Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Fagor CNC8 070

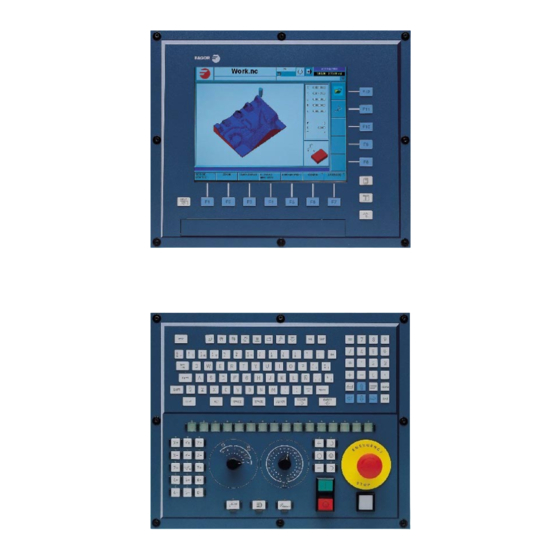

- Page 1 CNC8070...

- Page 3 RROR SOLUTIONS Unauthorized copying or distributing of this software is prohibited. All rights reserved. No part of this documentation may be transmitted, transcribed, stored in a backup device or translated into another language without Fagor Automation’s consent. ® ® Microsoft and Windows are registered trademarks of Microsoft Corporation, U.S.A.

-

Page 5: Table Of Contents

INDEX ERRORS 0000-0999 ..................1 ERRORS 1000-1999 ..................9 ERRORS 2000-2999 ..................79 ERRORS 3000-3999 ..................85 ERRORS 4000-4999 ..................93 ERRORS 5000-5999 ..................97 ERRORS 6000-6999 ..................99 ERRORS 7000-7999 ................105 ERRORS 8000-8999 ................111 TOOL AND TOOL MAGAZINE TABLE ...........121 MESSAGES OF THE PROFILE EDITOR ..........125 CNC8070 RROR SOLUTIONS INDEX... -

Page 7: Errors 0000-0999

ERRORS 0000-0999 0001 'SYSTEM ERROR' DETECTION During execution. CAUSE Software or hardware error that cause corrupt data and/or incoherent results. SOLUTION This type of errors usually force the CNC output. Contact your supplier. 0002 'SYSTEM WARNING' DETECTION During execution. CAUSE Warning of internal situations that could become system errors. - Page 8 0040 'M before-before or Before-After with subroutine does not admit movements in the block' DETECTION Machine parameter validation. CAUSE An M function with associated subroutine cannot be Before-Before or Before-After. The subroutine associated with an M function is always executed at the end of the block, after the rest of the block.

- Page 9 0049 ''A master axis cannot be a slave and vice versa' DETECTION Machine parameter validation. CAUSE If an axis is set as slave in another Gantry pair, cannot be the master of another pair. An axis already set as master cannot be the slave in another pair either. SOLUTION Check the Gantry axes table.

- Page 10 0058 'The CNC must be restarted too assume the changes in the HMI table,' DETECTION Machine parameter validation. CAUSE The CNC must be restarted in order to assume the changes made to the HMI table. SOLUTION Restart the CNC. 0059 'The CNC must be restarted too assume the changes in the tool magazine table,' DETECTION Machine parameter validation.

- Page 11 0069 'Gantry Axes: The slave cannot have DECINPUT (Home switch) if the master does not have one' DETECTION Machine parameter validation. CAUSE An axis of a Gantry pair cannot be homed with a home switch (DECINPUT = TRUE). SOLUTION DECINPUT = FALSE. 0070 'Gantry Axes: LIMIT+ and LIMIT- must be the same for the master and for the slave'...

- Page 12 The maximum number of SERCOS variables (100) has been exceeded. SOLUTION Decrease the number of variables. Errors 0000-0999 0088 'Trace of internal variables activated' DETECTION Machine parameter validation. CAUSE A trace of an internal variable is being executed. SOLUTION Contact Fagor. Page 6 of 128...

- Page 13 0089 'It starts up with a single channel due to errors detected in machine parameters.' DETECTION Machine parameter validation. CAUSE Errors or warnings have come up while validating machine parameters related to the axes or spindles of a channel. For example, a channel has an axis (CHAXISNAME) associated to it, but it is not on the list of the system axes (AXISNAME).

- Page 14 0105 'Parameters cannot be validated while executing a program' DETECTION During execution. CAUSE An attempt has been made to validate a machine parameter table while the program is in execution or interrupted. SOLUTION Finish or abort the program in order to be able to validate the machine parameter table.

-

Page 15: Errors 1000-1999

ERRORS 1000-1999 1000 'The function of instruction requires programming the axes' DETECTION During execution. CAUSE The axes affected by the programmed instruction or G function have not been programmed. SOLUTION Check the program. 1004 'Zero spindle speed' DETECTION During execution. CAUSE Being function G63 active, a zero spindle speed has been programmed. - Page 16 1010 'Program G4 K' DETECTION During execution. CAUSE The function has not been programmed correctly. SOLUTION There are two ways to program the dwell with G4: • G4 <time> • G4 K<time> . In both cases, the dwell must be programmed after G4. The second case does not allow "="...

- Page 17 1019 'No measurement has been taken on the requested axis (axes)' DETECTION During execution. CAUSE Function G101is being used to include the measurement offset on an axis for which: • No previous measurement has been taken (G100). • The measurement taken (G100) has been canceled (G102). SOLUTION Take a measurement with the axis on which to apply function G101.

- Page 18 1028 'The difference between the programmed center and the calculated one is too large' DETECTION During execution. CAUSE In a circular interpolation with function 265 active, the difference between the initial radius and the final one exceeds the values of machine parameters CIRINERR and CIRINFACT.

-

Page 19: Main Three Axes Of The Configuration

1040 'Home search not allowed on an axis in G201' DETECTION During execution. CAUSE An axis cannot be homed if it is in additive manual mode (G201). SOLUTION Use function G202 to cancel the additive manual mode of the axis in order to home it. - Page 20 1050 'Considering the tool offsets, it exceeds the data range' DETECTION During execution. CAUSE The tool dimensions exceed the maximum values. SOLUTION Modify the tool dimensions. 1052 'Values resulting from the measurement out of range' DETECTION During execution. CAUSE When taking a measurement with function G100, the obtained value is too large either for the coordinate where it probed, either for the offset obtained in that probing move.

- Page 21 1063 'Incompatible G functions (G108/G109/G193)' DETECTION During execution. CAUSE Two or more G functions of the same group cannot be programmed in the same block. SOLUTION Program them in different blocks. 1064 'Incompatible G functions (G196/G197)' DETECTION During execution. CAUSE Two or more G functions of the same group cannot be programmed in the same block.

- Page 22 1075 'Incompatible G functions (G96/G97/G192)' DETECTION During execution. CAUSE Two or more G functions of the same group cannot be programmed in the same block. SOLUTION Program them in different blocks. 1077 'Incompatible G functions (G115/G116/G117)' DETECTION During execution. CAUSE Two or more G functions of the same group cannot be programmed in the same block.

- Page 23 1090 'Nonexistent H function' DETECTION During execution. CAUSE The programmed H function does not exist. SOLUTION The maximum H function number is 65534. 1091 'T function programmed twice' DETECTION During execution. CAUSE More than one T function have been programmed in the same block. SOLUTION Program them in different blocks.

- Page 24 1101 '#SET IPOPOS instruction programmed wrong' DETECTION During execution. CAUSE The possible causes are: • The syntax of the instruction is wrong. • Only the block number of a label may be programmed in the same block as the instruction. SOLUTION In the first case, refer to the programming manual.

- Page 25 1109 'Wrong axis index' DETECTION During execution. CAUSE In functions G20 and G74, an index must be programmed with the axis name. That index is wrong. SOLUTION The axis index must be greater than 0 and must not exceed the maximum number of axes of the system or channel.

- Page 26 1119 'The $SWITCH <expression> instruction must be programmed alone in the block' DETECTION During execution. CAUSE Control instructions must be programmed alone in the block. SOLUTION Check the program. 1120 '$CASE not expected' DETECTION During execution. CAUSE The $CASE instruction has been programmed in a block, but no $SWITCH has been previously programmed.

- Page 27 1130 'The $ENDFOR instruction must be programmed alone in the block' DETECTION During execution. CAUSE Control instructions must be programmed alone in the block. SOLUTION Check the program. 1131 'The $WHILE <condition> instruction must be programmed alone in the block' DETECTION During execution.

- Page 28 1141 'The $CONTINUE instruction must be programmed alone in the block' DETECTION During execution. CAUSE Control instructions must be programmed alone in the block. SOLUTION Check the program. 1142 'The #TIME instruction must be programmed alone in the block' DETECTION During execution.

- Page 29 1154 'File name too long' DETECTION During execution. CAUSE The maximum number of characters allowed for the name of a program or subroutine has been exceeded. • The name of a program or subroutine may have a maximum of 63 characters. •...

- Page 30 1162 'M17/M29/#RET not expected' DETECTION During execution. CAUSE M17/M29/#RET has been detected as end of program. SOLUTION Program M30/M02 as the end of the main program. If the error persists, check that all the local subroutines (%L) and global ones end with M17/M29/#RET.

- Page 31 1172 'Instruction not allowed while tool radius compensation is active' DETECTION During execution. CAUSE An attempt has been made to activate a function that is incompatible with tool radius compensation. SOLUTION Cancel tool radius compensation to be able to activate the function. 1173 'The #UNLINK instruction must be programmed alone in the block' DETECTION...

- Page 32 1181 '#LINK: An axis active in G201 cannot be defined as slave' DETECTION During execution. CAUSE An attempt has been made to define as slave of a coupling an axis that is in additive manual mode with function G201. SOLUTION If the coupling is desired, the additive manual mode of the axis may be canceled with function G202.

- Page 33 1191 '#INCJOG: Negative or zero incremental jog distances are not allowed' DETECTION During execution. CAUSE A negative or zero value has been programmed for incremental jog distance. SOLUTION The value of the incremental movement of the axis in each position of the switch must be a positive value and other than zero.

- Page 34 1203 'The #SET IPOPOS instruction must be programmed alone in the block' DETECTION During execution. CAUSE Only the block number of a label may be programmed in the same block as a "#" instruction. SOLUTION Check the program. 1204 'Nonexistent instruction or programmed wrong' DETECTION During execution.

- Page 35 1215 'The #CALL AX/#SET AX instruction must be programmed alone in the block' DETECTION During execution. CAUSE Only the block number of a label may be programmed in the same block as a "#" instruction. SOLUTION Check the program. 1216 '#CALL AX/#CAX: axis name being used' DETECTION During execution.

- Page 36 1225 'Division by zero' DETECTION During execution. CAUSE An operation has been programmed whose execution involves dividing by zero. SOLUTION It is only possible to divide by numbers other than zero. When working with parameters, in the program history, that parameter may have taken the value of zero. Verify that the parameter does not reach the operation with that value (0).

- Page 37 1244 'Face axis close to the center: the spindle speed in G96 has been limited' DETECTION During execution. CAUSE While working at Constant Surface Speed, the spindle speed has been limited. The limitation is due to the proximity of the face axis to the rotating center. SOLUTION Do not bring the axis so close to the center, increase the maximum speed allowed or accept this limitation.

- Page 38 1256 'Acceleration percentage out of range' DETECTION During execution. CAUSE The acceleration percentage programmed with function G130 is too high. SOLUTION The maximum value allowed for the acceleration percentage is 2147483646. 1257 'The leadscrew pitch has been programmed twice' DETECTION During execution.

- Page 39 1265 'Programming not allowed while RTCP/TLC is active' DETECTION During execution. CAUSE An attempt has been made to execute one of the following functions while RTCP or TLC is active. • Home search (G74). • Modify software limits (G198 - G199). •...

- Page 40 1278 'G131/G133: wrong value' DETECTION During execution. CAUSE The possible causes are: • Function G131 has been used to program the wrong value for the percentage of acceleration to be applied to the axes. • Function G133 has been used to program the wrong value for the percentage of jerek to be applied to the axes.

- Page 41 1288 'Too many parameters programmed in the instruction' DETECTION During execution. CAUSE The instruction has not been programmed correctly. SOLUTION Check the syntax of the instruction in the programming manual. 1290 'I, J, K coordinates programmed wrong' DETECTION During execution. CAUSE The probable causes are: •...

- Page 42 1305 'Programming not allowed while #MCS is active' DETECTION During execution. CAUSE One of the following functions has been programmed while #MCS is active: • Zero offsets (G54-G59, G159, G92, G158, G101, G102, G53) on/off • Fixtures on/off ("V.G.FIX" variable). •...

- Page 43 1315 '#CS ON/#ACS ON: undefined system' DETECTION During execution. CAUSE The #CS ON/#ACS ON instruction has been programmed without parameters, but no transformation has been defined or activated previously. SOLUTION When programming the #CS ON/#ACS ON instruction without parameters, the CNC tries to activate the transformation stored last.

- Page 44 1325 'Block number defined several times' DETECTION During execution. CAUSE The same block number "N" has been defined several times in different points of the program. SOLUTION Do not repeat the block number. 1326 'Wrong value to be assigned to a variable' DETECTION During execution.

- Page 45 1337 'No CAXIS has been defined' DETECTION During execution. CAUSE None of the axes programmed in the #FACE/#CYL instruction is a C axis. SOLUTION One of the two axes programmed in the instruction must be a C axis. In other words, have machine parameter CAXIS = Yes.

- Page 46 1349 'Negative axis coordinate when activating #FACE' DETECTION During execution. CAUSE The linear axis that is part of the face C axis transformation is positioned in the negative portion with respect to the rotating axis. SOLUTION The possible solutions are: •...

- Page 47 1360 'G33/G63/G95/G96/G97 not allowed while the C axis is active' DETECTION During execution. CAUSE A G33/G63/G95/G96/G97 function has been programmed while the C axis was active. SOLUTION The C axis may be deactivated with the #CAX OFF instruction. 1363 'Wrong declaration of array variables' DETECTION During execution.

- Page 48 1376 'No default name has been defined for the C axis' DETECTION During execution. CAUSE The #CAX instruction has been programmed with no parameters, the name given to the master spindle of the channel to work as C axis is the one indicated by machine parameter CAXIS.

- Page 49 1385 'D and the tool length cannot be modified in the same block' DETECTION During execution. CAUSE An attempt has been made to write the "V.G.TOL" variable in the same block where a tool change or tool offset change is programmed. SOLUTION Programming in different lines.

- Page 50 1394 'The subroutine associated with the G function does not exist' DETECTION During execution. CAUSE The possible causes are: • Function G74 has been programmed alone in the block, but it has no subroutine associated with machine parameter REFPSUB. • A function G180-G189 has been programmed alone in the block, but it has no subroutine associated with machine parameter OEMSUB.

- Page 51 1403 '#LINK: a coupling (slaving) cannot be defined with a Hirth axis deactivated' DETECTION During execution. CAUSE An attempt has been made to activate a coupling between Hirth axis while one of them is deactivated. SOLUTION Activate both Hirth axes to be able to activate the coupling. 1404 'The gear associated with the programmed M does not exist' DETECTION...

- Page 52 1413 'The spindle positioning speed cannot be zero' DETECTION During execution. CAUSE The programmed positioning speed for function M19 is zero. SOLUTION Program a positioning speed greater than zero using the syntax: "S.POS =". 1414 '#PARK: this instruction only admits one axis' DETECTION During execution.

- Page 53 1425 'Block skip is only admitted at the beginning of the line' DETECTION During execution. CAUSE The "/" character is only admitted at the beginning of the program line. SOLUTION Check the program. 1426 'The pocket was resolved with a different tool radius' DETECTION Check the program.

- Page 54 1434 'An associated slave axis could not be included in the configuration' DETECTION During execution. CAUSE The instruction #CALL AX or #SET AX has been used to include in the system configuration the master axis of an active coupling (#LINK) or that of a Gantry pair. When including the master axis, the slave axis is also included automatically and it can never occupy one of the main three positions of the channel.

- Page 55 1444 'The main axes of the transformation must be linear' DETECTION During execution. CAUSE One of the main three axes involved in the programmed transformation or kinematics is neither a linear axis nor a C axis. SOLUTION The main three axes of the transformation or kinematics must be linear (machine parameter AXISTYPE) or a C axis (machine parameter CAXIS).

- Page 56 1453 'Axis name too long' DETECTION During execution. CAUSE The axis name has more than two characters. SOLUTION The valid axis names are: X, X1 … X9, Y, Y1, … Y9, …, Z, Z1, … Z9 A, A1 … A9, B, B1, … B9, …, C, C1, … C9 U, U1 …...

- Page 57 1464 'Programmed rotary axis out of the range of the module' DETECTION During execution. CAUSE The absolute coordinate (G90) programmed for the MODULE type rotary axis is wrong. SOLUTION The coordinate programmed for the axis must be between the limits set by its machine parameters MODUPLIM and MODLOWLIM.

- Page 58 1473 '#POLY cannot be programmed while pattern rotation is active' DETECTION During execution. CAUSE The #POLY instruction has been programmed while the coordinate system rotation (G73) was active. SOLUTION Check the program. 1475 'Radius programmed twice' DETECTION During execution. CAUSE The radius "R"...

- Page 59 1484 'Signal number out of range' DETECTION During execution. CAUSE The signal number programmed in the instruction #WAIT, #MEET or #SIGNAL is wrong. SOLUTION The signal programmed in the instructions #WAIT, #MEET and #SIGNAL must be between 1 and 10. 1485 '#WAIT/#MEET not effective' DETECTION...

- Page 60 1493 '#SPLINE ON, G41/G42 and G136 cannot be programmed at the same time' DETECTION During execution. CAUSE An attempt has been made to activate functions #SPLINE ON, G41, G42 and G136 at the same time at the CNC. SOLUTION Cancel some of these functions. 1494 'Wrong index' DETECTION...

- Page 61 1503 'The variable requires programming an axis' DETECTION During execution. CAUSE An axis variable has been programmed, but no axis has been indicated for which to read or write a variable. SOLUTION Refer to the programming manual for control variables. 1504 'The variable does not allow programming an array index' DETECTION...

- Page 62 1510 'The axis does not exist or is not available in the channel' DETECTION During execution. CAUSE The possible causes are: • An attempt has been made to move an axis that does not exist or is not available in the channel. •...

- Page 63 1518 'NR requires programming a movement in the block' DETECTION During execution. CAUSE The repetition (NR) of a block has been programmed that does not involve a movement. SOLUTION Programming block repetition with NR is only valid with blocks that involve a movement.

- Page 64 1527 'Wrong identifier after %' DETECTION During execution. CAUSE In the instruction #MSG, #ERROR or #WARNING , an invalid identifier has been programmed after "%". SOLUTION The valid identifiers are: • To display a number: %D or %d. • To display the "%" character: %%. 1529 'Expecting list of identifiers or "]"...

- Page 65 1535 'Program: #SETSP [sp1, sp2, ..]' DETECTION During execution. CAUSE The possible causes are: • The syntax of the instruction is wrong. • Only the block number of a label may be programmed in the same block as the instruction. SOLUTION In the first case, refer to the programming manual.

- Page 66 1545 'Spindle gear change is not possible while G63 or #CAX is active' DETECTION During execution. CAUSE The spindle gear change is not possible while tapping G63 is active or while working as C axis. SOLUTION Cancel G63 or #CAX, change the gear and activate functions G63 or #CAX again if so wished.

- Page 67 1553 'Too many user variables' DETECTION During execution. CAUSE The maximum number of user variables (V.P, V.S) that can be defined has been exceeded. SOLUTION The maximum number of user variables that can be defined is 20. 1554 'The PLC has not recognized the START in a #EXEC instruction' DETECTION Execution of #EXEC instruction.

- Page 68 1709 'DRILLING 1: P = 0' DETECTION Executing drilling cycle 1. CAUSE P (depth) programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0. 1710 'DRILLING 2: F = 0' DETECTION Executing drilling cycle 2. CAUSE F programmed in the cycle equal to 0.

- Page 69 1721 'REAMING: T = 0' DETECTION Executing the reaming cycle. CAUSE No tool T has been programmed in the cycle. SOLUTION Assign a tool T. 1722 'REAMING: P = 0' DETECTION Executing the reaming cycle. CAUSE P (depth) programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0.

- Page 70 1733 'BORING 2: T = 0' DETECTION Executing boring cycle 1. CAUSE No tool T has been programmed in the cycle. SOLUTION Assign a tool T. 1734 'BORING 2: P = 0' DETECTION Executing boring cycle 1. CAUSE P (depth) programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0.

- Page 71 1744 'PRE-EMPTIED POCKET: T = 0' DETECTION Executing pre-emptied pocket cycle. CAUSE No tool T has been programmed in the cycle. SOLUTION Assign a roughing or finishing tool T. 1745 'PRE-EMPTIED POCKET: P = 0' DETECTION Executing pre-emptied pocket cycle. CAUSE P (pocket depth) programmed in the cycle equal to 0.

- Page 72 1755 'RECTANGULAR BOSS :Finishing tool diameter smaller than delta' DETECTION Executing rectangular boss cycle. CAUSE The diameter of the finishing tool is smaller than the finishing stock in the main plane (delta). SOLUTION Choose a tool of a larger diameter to make the rectangular boss. 1756 'CIRCULAR BOSS :F = 0' DETECTION...

- Page 73 1766 'SURFACE MILLING: P = 0' DETECTION Executing the surface milling cycle. CAUSE P (surface milling depth) programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0. 1767 'SURFACE MILLING: L = 0 and H = 0' DETECTION Executing the surface milling cycle.

- Page 74 1777 'PROFILE: P = 0' DETECTION Executing the profiling cycle. CAUSE P (profile depth) programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0. 1778 'PROFILE: (FINISHING): Tool's cutting length < P' DETECTION Executing the profiling cycle. CAUSE The cutting length of the finishing tool defined in the tool table is smaller than the profile depth (P) defined in the cycle.

- Page 75 1788 'CIRCULAR POCKET: S = 0' DETECTION Executing circular pocket cycle. CAUSE Roughing or finishing S programmed in the cycle equal to 0. SOLUTION Assign a value greater than 0. 1789 'CIRCULAR POCKET: T = 0' DETECTION Executing circular pocket cycle. CAUSE No tool T has been programmed in the cycle.

- Page 76 1807 'G87: Tool diameter = 0' DETECTION Executing a G87 pocket. CAUSE Tool with radius 0. SOLUTION Modify the value of the tool radius in the tool table. 1808 'G87: Tool missing' DETECTION Executing a G87 pocket. CAUSE Tool missing at the spindle. SOLUTION Load a tool in the spindle before calling the cycle.

- Page 77 1818 'J = 0' DETECTION Executing a multiple machining cycle (G160-G165). CAUSE The J parameter (ordinate pass between machining operations) has been programmed with a 0 value in a multiple machining cycle. SOLUTION Assign a correct value to the cycle parameter. 1819 'K = 0' DETECTION...

- Page 78 1828 '360 must be multiple of parameter I' DETECTION Executing a multiple machining cycle in circle (G163). CAUSE The angular pass (I) must be multiple of 360º. SOLUTION Assign a correct value to the cycle parameter. 1829 'I = 0' DETECTION Executing a multiple machining canned cycle (G160-G165).

- Page 79 1839 'Pocket with islands: Wrong intersection of XY profiles' DETECTION Execution of a 2D or 3D pocket cycle with islands. CAUSE Two XY profiles have at least some straight or arc section in common. SOLUTION Check that the intersections of all the XY profiles only take place on points, never on sections.

- Page 80 1849 'RECTANGULAR POCKET: Finishing stock DELTA greater than the pocket' DETECTION Executing a rectangular pocket. CAUSE The defined pocket cannot be executed because half the shorter length of the pocket minus the tool radius is smaller than the finishing stock in the work plane (DELTA). SOLUTION Decrease the value of DELTA.

- Page 81 1860 'Program K = 0/1/2' DETECTION Executing the #PROBE 3 cycle (surface measuring cycle). CAUSE Parameter K only admits the values 0, 1, 2. SOLUTION Parameter K defines the axis to be used to measure the surface. Assign to K one of the following values: •...

- Page 82 1870 'Pocket with islands: Wrong finishing S' DETECTION Execution of a 2D or 3D pocket cycle with islands. CAUSE The spindle speed (S) programmed for the finishing operation has a value of 0. SOLUTION Program S with a value other than 0. 1871 'Pocket with islands: Wrong roughing pass' DETECTION...

- Page 83 1880 'Pocket with islands: Semi-finishing T missing' DETECTION Execution of a 3D pocket cycle with islands. CAUSE The tool number (T) programmed in the semi-finishing operation does not exist in the tool table. SOLUTION Insert the tool in the table or program another tool number that is in the table. 1881 'Pocket with islands: Wrong semi-finishing F' DETECTION...

- Page 84 CNC8070 . 0402 RROR SOLUTIONS Errors 1000-1999 Page 78 of 128...

- Page 85 ERRORS 2000-2999 2000 'Tool radius greater than the arc radius' DETECTION During execution. CAUSE The tool radius is greater than the radius of the arc to be machined. SOLUTION Use a tool with a smaller radius. 2001 'Profile damaged by tool radius compensation' DETECTION During execution.

- Page 86 2007 'While G138 is active, G40 is not allowed after the first compensation block' DETECTION During execution. CAUSE Tool radius cancellation (G40) has been programmed while the first compensation block is being processed in a direct selection (G138). SOLUTION Using direct compensation selection (G138) requires an additional block of motion in the plane in order to complete the beginning of the compensation and then be able to cancel it.

- Page 87 2101 'Negative software limit overrun in G5-G60' DETECTION During execution. CAUSE The path generated by the CNC to round the corner is out of the active travel limits. SOLUTION Program without G50 or G7 rounding . 2102 'Programming instruction #ROUNDPAR with parameter too small' DETECTION During execution.

- Page 88 2116 'Error when activating the spline' DETECTION During execution. CAUSE An attempt has been made to activate a spline mode without canceling the previous one. SOLUTION Before activating it, cancel the previous one. 2118 'SPLINE: wrong type of spline' DETECTION During execution.

- Page 89 'Internal error in C axis mode' DETECTION During execution. CAUSE C axis transformation not possible for the block. SOLUTION Eliminate the block that caused the error. Send the information to FAGOR. 2133 'Master axis missing' DETECTION During execution. CAUSE The master axis of the coupling is not available in the channel.

- Page 90 2141 'Circular path not allowed (less than 2 axes)' DETECTION During execution. CAUSE Not possible if there aren't at least two axes in the channel. SOLUTION Configure the channel with at least two axes to be able to work with circular interpolation.

- Page 91 ERRORS 3000-3999 3000 'An arc cannot be programmed with a slave axis' DETECTION During execution. CAUSE The possible causes are: 1. An attempt has been made to separately move an axis that is coupled to another axis. 2. An attempt has been made to separately move an axis that is associated as Gantry to another axis.

- Page 92 . 0402 DETECTION During execution. RROR SOLUTIONS CAUSE The coordinates of an axis do not match. SOLUTION Contact your Fagor supplier. 3023 'Axes missing in the new coordinate system' Errors 3000-3999 DETECTION During execution. CAUSE While defining the new coordinate system, one of the first three axes of the channel is not active.

- Page 93 DETECTION During execution. CAUSE The transformation from part coordinates to machine coordinates cannot be executed. SOLUTION Contact your Fagor supplier. 3029 'Error when calculating the direct RTCP transformation' DETECTION During execution. CAUSE The transformation from machine coordinates to part coordinates cannot be executed.

- Page 94 'Too many parameters pending to be reported' DETECTION During execution. CAUSE The system is overloaded. SOLUTION Close the Windows applications not related to the CNC. Contact Fagor. 3039 'The stop block has not been found in the block search' DETECTION While executing in dry run. CAUSE When executing the program in dry run, it does not go through the stop block.

- Page 95 'Jerk limit overshoot' DETECTION During execution. CAUSE Jerk overshoot on this path. SOLUTION Contact your Fagor supplier. 3506 'The Jerk limit will be exceeded' DETECTION During the execution of the command to analyze the frequencies. CAUSE The frequency is too high for the programmed amplitude.

- Page 96 3606 'The spindle positioning requires an absolute coordinate' DETECTION During execution. CAUSE After a spindle turn in open loop, the positioning must always be in absolute coordinates. SOLUTION Program the positioning in absolute coordinates. 3700 'Axis travel limit overrun' DETECTION During the movement of the axis.

- Page 97 3709 'Error when refreshing Analog Inputs' DETECTION When reading analog inputs. CAUSE Failure in the cyclic reading process for analog intputs. This could probably be due to problems in the COMPCI, CAN bus, analog input module, etc. SOLUTION Check the status of the CAN bus, analog input modules, connections, etc. 3710 'Position command values out of range' DETECTION...

- Page 98 3807 'Incremental jog index out of range (switch positions 1-5)' DETECTION During execution. CAUSE An attempt has been made to set via PLC an incremental jog position that is out of the permitted range. SOLUTION Check the writing of PLC.INCJOGIDX from the PLC. 3808 'The axis does not exist or is not available' DETECTION...

- Page 99 ERRORS 4000-4999 4000 'Error when initializing the Sercos ring' CAUSE Failed Sercos ring initializing process due to fiber optics connection problems, wrong CNC and drive parameter settings, problems on Sercos or drive boards, etc. Class Error when initializing the chip. The Sercos board is not detected or overflow at the DPRAM of the SERCON due to too many axes and data of the cyclic channel to be trasmitted.

- Page 100 Error when changing to Phase 3. Phase 4 command error. Error when changing to Phase 4. Error when reading Class Diagnostics 1. Default error. Error when reading Tncyc. Error when reading OpMode. Error when reading AxisType. Error when reading G00Feed. Error when reading Monit Window.

- Page 101 Wrong value 2+3 Other Sercos drive error codes. 5+0x10 Request of Abort/Suspend/Resume of a command that is not active. 7+0x7 Request to a busy service channel. 7+0x20 Wrong logic axis number. 8+0xFE0 Request to a busy service channel. SOLUTION Check the following: •...

- Page 102 4203 'Speed Enable (SPENA) missing' CAUSE While moving an axis, the SPENA signal (enable) of the PLC drops. SOLUTION Analyze the PLC maneuver to determine what causes the SPENA signal to drop. 4204 'Error when resetting the Sercos drive' CAUSE An error occurred when executing the command to reset the errors of a drive (ID 99).

- Page 103 ERRORS 5000-5999 5000 'PLC error: The timer does not exist' DETECTION PLC timer data reading processes. CAUSE Request to read a timer that does not exist. SOLUTION Valid timers: T1 - T256. 5001 'PLC error: The counter does not exist' DETECTION PLC counter data reading processes.

- Page 104 5009 'Syntax error when reading the variable from the PLC' DETECTION When executing CNCRD instructions. CAUSE The variable does not exist or it does not have reading permission. SOLUTION Check the syntax of the variable to be written. 5010 'Division by zero at the PLC' DETECTION When executing DVS/MDS instructions from the PLC program.

-

Page 105: Errors 6000-6999

ERRORS 6000-6999 6000 'Feedback alarm' DETECTION During execution. CAUSE Feedback error on analog axes. It is enabled by means of machine parameter FBACKAL. DIFFERENTIAL TTL: • One or more cables broken (A, B signals or their inverted signals). • Feedback input disconnected at the counter. DIFFERENTIAL SINUSOIDAL: •... - Page 106 6006 'One or several CAN nodes do not respond' CAUSE One or several remote nodes do not respond due to a reset, shortcircuit, poor performance, etc. SOLUTION See if all the modules are recognized in diagnosis mode. Contact our technical service department. 6007 'Watchdog in the COMPCI' CAUSE...

- Page 107 6013 'Timeout when initializing the CAN' DETECTION During startup. CAUSE Failed initialization of the BUS CAN due to BUS problems. Off/On sequence too fast. SOLUTION Make the following checks and take the following actions to assure the integrity of the BUS CAN: •...

- Page 108 6020 'CAN cycle overlap' CAUSE Failed reading of digital and analog inputs, counters and keyboard handwheels. A node did not send the message in time. SOLUTION Verify in diagnosis mode that all the modules and the CAN error counter are recognized.

- Page 109 6029 'Position increment limit exceeded at the CNC' CAUSE Excessive position increment of an analog axis. Hardware failure at the counter node, Accesses to the COMPCI (connections), etc. SOLUTION Contact our technical service department. 6030 'Position increment limit exceeded at the CAN counter node' CAUSE Excessive position increment of an analog axis.

- Page 110 CNC8070 . 0402 RROR SOLUTIONS Errors 6000-6999 Page 104 of 128...

-

Page 111: Errors 7000-7999

ERRORS 7000-7999 7001 'Two consecutive T's in cyclic magazine (M6 required)' DETECTION During execution. CAUSE Cyclic magazine and two consecutive T's have been programmed. SOLUTION Program an M6 after each T. 7002 'The tool is not in the magazine and ground tools are not allowed' DETECTION During execution. - Page 112 7009 'In load mode: M6 without T' DETECTION During execution. CAUSE In load mode, an M6 has been programmed without the corresponding T. SOLUTION First, program a T with the tool to be loaded. 7010 'In load mode: T with two M6' DETECTION During execution.

- Page 113 7020 'In Setting: D required' DETECTION During execution. CAUSE In Setting mode, the edge of the tool must be specified. SOLUTION Program the edge. 7021 'In Setting: D alone not allowed' DETECTION During execution. CAUSE A "D" cannot be programmed alone in unload mode. SOLUTION It cannot be programmed like this.

- Page 114 7030 M6 without T' DETECTION During execution. CAUSE An M6 has been detected without its corresponding T. If parameter "M6 ALONE = NO", an error is issued. SOLUTION M6 cannot be programmed without the corresponding T. 7031 'T with two M6' DETECTION During execution.

- Page 115 7041 'No tool is active' DETECTION During execution. CAUSE An edge has been programmed, but there is no active tool in the spindle. SOLUTION Place a tool in the spindle. 7042 'POS has been programmed and the magazine is not in LOAD mode' DETECTION During execution.

- Page 116 CNC8070 . 0402 RROR SOLUTIONS Errors 7000-7999 Page 110 of 128...

-

Page 117: Errors 8000-8999

ERRORS 8000-8999 8200 'Lexer fault when recognizing integers' DETECTION During editing and execution in MDI. CAUSE An error has occurred when converting a string of characters into a numerical value. It usually occurs because some value programmed in the instruction or variable is wrong. - Page 118 8209 'Wrong active axis' DETECTION During editing. CAUSE The axis name has been programmed with the wrong wild character. SOLUTION The names of the axis with wild character are @1 through @5. 8210 'Integer limits exceeded' DETECTION During editing. CAUSE The programmed integer value is too high.

- Page 119 8225 'G function out of range' DETECTION During editing and execution in MDI. CAUSE The programmed G function does not exist. SOLUTION Check the existing M functions in the programming manual. 8226 'H function out of range' DETECTION During editing. CAUSE The programmed H function does not exist.

- Page 120 8239 '"Y" programmed twice' DETECTION During editing. CAUSE The Y axis has been programmed more than once in the block. SOLUTION Program the Y axis only once in the block. 8240 '"Z" programmed twice' DETECTION During editing. CAUSE The Z axis has been programmed more than once in the block. SOLUTION Program the Z axis only once in the block.

- Page 121 8254 'Too many axes in G20' DETECTION During editing. CAUSE Some of the parameters programmed for G20 are not allowed. SOLUTION Check the G20 programming syntax. 8256 'Nonexistent interpolator cycle instruction' DETECTION During editing and execution in MDI. CAUSE The programmed instruction does not exist. SOLUTION Refer to the programming manual.

- Page 122 8279 'Mirror image repeated' DETECTION During editing. CAUSE The possible causes are: 1. Function G11, G12 or G13 has been programmed more than one in the same block. 2. Functions G10 and G11, G12 or G13 have been programmed in the same block. 3.

- Page 123 8297 'Parameter repeated' DETECTION During editing. CAUSE The possible causes are: 1. The parameter CONTERROR has been programmed more than once in the #HSC instruction. 2. In the subroutine calling instruction #PCALL, #MCALL or G function with associated subroutine, some parameter has been written more than once. 3.

- Page 124 8309 'Too many axes have been programmed' DETECTION During editing. CAUSE Too many axes have been programmed in the #POLY instruction. SOLUTION The maximum number of axes that can be programmed is 3. 8310 'Required parameter missing' DETECTION During editing. CAUSE The possible causes are: 1.

- Page 125 8318 'Only one active axis 1 allowed per block' DETECTION During editing. CAUSE The @1 axis has been programmed more than once in the block. SOLUTION Program @1 only once in the block. 8319 'Only one active axis 2 allowed per block' DETECTION During editing.

- Page 126 8402 'Wrong tool magazine number' DETECTION During editing. CAUSE The magazine number for which the variable of the tool manager is requested is wrong. SOLUTION The magazine number must be between 1 and 4. If the magazine number is not indicated, it will assume the first one.

-

Page 127: Tool And Tool Magazine Table

TOOL AND TOOL MAGAZINE TABLE ‘The tool cannot be loaded into position %1’ DETECTION During the manual loading of a tool from this dialog box, from the magazine list or loading the magazine table. CAUSE The tool does not fit in that magazine position, it is already in the magazine or it is not defined in the tool table. - Page 128 ‘Error when renaming the tool’ DETECTION When trying to change the tool name. CAUSE It cannot create the tool in the database (bd8070.mdb). The data base may be being used by another application or it may not have write permission. SOLUTION The data base must have write permission.

- Page 129 ‘Error opening file %1’ DETECTION When loading, saving or printing the tool table or magazine table. CAUSE The possible causes are: 1. When loading a table. The data file does not exist, it does not have read permission or is being used by another application. 2.

- Page 130 CNC8070 . 0402 RROR SOLUTIONS Tool and tool magazine table Page 124 of 128...

-

Page 131: Messages Of The Profile Editor

MESSAGES OF THE PROFILE EDITOR ‘Unresolved profile’ CAUSE The profile to be saved is not resolved completely either when “FINISHING” or when “SAVING AND CONTINUING” SOLUTION Resolve the profile to be saved. Only resolved profiled may be saved. ‘Insufficient memory’ CAUSE There isn’t enough system memory to go on with the profile editor. - Page 132 ‘Error in the axis of the plane’ CAUSE Some axis of the plane is wrong. The same axis has been placed in the “CONFIGURATION” of the plane or some axis of the selected profile is not defined at the CNC. SOLUTION The plane must be formed by two different axes.

- Page 133 CNC8070 . 0402 RROR SOLUTIONS Page 127 of 128...

- Page 134 CNC8070 . 0402 RROR SOLUTIONS Page 128 of 128...

Need help?

Do you have a question about the CNC8 070 and is the answer not in the manual?

Questions and answers

Fagor 0914 error