUTION Risk of injury due to unsuitable means of transport! The use of unsuitable means of transport can cause injuries. • Use suitable means of transport. -

Page 11: Fundamental Dangers

Falling loads may cause serious injuries and even death. • Stand clear of suspended loads and do not step into their swivel- ing range. • Never move loads without supervision. • Do not leave suspended loads unattended. 05.00|Clamping Device SVP-4|en... -

Page 12: Notes On Particular Risks

NOTICE Material damage due to incorrect insertion of the toolholder / re- duction insert! The gripping force of the TRIBOS clamping device SVP-4 goes up to 800 000 N! Incorrect insertion and positioning of the toolholder causes plas- tically deformation and loss of function of the toolholder. - Page 13 Property damage due to incorrect connection! Connecting a remote control during service and maintenance work on the built-in pump type CPT-60/400 will damage the control board. • Do not connect a remote control during servicing and mainte- nance work! 05.00|Clamping Device SVP-4|en...

-

Page 14: Technical Data

Hydraulic oil AGIP EXIDIA HG - 68 Ambient temperature [°C] +15 to +40 Dimensions (LxBxH) [mm] 610 x 320 x 460 Weight [kg] IP protection class RS-232 interface Pin1: +5VDC Pin2: TXD Pin3: RXD PIN5: GND 05.00|Clamping Device SVP-4|en... -

Page 15: Technical Characteristics And Functions

• The device is controlled by a microcontroller. • The pressure is monitored by an electronical pressure sensor. • Electronically managed service management. • The traceability of the pressure cycles is ensured by automatic re- cording and saving on an internal memory. 05.00|Clamping Device SVP-4|en... -

Page 16: Technical Data Of The Optional Handhold Scanner

CR6000 IP class housing IP64 Lightning Diffuse bright field, dark field Interface seriel RS-232 Supply voltage [VDC] Power consumption [W] Weight [g] Operating/storage humidity 5% to 95% non-condensing Ambient temperature [°C] +15 to +40 Material Polycarbonat housing 05.00|Clamping Device SVP-4|en... -

Page 17: Position Of The Safety Notes And Type Plates

Technical data Position of the safety notes and type plates 3.3.1 Type plates and safety notes 230 V-Version 110 V-Version Safety note voltage 05.00|Clamping Device SVP-4|en... -

Page 18: Assembly And Installation

Due to tilting, falling of the clamping device hands and feet may be squeezed and jammed. • Fix clamping device. In the base plate of the TRIBOS clamping device SVP-4 are four bore holes. The SVP-4 has to be fastened to a work bench through the mounting... - Page 19 The pump´s serial number and warranty period are stored here (among other information), as well as the meter reading for the clamping procedures carried out. The service meter, pressing time, target pressure and maximum pressure are also stored here. 05.00|Clamping Device SVP-4|en...

- Page 20 Assembly and installation 4.2.2.2 "Programs" menu item Individual pressure values can be stored here. 1 Select program number (1). 05.00|Clamping Device SVP-4|en...

- Page 21 The data can be read into the controller as follows: 1 Click on "Scan data" button. 2 Then click on "Write PLC" (5). This procedure should always be used as soon as the clamping de- vice is shipped for service. 05.00|Clamping Device SVP-4|en...

- Page 22 2 Press and hold the start and stop buttons at the same time and reconnect the power supply or power plug. 3 The two LEDs in the control unit display light up red alternately (3). 4 Release the start and stop buttons. 05.00|Clamping Device SVP-4|en...

- Page 23 Assembly and installation 5 Click button "FW Update" and select update from firmware file (.hex) (5). 6 Update starts automatically. 7 Update is complete once the message:"firmware transferred successfully" appears (7). 05.00|Clamping Device SVP-4|en...

-

Page 24: Assembly Of The Length Adjustment For Tribos Svp-4

Assembly and installation Assembly of the length adjustment for TRIBOS SVP-4 Check that all the parts have been provided: • 1 Caliper gauge (1) • 2 Measuring legs (2) • 2 Brackets for the measuring pins (3) • 2 Knurled screws (4) •... -

Page 25: Operation

Earlier versions of the Type S toolholders may still be a version with- out latching surfaces. To prevent damage to the toolholders caused by incorrect clamping operations, please contact SCHUNK (+49-7133- 103-2333) before clamping these toolholders in the SVP-4 clamping device. NOTICE... - Page 26 4 NOTICE! Check that the toolholder and the reduction insert are correctly inserted to the stop and that any possible toolholder play is eliminated. 5 Set the clamping device SVP-4 into operation with the "Start but- ton". The tool/workpiece can now be inserted or removed.

-

Page 27: Operating The Module For Stationary Use And The Pressure Regulator

• To switch off the device, hold down the ON/OFF button for 3 sec- onds. • If left inactive, the device automatically switches off after 3 minutes. An initial page will appear on the display with four tabs. 05.00|Clamping Device SVP-4|en... - Page 28 Initial page, Information 1, Information 2 and Progress of work cycle. To activate the initial page again, just select it with the I-Drive and press the Enter key, the corresponding symbol will again be posi- tioned on a black background. (►). 05.00|Clamping Device SVP-4|en...

-

Page 29: Tab "Initial Page

Pressure setting is possible only on special version 2 Program designation 5 Visualisation of state of charge 3 Program-No. 1 - 47 You can raise and lower the system pressure using the "Start" and "Stop" button 05.00|Clamping Device SVP-4|en... -

Page 30: Tab "Information 1

The service program is de- signed for remote diagnostics by a service technician. Cycles to service = work cycles until maintenance. 05.00|Clamping Device SVP-4|en... -

Page 31: Tab "Progress Of Work Cycle

Tab "Progress of work cycle" The "Progress of work cycle" tab displays the last completed work cy- cle in graphic form, including the pressure reached and the time tak- en to reach it. 5.2.5 Handhold scanner for DataMatrix-Code 05.00|Clamping Device SVP-4|en... - Page 32 (delivery state). The unlock code can be found on the TRIBOS pres- sure table ( 5.6, Page 37). After scanning the unlock code, only manual operation is active. Scanning the code with the handheld scanner is no longer possible. 05.00|Clamping Device SVP-4|en...

-

Page 33: Behavior In The Event Of Malfunctions

Flashing red Field of work not reached at Flashing red timeout Operating value in red area Flashing red Operating value in yellow area Flashing red Operating value in green area Flashing green Battery tension low Flashing red 05.00|Clamping Device SVP-4|en... - Page 34 Flashing red (check battery) Low tension of 3.3 V Flashing red Pressure sensor error; pres- Flashing red sure below calibration value of 0 bar I-Fuse error. Shunt/fuse is Flashing red blown or motor is running without activation 05.00|Clamping Device SVP-4|en...

-

Page 35: Notes On Clamping And Unclamping

• Sometimes, the tool shanks are marked. These markings are often "wrapped". This impairs the insertion of the TRIBOS toolholder or even makes an insertion impossible. In this case, re-move the wrapping. 05.00|Clamping Device SVP-4|en... - Page 36 HRC 50 (shank stiffness min. 1000 N/mm2) in order to avoid a de- formation of the tool shank. If the degree of hardness or stiffness should be lower, the compression joint is not properly covered and therefore results a reduced force transmission of the clamping sys- tem. 05.00|Clamping Device SVP-4|en...

-

Page 37: Tribos Pressure Table

Operation TRIBOS pressure table Generally the following applies: Observe TRIBOS pressure table 05.00|Clamping Device SVP-4|en... -

Page 38: Troubleshooting

(engaging surface must be Too much pressure could have been ap- aligned with the segment). plied to toolholder/reduction insert causing constant deformation. TRIBOS toolholder not turned to right-hand stop. Turn TRIBOS toolholder to right-hand stop 05.00|Clamping Device SVP-4|en... - Page 39 Toolholder has already been over- pressurized before. Clamping area dirty. Keep clamping area clean. Keep clamping area clean at the outer diameter. It must be possible to insert the reduction insert properly. Stickers or the like on the clamping area. 05.00|Clamping Device SVP-4|en...

-

Page 40: Tool Shank Can Only Be Partially Inserted Into The Toolholder

Bad quality of tool shank e.g. it may have a Check tool shank. slightly conical shape. Use tool shank with tolerance h6. 05.00|Clamping Device SVP-4|en... -

Page 41: Tool Cannot Be Removed From The Toolholder

Tool broke off. Actuate clamping device on release pressure for the toolholder. Drive out the tool shank using a hammer and a suitable drift punch. Clean clam- ping bore and clamp new tool. 05.00|Clamping Device SVP-4|en... -

Page 42: Tool Shank Can Be Inserted Outside The Pressure Range If Slight Pressure Is Applied

Tool shank can be inserted outside the pressure range if slight pressure is applied Possible cause Corrective action Send back the toolholder to SCHUNK for inspec- tion/repair. Observe TRIBOS pressure table (do not exceed max. pressure). Toolholder pressed in wrong angle (clamp- ing area is deformed). -

Page 43: Torque / Clamping Force / Holding Force Too Low

Troubleshooting Torque / clamping force / holding force too low Possible cause Corrective action Send the toolholder to SCHUNK for inspec- tion/repair. Observe TRIBOS pressure table (do not exceed max. pressure). Toolholder pressed in wrong angle (clamp- ing area is deformed). -

Page 44: Concentricity Errors On The Clamped Tool

Possible cause Corrective action Toolholder damaged, improper handling. Check toolholder for collision or damage and send back to SCHUNK for inspection/repair if necessary. Machine spindle damaged, concentricity Check machine spindle for damage and check error/axial eccentricity error on the ma- true running. -

Page 45: Maintenance

Service and repair work in accordance with the service instructions may only be carried out by qualified personnel. These include SCHUNK service technicians or specialist personnel trained by SCHUNK. As soon as the number of service cycles has been reached, the INFO LED lights up alternately green/red after each cycle. -

Page 46: Short Manual

Short manual Short manual 05.00|Clamping Device SVP-4|en... -

Page 47: Declaration Of Conformity

Declaration of conformity in terms of the Directive 2006/42/EC, Annex II, Part 1.A of the European Parliament and of the Council on machinery. Manufacturer/ SCHUNK GmbH & Co. KG Spann- und Greiftechnik Distributor Bahnhofstr. 106 – 134 D-74348 Lauffen/Neckar We hereby declare that on the date of the declaration the following partly completed ma- chine complied with all basic safety and health regulations found in the directive 2006/42/EC of the European Parliament and of the Council on machinery. - Page 48 05.00|Clamping Device SVP-4|en...

Need help?

Do you have a question about the SVP-4 and is the answer not in the manual?

Questions and answers