Table of Contents

Advertisement

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

NOTICE: DO NOT discard this manual!

Models:

This appliance may be installed as an OEM

installation in manufactured home (USA

only) or mobile home and must be installed

in accordance with the manufacturer's

instructions and the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 in the United States, or the

Standard for Installation in Mobile Homes,

CAN/CSA Z240 MH Series, in Canada.

This appliance is only for use with the type(s)

of gas indicated on the rating plate. This

appliance is not convertible for use with other

gases, unless a certified kit is used.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas fitter.

See Table of Contents for location of additional Commonwealth

of Massachusetts requirements.

Installation Manual

Installation and Appliance Setup

Heat & Glo • 6000CLX-IFT, 8000CLX-IFT Installation Manual • 2506-980 Rev. B • 3/18

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

• DO NOT store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

• What to do if you smell gas

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch. DO

NOT use any phone in your building.

- Leave the building immediately.

- Immediately call your gas supplier from

a neighbor's phone. Follow the gas sup-

plier's instructions.

- If you cannot reach your gas supplier, call

the fire department.

• Installation and service must be performed

by a qualified installer, service agency, or the

gas supplier.

DANGER

DO NOT TOUCH GLASS

NEVER ALLOW CHILDREN

A barrier designed to reduce the risk of

burns from the hot viewing glass is provided

with this appliance and shall be installed for

the protection of children and other at-risk

individuals.

HOT GLASS WILL

CAUSE BURNS.

UNTIL COOLED.

TO TOUCH GLASS.

1

Advertisement

Table of Contents

Summary of Contents for Heat & Glo 6000CLX-IFT-S

- Page 1 Installation Manual Installation and Appliance Setup INSTALLER: Leave this manual with party responsible for use and operation. OWNER: Retain this manual for future reference. NOTICE: DO NOT discard this manual! WARNING: FIRE OR EXPLOSION HAZARD Failure to follow safety warnings exactly could result in serious injury, death, or Models: property damage.

-

Page 2: Table Of Contents

Safety Alert Key: • DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury. • WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury. • CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. •... -

Page 3: Installation Standard Work Checklist

Installation Standard Work Checklist ATTENTION INSTALLER: Follow this Standard Work Checklist This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in this installation manual. Customer: Date Installed: Lot/Address: Location of Fireplace: Installer: Model (circle one): 6000CLX-IFT 8000CLX-IFT... -

Page 4: Product Specific And Important Safety Information

D. High Altitude Installations NOTICE: If the heating value of the gas has been reduced, these rules do not apply. Check with your local gas utility MODELS: 6000CLX-IFT-S, 6000CLX-IFTLP-S, or authorities having jurisdiction. 6000CLX-IFT-G, 6000CLX-IFTLP-G, When installing above 2000 feet elevation:... -

Page 5: Requirements For The Commonwealth Of Massachusetts

Inspection Note: The following requirements reference various The state or local gas inspector of the side wall horizon- Massachusetts and national codes not contained in this tally vented gas fueled equipment shall not approve the document. installation unless, upon inspection, the inspector ob- serves carbon monoxide detectors and signage installed H. -

Page 6: Getting Started

Getting Started A. Design and Installation Considerations B. Good Faith Wall Surface Heat & Glo direct vent gas appliances are designed to FIREPLACE operate with all combustion air siphoned from outside of OPENING TO CEILING the building and all exhaust gases expelled to the outside. 127°F No additional outside air source is required. -

Page 7: Inspect Appliance And Components

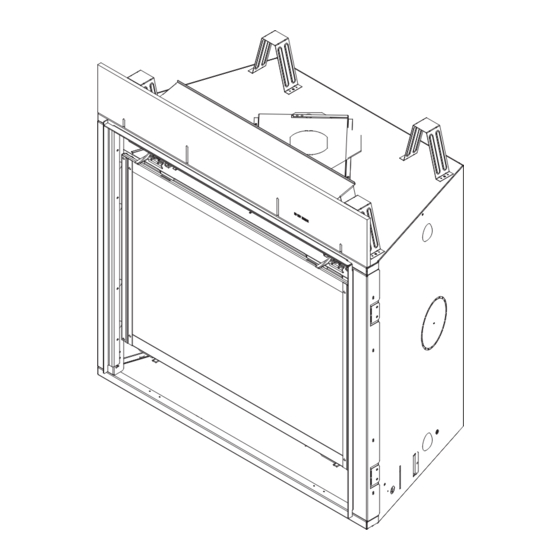

D. Inspect Appliance and Components • Carefully remove the appliance and components from the packaging. • The vent system components and decorative doors and fronts may be shipped in separate packages. • If packaged separately, the log set and appliance grate must be installed. -

Page 8: Framing And Clearances

Framing and Clearances A. Appliance/Decorative Front Dimension Diagrams Dimensions are actual appliance dimensions. Use for reference only. For framing dimensions and clearances refer to Section 5. TOP VIEW HEAT MANAGEMENT SYSTEMS ACCESS ELECTRICAL ACCESS (LEFT & RIGHT SIDES) GAS LINE (C) L ACCESS LEFT SIDE... - Page 9 TOP VIEW ELECTRICAL ACCESS HEAT MANAGEMENT SYSTEMS ACCESS (LEFT & RIGHT SIDES) (C) L GAS LINE ACCESS LEFT SIDE FRONT VIEW RIGHT VIEW Appliance Dimensions Table Location Inches Millimeters Location Inches Millimeters 1219 11-11/16 43-1/8 1096 35-1/2 35-1/2 17-3/4 36-5/8 8-1/2 2-3/8 2-7/8...

- Page 10 FOLIO DECORATIVE FRONTS 32-7/16 23-1/8 35-13/16 1-1/2 8-1/4 32-1/8 33-9/16 6000 FOL-36 39-7/16 25-5/16 42-13/16 1-1/2 8-1/4 34-1/8 35-11/16 8000 FOL-42 1002 1087 ARCADIA DECORATIVE FRONTS 32-7/16 20-1/2 37-1/4 1-1/4 7-11/16 32-7/8 34-1/8 6000 ARC-36 39-7/16 22-7/16 44-1/4 1-1/4 7-11/16 34-13/16 36-1/16 8000...

- Page 11 HALSTON DECORATIVE FRONTS 32-7/16 21-1/4 37-1/4 1-1/4 7-1/4 32-7/8 34-1/8 6000 HAL-36 39-7/16 23-1/8 44-1/4 1-1/4 7-1/4 34-13/16 36-1/16 8000 HAL-42 1002 1124 CHATEAU DECORATIVE FRONTS 20-1/2 32-7/16 37-1/4 1-1/2 7-7/8 32-7/8 34-1/8 6000 CHA-36 22-7/16 39-7/16 44-1/8 1-1/4 7-7/8 34-13/16 36-1/16 8000...

- Page 12 CHATEAU FORGE DECORATIVE FRONTS 32-1/4 20-3/4 1-3/16 7-9/16 32-7/8 34-1/8 6000 CHAF-36 39-1/4 22-5/8 1-1/4 7-5/8 34-3/4 8000 CHAF-42 1118 GALLERIA DECORATIVE FRONTS 31-9/16 20-7/8 37-1/8 1-1/4 7-1/2 32-7/8 34-1/16 6000 GALLERIA-6 38-9/16 22-3/4 44-1/16 1-1/4 7-1/2 34-3/4 8000 GALLERIA-8 1121 Figure 3.5 Decorative Front Dimensions - Chateau Forge and Galleria Heat &...

- Page 13 CLEAN FACE DECORATIVE FRONTS 31-9/16 22-1/8 35-13/16 4-5/8 6-15/16 26-3/4 31-3/8 6000 CF-36 38-1/2 24-1/16 42-3/4 4-5/8 6-15/16 28-11/16 33-5/16 8000 CF-42 1086 IRON AGE DECORATIVE FRONTS 27-3/8 23-1/8 37-3/16 1-1/4 6-3/4 32-7/8 34-1/8 6000 FSI-36 34-3/8 25-3/16 44-3/16 1-1/4 6-3/4 34-13/16 36-1/16...

-

Page 14: Clearances To Combustibles

B. Clearances to Combustibles NOTICE: Illustrations reflect typical installations and are FOR DESIGN PURPOSES ONLY. Illustrations/diagrams When selecting a location for the appliance it is important are not drawn to scale. Actual installation may vary due to to consider the required clearances to walls (see Figure individual design preference. - Page 15 COMBUSTIBLE FLOORING MAY BE INSTALLED NEXT TO THE FRONT OF THE APPLIANCE. MINIMUM FRAMING DIMENSIONS Rough Rough Rough Rough Clearance to Ceiling Models Combustible Combustible Behind Sides of Front of Opening Opening Opening Opening (Measured from top of Floor Flooring Appliance Appliance Appliance...

-

Page 16: Constructing The Appliance Chase

C. Constructing the Appliance Chase A chase is a vertical box-like structure built to enclose the gas appliance and/or its vent system. In cooler climates the vent should be enclosed inside the chase. NOTICE: Treatment of ceiling firestops and wall shield firestops and construction of the chase may vary with the type of building. -

Page 17: Termination Location And Vent Information

Termination Location and Vent Information A. Vent Termination Minimum Clearances 6 in. (minimum) up to 20 in. 18 in. minimum WARNING 152 mm/508 mm 457 mm 20 in. and over 0 in. minimum Fire Risk. Gas, Wood or Fuel Oil Maintain vent clearance to combustibles as Termination Cap specified. -

Page 18: Chimney Diagram

B. Chimney Diagram H or i Electrical Service = VENT TERMINAL = AIR SUPPLY INLET = AREA WHERE TERMINAL IS NOT PERMITTED = 12 inches....clearances above grade, veranda, Covered Alcove Applications porch, deck or balcony (Spaces open only on one side and with an overhang) = 12 inches....clearance to window or door that may = 6 inches ... -

Page 19: Approved Pipe

C. Approved Pipe This appliance is approved for use with Hearth & Home Technologies DVP or SLP venting systems. Refer to Sec- tion 12.A for vent component information and dimensions. DO NOT mix pipe, fittings or joining methods from differ- ent manufacturers. -

Page 20: Use Of Elbows

D. Use of Elbows Diagonal runs have both vertical and horizontal vent as- pects when calculating the effects. Use the rise for the vertical aspect and the run for the horizontal aspect. See Figure 4.4. Two 45º elbows may be used in place of one 90º elbow. On 45º... -

Page 21: Measuring Standards

E. Measuring Standards Vertical and horizontal measurements listed in the vent diagrams were made using the following standards: • Pipe measurements are shown using the effective length of pipe. See Section 12.A (Figure 12.1 for DVP, Figure 12.7 for SLP) for information on effective length of pipe components. -

Page 22: Vent Diagrams

F. Vent Diagrams WARNING General Rules: Fire Risk. Explosion Risk. • SUBTRACT 3 ft. from the total H measurement for each Do NOT pack insulation or other combustibles 90º elbow installed horizontally. between ceiling firestops. • SUBTRACT 1-1/2 ft. from the total H measurement for •... - Page 23 Top Vent - Horizontal Termination One Elbow WARNING! Risk of Fire! Elbow heat shield required Note: For corner installations: A 6 inch (152 when V = 2 ft. or less. Clearances to combustibles mm) section of straight pipe may need to must be maintained.

- Page 24 Top Vent - Horizontal Termination - (continued) Two Elbows Note: For corner installations: A 6 in. (152 mm) section of straight pipe may need to be attached to the appliance before a 90º elbow, to allow the vent pipe to clear the top standoffs. 8000CLX 6000CLX Minimum...

- Page 25 Top Vent - Horizontal Termination - (continued) Three Elbows Min. Max. Min. Max. Elbow only 1 ft. 305 mm 0 in. 0 mm 1 ft. 305 mm 6 in. 152 mm 2 ft 610 mm 6 in. 152 mm 2 ft. 610 mm 1 ft.

- Page 26 Top Vent - Vertical Termination Flue Restrictor Instructions No Elbow 1. Remove the top piece of refractory, if already installed. See Figure 4.13. 2. Orientate and align the two pieces of the flue restrictor = 40 ft. Max. (12.4 m) as shown in Figure 4.15.

- Page 27 Top Vent - Vertical Termination (continued) ALWAYS USED WITH THE HOLES TO THE RIGHT 4 3 2 1 4 3 2 1 ALWAYS USED WITH THE FLUE RESTRICTOR SET TO 4-4 HOLES TO THE LEFT Note: If the DVP-2SL or DVP-SLP24 adapter is used with SLP pipe, you MUST subtract one number from the table in Figure 4.14.

- Page 28 Top Vent - Vertical Termination - (continued) Three Elbows Minimum Maximum Elbow only 1 ft. 305 mm 1 ft. 305 mm 6 in. 152 mm 2 ft. 610 mm 2 ft. 610 mm 1 ft. 305 mm 2 ft. 610 mm 2 ft.

- Page 29 Rear Vent - Horizontal Termination Maximum No Elbow 6000CLX 16 in. (406 mm) 8000CLX 12 in. (305 mm) Figure 4.18 One 45º Elbow Do not use a 45º elbow in corner installations. Use two 90º elbows instead. Figure 4.19 Heat & Glo • 6000CLX-IFT, 8000CLX-IFT Installation Manual • 2506-980 Rev. B • 3/18...

- Page 30 Rear Vent - Horizontal Termination - (continued) Maximum Minimum Maximum Two Elbows Back to Back 6 in. 152 mm 1 ft. 305 mm 1.5 ft 457 mm 90º Elbows 1 ft. 305 mm 6 in. 152 mm 1.5 ft. 457 mm 2.5 ft.

- Page 31 Rear Vent - Vertical Termination Minimum Maximum One Elbow 6 in. 152 mm 2 ft. 610 mm 1 ft. 305 mm 3 ft. 914 mm 2 ft. 610 mm 5 ft. 1.5 m 3 ft. 914 mm 7 ft. 2.1 m 4 ft.

- Page 32 Rear Vent - Vertical Termination - (continued) Maximum Minimum Maximum Three Elbows 2 ft. 610 mm 6 in. 152 mm 2 ft. 4 ft. 1.2 m 3 ft. 914 mm 1 ft. 305 mm 4 ft. 1.2 m 7 ft. 2.1 m 5 ft.

-

Page 33: Vent Clearances And Framing

Vent Clearances and Framing A. Pipe Clearances to Combustibles The attached insulation has been tested and approved by Hearth & Home WARNING! Risk of Fire! Maintain air space clearance Technologies and is UL approved. to vent. DO NOT pack insulation or other combustibles: This insulation may contact the vent pipe. -

Page 34: Wall Penetration Framing/Firestops

B. Wall Penetration Framing/Firestops Combustible Wall Penetration Whenever a combustible wall is penetrated, you must frame a hole for the wall shield firestop(s). The wall shield firestop maintains minimum clearances and prevents cold air infiltration. • The opening must be framed on all four sides using the same size framing materials as those used in the wall construction. -

Page 35: Ceiling Firestop/Floor Penetration Framing

C. Ceiling Firestop/Floor Penetra- tion Framing A ceiling firestop MUST be used between floors and attics. • DVP pipe only - Frame an opening 10 in. by 10 in. (254 mm by 254 mm) whenever ATTIC ABOVE the vent penetrates a ceiling/floor. See Figure 5.4. -

Page 36: Appliance Preparation

Appliance Preparation A. Vent Collar Preparation NOTICE: Once the seal cap has been removed it CANNOT be reattached. CAUTION! Risk of Cuts, Abrasions or Flying Debris. Wear protective gloves and safety glasses during instal- lation. Sheet metal edges are sharp. NOTICE: Once appliance is set up for top or rear venting, it CANNOT be changed at a later time. -

Page 37: Rear Vent

Figure 6.6 (Generic Fireplace Shown) To attach the first section of vent pipe, make sure to use the fiberglass gasket in the manual bag to seal between the first vent component and the outer fireplace wrap. Caulk with a minimum of 300 ºF continuous exposure rating may be used to hold the part in place. -

Page 38: Installing Optional Heat Management Systems

B. Installing Optional Heat Management Sys- tems • Remove the knockout from the fireplace and discard it See Figure 6.12. • Center the duct collar around the exposed hole and attach it to the fireplace with 3 screws. Note: Do this BEFORE final positioning of fireplace. •... -

Page 39: Securing And Leveling The Appliance

C. Securing and Leveling the Appliance WARNING! Risk of Fire! Prevent contact with: • Sagging or loose insulation • Insulation backing or plastic • Framing and other combustible materials Block openings into the chase to prevent entry of blown- in insulation. Make sure insulation and other materials are secured. -

Page 40: Venting And Chimneys

Venting and Chimneys A. Assemble Vent Sections (DVP Pipe Only) from horizontal to vertical, one screw minimum should be put in the outer flue at the horizontal elbow joint to prevent the Attach Vent to the Firebox Assembly elbow from rotating. Use screws no longer than 1/2 in. (13 mm). -

Page 41: Assemble Vent Sections (Slp Only)

C. Assemble Slip Sections B . Assemble Vent Sections (SLP Only) • Slide the inner flue of the slip section into the inner flue To attach the first vent component to the starting collars of the pipe section and the outer flue of the slip section of the appliance: over the outer flue of the pipe section. -

Page 42: Secure The Vent Sections

D. Secure the Vent Sections E. Disassemble Vent Sections • Vertical runs originating off the top of the appliance, with • Rotate either section (see Figure 7.10) so the seams on no offsets, must be supported every 8 ft. (2.44 m) after both pipe sections are aligned as shown in Figure 7.11. -

Page 43: Vertical Termination Requirements

F. Vertical Termination Requirements Install Metal Roof Flashing • See minimum vent heights for various pitched roofs CAULK (Figure 7.12) to determine the length of pipe to extend through the roof. • Slide the roof flashing over the pipe sections extending through the roof as shown in Figure 7.13. -

Page 44: Horizontal Termination Requirements

Install Vertical Termination Cap G. Horizontal Termination Requirements • Attach the vertical termination cap by sliding the inner Heat Shield Requirements for Horizontal collar of the cap into the inner fl ue of the pipe section Termination while placing the outer collar of the cap over the outer WARNING! Risk of Fire! To prevent overheating and fi re, fl ue of the pipe section. - Page 45 Install Horizontal Termination Cap (DVP and Note: When using termination caps with factory-supplied heat shield attached, no additional wall shield firestop is SLP Pipe) required on the exterior side of a combustible wall. WARNING! Risk of Fire! The telescoping flue section of the termination cap MUST be used when connecting vent.

-

Page 46: Electrical Information

Electrical Information Junction Box Installation A. General Information If the box is being wired from the INSIDE of the appliance: WARNING! Risk of Shock or Explosion! DO NOT wire 110-120 VAC to the valve or to the appliance wall switch. •... -

Page 47: Wiring Requirements

B. Wiring Requirements Intellifire™ Touch Ignition System Wiring • Wire the appliance junction box to 110-120 VAC for NOTICE: Batteries should only be used as a power source proper operation of the appliance. in the event of an emergency power outage. Batteries should not be used as a primary long-term power source. - Page 48 Wall Switch Installation for Fan (Optional) If the box is being wired to a wall mounted switch for use with a fan. See Figure 8.3: Switch Minimum 14-3 AWG • The power supply for the appliance must be brought into with Ground a switch box.

-

Page 49: Gas Information

Gas Information A. Fuel Conversion C. Gas Connection • Make sure the appliance is compatible with available gas • Refer to Reference Section 3 for location of gas line types. access in appliance. • Conversions must be made by a qualified service •... -

Page 50: Air Shutter Setting

E. Air Shutter Setting Air shutter settings should be adjusted by a qualified ser- vice technician at the time of installation. The air shutter is set at the factory for minimum vertical vent run. Adjust air shutter for longer vertical runs. See Figure 9.1. •... -

Page 51: Finishing

Finishing A. Facing Material • Metal front faces may be covered with non-combustible materials only. FACTORY-INSTALLED NON-COMBUSTIBLE BOARD DO NOT REMOVE • Facing and/or finishing materials must not interfere with air flow through or removal of decorative fronts or access for service. -

Page 52: Mantel And Wall Projections

B. Mantel and Wall Projections Mantel Legs or Wall Projections WARNING! Risk of Fire! Comply with all minimum clear- ances as specified. Framing closer than the minimums list- INTERIOR WALL ed must be constructed entirely of noncombustible materials (i.e., steel studs, concrete board, etc.) TOP VIEW Mantels - Combustible or Painted Surfaces Note: All... -

Page 53: Decorative Fronts

C. Decorative Fronts Finishing Material: 1 Inch Thick or Less Only decorative fronts certified for use with this appliance model may be used. Contact your dealer for a list of dec- orative fronts that may be used. Once you have deter- Remove Finishing Strips. - Page 54 Finishing Material Thickness: 1-6 Inches Maximum NOTICE: Remove finishing strips before firing appliance. FINISHING STRIPS USED NON-COMBUSTIBLE FINISHING MATERIAL (Outside decorative front width) (Includes 1/8 in. opening each side of decorative front) Finishing material thickness, 1-6 inches maximum B = Top of decorative front to bottom of fireplace. D = Bottom of Finishing Material to Bottom of Fireplace 8000 Models 6000 Models...

- Page 55 Finishing Material Thickness: Removal of Finishing Strips 0-6 Inches Maximum NOTICE: Remove finishing strips before firing appliance. NOTICE: Remove finishing strips before firing appliance. Remove glass frame assembly to access finishing strip screws. FINISHING STRIP NOT USED (See Figure 10.9 for removal instructions) NON-COMBUSTIBLE FINISHING MATERIAL...

-

Page 56: Appliance Setup

Appliance Setup A. Remove Fixed Glass Assembly D. Burner Top Installation WARNING! Risk of Asphyxiation! Handle fixed glass 1. Bend the two tabs upward as shown in Figure 11.2. assembly with care. Inspect the gasket to ensure it is 2. To install the fiber burner, mate the locating holes with undamaged and inspect the glass for cracks, chips or the guide sleeves. -

Page 57: Install The Fiber Refractory

E. Install the Fiber Refractory 6000CLX-IFT-S, 6000CLX-IFTLP-S, REFRACTORY 8000CLX-IFT-S, 8000CLX-IFTLP-S FOOT NOTCH CAUTION! Refractory is fragile. Handle with care. CAUTION! Risk of Cuts, Abrasions or Flying Debris. Wear protective gloves and safety glasses during instal- LOWER lation. FIREBOX LIP Step 1. Back Refractory Panel Installation The back refractory panel has a rectangular notch on the bottom side. - Page 58 Step 4. Top Refractory Installation Step 3. Left Refractory Installation 7. Using both hands, hold the top refractory panel with 6. Steps for installation of left refractory side are the same the brick pattern facing down. as right side. Repeat the same procedure as Step 2. 8.

-

Page 59: Black Glass Refractory Installation

F. Black Glass Refractory Installation 6. Install top refractory panel. Rest it on top of the side glass panels and gently push to the rear. See Figure 6000CLX-IFT-G ,6000CLX-IFTLP-G, 8000CLX-IFT-G, 8000CLX-IFTLP-G 1. Install rear glass panel in front of insulation board on rear refractory bracket. -

Page 60: Ember Placement

G. Ember Placement WARNING! Risk of Explosion! Follow ember placement instructions in manual. DO NOT completely block burner ports with ember material. Replace ember material an- nually. Improperly placed embers interfere with proper burner operation. Ember material is shipped with this gas appliance. To place the ember material: •... -

Page 61: Install The Teco-Sil

H. Install the Teco-Sil NOT PAINTED Teco-Sil Placement 1. Pour Teco-Sil between the left and right base refracto- ries as shown in Figure 1. Figure 2. Teco-Sil Not Painted TOO LIGHT BASE REFRACTORY Figure 1. Placement of Embers 2. Fog the Teco-Sil to the desired look, using high tem- perature black paint (Hearth &... -

Page 62: Install The Log Assembly

LOG PLACEMENT INSTRUCTIONS I. Install the Log Assembly Log Set Assembly: LOGS-6000CLX Models: 6000CLX-IPI-S, 6000CLX-IPILP-S 6000CLX-IPI-T, 6000CLX-IPILP-T, HE36CLX-S, HE36CLXLP-S, 6000CLX- IFT-S, 6000CLX-IFTLP-S, 6000CLX-IFT-G, 6000CLX-IFTLP-G LOCATING HOLES LOCATING HOLES FIBER BURNER TOP FIBER BURNER TOP TAB BENT IN = NG PILOT COVER BURNER SHIELD PILOT COVER BURNER SHIELD... - Page 63 LEFT GRATE TINE RIGHT GRATE TINE Figure 7 Figure 8 Log #3 (2166-723): Mate the groove located on the bottom of Log #3 with the right log placement protrusion on top of Log #1. After groove and protrusion have been fitted together, mate the groove located on the bottom of Log #3 with the horizontal grate bar and slide Log # 3 toward the right until it rests against the far right grate tine.

-

Page 64: Log Placement Instructions

LOG PLACEMENT INSTRUCTIONS Log Set Assembly: LOGS-8000CLX Models: 8000CLX-IPI-S, 8000CLX-IPILP-S, 8000CLX-IPI-T, 8000CLX-IPILP-T 8000CLX-IFT-S, 8000CLX-IFTLP-S, 8000CLX-IFT-G, 8000CLX-IFTLP-G LOCATING HOLES FIBER BURNER TOP TAB BENT IN = NG LOG PLACEMENT TABS BURNER SHIELD PILOT COVER GRATE TINE BURNER ASSEMBLY TAB NOT BENT = LP GUIDE SLEEVES LOG PLACEMENT INDENTATIONS Figure 2... - Page 65 RIGHT GRATE TINE NOSE HORIZONTAL GRATE BAR Figure 7 Figure 8 Log #3 (2170-723): Mate the groove located on the bottom of Log #3 with the right log placement protrusion on top of Log #1. After groove and protrusion have been fitted together, mate the groove located on the bottom of Log #3 with the horizontal grate bar and far right grate tine.

-

Page 66: Intellifire™ Touch Control System Setup

J. Intellifire™ Touch Control System Setup K. Install Fixed Glass Assembly • Detailed instructions for electrical wiring and connec- WARNING! Risk of Asphyxiation! Handle fixed glass tions are provided in Section 8. assembly with care. Inspect the gasket to ensure it is undamaged and inspect the glass for cracks, chips or •... -

Page 67: Reference Materials

Reference Materials A. Vent Components Diagrams Effective Length Pipe Inches Millimeters DVP4 10-1/2 in. (267 mm) 45 ° Effective DVP6 Height/Length DVP12 DVP24 4-7/8 in. (124 mm) DVP36 10-7/8 in. DVP48 1219 (276 mm) DVP Pipe (see chart) DVP6A 3 to 6 76 to 152 DVP45 (45º... - Page 68 A. Vent Components Diagrams (continued) Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm). The heat shield is designed to be used on a wall 4 in. to 7-1/4 in. (102 mm to 184 mm) thick. If wall thickness is less than 4 in. (102 mm) the existing heat shields must be field trimmed.

- Page 69 A. Vent Components Diagrams (continued) 31 in. (787 mm) 13-1/4 in. (337 mm) 24-5/8 in. (625 mm) 27-1/2 in. 24-5/8 in. (699 mm) (625 mm) 13-1/4 in. (337 mm) RF12 Roof Flashing Roof Flashing 11-7/8 in. 5 in. (302 mm) (127 mm) 13-7/8 in.

- Page 70 A. Vent Components Diagrams (continued) 7-3/8 in. (187 mm) 1-1/2 in. (38 mm) 12 in. 305 mm 14 in. 17-3/4 in. (356 mm) (451 mm) 7-1/4 in. (184 mm) 6 in. 12-1/2 in. 152 mm (318 mm) 5-1/4 in. 12 in. (133 mm) (305 mm) DVP-TVHW...

- Page 71 A. Vent Components Diagrams (continued) 8-1/8 in. 13 in. (206 mm) (330 mm) Effective Length 5-1/2 in. 8-3/8 in. 5-3/4 to 8-3/8 in. 140 mm 213 mm 146 to 213 mm 3° 87° 15 in. (381 mm) 10-1/2 in. 267 mm 10-7/8 in.

- Page 72 A. Vent Components Diagrams (continued) Optional Wire Harness 13-5/8 IN. DESCRIPTION PART NUMBER 346 mm EFFECTIVE LENGTH 32 IN. (813 mm) MIN. 10 FT PV Wire Harness PVI-WH10 35 IN. (889 mm) MAX. 20 FT PV Wire Harness PVI-WH20 40 FT PV Wire Harness PVI-WH40 12-1/2 IN.

- Page 73 A. Vent Components Diagrams (continued) Top View 6-1/4 IN. 159 mm 1-1/2 IN. 38 mm Front View Side View 2-1/4 IN. 15-1/2 IN. 57 mm 394 mm 4-3/4 IN. 121 mm 8 IN. 14 IN. 9-1/2 IN. 203 mm 356 mm 241 mm 5-1/4 IN.

- Page 74 A. Vent Components Diagrams (continued) 6-1/2 in. 165 mm 6-1/2 in. 165 mm 6-1/2 in. 165 mm 8-3/4 in. 9-1/4 in. 222 mm 6 in. 235 mm 152 mm 6-5/8 in. 168 mm 6-5/8 in. SLP45 168 mm 45° Elbow 9-7/8 in.

- Page 75 A. Vent Components Diagrams (continued) Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm). The heat shield is designed to be used on a wall 4 in. to 7-1/4 in. (102 mm to 184 mm) thick. If wall thickness is less than 4 in. (102 mm) the existing heat shields must be field trimmed.

- Page 76 A. Vent Components Diagrams (continued) 10-11/16 in. 271mm 12 in. 305 mm 12-1/2 in. 28-1/2 in. 4-1/8 in. 318 mm 724 mm 105 mm SLP-TVHW Vertical Termination Cap 13-1/2 in. 4-3/4 in. 343 mm 121 mm SLK-SNKD Snorkel Termination Cap 14 in.

-

Page 77: Accessories

B. Accessories Remote Controls, Wall Controls and Wall Switches Follow the instructions supplied with the control installed to operate your fireplace: For safety: • Install a switch lock or a wall/remote control with child protection lockout feature. • Keep remote controls out of reach of children. See your dealer if you have questions.

Need help?

Do you have a question about the 6000CLX-IFT-S and is the answer not in the manual?

Questions and answers