Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Anet A3-S

-

Page 2: Table Of Contents

Contents INTRODUCTION ........................2 A. Security Considerations ....................3 B. Product Details .........................4 1.Specifications .......................4 2.Machine parts ......................4 3.Exploded drawing ......................5 4.Tool List ........................6 C.Cura Software ......................7 1.Installation of Cura14.07....................7 1.1 File location in the TF card .................7 2. Cura Setting ......................16 2.1 Clear platform ....................16 2.3 Layer height settings ..................21 D. -

Page 3: Introduction

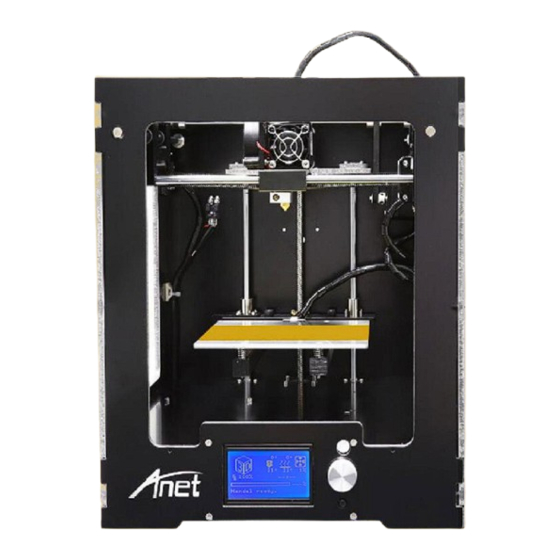

INTRODUCTION A3-S FDM 3D printer can print CAD 3D printer model to real . A3-S uses Acrylic to build its frame while it uses linear bearings , belts and threaded rods to build X , Y , Z axis . -

Page 4: Security Considerations

A. Security Considerations To avoid danger when using 3D printer , please pay attention to precautions below . Danger During Operation , the maximum temeprature of nozzle can be 260 ℃ while hotbed can be 100 ℃ . For your safety , during printing or cooling down , do not touch the nozzle , hotbed and models under printing . -

Page 5: Product Details

B. Product Details 1.Specifications Model:A3-S Nozzle diameter: 0.4mm Layer thickness:0.1-0.3mm Machine size: 315mm*333mm*375mm Printing speed:10-300mm/s Machine weight:10KG X Y axis position accuracy:0.012mm Packing size:400*380*440mm Z axis position accuracy:0.004m Gross weight:11.4KG Printing material:ABS,PLA Build size:150*150*150mm Material tendency:PLA LCD screen:12864 LCD Filament diameter :1.75mm Offline printing:SD CARD... -

Page 8: Tool List

4.Tool List... -

Page 9: C.cura Software

C. Cura Software 1.Installation of Cura14.07 Where can I find the software? 1) SD card with shipment; 2) download from Internet; b: Installation process 1) From SD card with shipment File location in the TF card Insert SD card and open the file 1) Insert SD card , open the file 2) Download from Internet... - Page 10 Official Website : https://ultimaker.com/en/cura - software/list Choose corresponding software to download...

- Page 11 b.Software Installation Process 1. Installation Positioning . Click Next Choose 3 options below 4 . Click Install...

- Page 12 Please wait for installation 1 .Click Next...

- Page 13 1 .Installation Success 2 .Click to finish Installation complete Click Next...

- Page 14 1 .Choose to run Cura 2 . Click to finish Click Next...

-

Page 18: Cura Setting

Now you have finished the installation. Next , enter Cura . 2. Cura Setting 2.1 Clear platform Delete the dog. Two ways for you : 1.Move mouse to dog ,right click, click “delete object”. - Page 19 2 .Left click “ File ” , choose ” Clear platform ”.

- Page 20 Switch to full settings for parameter setting...

- Page 21 Position of configuration file: Computer/SD card)/ configuration file for cura-14.07 (suggestion :keep this file copy to your computer)...

- Page 22 If print once at a time , it will influence the printing quality, even cause damage to priner. So please choose “ Printer at once ”.

- Page 29 Attention:Normally this option cannot be changed , if changed ,it ’ s at your peril . Attention:Normally this option cannot be changed , if changed , it ’ s at your peril . Starting Ending...

-

Page 30: Expert Setting

3.Expert Setting... - Page 32 Skirt is to avoid extruder unfilled before printing , and it appears only when platform attachment type is None. Normally “1” is ok . Change it to “0” when your model reaches the maximum size , or the printing size will be too big. Peripheral line quantity: 1 Peripheral line quantity: 1 Start distance: 3...

- Page 34 If no solid infill top , the only qualification is the surface thickness . No solid infill top With solid infill top...

- Page 35 With solid infill bottom No solid infill bottom Infill coverlap: 40 Infill coverlap: 20...

- Page 37 It’s difficult to seperate if the distance between support and the supported place is too close; The surface will be influenced if the distance is too far. Different angle will generate different support , you can try the examples we provide above which will have different effect.

- Page 40 Guidance to use Raft if needed: Expert → Expert Settings → Support → Support Types → Raft. The images above are only for reference , please set the parameter according to actual requirement.

-

Page 46: Interface Introduction

1.Interface Introduction... -

Page 49: Filament Feeding

2. Filament Feeding 2.1 Set Preheat... -

Page 50: Filament Installation

2.2 Filament Installation... -

Page 52: Pull Out Filament

2.3 Pull out filament... -

Page 55: Printing

4.Printing 1) SD Card Offline Printing a. Loading mode Cura supports STL file & G-code file. - Page 56 b. Code Saving c. Introduction of Stop print , Pause print , Continue Print: Only when the printer is printing can we use Stop print, Pause print, Continue Print.

- Page 57 d.Judgment of the gap between nozzle and platform. 1. Too big gap: The printed model is uneven, curled with gap. It means the gap is too big for filament to reach the platform, making the printing effect so bad. 2. Too close gap: The printed model edge has irregular projections. It means the gap is too close to print normally.

- Page 58 2) USB Online Printing a. Machine settings ( Use USB to connect to PC ) b. Online Pringting...

-

Page 59: Faq

1. N ozzl e blocking Tips: We have removed fan to show obviously. Please cosider movement according to actual requirment. E. FAQ A. Only a little filament left in the nozzle and difficult to take out:... - Page 60 B. Filament full filled in spout...

-

Page 61: Faq

2. FAQ Symptom Reason Method Synchronous wheel/belt Tighten set screws or Print model dislocation loose. fasten belt Extruder temp is too high Too high temp or slicing and retracting speed & Glitch with the print model problem. distanse is too small Rise extruder temp or check if brass nut and bearing is good. -

Page 62: Maintenance

F. Maintenance Important maintenance tips: 1. maintenance of X,Y,Z axis: Add some lubricants on the rods to reduce friction when the machine works noisy and a little bit shake. 2. Please refer to the USER MANUAL before printing, do preparation of hot bed adjustment first. 3. -

Page 63: Maintenance Service Provision

G. Maintenance Service Provision 1. This product executes regulations of “Product Warranty Card”. 2. Please contact supplier or customer service if the product have any problems . Do not repair it by yourself, otherwise you need to bear all the consequences.

Need help?

Do you have a question about the A3-S and is the answer not in the manual?

Questions and answers