Summary of Contents for ABB Orion 3 Base

- Page 1 Original instructions Orion3 Base Safety light grids Type 4 Active Opto-electronic Protective Device (AOPD) ABB Jokab Safety Varlabergsvägen 11, SE-434 39 Kungsbacka, Sweden www.abb.com/jokabsafety...

- Page 2 DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. In no event shall responsibility of ABB JOKAB SAFETY for any act exceed the individual price of the product on which liability asserted.

-

Page 3: Table Of Contents

Important notes on connections ........................22 Connection examples ............................23 Alignment procedure ........................27 Alignment mode .............................. 28 Correct alignment procedure ........................... 28 Functions ............................31 Acknowledge function ............................. 31 Reset function ..............................31 EDM function ..............................32 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... - Page 4 11 Technical data ........................... 37 12 Model overview ..........................39 13 Dimensions ............................40 13.1 Profiles ................................40 13.2 Angled fixing bracket ............................41 13.3 Fixing bracket with profile ..........................41 14 EC Declaration of conformity ......................42 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

-

Page 5: Introduction

This document is intended for authorized installation personnel. 1.3 Prerequisites It is assumed that the reader of this document has knowledge of the following: Basic knowledge of ABB Jokab Safety products. Knowledge of machine safety. 1.4 Abbreviations ACM:... -

Page 6: Overview

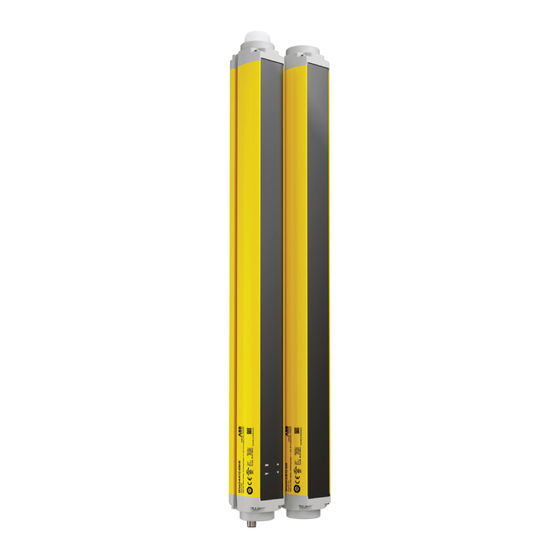

As soon as an object, a limb or the operator’s body accidentally interrupts one or several of the infrared beams sent by the transmitter, the OSSD outputs switch off and block the Machine Primary Control Element, MPCE (if correctly connected to the OSSD outputs). 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 7: Resolution

Therefore, the resolution depends only on the geometrical characteristics of the lenses, diameter and distance between centers, and is independent of any environmental and operating conditions of the AOPD. See paragraph 12 – “Model overview” for the resolution of each model 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 8: Protected Height

For the values of Hp for each model, see paragraph 12 – “Model overview”. Figure 2 – Orion3 Base with 2 beams Figure 3 – Orion3 Base with 3 beams Figure 4 – Orion3 Base with 4 beams 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 9: Minimum Installation Distance

. The minimum distance S is the greater of the two. NB: If access to the hazard zone by reaching over the AOPD can be excluded, e.g. by the provision of guards or other protective measures, step b) and c) are not necessary. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 10: Horizontally Assembled Aopd

(value as ex.) C, for AOPD with resolution > 40 mm 850 mm 850 mm K, for AOPD with resolution > 40 mm 1600 mm/s 1600 mm/s S, minimum installation distance 1475.6 mm 1477.2 mm 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 11: Safety Information

If the external device monitoring (EDM) function is used, it must be activated by connecting a specific wire to the device, see paragraph 5 – “Electrical connections”. Please carefully read the instructions for the correct functioning before powering the AOPD. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 12: Installation

Do not place the AOPD near strong and/or flashing light sources or similar devices. Strong electromagnetic interferences can jeopardize the function of the AOPD. Please contact your ABB Jokab Safety representative for advice. The operating distance of the device can be reduced in presence of smog, fog or airborne dust. -

Page 13: Minimum Installation Distance

These reflections can affect the recognition of an object inside the detection zone (see Figure 10). For example, if the receiver (RX) detects a secondary beam (reflected by the side-reflecting surface), the object might not be detected, even if the object interrupts the main beam. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... - Page 14 The diagram below shows the minimum distance to the reflecting surface (D ), based on the operating distance for a Type 4 AOPD: Figure 11 – Minimum distance to a reflective surface as a function of the operating distance 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

- Page 15 AOPD at longer distances is not recommended. Always check the correct function and that no dangerous reflections towards the receiving optics are generated by shiny objects (see Figure 12). Figure 12 – Reflection by shiny objects 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

-

Page 16: Minimum Distance Between Adjacent Devices

Warning! Please note that the Passive A can interfere with Active B in the same way as Passive B with Active A and, if the two pairs of AOPD have different operating distances, the longest one should be used for the calculation of D 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 17: Installation Of Several Adjacent Aopds

Figure 15 provides some examples of correct and incorrect installations when it comes to interferences. Figure 15 – Installation of several devices close to each other 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 18: Active And Passive Units Orientation

2 or more mirrors (for more details, refer to the technical specifications of the mirrors used). Do not use more than three mirrors for each device. The presence of dust or dirt on the reflecting surface of the mirror causes a drastic reduction in the range. 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 19: Checks After First Installation

OSSD OFF state for the same period of time. All additional functions behave as expected by activating them in different operating conditions. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 20: Mechanical Mounting

Angled fixing brackets are supplied with all Orion3 Base models. To mount the AOPD, insert the supplied “double nut plate” (M5) into the grooves on the two units (see Figure 18). Figure 18 – Mounting with angled fixing brackets 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 21: Electrical Connections

Supply Earth Earth Colors according to ABB Jokab Safety standard cables. The “RESET/ACKNOWLEDGE/RESET MODE” wire, the “EDM SELECTION” wire and the supply wires MUST be connected in order for the device to function. The other wires may be floating. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety... -

Page 22: Important Notes On Connections

Warning! The RESET/ACKNOWLEDGE button must be located in such a way that the operator can check the entire hazard zone during any Reset operation (see paragraph 7 – “Functions”). 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 23: Connection Examples

5.3 Connection examples Figure 19 – Connection to a RT9 safety relay 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... - Page 24 Figure 20 – Connection to a Pluto B20 safety PLC 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

- Page 25 NB: Connect both OSSD outputs to the activating device. Failure to connect an OSSD to the activating device jeopardises the SIL and/or PL of the system that the AOPD controls. Figure 21 – Correct connection of OSSD outputs Figure 22 – Incorrect connection of OSSD outputs 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

- Page 26 Figure 23 – Time chart of the OSSD outputs 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

-

Page 27: Alignment Procedure

The standard installation described hereinafter is the one shown in Figure 25, i.e. with the connectors pointing down. Obviously, the first and the last couples coincide when the AOPD has only 2 beams. Figure 25 – First and last transmitter/receiver couple 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 28: Alignment Mode

The alignment is performed after having completed the mechanical installation and the electrical connections as described above. Compare alignment results with those given in the following table. Enter the alignment mode as described above. In alignment mode, the display informs the user of the level of alignment reached. 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... - Page 29 Once the AOPD has been aligned and correctly fastened, the signal on the display is useful both to check the alignment and to show a change in the environmental conditions (presence of dust, light disturbance and so on). The behaviour is summarized in the next table. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

- Page 30 Every couple over the lower light reception threshold and one couple over the upper light reception threshold Every couple over the upper light reception threshold Excellent 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

-

Page 31: Functions

Automatic Reset function is unsafe when the operator can stand in the hazard zone without being detected. In this case, the Manual Reset of the AOPD or the safety relay is necessary (see paragraph 5.2 – “Important notes on connections”). 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 32: Edm Function

≤ 350 ms: the external NC contacts must open within this time after the OSSD outputs have switched on. ≤ 100 ms: the external NC contacts must close within this time after the OSSD outputs have switched off. 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 33: Diagnostic Functions

OSSD outputs. Make sure that there is no short-circuit between them OSSD error, one or or with the supply voltage. both. Error mode Then Acknowledge. OSSD outputs off. If the error persists, contact your ABB Jokab Safety representative. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... - Page 34 Display Status Description Action Turn AOPD off and on. If the error persists, Error mode Microprocessor error. contact your ABB Jokab Safety (critical) OSSD outputs off. representative. Acknowledge the error. If the error persists, Optical error. Error mode contact your ABB Jokab Safety OSSD outputs off.

-

Page 35: Periodical Checks

Access to the hazard zone of the machine from any unprotected area is not possible. The AOPD and the external electrical connections are not damaged. The frequency of the checks depends on the particular application and on the operating conditions of the AOPD. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 36: Device Maintenance

Use soft cotton cloths damped in water. Do not apply too much pressure on the surface in order to avoid making it opaque. Do not use the following on plastic surfaces or on painted surfaces: Alcohol or solvents Wool or synthetic cloths Paper or other abrasive materials 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 37: Technical Data

11 Technical data Manufacturer Address ABB JOKAB SAFETY Varlabergsvägen 11 SE-434 39 Kungsbacka Sweden Electrical Data +24 VDC 20% Power supply: Consumption, Active unit: 6.5 W max (without load) Outputs 2 PNP Short-circuit protection: 1.4 A at 55°C Output current: 0.5 A max / output... - Page 38 EN IEC 61508-1:2010 SIL 3 EN IEC 61508-2:2010 EN IEC 61508-3:2010 EN IEC 61508-4:2010 EN IEC 62061:2005/A1:2013 SIL CL 3 Prob. of Dangerous Failure/Hour (1/h) 9.28 ×10 Life span (years) Mean Time to Dangerous Failure (years) MTTF 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

-

Page 39: Model Overview

Type axis distance (mm) (mm) Beams (mm) (ms) Orion3-4-K1C-050-B 2TLA022306R0000 519,75 0.5..8 Orion3-4-K2C-080-B 2TLA022306R0100 399,75 0.5..8 Orion3-4-K2C-090-B 2TLA022306R0200 319,75 0.5..6.5 Orion3-4-K2C-120-B 2TLA022306R0300 1200 419,75 0.5..8 Orion3-4-M1C-050 2TLA022306R1000 Orion3-4-M2C-080 2TLA022306R1100 Orion3-4-M2C-090 2TLA022306R1300 Orion3-4-M2C-120 2TLA022306R1400 1200 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 40: Dimensions

Orion3-4-K2C-080-B (Figure 33) 906,35 820,5 Orion3-4-K2C-090-B (Figure 33) 1006,35 920,5 Orion3-4-K2C-120-B (Figure 33) 1306,35 1220,5 Orion3-4-M1C-050 (Figure 34) 580,5 520,5 Orion3-4-M2C-080 (Figure 34) 880,5 820,5 Orion3-4-M2C-090 (Figure 34) 980,5 920,5 Orion3-4-M2C-120 (Figure 34) 1280,5 1220,5 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 41: Angled Fixing Bracket

Figure 35 – Dimensions of the angled fixing bracket NB: All dimensions in millimetres. 13.3 Fixing bracket with profile Figure 36 – Dimensions of the angled fixing bracket with a profile NB: All dimensions in millimetres. 2TLC 172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17... -

Page 42: Ec Declaration Of Conformity

14 EC Declaration of conformity 2TLC172289M0201 Rev C www.abb.com/jokabsafety 2018-04-17...

Need help?

Do you have a question about the Orion 3 Base and is the answer not in the manual?

Questions and answers