Table of Contents

Advertisement

OPERATION

&

MAINTENANCE

MANUAL

Table-Top Autoclaves

models

1730, 2340, 2540, 3140, 3850, 3870 M & MK

1730MK Valueklave

Cat. No. MAN205-0007-000E Rev. K

Tuttnauer U.S.A., 25 Power Drive Hauppauge, NY, 11788, USA.

Tel (631) 737 4850, (800) 624 5836,

Fax: (631) 737 0720

Tuttnauer Europe b.v., Paardeweide 36, 4824 EH, Breda, P.O. Box 7191, 4800 GD Breda, Netherlands.

+31/76-5423510,

Fax: +31/76-5423540

Advertisement

Table of Contents

Summary of Contents for Tuttnauer 1730 M

- Page 1 Cat. No. MAN205-0007-000E Rev. K Tuttnauer U.S.A., 25 Power Drive Hauppauge, NY, 11788, USA. Tel (631) 737 4850, (800) 624 5836, Fax: (631) 737 0720 Tuttnauer Europe b.v., Paardeweide 36, 4824 EH, Breda, P.O. Box 7191, 4800 GD Breda, Netherlands. +31/76-5423510, Fax: +31/76-5423540...

-

Page 3: Table Of Contents

TABLE OF CONTENTS PARAGRAPH PAGE NO. GENERAL....................3 Incoming Inspection .................3 Warranty....................3 Warranty Statement ................3 TECHNICAL DATA ..................5 Introduction ..................5 Storage conditions................6 Operating Condition................6 Standards...................6 Construction..................6 Utilities ....................6 Waste Water Disposal ...............7 Environment Emission Information..........7 Dimensions..................8 2.10 Technical Specifications ..............9 2.11 Electrical Data ................10 2.12 Maximum Load Sizes ..............10... - Page 4 TABLE OF CONTENT (Cont.) DRAWINGS PAGE NO. Front View........................11 Rear View ........................12 Tray Handle CMT240-0001..................42 Pouch Rack .........................42 Tray ..........................42 Tray Holder .........................42 Tray Holder .........................43 Alternative Tray Holder ....................43...

-

Page 5: General

No product will be received or accepted for repair without prior return authorization from Tuttnauer. All transportation charges to and from Tuttnauer must be paid by the owner of the autoclave. During the first 90 days after purchase of an autoclave, Tuttnauer will pay shipping... - Page 6 Technical Service Depts that can be reached at one of the following addresses. Do not attempt to service this instrument yourself. Tuttnauer USA Co. 25 Power Drive Hauppauge, NY, 11788, USA : (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720 e-mail:info@tuttnauer.com...

-

Page 7: Technical Data

TECHNICAL DATA Introduction This table-top autoclave is designed for the sterilization of wrapped and unwrapped instruments and related items found in dental, medical and veterinary clinics, first aid rooms, hospitals, laboratories etc. This autoclave is an electrically - heated sterilizer using steam as the sterilizing agent. -

Page 8: Storage Conditions

Storage conditions The packed or unpacked autoclave shall be stored in “indoor conditions” (protected from rain and water). Operating Condition This device is to be used for indoor use. This autoclave is intended for NORMAL environment conditions as follows: ● - Altitude up to 2000m. ●... -

Page 9: Waste Water Disposal

Waste Water Disposal Caution ! Waste-water may be brought into the public water piping in accordance with the local rules or requirements. I.e. only non-hazardous liquids may be disposed in public sewage! Environment Emission Information A. The peak sound level generated by the sterilizer is « 78 / dBA with background noise of 60 dB. -

Page 10: Dimensions

Dimensions Model 1730 2340 2540 3140 3850 3870 M, MK M, MK M, MK Valueklave Dimensions A 17.4 20.0 20.0 23.2 26.0 26.0 Overall B 12.0 14.4 14.4 17.7 20.7 20.7 Dimensions C 17.9 21.5 21.5 21.9 27.5 34.5 Maximum D 29.5 35.8 35.8... -

Page 12: Electrical Data

2.11 Electrical Data Model 1730 2340 2540 3140 3850 3870 Specifications MK-V Total power 20.0 8.8A 11.2A 11.7A 11.7A model 120V Total power 10.4 10.4 4.6A 5.9A 6.0A 9.6A 6.0A 9.6A model 230V Heaters W 1050 1350 1400 2200 1400 2200 2400 2400 3000 Degree of protection by enclosure IP31 2.12... -

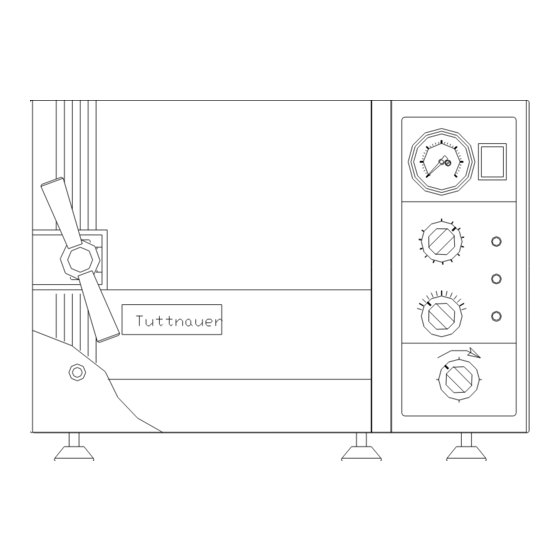

Page 13: Front View

FRONT VIEW Models 1730 M, MK 1. Front legs Air trap jet 2. Reservoir water drain 10. Pressure gauge valve. 11. Timer 3. Door Closing Device 12. Thermostat (B10) knob 4. Door Micro-switch 13. Multipurpose valve 5. Autoclave cover 14. Heat indicator light 6. -

Page 14: Rear View

REAR VIEW... -

Page 15: Description Of Components

DESCRIPTION OF COMPONENTS The item numbers refer to the front view in the previous page Control Panel Description Operation Item 0-60 psi, (0-4bar) indicates the chamber pressure and PRESSURE GAUGE includes maximum point indicator. Sets the time for sterilization and drying cycles (see section 7 for correct cycle time settings). -

Page 16: Installation Instructions

INSTALLATION INSTRUCTIONS Caution: The sterilizer must be placed on a rigid and leveled surface. The stand must be able to hold the load of the device and loaded material. Note: Make sure while placing the autoclave, to leave space around the machine, to give the technician access to service the machine. -

Page 17: Lifting And Carrying

♦ The chamber pitch now needs to be adjusted ♦ Measure to the proper amount of distilled water for the appropriate model unit as listed below (the tolerances on these amounts are +2 oz. and –0 oz) 1730 2340/2540 3140 3850 3870 10-12... -

Page 18: Water Quality

WATER QUALITY The distilled or mineral – free water supplied to the autoclave should have the physical characteristics and maximum acceptable level of contaminants indicated in the table below: Physical characteristics and acceptable contaminants levels in water, for sterilizers ≤ 15 mg/l Evaporate residue ≤... -

Page 19: Preparation Before Sterilization

Such substances may cause damage to the instruments themselves or the sterilizer. 1. Clean instruments immediately after use. It is recommended that instruments be ultrasonically cleaned in a Tuttnauer Clean and Simple Ultrasonic using Tuttnauer Clean and Simple enzymatic cleaning solution. - Page 20 22. Do not stack pouches. It is recommended that a Tuttnauer Pouch Rack be used. This will allow the operator to place pouches on their side, which will increase capacity and...

- Page 21 23. If spotting is detected on the instruments the first step would be to use an ordinary eraser to remove the spot. If there is no pitting under the spot then the spot was only dirt. Dirt spots on an instrument may be an indication that the autoclave needs to be cleaned or that the instruments were not adequately cleaned or dried.

- Page 22 26. Tubing 1. When placing in a tray, make sure that both ends are open, without sharp bends or twists. Wrong Right 27. Cassettes 1. Instruments may be sterilized in cassettes. The advantage of the cassettes is that the sterilized instruments may remain organized in the cassettes ready for use, while stored in a sterile area.

-

Page 23: Operation

OPERATION To avoid possible damage, do not leave the autoclave un-attended while in operation. Make sure the power cord is plugged into the back of the unit and also plugged into a power source. Loading and unloading the Device 7.1.1. Safety Protective equipment and clothes and other safety instructions should be implemented in accordance with local... - Page 24 7.2.5. USE DISTILLED WATER ONLY. Use water-having characteristics as per table in sec 5. The impurities in tap water will create the need for more frequent cleaning and maintenance, in addition they will accumulate and block the hole of the Air Jet. This will prevent the temperature in the chamber from rising properly.

- Page 25 7.7. Shut the door, move the Door Closing Devise into position and tighten, making sure that the Door Switch is activated. NOTE: Due to the inherent elasticity of the door gasket, it is important to tighten the door bolt until “hand tight”. Do not over - tighten the bolt as this may result in damage to the gasket.

- Page 26 7.9. Set the Timer to the desired sterilization cycle time according to the Sterilization Time Table. 7.9.1. The Heat Light will come on, indicating that power is being supplied to the Heating Elements and remain on until the correct sterilization pressure is achieved. 7.9.2.

- Page 27 7.11.4. Leave the Multi-purpose valve knob in the Exhaust / Dry position. 7.11.5. Now reset the Timer for drying, 20 – 30 minutes, the Dry Light will come on indicating that Drying is active and the Heating Elements are back on. 7.11.6.

-

Page 28: Service And Maintenance Instructions

Should the need arise technical assistance or a service technician can be requested by either calling your dealer or Tuttnauer USA. 8.1.1 Daily Clean door gasket with a mild detergent, water and a soft cloth or sponge. -

Page 29: Draining The Reservoir

Draining the Reservoir Caution Before starting, ensure that the electric cord is disconnected and there is no pressure in the autoclave. The drain valve is located on the front left side of the autoclave after the door is opened. The function of the drain valve is to drain the water reservoir. -

Page 30: Cleaning Air Jet

Cleaning Air Jet (Located in the water reservoir.) A dirty air jet is the number one cause of failed spore tests The elimination of air from the sterilization chamber during heat up is critical to the proper operation of the autoclave. Failure of the air removal system will be responsible for incomplete sterilization, indicator strips that do not turn and failed spore tests. -

Page 31: Replacing The Door Gasket

Replacing the Door Gasket Pull off the gasket from the door groove. Install the new gasket as described in drawings 1, 2 and 3 below. Caution! This gasket is designed with a trapezoidal cross section. The gasket should be placed with the widest side towards the door. -

Page 32: Checking The Safety Valve

Checking the Safety Valve (Located in the water reservoir) In order to prevent the safety valve from becoming blocked, it is necessary to allow the steam pressure to escape through the valve. This procedure should be done every month as follows: Run a sterilization cycle with a sterilization temperature of 273ºF according to the manual. -

Page 33: Unclogging The Multi-Purpose Valve Or Fill Piping

Unclogging the multi-Purpose Valve or Fill piping. Pour distilled water into the chamber, according to quantities mentioned in para. 4 (Installation Instructions). Close the door. Turn the multi-purpose valve to STE. position. Move the main switch to the START position. Turn the Thermostat knob to 273ºF (134ºC). -

Page 34: Cleaning Table Top Autoclaves With Chamber Brite™32 Troubleshooting

CLEANING TABLE TOP AUTOCLAVES WITH CHAMBER BRITE™ CHAMBER BRITE ™ is a cleaning and descaling agent designed specifically for the cleaning and removal of water deposits, oxides and other sediments that are found in steam sterilizers. The material is a combination of acidic salts and additional cleaning materials. - Page 35 For models 3140, 3850, 3870 use two packets of CHAMBER BRITE ™. Clean every 20 cycles or as needed. Total cycle time for cleaning Tuttnauer “M” series is 30 minutes at 273°F (134°C). Total cycle time for cleaning Tuttnauer “MK” series is 15...

-

Page 44: Tray Handle Cmt240-0001

TRAY HANDLE CMT240-0001 For 1730, 2340, 2450 models only POUCH RACK CAT No. TYPE 2340 ACS215-0008 2540 3870 ACS215-0010 TRAY MODEL SIZE CAT. No. 1730 TRY173-0001 2340 TRY240-0001 2540 TRY240-0001 TRY314-0001 3140 Small TRY314-0002 TRY385-0003 3850 Small TRY385-0004 TRY387-0001 3870 Small TRY387-0003... -

Page 45: Tray Holder

TRAY HOLDER MODEL TRAY HOLDER CAT. NO. 1730 TRH173-0001 2340 TRH234-0001 2540 TRH254-0001 3140 TRH314-0000 3850 TRH385-0001 3870 TRH387-0001 ALTERNATIVE TRAY HOLDER These tray holders are designed for use in models 2340 & 2540 only. Model Tray holder cat. No. 2340 TRH234-0008 2540... -

Page 46: List Of Accessories

LIST OF ACCESSORIES Cat. No. Description 1730 2340 2540 3140 3850 3870 Handle, Tray, TTA CMT240-0001 CMT240-0001 CMT240-0001 — — — 1730, 2340, 2540 Pouch Rack — ACS215-0008 ACS215-0008 — — ACS215-0010 TRY314-0001 TRY385-0003 TRY387-0001 Tray TRY173-0001 TRY240-0001 TRY240-0001 Small TRY314-0002 TRY385-0004 TRY387-0003 Holder, Tray TRH173-0002 TRH234-0001 TRH254-0001 TRH314-0000 TRH385-0001 TRH387-0002... -

Page 47: Conversion Table

CONVERSION TABLE º º 18.0 22.2 29.6 37.0 44.4...

Need help?

Do you have a question about the 1730 M and is the answer not in the manual?

Questions and answers