Bunn ICB Installation & Operating Manual

Infusion series, platinum edition

Hide thumbs

Also See for ICB:

- Operating & service manual (70 pages) ,

- Programming manual (39 pages) ,

- Service and repair manual (37 pages)

Table of Contents

Advertisement

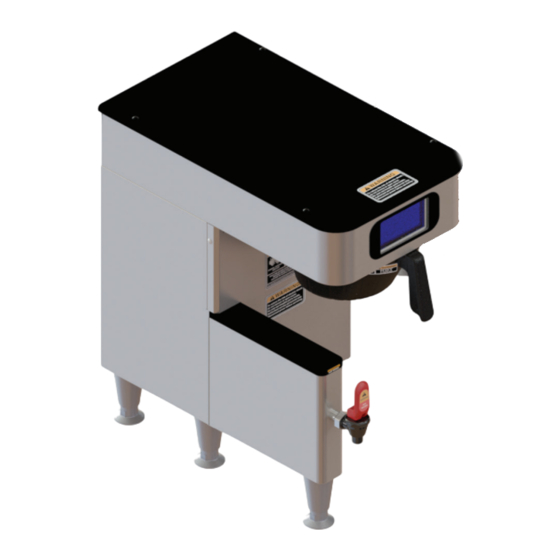

Infusion Series

®

ICB, ICB Twin, ICB Twin

Tall, ICB-DV, ICB DV Tall

Platinum Edition

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601

FAX: (217) 529-6644

www.bunn.com

To ensure you have the latest revision of the Operating Manual, Illustrated Parts Catalog, Programming Manual, or Service

Manual, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

55079.0000A

05/18 © 2018 Bunn-O-Matic Corporation

Advertisement

Table of Contents

Summary of Contents for Bunn ICB

- Page 1 To ensure you have the latest revision of the Operating Manual, Illustrated Parts Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

-

Page 2: Warranty

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages. -

Page 3: Table Of Contents

Viewing Asset, Serial and Service Number ............13 Calibration ......................10 Programming/Service Access ................11 Programming/Service Menu ................11 Viewing Asset, Serial and Service Number ............13 Sprayhead/Bypass Calibration ................13 Edit Recipes ......................14 Machine Settings ....................17 ICB-DV ........................Dual Voltage Machine ICB Twin ....................... 120/208-240V or 230V Page 3 050718... -

Page 4: Ce/North American Requirements

OPERATING MANUAL BEFORE Disconnect power before servicing. Read all instructions for additional graphic layer USING THIS PRODUCT prior to installing and programming. 00986.0000M 10/14 ©1994 Bunn-O-Matic Corporation 39175.0000C 07/15 ©2006 Bunn-O-Matic Corporation #37881.0000 #39175.0000 #00986.0000 #00658.0000 120/208V... -

Page 5: Electrical Requirements

ELECTRICAL REQUIREMENTS Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements. WARNING - The brewer must be disconnected from the power source until specified. WARNING - The power cord must be UL Listed, Flexible Cord Type SO, SJO, SJTO, HSJO or SJOW, Rated 90° C, and the attachment plug cap must be UL Listed, in order to avoid a hazard. -

Page 6: Plumbing Requirements

NOTE - Bunn-O-Matic recommends 3⁄8" copper tubing for all installations from the 1⁄2" water supply line. A tight coil of tubing in the water line will facilitate moving the brewer to clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this type of device may restrict water flow. -

Page 7: Initial Set-Up

8. The brewer is now ready for use in accordance with the 8000 197.4 91.9 87.8 8500 196.5 91.4 87.2 instructions for Coffee Brewing. 9000 195.5 90.8 86.7 9500 194.6 90.3 86.1 193.7 89.8 85.6 10000 35665.0000A 05/04 © 2004 Bunn-O-Matic Corporation Page 7 050718... -

Page 8: Brewing Coffee

BREWING WITH A SMART FUNNEL AND G9-2T DBC or MHG GRINDER 1. Select the desired batch size on the grinder. 2. Insert a BUNN filter into the gourmet funnel. 3. Grind the selected amount of fresh coffee into the Smart Funnel using the G9-2T DBC or MHG with Smart Funnel operation and level the grounds by gently shaking. -

Page 9: Cleaning

5. Prepare a warm soapy solution with nonabrasive, liquid detergent (140˚ F). Then use a clean, damp cloth wetted in the solution to wipe down all surfaces on the BUNN equipment. Do NOT clean this equipment with a water jet device. -

Page 10: Operating Controls

When the main screen is visible, select the BREW button to begin a brew cycle on the selected side. B. PROGRAMMING Touch the BUNN logo for 2 seconds to enter the programming. C. BATCH SELECTOR SWITCHES Selecting the icon corresponding to Small, Medium, and Large batch selects the amount of product to be brewed on the selected side. -

Page 11: Programming/Service Access

BREW HOW TO EXIT PROGRAMMING To exit the programming mode at any time, select the BUNN logo at the top of the display. The display will return to the home screen. If there is no interaction with the touchscreen within a 5-minute period while in programming mode, the display will automatically return to the home screen. - Page 12 PROGRAMMING (cont.) SERVICE ACCESS OPTIONS EVENT HISTORY - Select this icon to view current cycles, lifetime cycles, and the length/number of times certain components are activated. STATISTICS - Select this icon to view the amount of brew cycles per batch size. Twin models will show separate numbers for left and right brew cycles.

-

Page 13: Viewing Asset, Serial And Service Number

5. At the SERVICE MENU screen, select the CALIBRATION icon. 4. For Single ICB models, there is only 1 sprayhead to calibrate. For Twin ICB models, there is a left and a right sprayhead to calibrate. Ensure the container is under the correct sprayhead for calibration. -

Page 14: Edit Recipes

10. Select SAVE. 11. The display should now show the actual flow rate of the bypass. 12. Repeat steps 1-7 to calibrate the other side. (Twin ICB models only) RENAMING A RECIPE There are 5 pages containing 6 recipe names (30 total). By default, recipe names are preset from the factory. - Page 15 PROGRAMMING (cont.) 4. In the SERVICE MENU screen, select the RECIPE icon. 5. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the screen to navigate to the desired recipe name to edit. Select the recipe name. 6.

- Page 16 PROGRAMMING (cont.) PULSE BREW (cont.) - How long to turn the sprayhead off; this is not an accumulated time. This time is the length that the sprayhead will turn off during the pulse routine then turn back on. Both on and off times will have limits the operator is able to set depending on the parameters of the recipe.

-

Page 17: Machine Settings

Selecting each button will navigate the user to that respective category. The BUNN programming button will navigate the user to the main home screen. BREWER SETTINGS - Machine settings lets the operator make changes to the energy saver, funnel detect, and screen saver.

Need help?

Do you have a question about the ICB and is the answer not in the manual?

Questions and answers