Datalogic Magellan 9300i Product Reference Manual

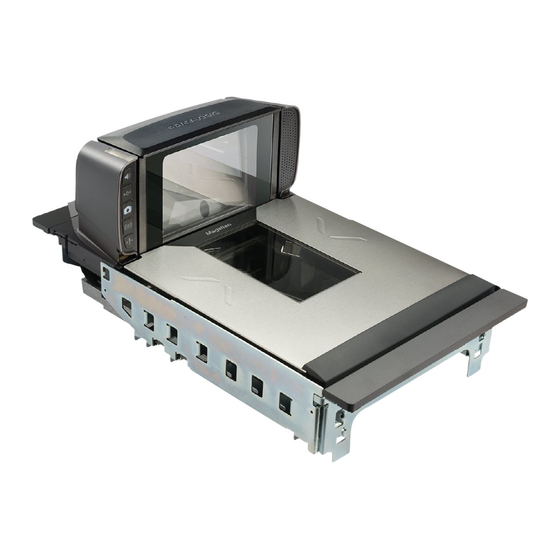

Scanner and scanner-scale with imaging technology

Hide thumbs

Also See for Magellan 9300i:

- Quick reference manual (16 pages) ,

- Setup manual (14 pages) ,

- Setup manual (14 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Quick Reference Manual

Advertisement

Table of Contents

Summary of Contents for Datalogic Magellan 9300i

- Page 1 Magellan™ 9300i / 9400i Scanner and Scanner-Scale with Imaging Technology Product Reference Guide...

- Page 2 Datalogic S.p.A. or its subsidiaries or affiliates ("Datalogic" or “Data- logic USA, Inc.”). Owners of Datalogic products are hereby granted a non-exclusive, revocable license to reproduce and transmit this documentation for the purchaser's own internal business purposes.

-

Page 3: Table Of Contents

1D Symbologies ..................................14 2D Symbologies ..................................14 References ....................................... 14 Technical Support ................................... 15 Datalogic Website Support ..............................15 Reseller Technical Support ..............................15 Telephone Technical Support ..............................15 Chapter 2. SITE PREPARATION AND INSTALLATION...........................17 SECTION I. Pre-Installation Considerations ..........................17 Ergonomic Recommendations .............................. - Page 4 Power-Up/Selftest & Pre-Operation ........................... 53 Operating Mode ..................................54 Additional Functions ..................................55 Programming ..................................55 Diagnostic Mode ..................................55 Scanner and Scale Reset ................................ 55 Scale Adjustments .................................. 55 Operational Maintenance ................................57 Cleaning ....................................57 Vertical Scan Window Replacement ............................. 58 Chapter 4.

- Page 5 Customizing Your Scanner’s Operation ............................95 Programming Overview ................................. 96 Programming via Handheld Device ............................96 What Is Programming Mode? ..............................96 Entering and Exiting Programming Mode ........................... 96 Programming Session ................................97 Programming Sequence ................................ 98 LED and Beeper Indicators ..............................100 If You Make a Mistake...

- Page 6 Scale Zero Button and Scale Indicator LED ..........................153 Scale Sentry ....................................154 Scale Sentry Override Button .............................. 155 Scale Sentry Mode ................................156 Scale Sentry Visual Indicator ............................... 157 Scale Sentry Beep Enable ..............................158 Scale Sentry GRI Enable ............................... 159 Scale Sentry Adaptive Scale Indication State ........................

- Page 7 Single Cable RS-232 Use ACK/NAK ............................ 248 Single Cable RS-232 Use STX .............................. 249 Single Cable RS-232 Use ETX .............................. 251 Single Cable RS-232 Datalogic Extensions ........................253 Single Cable RS-232 Pacesetter Plus ..........................254 USB Keyboard and Keyboard Wedge Features ......................... 255 USB Keyboard and Keyboard Wedge Intercharacter Delay .....................

- Page 8 1D SYMBOLOGY PROGRAMMING..............................281 1D Symbologies .................................... 281 Coupon Control ....................................282 Coupon Control Enable ................................. 282 Coupon Label Priority Timer ..............................283 UPC-A ......................................284 UPC-A Enable ..................................284 UPC-A Number System Character Transmission ......................285 UPC-A Check Character Transmission ..........................286 UPC-A Minimum Read .................................

- Page 9 DataBar Omnidirectional Minimum Read .......................... 336 DataBar Omnidirectional Double Read Timeout ....................... 337 DataBar Limited .................................... 338 DataBar Limited Enable ............................... 338 DataBar Limited Minimum Read ............................339 DataBar Limited 2D Component Enable ..........................340 DataBar Limited EAN128 Emulation Enable ........................341 DataBar Expanded ..................................

- Page 10 Codabar ......................................384 Codabar Enable ..................................384 Codabar Start Stop Character Transmission ........................385 Codabar Start Stop Character Set ............................386 Codabar Start Stop Character Match ..........................387 Codabar Check Character Calculation ..........................388 Codabar Check Character Transmission ..........................389 Codabar Minimum Read ..............................

- Page 11 Accepting Commands from an RS-232 Scanner Host ......................469 Appendix F. FACTORY DEFAULTS................................. 471 Appendix G. HANDHELD DATA FORMAT REQUIREMENTS........................ 495 Handheld Data Format Requirements General ........................495 Datalogic Handheld Data Format Requirements ......................496 AIM Formats ..................................500 Product Reference Guide...

- Page 12 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 13: Chapter 1 Introduction

Introduction This manual provides details for installation, configuration, calibration and operation of the scanner or scanning-scale. For the purposes of this manual, any Magellan 9300i / 9400i model may be termed as simply “scanner” (including scanning- scale models). Because of differences due to multiple model types and options,... -

Page 14: How To Use This Manual

Appendix C, Keypad, furnishes bar codes representing the digits and characters required to enter extended programming data needed during certain program- ming sessions. Appendix E, Host Commands, contains a partial listing of available host com- mands that can be used with a compatible host interface. Appendix F, Factory Defaults, provides a listing of factory default settings based on the most common interface. -

Page 15: Scanner Features

Scanner Features Scanner Features The parts and features of the scanner are shown in Figure 1. Control Panel but- tons and indicators are described in more detail in Appendix A Optional features include the Scale (for weighing items) Cus- tomer Service Scanner (CSS) and Electronic Article Surveillance (EAS). -

Page 16: Connectors And Ports

Connectors and Ports Connector port availability and appearance will differ between models, since these optional features may sometimes be added at the time of purchase. See the illustrations in Figure Figure 2 Figure • Checkpoint ® or Nedap ® Electronic Article Surveillance (EAS) Feature •... - Page 17 To Checkpoint® or Nedap® EAS System Figure 3. Connector Panel AUXILIARY PORT SCALE HOST HOST PORT · Application Download · Provides Good Read Scale Data (dual · Label Data to attached RS-232 output to enable EAS cable scanner/scale) · Scale Data (for Handheld Scanner antenna RF output single cable interfaces)

-

Page 18: Physical Parameters

Physical Parameters This section provides specifications for performance, environmental and elec- trical parameters. Reference the second section of this manual, Site Preparation and Installation on page 17, for physical measurements of all models and some accessories. Scanning A scan zone (Figure 4) exists in the area between the horizontal and vertical scan windows. -

Page 19: Weighing

Physical Parameters Weighing Specifications for scale capacity, settling time, minimum and maximum static weight, zeroing, and warm-up time are given below. For more information regarding the topic: Proper Weighing Technique (Scale Models), refer to the Operation and Maintenance on page 49 section of this manual. -

Page 20: Warm-Up Time

+70° C +158° F Sunlight: Artificial Light: 0-8,000 Foot-candles 0-450 Foot-candles (86,114 LUX) (4844 LUX) -40° C -40° F Humidity Temperature Spill Proof 5 - 95% -40° to +70° C (Datalogic MS-0006-13-0004) -40° to +158° F Magellan™ 9300i / 9400i Scanners... -

Page 21: Electrical Specifications

Electrical Specifications Electrical Specifications Before installation, always verify that the site’s electrical service meets the scanner’s requirements. The scanner has been engineered for compatibility with most international electrical systems operating in ranges from 100 to 240VAC at 50-60 Hz. Verify that the power source will supply “clean” electrical power to the equipment;... -

Page 22: Safety Precautions

Safety Precautions No adjustments or alteration of the scanner or scanning-scale hous- ing are to be attempted by the user. CAUTION This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against WARNING harmful interference in a residential installation. -

Page 23: Labeling

Labeling Labeling Regulatory, reference and safety labeling are shown in Figure Figure 6. Labeling SCALE HOST 0.00 IMAGE REMOTE DISPLAY POWER PORT HOST PORT 0.00 IMAGE HOST SCALE REMOTE PORT POWER DISPLAY PORT HOST Underside of Scanner Beneath the Scanner’s Platter Connector Bulkhead Label Serial Number Label Scale Regulatory Label (units with scales... -

Page 24: Agency Compliances

Agency Compliances The scanner and scanning-scale meets or exceeds the requirements for its device type as set forth by the following agencies and regulations: COUNTRY COMPLIANCE COMMENTS Safety United States UL60950-1 cULus Approved World IEC60950 CB certification Korea K-60950-1 Included in CB EMC/EMI 47 CFR Part 15B - 15.107 &... - Page 25 BSMI CNS 13438 Safety and EMC GB17625-1, China GB4942.1, GB9254 Argentina IRAM S mark Safety South Africa SABS Safety Contact Datalogic USA, Inc. or your Datalogic representative for a complete list- ing of approvals for other countries. Product Reference Guide...

-

Page 26: Bar Codes Supported

Bar Codes Supported The scanner can read/decode the following 1D and 2D bar code types (symbol- ogies): 1D Symbologies • UPC Versions A & E • Plural Stage Dual UPC Bar Codes for Japan (2 label read) • GSI DataBar Omnidirectional, DataBar •... -

Page 27: Technical Support

Telephone Technical Support If you do not have internet or email access, you may contact Datalogic technical support at (541) 349-8283 or check the back cover of your manual for more contact information. - Page 28 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 29: Chapter 2. Site Preparation And Installation

Chapter 2 Site Preparation and Installation This chapter provides instructions for design and preparation of the checkstand for scanner or scanner-scale installation. It also specifies physical parameters, power and ventilation considerations, cable routing information and unit instal- lation for different models. There are three basic steps: SECTION I. -

Page 30: Ergonomic Recommendations

Ergonomic Recommendations 1. Select a design which allows load-sharing by several muscle groups (for example designs which allow the cashier to use both hands for scanning and bagging). 2. Use a powered in-feed conveyor to help cashiers bring the items to their best work zone, rather than leaning and reaching to get items further up the conveyor. -

Page 31: Checkstand Design

Ergonomic Recommendations Checkstand Design Counter Preparation Since the majority of grocery checkout lanes are designed as “left-hand take away,” the counter drawings in this section focus on this counter design. Simply reverse the layout for a “right-hand take away” requirement. The unit scans equally well in either configuration. -

Page 32: Site Requirements

Site Requirements Consider the following factors before installing the scanner/scanner-scale and its optional Remote Scale Display. Ventilation Requirements The scanner operates without the use of a ventilation fan. As long as there is adequate convective air flow and no major heat producing equipment in close proximity, the unit’s housing provides adequate heat dissipation. - Page 33 Ergonomic Recommendations Service Access Requirements The scanner and scanner-scale have been engineered to allow performance of all routine service and maintenance (such as “zeroing” and calibration) without removing the scanner from the checkstand. Additionally all cable connections made at the scanner can be connected and removed while the unit is sitting on the countertop.

- Page 34 Vertical Clearance A minimum vertical clearance of 3.8 cm (1.5”) MUST be provided (reference Fig- 9). This will facilitate ease of scanning, and allow adequate space above the scanner bonnet for removal and replacement of the All Weighs™ Platter (the L- shaped platter).

- Page 35 Ergonomic Recommendations Figure 10. Scanner and Scanner/Scale Models Model 939401 Short Scanner Model 939403 Medium Scanner Model 939405 Long Scanner Model 939406 Model 939404 Long Scanner/ Medium Scanner/ Scale Scale Scanner Weights When selecting materials and designing supports for scanner installation, don't forget to factor in the weight of the scanner or scanner-scale and the products that will need to be weighed or scanned during checkout.

- Page 36 Flange Mount vs. Shelf Mount Flange mount scanners and scanner-scales are supported in the counter by brackets built into the front and back of the scanner. The flange brackets rest in a recessed pocket in the countertop and the scanner is suspended between them.

-

Page 37: Scanner Dimensions

Ergonomic Recommendations Scanner Dimensions For reference only - see "Counter Cutout" on page 27 for actual counter cutout dimensions for your model. NOTE 117.9mm (4.64”) 128.8mm Window (5.07”) 103.3mm 100.5mm (4.06”) (3.95”) 121.1mm (4.76”) 292.1mm (11.5”) SHORT (SHELF MT) Model 939401 351.9mm (13.85”) 117.9mm (4.64”) 128.8mm... - Page 38 Scanner Dimensions (continued) For reference only - see "Counter Cutout" on page 27 for actual counter cutout dimensions for your model. NOTE 435mm (17.126”) 117.86mm (4.64”) Window 128.68mm (5.06”) 103.6mm 100.6mm 90.8mm (4.08”) (3.96”) (3.57”) 44.7mm 34.9mm (1.37”) 292.1mm (1.76”) (11.5”) 265.01mm (10.43”) LONG (FLANGE MT)

-

Page 39: Section Ii. Checkstand Preparation

Ergonomic Recommendations SECTION II. CHECKSTAND PREPARATION When performing a first-time installation into a new checkstand, verify before cutting that room will be allowed for cabling and the AC/DC Power Supply. When making the opening, take extra care to accurately cut to the correct dimensions. - Page 40 Figure 12. Installation Overview (Models and connections vary) Counter Cutout Item Diverter AC/DC Power Routed Supply Support Cabling Support Rails Follow these basic steps to prepare the counter for the unit: 1. Select a position for the scanner that offers a smooth product flow which best accommodates the reaching distance of the average operator.

- Page 41 Ergonomic Recommendations Figure 13. Counter Cutout and Scanner Support Dimensions - Short COUNTER CUTOUT DIMENSIONS SHORT Model 939401 Max. Radius = 0.635cm (0.25") 4x 35.6cm (14.00") min. 29.53cm (11.625") min. 103.6mm (4.08") Liquid Liquid Drainage Drainage Support Rails Product Reference Guide...

- Page 42 Figure 14. Counter Cutout and Scanner Support Dimensions - Medium COUNTER CUTOUT DIMENSIONS MEDIUM Model 939403 and 939404 Max. Radius = 0.25" (0.635cm) 4x 15.825" (40.2cm) min. 11.625" (29.53cm) min. 103.6mm (4.07") Liquid Liquid Support Rails Drainage Drainage Magellan™ 9300i / 9400i Scanners...

- Page 43 Ergonomic Recommendations Figure 15. Counter Cutout and Scanner Support Dimensions - Long COUNTER CUTOUT DIMENSIONS LONG (FLANGE MOUNT) Models 9805 and 9806 51.12cm Max. Radius = 0.64cm (20.13") (0.25") 4x Flange Support 47.31cm (18.63") 1.91cm (0.75") 7.77cm 29.53cm (3.06") (11.63") 7.77cm (3.06") Flange Support...

-

Page 44: Section Iii. Installation

SECTION III. INSTALLATION Overview The preceding Site Requirements on page 20 dealt with installed location and counter preparations to accommodate the scanner or scanner-scale. Having completed those steps, physical installation of the scanner or scanner-scale can begin. The following instructions apply to all models. These setup and installation procedures assume that you have already prepared your checkstand to receive the scanner or scanner-scale. - Page 45 Ergonomic Recommendations Figure 16. Remove Protective Vinyl Protective vinyl MUST be removed from the platter before use. Foam Spacer MUST be removed from (Models vary) beneath the plat- ter before use. Removal of the scale spacer is not applicable to Adaptive Scale models.

- Page 46 Route & Connect Cables Route the Cables Considerations when routing the power and interface cables for the scanner and scanner-scale are: • Ensure that cables are not pinched, kinked or pierced. • Do not route interface cables in close proximity to electrical motors or other sources of electromagnetic interference.

- Page 47 Ergonomic Recommendations AC/DC Adapter Figure 18 provides physical dimensions for the AC/DC Adapter (part number 90ACC0078). Figure 18. Physical Measurements: AC/DC Adapter 1.23" (3.1 cm) Grounding The AC/DC Power Supply should have an AC outlet with a clean earth ground. If you are not sure how to verify the amount of electrical noise (interference) on the power line, ask a qualified electrician to measure the input line voltage.

- Page 48 Figure 19. Connecting Cables to the Scanner/Scale SCALE 0.00 REMOTE IMAGE HOST PORT POWER HOST DISPLAY PORT USB ‘B’ AUXILIARY REMOTE EAS* SCALE HOST HOST PORT USB PORTS* POWER IMAGE PORT* DISPLAY PORT* Scale Data (dual cable scanner/ Label Data Connects to scale) USB Handheld...

- Page 49 Ergonomic Recommendations Powerup & Operational Verification Connect the power cable first at the scanner, then at the AC outlet. 1. Plug your scanner into an electrical outlet that has been wired to meet all applicable electrical codes, laws, and regulations and has a common ground with the Point-of-Sale terminal.

- Page 50 The unit should be permitted to reach thermal equilibrium before pro- Warm-Up Time on page 8 ceeding to the next steps (see ). When the unit is moved from a cooler temperature (such as a storage area) to a warmer environment (such as a checkstand location), a period of 60 NOTE minutes must be allowed to acclimate the unit to ambient conditions.

- Page 51 Ergonomic Recommendations Verify that 0.00 lb (0.000 kg) is displayed, then place an Remote Scale Display — item on the weighing platter. Verify that the display shows a weight and that the yellow LED goes out. Remove the item and observe that Remote Scale Display shows 0.00 lb (0.000 kg) and that the yellow LED is On.

- Page 52 CHARACTERS EXPLANATION OF INDICATION Is the value of a custom data string (if present — no data may customdata be displayed if the item value is not set. The sequence will be repeated Upon successful completion, the scanner will automatically reset, displaying an 8.

- Page 53 Ergonomic Recommendations Integration with POS The System Power-Up procedure may vary depending upon the requirements of your POS system. It is generally a good practice to power down (switch off) all equipment prior to connecting cables. Check with your System Supervisor and/ or refer to your POS terminal manual for proper powerdown and powerup pro- cedures and interface requirements when connecting any peripheral device.

- Page 54 Scanner In-Counter Installation These setup and installation procedures assume that you have already prepared your checkstand to receive the scanner or scanner-scale. If you have not already made the counter cutout and routed power and interface cables, do so now as described in the previous instructions. Checkstand Mounting There are a number of things to take into account when installing the unit into a checkstand.

- Page 55 Ergonomic Recommendations 1. Remove the All Weighs™ Platter to gain access to the lift handles. Lift the top edge of the platter bezel as shown in Figure 23 and gently lift it from the scanner. If the top edge of the platter is blocked, you may find it easier to grasp edges of the platter as shown by the blue arrows.

- Page 56 3. Lower the unit into the counter opening, ensuring that none of the cables are pinched, pierced or crimped. 4. View the bubble level (if present ) located on the scanner's spider assem- bly to ensure the scanner is level. As shown in the insert of Figure 23, the air bubble should appear fully within the circle indicated.

-

Page 57: Optional Remote Scale Display

Optional Remote Scale Display Optional Remote Scale Display Placement/Installation When installing the optional Remote Scale Display, consider both the cus- tomer’s viewing angle and the daily ambient light conditions anticipated at your installation site. Figure 25 shows available adjustment for the display head. Lighting Considerations The display(s) will be easily readable unless placed in direct sunlight or other very strong light sources. - Page 58 Remote Display Cabling Your installation should also take into account the routing of Remote Display cabling. Ensure that distance and obstacles spanned by the routed cable will not kink, pinch or stretch it. Also keep in mind you may need to drill a hole through which to route it.

- Page 59 Optional Remote Scale Display Figure 27. Remote Scale Display Mounting Mounting Example Dual Display Heads Single Display Head (optional cable routing) Figure 28. Remote Scale Display Mounting Template 116.39mm 41.99mm 25.5mm 85.1mm Product Reference Guide...

- Page 60 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 61: Chapter 3. Operation And Maintenance

Chapter 3 Operation and Maintenance The information in this section describes how to operate and maintain the scanner, scale and EAS system. Topics include “how to’s” on scanning, EAS tag deactivation, weighing, re-zeroing the scale, removing the top cover and clean- ing the upper and lower windows. -

Page 62: Proper Weighing Technique (Scale Models)

Proper Scanning Technique The scanner was designed to provide the ultimate in ergonomic enhancements for Point-Of-Sale (POS) scanning. To take advantage of these advancements: Practice the techniques below to improve scanning efficiency: • Move the product across the horizontal window (See Figure 29). -

Page 63: Deactivating Security Labels

Scanning Items Using the Optional ScaleSentry Feature If the scanning-scale has been equipped with ScaleSentry , infrared (IR) beam(s) are emitted along one or both long edges of the platter (See Figure 30b). During the process when items are being weighed, if an item approaches too closely or extends past the edges of the weighing surface, this is detected by the IR beam(s) and the scanner will indicate a ScaleSentry event by illuminat- ing its ScaleSentry indicator LED and/or sounding a special ScaleSentry tone. - Page 64 EAS Deactivation Indicators The scanner can be programmed to beep in acknowledgment of deactivation or upon deactivation failure. Additionally, the tri-color indicator (the bottom-most LED) displays deactivation status. (For more information about Beeper and LED indications, see the LED/Audio Indications & Controls section of this manual. Also reference the programming section for their configurable features.) By general default, LED indications are: •...

-

Page 65: Operational Controls

Operational Controls Operational Controls The function of scanner and scale controls and indicators is listed in Appendix . Turn to that appendix for full details. LED/Audio Indications & Controls Operational Modes The scanner or scanner/scale features a number of modes that are important to both the user and the system support personnel. -

Page 66: Operating Mode

Operational Configuration Once Selftest diagnostics have been successfully run, a tone is emitted (if con- figured to do so, and the unit enters an operational configuration state. The scanner or scanner/scale will automatically load your specific interface settings which are required to communicate with the host system. There are two condi- tions that must be met before the unit can enter Operating Mode: •... -

Page 67: Additional Functions

Additional Functions Additional Functions Additional scanner and scale functions include programming, running scanner or scale diagnostics, initiating a reset, zeroing the scale, and calibrating the scale. Programming When your scanner or scanner/scale is shipped from the factory it is configured to work with the POS system interface at your store and read the bar code sym- bologies you designated. - Page 68 Zeroing the Scale The zeroing operation may be performed by checkers and other store person- nel. Pressing and releasing the Scale Zero Button should return the scale to Normal Operation. If the zero point moves out of the zero range due to debris accumulation or other causes, pressing the Scale Zero Button will not reset the zero point.

-

Page 69: Operational Maintenance

Operational Maintenance Operational Maintenance The scanner or scanner/scale will provide dependable service for many years. The following maintenance procedures will keep your scanner or scanner/scale operating at peak performance. Cleaning Exterior surfaces and scan windows exposed to spills, smudges or debris accu- mulation require periodic cleaning at least twice daily to assure best perfor- mance during scanning and weighing operations. -

Page 70: Vertical Scan Window Replacement

Vertical Scan Window Replacement The Vertical Scan Window installed in the weigh Platter is replaceable. Follow these instructions to remove and replace a Vertical Window: To remove a Vertical Scan Window: 1. Handling by the features shown, remove the Platter as referenced in Figure 32 and gently lift it straight up and off of the scanner. - Page 71 Operational Maintenance Figure 33. Vertical Scan Window Removal/Replacement Top Bezel Vertical Window Bezel Lip To Replace a Vertical Scan Window: 1. Carefully clean all adhesive or other obstructions from the Vertical Window frame area of the Platter. 2. Apply adhesive squares to the corners of the backside of the Vertical Win- dow.

- Page 72 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 73: Chapter 4. Image Capture And Customer Service Scanner

Chapter 4 Image Capture and Customer Service Scanner The scanner provides an image capture function, and can optionally include a Customer Service Scanner (CSS) for customer convenience. These premium fea- tures offer state-of-the-art functionality to point of sale transactions. Image Capture Feature In addition to scanning bar codes, the scanner can optionally be used to photo- graph images presented to the right side of the vertical window . -

Page 74: Optional Css Feature

Optional CSS Feature The Customer Service Scanner (CSS) provides a convenient way for the customer to present digital coupons or other bar codes from a cell phone or other device for convenient reading during checkout. Items to be scanned are presented to the down-facing CSS as shown in Figure Enable/Disable CSS... -

Page 75: Chapter 5. Problem Isolation

Chapter 5 Problem Isolation The troubleshooting references provided in this section should be used in the event of a suspected functional problem. This information will assist you in identifying and resolving any problems. The scanner/scale has a number of features that indicate when a scanner, EAS deactivation system, or scale problem occurs. -

Page 76: Diagnostic Procedures

Diagnostic Tests Chapter 2, Scale Diagnostic Mode, for details about running diagnostic tests for the scanner and/or scale. If a problem is discovered during diagnos- tics, the scanner will provide feedback about the source of the problem. The remainder of this section describes these failure indications and includes trou- bleshooting flowcharts to help isolate the problem. - Page 77 Error Codes Figure 36. FRU Indication Sequence Step 1 Step 2 Step 3 Step 4 Sequence Divider Start Symbol Indication Symbol Code (”Equals”) (Varies) (”Hyphen”) (Varies) Health and Status Indicator (Samples) (Samples) Table 1 on page 66 describes what the FRU indication codes in step 2 mean, and what corrective action might be taken for each.

- Page 78 Table 1. Error Code Table Health & Probable Cause Corrective Action Status Indicator Make sure the correct interface is selected, then scan the factory defaults bar code and reset the unit. Also, see Chapter 7, Pro- Configuration Error gramming, for details about configuring the scanner using pro- gramming bar codes.

-

Page 79: Scale Error Reporting

Scale Error Reporting Scale Error Reporting Scale diagnostics uses the optional Remote Scale Display and the Zero Status lamp to communicate specific scale failures. This does not apply to Adaptive Scale models. The following chart shows the Remote Display messages, the Scale Status lamp indication, the problem that the scale is experiencing and what action should be taken. -

Page 80: Flowcharts

Flowcharts The problem isolation flowcharts on the following pages allow you to identify and troubleshoot problems with your system. Figure 38. Problem Isolation: Start For units using an AC/DC adapter, verify that... 1. AC power cord is connected to a functional AC outlet. 2. - Page 81 Flowcharts Figure 39. Problem Isolation: Selftest SELFTEST START Scan the Factory Does the Does the Does the Defaults bar code in Health & Status Health & Status Health & Status Section 6 to enable the Indicator show Indicator show Indicator show default configuration file.

- Page 82 Figure 40. Problem Isolation: Poor/No Reading Have you verified that all scan windows are clean and scratch-free? POOR/NO READING Before proceeding, verify that START bar code samples presented to scanner are of good quality and a symbology the scanner Enter Scanner Diagnostic Mode by is configured to read.

- Page 83 Flowcharts Figure 41. Problem Isolation: No Transmit to POS NO TRANSMIT TO POS START Check the interface (I/F) Verify programmable cable connections. If parameters using the Does the possible, retest the information and programming scanner pass system using a bar codes provided in the DONE the data to known-good I/F cable.

- Page 84 Figure 42. Problem Isolation: Scale If this is a new installation, SCALE START make sure any foam packing pieces have been removed from the scale cavity before proceeding. Lift off the platter View the Remote Call Tech Support Call Tech Support to verify, then set the platter Display and/or the Yellow scale status LED...

- Page 85 Flowcharts Figure 43. Problem Isolation: Remote Display REMOTE DISPLAY Scanner-scale models that include START a Remote Display when shipped from the factory, are configured for use with the display. If you're unsure of the settings for your unit, contact Tech Support. Is the Use the programming bar unit configured...

- Page 86 Figure 44. Problem Isolation: EAS System NO EAS DEACTIVATION START Ensure operator has been trained in proper EAS system use (reference the topic “Deactivating Security Labels”). Verify programmable Check all EAS Does the parameters using the If possible, retest the cable connections.

-

Page 87: Chapter 6. Calibration Procedures

Chapter 6 Calibration Procedures This section applies to scanner/scale models with single or dual interval. Make sure to follow the proper associated procedure for each of these options. Procedures specific to single interval units NOTE is highlighted in a coral color. -

Page 88: Description Of Calibration Sequence

Description of Calibration Sequence The Calibration Sequence sets the scale to an accurate reference point for weighing. This process involves the use of a Field Standard Weight Set (31.5- pounds) for calibration in pounds, (18.5-kilograms) for Metric calibration. Once calibration has been successfully completed, the scanner/scale uses the certi- fied weight as a reference for subsequent weighing activities. -

Page 89: Automatic Zero Setting Test

Automatic Zero Setting Test Automatic Zero Setting Test This test verifies that the scanner/scale automatic zero setting mechanism is operating correctly. SINGLE INTERVAL DUAL INTERVAL Place 0.006 pounds (3 grams for metric) on Place 0.0035 pounds (1.6 grams for metric) on the center of the weighing platform. -

Page 90: Calibrating The Scale (Pounds & Kilograms)

Calibrating the Scale (Pounds & Kilograms) 1. Before proceeding, ensure that the scanner/scale has been prepared for this process by performing the preceding steps titled, Preparing the Scan- ner/Scale for Calibration 2. Verify that there are no obstructions under the weigh platter. Remove the weigh platter ... - Page 91 Calibrating the Scale (Pounds & Kilograms) must be performed to assure that a scale will pass Weights and Measures requirements before it is placed into commercial/retail service. You have completed the scale calibration procedure. Before replacing the Cali- bration Switch Cover and sealing the scale, you must now continue with the cal- ibration verification tests to complete the scale’s calibration.

- Page 92 Figure 46. EAS antenna EAS Antenna Calibration Switch Cover Magellan™ 9300i / 9400i Scanners...

-

Page 93: Calibration Verification (Pounds)

Calibration Verification (Pounds) Calibration Verification (Pounds) Once you have completed the calibration sequence, you may be required to perform these step-by-step verification procedures. These procedures follow the National Institute of Standards and Technology Handbook-44 guidelines for grocery scale installations. You may be required by state or local law to have these procedures performed by a certified technician or verified by a proper official. -

Page 94: Shift Test (6 Pounds Dual Interval Only)

Shift Test (6 Pounds Dual Interval ONLY) The Shift Test checks to ensure that items placed anywhere on the weighing surface of the scanner/scale are weighed properly. Refer to Figure 47 when performing this test. DUAL INTERVAL 1. Place and remove, in succession, a six- pound load on the center of each of the four quadrants: 1, 2, 3, and 4, (as shown Figure... -

Page 95: Increasing- Load Test (Phase 2 Dual Interval)

Calibration Verification (Pounds) Increasing- Load Test (Phase 2 Dual Interval) The upper limit of the scale is configurable according to the POS interface type and may not necessarily be set at 30 pounds, which is the standard setting. For this test, continue to place weights in two pound increments only up to the upper weight limit NOTE set for your scale. -

Page 96: Increasing- Load Test (Single Interval Phase 2) (Dual Interval Phase 3)

Increasing- Load Test (Single Interval Phase 2) (Dual Interval Phase 3) After completing the Shift Test, you must complete the Increasing Load Test using 20.0, 25.0 and 30.0 pounds of weight. The upper limit of the scale is configurable according to the POS interface type and may not necessarily be set at 30 pounds, which is the standard setting. -

Page 97: Decreasing-Load Test

Calibration Verification (Pounds) Decreasing-Load Test This test ensures that the scanner/scale responds properly when a heavy object is followed by a significantly smaller object. If the upper weight limit for your scale is set to other than 30 pounds, begin by placing weight equaling your upper limit set- ting. -

Page 98: Calibration Verification (Kilograms)

Calibration Verification (Kilograms) Once you have completed the calibration sequence, you may be required to perform these step-by-step verification procedures. These procedures follow the National Institute of Standards and Technology Handbook-44 guidelines for grocery scale installations. You may be required by state or local law to have these procedures performed by a certified technician or verified by a proper official. -

Page 99: Increasing-Load Test (Phase 1)

Calibration Verification (Kilograms) Increasing-Load Test (Phase 1) SINGLE INTERVAL DUAL INTERVAL This test checks Scale operation for increasing This test checks scale operation for increasing loads from 0.100 kg and 7.50 kg. loads from 0.050 kg and 3 kg. 1. Check that the display reads 0.000 kg 1. -

Page 100: Shift Test Metric (2 Kilogram Dual Interval Only)

Shift Test Metric (2 Kilogram Dual Interval ONLY) The Shift Test checks to ensure that items placed anywhere on the weighing surface of the scanner/scale are weighed properly. Refer to Figure 48 when performing this test. DUAL INTERVAL 1. Place and remove, in succession, a 2 kilogram load on the center of each of the four quadrants: 2, 3, 4, and 5, and in the center (1) of the scanner/scale’s... -

Page 101: Increasing Load Test (Phase 2 Dual Interval Only)

Calibration Verification (Kilograms) Increasing Load Test (Phase 2 Dual Interval ONLY) After completing the Shift Test, you must complete the Increasing Load Test using 4, 5 and 6 kilograms of weight. The upper limit of the scale is configurable according to POS interface type and may not necessarily be set at 15 kilograms, which is the standard setting. -

Page 102: Increasing- Load Test (Single Interval Phase 2/Dual Interval Phase 3)

Increasing- Load Test (Single Interval Phase 2/Dual Interval Phase 3) The upper limit of the scale is configurable according to POS interface type and may not necessarily be set at 15 kilograms, which is the standard setting. For this test, continue to place weights in 2.50 kilograms increments only to the upper weight NOTE limit set for your scale. -

Page 103: Decreasing-Load Test

Calibration Verification (Kilograms) Decreasing-Load Test This test ensures that the scanner/scale responds properly when a heavy object is followed by a significantly smaller object. If the upper weight limit for your scale is not set at 15 kilograms, begin by placing weight equaling your upper limit plus 0.8 kilograms. - Page 104 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 105: Chapter 7. Programming

Chapter 7 Programming Introduction to Label Programming The programming bar code labels contained in this manual will allow you to customize and configure features and settings for your scanner (scanner/ scale). To ensure full compatibility and proper function, use only the program- ming bar codes in this manual and other product-specific publications to pro- gram scanner features. -

Page 106: Bar Code Mask

Bar Code Mask Cut a hole in this page and remove it from the manual as indicated to create a sleeve through which bar codes (starting in the following section) can be indi- vidually viewed and scanned. It is important that only one bar code at a time be presented to the scanner. -

Page 107: Integrating The Scanner With Your Host System

Integrating the Scanner With Your Host System Integrating the Scanner With Your Host System Your scanner MUST be equipped with the correct hardware (interface board, cable, etc.) to properly communicate with your host system. Contact your dealer for information if you have questions about your scanner’s hardware compatibility. -

Page 108: Programming Overview

Eligible handheld devices must have the ability to transmit the C128 1D and Data Matrix 2D programming bar codes presented in this manual. Several Datalogic handheld models support this functionality. Handheld data format requirements (baud rate, parity, etc.) are... -

Page 109: Programming Session

Programming Overview Programming Session A typical programming session is conducted as follows: 1. Scan the Enter/Exit Programming Mode bar code to place the scanner in Programming Mode. Depending upon its current programming, the scan- ner may emit a beep or beeps, indicating it has read the bar code and the green LED will flash on and off slowly while the scanner remains in Pro- gramming Mode. -

Page 110: Programming Sequence

— five minutes have passed without scanning activity. Any data pro- grammed during the current session will be ignored, and the scanner will reset and revert to its condition previous to initiating the exited ses- sion. — power is disconnected. Disconnecting power during Programming Mode, before scanning the Enter/Exit Programming Mode bar code, will cause all new settings to be ignored . - Page 111 Programming Overview C. The programming sequence shown in example C requires scanning of a single, extended length bar code. This special programming bar code con- tains all the data necessary to enter Programming Mode, set the Item Tag and Item Value, and exit Programming Mode (all in one step). Table 2.

-

Page 112: Led And Beeper Indicators

LED and Beeper Indicators The scanner provides a set of indicators that verify/announce the various scan- ner functions. See Appendix A for more details. If You Make a Mistake... If, during a programming session, you find that you are unsure of the scanner’s settings or wish to reset the scanner’s configuration, use the Return to Factory Settings label below to return the scanner’s configuration to the factory set- tings. -

Page 113: Test Mode

Programming Overview Test Mode Use this feature to place the scanner into a testing, or “demo” mode. This spe- cial mode disables the scanner interface, meaning that bar code data is not sent out to the host via the scanner interface. This allows the bar code to be scanned continuously without requiring a response from the POS terminal. - Page 114 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 115: Imaging And Css Features

Imaging and CSS Features starting on page 104 MAGING EATURES Image Capture to the Host by Host Command on page 105 • Image Capture to the Host by Camera Button on page 106 • Camera Button Mode on page 106 Image Destination on page 107 Picture Retrieval Timeout on page 108 Image Capture Delay on page 110... -

Page 116: Imaging Features

Enter/Exit Programming Mode Imaging and CSS Features Imaging Features The imaging features in this chapter pertain only to the imaging feature avail- able via the vertical window (or, optionally, the horizontal window) using the Image Capture / CSS Button, below. Image Capture / CSS Button Magellan™... -

Page 117: Image Capture To The Host By Host Command

Enter/Exit Programming Mode Image Capture to the Host by Host Command This feature is only available for RS-232 and USB COM interfaces If the USB COM interface has been selected, follow the instruc- tions in the Interface Related Features on page 203 chapter of this guide. -

Page 118: Image Capture To The Host By Camera Button

Enter/Exit Programming Mode Imaging and CSS Features Image Capture to the Host by Camera Button Perform the following steps to set up the Camera Button. 1. Set the Camera Button feature to enabled 2. Set the Image Capture destination to host port 3. - Page 119 Enter/Exit Programming Mode Image Destination Specifies the destination for pictures/images taken with a camera button press. Options are: • 00=Disabled • 01=SD Card • 02=USB-B port • 03=Host port 042500(CR) DEFAULT Image Destination = Disable 042501\r Image Destination = SD card 042502\r Image Destination = USB-B port 042503\r...

- Page 120 Enter/Exit Programming Mode Imaging and CSS Features Picture Retrieval Timeout This feature sets the amount of time after the picture retrieval label is sent to the POS that the scanner will allow subsequent picture taking requests via but- ton press. If set to 0, the picture retrieval timeout will not be used and a pic- ture will remain accessible until another is taken or the scanner is reset.

- Page 121 Enter/Exit Programming Mode Picture Retrieval Timeout (continued) 042306(CR) Picture Retrieval Timeout = 6 seconds 042307(CR) Picture Retrieval Timeout = 7 seconds 042308(CR) Picture Retrieval Timeout = 8 seconds 042309(CR) Picture Retrieval Timeout = 9 seconds 04230A(CR) Picture Retrieval Timeout = 10 seconds Product Reference Guide...

- Page 122 Enter/Exit Programming Mode Imaging and CSS Features Image Capture Delay This feature specifies the amount of time after the image capture is initiated by a button press until the picture is taken. 042700(CR) Image Capture Delay = 0 seconds 042701(CR) Image Capture Delay = 1 second 042702(CR) Image Capture Delay = 2 seconds...

- Page 123 Enter/Exit Programming Mode Image Capture Delay Lamp Color Specifies the visual indicator color that flashes during image capture delay. indicator. 8-bit RGB values for camera button countdown timer visual • Byte 1 - red=0x00-0xff • Byte 2 - green=0x00-0xff • Byte 3 - blue=0x00-0xff 042600C7C7(CR) DEFAULT...

-

Page 124: Image Camera

Enter/Exit Programming Mode Imaging and CSS Features Image Camera This option selects the default imager for picture taking (optional camera func- tionality). Choices are: Vertical window imager selected for taking pictures. Vertical — Horizontal window imager selected for taking pictures. Horizontal —... -

Page 125: Image Format

Enter/Exit Programming Mode Image Format This feature specifies the output format for images taken using the camera function of the scanner. Choices are: • • • TIFF 03E900(CR) DEFAULT Image Format = JPG 03E901(CR) Image Format = BMP 03E902(CR) Image Format = TIFF Product Reference Guide... -

Page 126: Image Size

Enter/Exit Programming Mode Imaging and CSS Features Image Size This feature specifies the size of the captured image. Choices are: Video Graphics Array. 640 x 480 pixels. VGA — Wide Video Graphics Array, various physical sizes, 16:9 shape WVGA — Maximum image height and width. -

Page 127: Image Brightness

Enter/Exit Programming Mode Image Brightness Specifies the image brightness value. The selectable range is from 0 to 10, with 10 being the brightest. 03EB00(CR) DEFAULT Image Brightness = 0 03EB01(CR) Image Brightness = 1 03EB02(CR) Image Brightness = 2 03EB03(CR) Image Brightness = 3 03EB04(CR) Image Brightness = 4... - Page 128 Enter/Exit Programming Mode Imaging and CSS Features Image Brightness (continued) 03EB08(CR) Image Brightness = 8 03EB09(CR) Image Brightness = 9 03EB0A(CR) Image Brightness = 10 Magellan™ 9300i / 9400i Scanners...

-

Page 129: Image Contrast

Enter/Exit Programming Mode Image Contrast This feature sets the contrast level for a captured image. The selectable range is from 0 to 10, with 0 being the lowest and 10 being the highest contrast. 03EC00(CR) DEFAULT Image Contrast = 0 03EC01(CR) Image Contrast = 1 03EC02(CR) - Page 130 Enter/Exit Programming Mode Imaging and CSS Features Image Contrast (continued) 03EC08(CR) Image Contrast = 8 03EC09(CR) Image Contrast = 9 03EC0A(CR) Image Contrast = 10 Magellan™ 9300i / 9400i Scanners...

-

Page 131: Image Compression

Enter/Exit Programming Mode Image Compression Specifies the starting image compression factor. 03ED05(CR) Image Compression = 5 03ED0A(CR) Image Compression = 10 03ED19(CR) Image Compression = 25 03ED32(CR) Image Compression = 50 03ED46(CR) Image Compression = 70 03ED50(CR) Image Compression = 80 03ED5A(CR) Image Compression = 90 03ED64(CR) -

Page 132: Region Of Interest (Roi)

Enter/Exit Programming Mode Imaging and CSS Features Region of Interest (ROI) This feature specifies the X-Y coordinates for the Region of Interest (ROI). The region of interest coordinates are defined as follows: Where xmax is the x-size of a full size image (1279 pixels), and ymax is the y-size of a full size image (1023 pixels). - Page 133 Enter/Exit Programming Mode Region of Interest (continued) 04EC000004FF000003FF(CR) DEFAULT Region of Interest = default 04EC0000028000000200(CR) Region of Interest = upper left quadrant 04EC028004FF00000200(CR) Region of Interest = upper right quadrant 04EC00000280020003FF(CR) Region of Interest = lower left quadrant 04EC028004FF020003FF(CR) Region of Interest = lower right quadrant Product Reference Guide...

-

Page 134: Css Features

Enter/Exit Programming Mode Imaging and CSS Features CSS Features The Customer Service Scanner (CSS) is an optional scanning unit with which your scanner may be equipped. The following options are available for the CSS: Image Capture / CSS Button The scanner’s Image Capture/CSS button can be programmed for use by the sales associate to activate or deactivate the CSS using that button. -

Page 135: Css Beep Control

Enter/Exit Programming Mode CSS Beep Control This feature controls sending the force beep command to the optional reader on a label read. 04E900(CR) CSS beep disabled 04E901(CR) DEFAULT CSS beep enabled Product Reference Guide... - Page 136 Enter/Exit Programming Mode Imaging and CSS Features NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 137: General Scanner And Scale Features

General Scanner and Scale Features starting on page 127 CANNING EATURES 1D Double Read Timeout on page 127 • 2D Double Read Timeout on page 128 • Digital Watermark (DWM) Features on page 129 • Digital Watermark (DWM) Enable on page 129 Digitally Watermarked (DWM) Double Read Timeout on page Digital Watermark (DWM) Operation Mode on page 131 Digital Watermark (DWM) Data Format on page 132... - Page 138 Enter/Exit Programming Mode General Scanner and Scale Features starting on page 161 CALE NABLE Scale Diagnostics Mode on page 162 • Scale Stale Weight Timeout on page 163 • Scale Enforced Zero Return on page 164 • Scale Interface Type on page 165 •...

-

Page 139: Scanning Features

Scanning Features Enter/Exit Programming Mode SCANNING FEATURES 1D Double Read Timeout The 1D Double Read Timeout feature specifies the minimum allowable time which must pass before reading the same 1D label again (e.g. two identical items in succession). To set the Double Read Timeout: 1. -

Page 140: Double Read Timeout

Enter/Exit Programming Mode General Scanner and Scale Features 2D Double Read Timeout The 2D Double Read Timeout feature specifies the minimum allowable time which must pass before reading the same 2D label again (e.g. two identical items in succession). To set this feature: 1. -

Page 141: Digital Watermark (Dwm) Features

Scanning Features Enter/Exit Programming Mode Digital Watermark (DWM) Features Digital Watermark (DWM) Enable Enables/Disables the ability of the scanner to decode Digital Watermarks. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 142: Digitally Watermarked (Dwm) Double Read Timeout

Enter/Exit Programming Mode General Scanner and Scale Features Digitally Watermarked (DWM) Double Read Timeout Specifies the minimum allowable time which must pass before reading the same Digitally Watermarked (DWM) label again (e.g. two identical items in suc- cession). To set this feature: 1. -

Page 143: Digital Watermark (Dwm) Operation Mode

Scanning Features Enter/Exit Programming Mode Digital Watermark (DWM) Operation Mode Selects processing engine allocation for the watermark reader. Choices are: • Dedicated - allocate a decode engine for exclusive use • Shared with 2D - share the 2D decode engine 1. -

Page 144: Digital Watermark (Dwm) Data Format

Enter/Exit Programming Mode General Scanner and Scale Features Digital Watermark (DWM) Data Format Selects the format for the watermark data. Choices are: • Compatibility mode • Databar-14 • Native 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 145: Digital Watermark (Dwm) 2D Time

Scanning Features Enter/Exit Programming Mode Digital Watermark (DWM) 2D Time This feature specified the maximum time for 2D digital watermark decoder to process an image • Digital Watermark Decoder Timeout = .04 seconds • Digital Watermark Decoder Timeout = .1 seconds •... -

Page 146: Label Gone Timeout

Enter/Exit Programming Mode General Scanner and Scale Features Label Gone Timeout Specifies the amount of time in cycles (one cycle = 25ms) that data segments are stored by the software before being discarded if a label has not been suc- cessfully decoded during the current “label in volume session,”... -

Page 147: Sleep Mode Timer

Scanning Features Enter/Exit Programming Mode Sleep Mode Timer This feature specifies the amount of time of inactivity (with no label reads) before the scanner enters sleep mode. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan the bar code, Set Sleep Mode Timer on page 135 below. -

Page 148: Low Power Level 1 Timeout

Enter/Exit Programming Mode General Scanner and Scale Features Low Power Level 1 Timeout This feature specifies the amount of time of inactivity (with no label reads) before the scanner enters Low Power Level 1. This low power mode provides power savings by turning off illumination on the horizontal imagers. The vertical imager remains fully operational in this mode. - Page 149 Scanning Features Enter/Exit Programming Mode Low Power Level 1 Timeout (continued) 04ED001E(CR) Low Power Level 1 Timeout = 30 seconds 04ED002D\r Low Power Level 1 Timeout = 45 seconds 04ED003C(CR) Low Power Level 1 Timeout = 1 minute 04ED012C\r Low Power Level 1 Timeout = 5 minutes Product Reference Guide...

-

Page 150: Low Power Level 3 Timeout

Enter/Exit Programming Mode General Scanner and Scale Features Low Power Level 3 Timeout This feature specifies the amount of time of inactivity (with no label reads) before the scanner enters Low Power Level 3. This low power mode provides the maximum power savings by turning off all illumination and the horizontal imagers. -

Page 151: Inverse Read Control

Scanning Features Enter/Exit Programming Mode 1D Inverse Read Control This configuration item is used to toggle inverted label reading for 1D bar codes, for example, a label printed as white on black as opposed to black on white. To set this feature: 1. -

Page 152: Inverse Read Control

Enter/Exit Programming Mode General Scanner and Scale Features 2D Inverse Read Control This configuration item is used to toggle inverted label reading for 2D bar codes, for example, a label printed as white on black as opposed to black on white. -

Page 153: Contrast Improvement

Scanning Features Enter/Exit Programming Mode 2D Contrast Improvement This feature enables / disables the scanner’s ability to enhance the image con- trast for scanned 2D symbologies. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 154: Vl Shared Decode Timeout

Enter/Exit Programming Mode General Scanner and Scale Features 1D VL Shared Decode Timeout This feature sets the 1D VL decoding timeout when the decode processor is dynamically shared with the 2D or Watermark decoders To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 155: Illumination Control

Scanning Features Enter/Exit Programming Mode Illumination Control This feature allows illumination to be turned off when the scanner is disabled. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below: = Illumination remains on during the time the scanner is disabled. -

Page 156: Led And Beeper Indicators

Enter/Exit Programming Mode General Scanner and Scale Features LED AND BEEPER INDICATORS Good Read LED Idle State This feature specifies the state of the green scanner LEDs when the scanner is idle and ready to read a label. Options are: •... -

Page 157: Good Read Lamp Color

LED and Beeper Indicators Enter/Exit Programming Mode Good Read Lamp Color Determines the color for the good read indicator. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan the bar code, Set Good Read Lamp Color on page 145 below. -

Page 158: Scanner Control Button Options

Enter/Exit Programming Mode General Scanner and Scale Features Scanner Control Button Options Configure the Scanner Control Button to one of the following modes of opera- tion: • Enable all functions: Volume, tone, diagnostics and reset. • Enable only volume, tone and reset. •... -

Page 159: Power-Up Tone Control

LED and Beeper Indicators Enter/Exit Programming Mode Power-up Tone Control Specifies the type of audible indication that is made when entering scanner- active mode on power-up. Choices are: • No tone • Play tone To set the Power-up tone: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 160: Good Read Beep Control

Enter/Exit Programming Mode General Scanner and Scale Features Good Read Beep Control This feature enables/disables scanner beep upon successfully decoding of a label. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 161: Good Read Beep Frequency

LED and Beeper Indicators Enter/Exit Programming Mode Good Read Beep Frequency Adjusts the scanner’s good read beep to sound at low, medium, or high fre- quency (controls the beeper’s pitch/tone). • • Medium • High To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 162: Good Read Beep Length

Enter/Exit Programming Mode General Scanner and Scale Features Good Read Beep Length Specifies the duration of a good read beep. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan the bar code, Set Good Read Beep Length on page 150. -

Page 163: Good Read Beep Volume

LED and Beeper Indicators Enter/Exit Programming Mode Good Read Beep Volume Selects the beeper volume upon a good read beep. There are five selectable volumes, with each volume increment adding approximately five decibels to the previous level: • • Medium High •... -

Page 164: Good Read When To Indicate

Enter/Exit Programming Mode General Scanner and Scale Features Good Read When to Indicate This feature specifies when the scanner will provide indication (beep and/or flash its green LEDs) upon successfully reading a bar code. • Good Read = Indicate after decode. For scanner models having intelligent integrated EAS, label transmission (and hence the good read beep) is completed after the EAS logic executes. -

Page 165: Scale Features

Scale Features Enter/Exit Programming Mode SCALE FEATURES Scale Zero Button and Scale Indicator LED Here are the configurable options for the Scale Zero Button and Scale Indicator LED: • Scale Zero Button and Scale Indicator LED active • Scale Indicator LED active •... -

Page 166: Scale Sentry

Enter/Exit Programming Mode General Scanner and Scale Features Scale Sentry This option enables or disables the ability of the scanner to monitor items placed on the platter to ensure they are not overhanging non-weighing sur- faces. See the topic Scale Sentry Option on page 7 in the Introduction on... -

Page 167: Scale Sentry Override Button

Scale Features Enter/Exit Programming Mode Scale Sentry Override Button This option allows a press of the Scale Sentry Override Button to manually clear a Scale Sentry event. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 168: Scale Sentry Mode

Enter/Exit Programming Mode General Scanner and Scale Features Scale Sentry Mode Specifies the operating mode for Scale Sentry. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 169: Scale Sentry Visual Indicator

Scale Features Enter/Exit Programming Mode Scale Sentry Visual Indicator Sets the Red, Green, Blue values for the Scale Sentry visual indicator. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan the bar code, Set Color Scale Sentry Visual Indicator on page 157 below. -

Page 170: Scale Sentry Beep Enable

Enter/Exit Programming Mode General Scanner and Scale Features Scale Sentry Beep Enable Enables/disables the beep indication for Scale Sentry. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 171: Scale Sentry Gri Enable

Scale Features Enter/Exit Programming Mode Scale Sentry GRI Enable Enables/Disables use of good read indicator for scale sentry indications. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 172: Scale Sentry Adaptive Scale Indication State

Enter/Exit Programming Mode General Scanner and Scale Features Scale Sentry Adaptive Scale Indication State Defines the indication state of the adaptive Scale Sentry output pin. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 173: Scale Enable

Scale Features Enter/Exit Programming Mode Scale Enable Use this feature to enable or disable scale operation. Recalibration/recertification may be required when adding scale functionality. Consult your local Weights and Measures authority. NOTE To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 174: Scale Diagnostics Mode

Enter/Exit Programming Mode General Scanner and Scale Features Scale Diagnostics Mode Use this feature to allow or disallow the ability of an operator to initiate the advanced feature, scale diagnostics. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 175: Scale Stale Weight Timeout

Scale Features Enter/Exit Programming Mode Scale Stale Weight Timeout This option specifies the amount of time that scale data is presented to the host before being discarded. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan the bar code, Set Scale Stale Weight Timeout on page 163 below. -

Page 176: Scale Enforced Zero Return

Enter/Exit Programming Mode General Scanner and Scale Features Scale Enforced Zero Return This feature sets the mode of enforcing the scale re-zeroing operation: • Disable • Non-zero for more than 4 minutes OR below zero • Non-zero for more than 4 minutes OR below zero OR no zero between weights To set this feature: 1. -

Page 177: Scale Interface Type

Scale Features Enter/Exit Programming Mode Scale Interface Type Use this feature to select the scale interface type. Choices are:. • No scale interface • IBM 46XX (Port 17 ignored) • Mettler Toledo 8217 • USB (IBM ignored) • RS-232 - SASI •... - Page 178 Enter/Exit Programming Mode General Scanner and Scale Features Scale Interface Type (continued) 040403(CR) Scale Interface Type = USB (IBM ignored) 040404(CR) DEFAULT Scale Interface Type = RS-232 - SASI 040405(CR) Scale Interface Type = RS-232 - ICL 040406(CR) Scale Interface Type = Legacy ICL 040407(CR) Scale Interface Type = Tesco ICL 040408(CR)

- Page 179 Scale Features Enter/Exit Programming Mode Scale Interface Type (continued) 04040F(CR) Scale Interface Type = Toledo Brazil P05A 040410(CR) Scale Interface Type = Dialog04/02 040411(CR) Scale Interface Type = Dialog06 Product Reference Guide...

-

Page 180: Scale Baud Rate

Enter/Exit Programming Mode General Scanner and Scale Features Scale Baud Rate This feature sets the RS-232 scale baud rate setting for scale interfaces that have adjustable baud rate. The options are: • default • 38400 baud • 1200 baud • 57600 baud •... - Page 181 Scale Features Enter/Exit Programming Mode Scale Baud Rate (continued) 041304(CR) Scale Baud Rate = 9600 041305(CR) Scale Baud Rate = 19200 041306(CR) Scale Baud Rate = 38400 041307(CR) Scale Baud Rate = 57600 041308(CR) Scale Baud Rate = 115200 041309(CR) Scale Baud Rate = 230400 04130A(CR) Scale Baud Rate = 460800...

-

Page 182: Scale Interface Settings

Enter/Exit Programming Mode General Scanner and Scale Features Scale Interface Settings This feature sets the parity, stop bit and data bits for the scale interfaces. Bits 0-1 = Parity • 0 = default • 2 = odd • 1 = even •... -

Page 183: Scale Interface Options

Scale Features Enter/Exit Programming Mode Scale Interface Options Specifies various tare and price-weight related scale options. • Bit 0 = Don't transmit MT8213/MT8217 decimal point • Bit 1 = Reserved for future use • Bit 2 = Clear the tare after every weight request •... -

Page 184: Icl Scale Interface Dc1 Character Delay

Enter/Exit Programming Mode General Scanner and Scale Features ICL Scale Interface DC1 Character Delay When using the RS-232 ICL scale interface type, this option enables/disables the ability of the scanner to delay DC1 response for 40 milliseconds. To set this feature: 1. -

Page 185: Scale Calibration Notification

Scale Features Enter/Exit Programming Mode Scale Calibration Notification This option enables a notification that scale calibration has taken place. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 186: Scale Intercharacter Delay

Enter/Exit Programming Mode General Scanner and Scale Features Scale Intercharacter Delay With regard to scale functions, this feature specifies a delay between the end of one character and the beginning of the next in 10-millisecond increments. To set the Scale Intercharacter Delay: 1. -

Page 187: Adaptive Scale Led Option

Scale Features Enter/Exit Programming Mode Adaptive Scale LED Option Defines which LED is used for adaptive scale indication. To set this feature: 1. Scan the ENTER/EXIT Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 188: Remote Display - Enable/Disable

Enter/Exit Programming Mode General Scanner and Scale Features Remote Display — Enable/Disable The scanning-scale can be configured to operate with or without a Remote Dis- play. Recalibration/recertification may be required when adding a Remote Display. Consult your local Weights and Measures authority. -

Page 189: Auxiliary Port Mode

Selects the usage for the scanner’s optional auxiliary port. The choices listed below are mutually exclusive (only one option can be active at a time). • Disabled — Port is inactive • External Handheld Input — Supports non-Datalogic handheld scanners • Datalogic Handheld Input — Supports Datalogic handheld scanners (QuickScan... -

Page 190: Auxiliary Usb Mode

Enter/Exit Programming Mode General Scanner and Scale Features Auxiliary USB Mode This option specifies the function of the USB auxiliary port. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 191: Usb Device Port Location

Scale Features Enter/Exit Programming Mode USB Device Port Location This option specifies the USB Device Port location. The USB Device Port is used by authorized personnel to set factory configuration. NOTE Options are: • under scale platter • on back panel To set this feature: 1. -

Page 192: Productivity Index Reporting (Pir) / Cashier Training (Ct)

Enter/Exit Programming Mode General Scanner and Scale Features Productivity Index Reporting (PIR) / Cashier Training (CT) When PIR/CT is enabled, label quality data is appended to decoded data before being presented to the POS. The PIR feature allows the scanner to provide infor- mation to an external computer indicating how easy the label was to read. -

Page 193: Pir/Ct Auxiliary Port Baud Rate

Scale Features Enter/Exit Programming Mode PIR/CT Auxiliary Port Baud Rate This feature specifies the baud rate of the auxiliary port when operating in PIR/ CT Mode. This setting is valid ONLY when Auxiliary Port Mode on page 177 is set to PIR/CT + Diagnostics Reporting. NOTE To set this feature: 1. - Page 194 Enter/Exit Programming Mode General Scanner and Scale Features PIR/CT Auxiliary Port Baud Rate (continued) 051600(CR) DEFAULT PIR/CT Auxiliary Port Baud Rate = 19200 051606(CR) PIR/CT Auxiliary Port Baud Rate = 38400 051607(CR) PIR/CT Auxiliary Port Baud Rate = 57600 051608(CR) PIR/CT Auxiliary Port Baud Rate = 115200 Magellan™...

-

Page 195: Host Download To Handheld

Scale Features Enter/Exit Programming Mode Host Download To Handheld Attached Datalogic handheld scanners can be updated via the host port. Con- tact Technical Support for details. Handheld Host Download Timeout This feature sets the timeout (in seconds) to wait for a response from the hand- held when performing a host download to the handheld. - Page 196 Enter/Exit Programming Mode General Scanner and Scale Features NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 197: Eas Features

EAS Features starting on page 186 EAS F — S EATURES ENSORMATIC EAS Mode on page 186 • EAS Notification on page 188 • EAS Security Level on page 189 • EAS Good Beep Mode on page 190 • EAS Beep Duration on page 191 •... -

Page 198: Eas Features - Sensormatic

Enter/Exit Programming Mode EAS Features EAS Features — Sensormatic These features control the Sensormatic® AMB-9010 or Scan- MaxPro EAS controller box. This orderable option is installed at the time of manufacture. See " EAS Features — Checkpoint" on page 200 to set options for the Checkpoint® EAS system. NOTE EAS Mode This controls the mode of operation for interfacing with the Sensormatic... - Page 199 Enter/Exit Programming Mode EAS Mode (continued) Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. 058000(CR) DEFAULT EAS Mode = Disable 058001(CR) EAS Mode = Coupled Mode 058002(CR) EAS Mode = Decoupled Mode...

-

Page 200: Eas Notification

Enter/Exit Programming Mode EAS Features EAS Notification This feature specifies the output mode and activation of EAS event notification when operating in Coupled Mode. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 201: Eas Security Level

Enter/Exit Programming Mode EAS Security Level This feature defines the level of EAS security for operating in coupled mode. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 202: Eas Good Beep Mode

Enter/Exit Programming Mode EAS Features EAS Good Beep Mode This feature sets the mode of operation for the EAS deactivation beep while operating in coupled mode. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 203: Eas Beep Duration

Enter/Exit Programming Mode EAS Beep Duration Sets the duration of the EAS successful deactivation beep, specified in 10ms increments. The beep only occurs if EAS mode is not disabled. To set the EAS Beep Duration: 1. Scan the Enter/Exit Programming Mode bar code. 2. -

Page 204: Eas Retry Count

Enter/Exit Programming Mode EAS Features EAS Retry Count This feature sets the number of times the deactivation sequence (defined by the feature, “EAS Deactivation Duration — Retry ”) is restarted after a failed deacti- vation attempt. To set this feature: 1. -

Page 205: Eas Exception Button

Enter/Exit Programming Mode EAS Exception Button This feature is for use in Coupled Mode . When it is enabled, EAS deactivation can be manually initiated by placing the item with the EAS tag downstream the horizontal scan window and pushing the EAS Exception Push Button momentarily. - Page 206 Enter/Exit Programming Mode EAS Features EAS Exception Button (continued) To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan.

-

Page 207: Eas Deactivation Duration - Coupled

Enter/Exit Programming Mode EAS Deactivation Duration — Coupled Specifies the amount of time EAS deactivation is operative once the function has been initiated following a bar code read. This setting pertains only to units configured for EAS Coupled Mode. Reference the EAS Mode on page 186 description for more information about Coupled and Decoupled EAS operation. -

Page 208: Eas Deactivation Duration - Retry

Enter/Exit Programming Mode EAS Features EAS Deactivation Duration — Retry Specifies the amount of time EAS deactivation is operative once the function has been initiated following EAS tag detection (prior to bar code read). This setting pertains only to units configured for EAS Coupled Mode. -

Page 209: Eas Deactivation Duration - Exception

Enter/Exit Programming Mode EAS Deactivation Duration — Exception Specifies the amount of time EAS deactivation is operative upon pushing the EAS Exception Button. This setting pertains only to units configured for EAS Coupled Mode. Reference the EAS Mode on page 186 description for more information about Coupled and Decoupled EAS operation. -

Page 210: Eas Pre-Read Time

Enter/Exit Programming Mode EAS Features EAS Pre-Read Time This feature specifies the time duration that must elapse before reading a label once an EAS tag is sensed. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan the bar code, Set EAS Pre-Read Time on page 198 below. -

Page 211: Eas Error Tones

Enter/Exit Programming Mode EAS Error Tones Enable or disable error tones when deactivation fails. To set this feature: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan your selection from the bar codes below. You’ll need to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. -

Page 212: Eas Features - Checkpoint

Enter/Exit Programming Mode EAS Features EAS Features — Checkpoint The features in this section apply only to Checkpoint EAS systems. ® ERI Active State Specifies the active state polarity of ERI; the inactive state is its opposite polar- ity. ERI output goes active during the good read of a bar code, allowing the EAS device to deactivate a tag on the product. -

Page 213: Eri Timeout

Enter/Exit Programming Mode ERI Timeout Specifies the amount of time that an ERI signal is held in its active state for a good read. To set the ERI Timeout: 1. Scan the Enter/Exit Programming Mode bar code. 2. Scan the bar code, Set ERI Timeout on page 201 below. - Page 214 NOTES Magellan™ 9300i / 9400i Scanners...

-

Page 215: Interface Related Features

Interface Related Features starting on page 205 NTERFACE RS-232 Interface Selection on page 207 • USB Interface Selection on page 208 • IBM Interface Selection on page 209 • Keyboard Interface Selection on page 210 • starting on page AXIMUM RANSMITTED ESSAGE ENGTH... - Page 216 Set Single Cable RS-232 STX Character on page 250 Single Cable RS-232 Use ETX on page 251 • Set Single Cable RS-232 ETX Character on page 252 Single Cable RS-232 Datalogic Extensions on page 253 • Single Cable RS-232 Pacesetter Plus on page 254 •...

-

Page 217: Interface Type

Enter/Exit Programming Mode Interface Type Specifies the current scanner interface. To access a scanner’s interface identifi- cation number, place the scanner in Scanner Diagnostic Mode and view the 7- segment FRU display (reference Chapter 2, Scale Diagnostic Mode, for more information). - Page 218 Enter/Exit Programming Mode Interface Related Features Interface Type (continued) To select the desired interface: 1. Disconnect current interface cable(s) if currently connected. 2. Scan the Enter/Exit Programming Mode bar code. 3. Scan the bar code representing the appropriate interface located on the following pages.

-

Page 219: Interface Selection

Enter/Exit Programming Mode RS-232 Interface Selection Remember to cover any unused bar codes on this and the facing page to ensure that the scanner reads only the bar code you intend to scan. Great care should be taken to select the correct interface type, since you can cause damage to the scanner and/or POS termi- nal by attempting to change to an incompatible interface. -

Page 220: Usb Interface Selection