Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Anet A9

-

Page 2: Table Of Contents

Contents Print Welcome Stick the Masking Tape Security Considerations Hotbed Levelling Product Details Filament Installation Print File Open the Package Pull Out Filament Open the package Machine Maintenance Tool List Maintenance Machine Parts Lubrication Menu Commands FAQ and Solution Menu Settings and Calibration Problems Main Interface Extruder Problems... -

Page 3: Welcome

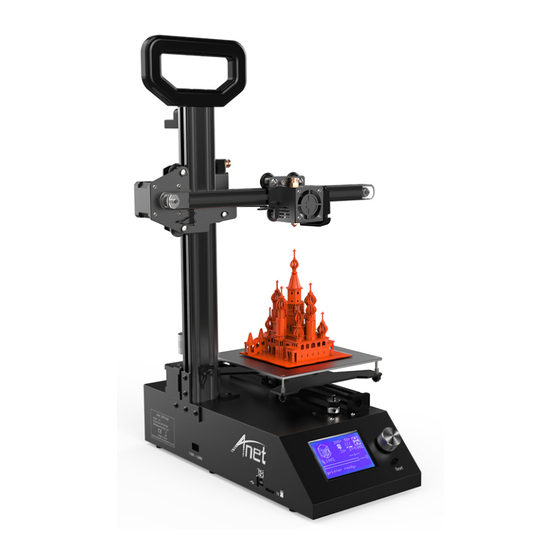

Welcome Use Anet This user manual will quikly guide you to use Anet A9 As a huge improvement, A9 will provide you with a more high precision print effect and more print ways Now, start to print your idea! -

Page 4: Security Considerations

Hotbed and Extruder head Warning: A9 will produce high temperatures during printing or heating, including moving parts that could cause personal injury. To avoid burns, do not touch the extruder or the heating aluminum block. Warning: Don't leave the machine too long during the printing process.If you have to do so, please follow... -

Page 5: Product Details

Product Details Model#:A9 Extruder Dia.:Normally 0.4mm Print Precision:0.1-0.4mm Machine Dimensions:375mm*335mm*525mm Printing Speed:10-120mm/s Machine Weight:5.7kg XY Axis Positioning Accuracy:0.012mm Package Dimensions:440mm*385mm*200mm Z Axis Positioning Accuracy:0.004mm Package Weight: 7.5kg Filament Materials: PLA,ABS Build Size:160mm*160mm*200mm Filament Tendency:PLA LCD Monitor Screen:LCD12864 Filament Dia.:1.75mm Offline Printing:Support Software Language:Chinese, English... -

Page 6: Open The Package

Open the Package Each A9 has been rigorously tested, and it was carefully packed, then send it away from factory, Hope you can read this section and assemble your A9 successfully. -

Page 7: Open The Package

开箱 Open the Package 1.Please put the box on the enough 2.Please open the box, and make sure 3.Please check goods and tools place to assemble. foam, carton and paperboard are not quantity. damaged... -

Page 8: Tool List

物品清单 1.X轴型材组合件 *1 Installation package of left and right fixing plate holder *1 Chassis *1 Nozzle kit *1 Linear bearing holder *1 Z-axis profile assembly 8GTF Card and Reader Z axis rod *1 Black Ribbon Material racks*1 1.5M Power line*1 Rack connector*1 5mm*160mm screwdriver*1... -

Page 9: Machine Parts

Install the video in the "Video" folder on the TF card 外型介绍 Machine Parts Handle need to print,print the file in the “Test file GCODE”>“Handle”. -

Page 10: Menu Commands

Menu Commands In this chapter, you can learn more menu interface in detail. -

Page 11: Menu

菜单 Menu... -

Page 12: Main Interface

主界面 Main Interface... -

Page 13: Slice Software

Slice Sofeware This chapter will guide you how to install and use the slice software... -

Page 14: Installation And Usage

Assembly and Usage Open TF data first, then click “software” file to find “setupRepetierHost_2_0_1”file to finish your installation. Please install referring to the pictures. Please select your language shown... - Page 15 16.”C”: Slice the object by its position,obliquity and azimuth. Assembly and Usage 17.“M” can make the object flip oppositely 1. “Rotation”means active status, you can use your mouse to rotate the 18. Connect the mahcine:after connectting the USB cable and the 3D printer,it can be operated in solfware. model and view the object from different angels 2.

-

Page 16: Print

Print This chapter will guide you how to use A9 step by step More use details, please click the instructions... -

Page 17: Stick The Masking Tape

贴胶纸 1.将热床表面清理干净 2.请勿将胶纸覆盖在螺丝上 4.去掉边缘的胶带 3.您可以使用小卡片 来辅助刮平. -

Page 18: Hotbed Levelling

Hotbed Leveling Move X axis to the first position of the Hotbed . Please tie the four screws to the Put the card between the bottom tightly in order to avoid the nozzle and the hotbed gap. nozzle knocking the Hotbed. Tight the screws. -

Page 19: Filament Installation

Installation of filament Insert the filament to the extruder( or push the 1. First preheat the nozzle: filament into it by hand) Enter the menu from Quick settings” and control the rotation to “Preheat PLA(ABS) of the extruder. Make the filament get to the nozzle. -

Page 20: Print File

File printing Insert TF into the machine. Open slice software, choose STl file to slice. Put the sliced file into TF card Z axis will move up when print completed. Heating the Enter the menu and Hotbed to 50℃ will make the choose “SD card”... -

Page 21: Pull Out Filament

Remove the Filament 1. Remove the guide tube and 2. preheat the nozzle to enter cut off the consumable closest the menu”Quinck settings” to the extrusion head >“Preheat PLA( ABS)” Waiting for preheating 3. Use a tool to push the 4. -

Page 22: Machine Maintenance

Machine Maintenance The routine maintenance is very necessary to keep the type of A9 in the good status. This chapter will introduce some basic skills to maintain the 3D printer... -

Page 23: Maintenance

Maintenance Hot bed Make sure the hot bed is free of dust, grease and scratches 1. Use tweezers to remove filament residue. 2. Do not touch the hotbed with sharp objects. 3If the printer is left unused for a long period of time, clean the surface of the machine, clean the hot bed, and completely loosen the 4 screws on the hot bed. -

Page 24: Lubrication

lubricating Clean X, Y, Z axis polished rod and screw rod Regular lubrication of X, Y, Z axis rod and screw can keep it lubricated. -

Page 25: Faq And Solution

FAQ and Solution This chapter will help to diagnose and solve the common problem when it appears. Please look up the instruction in electronic document or contact service support center when you meet the problem unable to solve. -

Page 26: Settings And Calibration Problems

Setup and calibration problems Nozzle heating failed 1.The heating tube is loosely connected, please check the black top wire and the heating tube under the heating block, insert the heating tube and tighten the black top wire. 2 . Heating: Temperature settings for several common filaments. -

Page 27: Hardware Problems

Hardware problem Even if the screws on the hot bed have been screwed up to the top, the hot bed sheet is still too far away from the nozzle (the distance There is a leak on the side of the model between the hot bed and the nozzle is too far to adjust). - Page 28 How to deal with filament stuck in the extruder? Remove the card out of filament Take out the filament...

- Page 29 How to Disassemble and Install the Extruder 1.Remove filament and the feeding 2.Increase the nozzle pipe out temperature to 210℃ to let the remain filament flow out automatically and then drop the temperature down to 30 ℃ 3. screw out the jack 4.

- Page 30 How to Clean the Nozzle? Increase the nozzle When liquid filament is ran temperature to 210℃ out , clean the nozzle and drill to let the remain with tool squeezing in the hole filament flow down automatically...

- Page 31 How to Replace Heat Pipe and Thermistor? Disassemble 2.Remove heat extruder and pipe and thermistor screw out the screw on the heat block Replace the heat Connect to the right pipe and thermistor interrupts referring to the with new ones. Reinsert mainboard the heat block accordingly...

Need help?

Do you have a question about the A9 and is the answer not in the manual?

Questions and answers