Table of Contents

Advertisement

Thank you for using FV100 series Variable Frequency Drive made by Kinco Automation.

FV100 satisfies the high performance requirements by using a unique control method to achieve high torque, high

accuracy and wide speed-adjusting range. Its anti-tripping function and capabilities of adapting to severe power

network, temperature, humidity and dusty environment exceed those of similar product made by other companies,

which improves the product's reliability noticeably;

FV100 use modularization design, in the premise of satisfying the demand of customer, we also can satisfy

customer's personalized and industrization demand by expansion design, and this fit the trend of VFD development.

Built-in PG connector, strong speed control, flexible input/output terminal, pulse frequency setting, saving parameters

at power outage and stop, frequency setting channel, master and slave frequency control and so on, all these satisfy

various of high accuracy and complex drive command, at the same time we provide the OEM customer high

integration total solution, it values highly in system cost saving and system reliability improving.

FV100 can satisfy the customers' requirements on low noise and EMI by using optimized PWM technology and

EMC design.

This manual provides information on installation, wiring, parameters setting, trouble-shooting, and daily

maintenance. To ensure the correct installation and operation of FV100, please read this manual carefully before

starting the drive and keep it in a proper place and to the right person.

Unpacking Inspection Note

Upon unpacking, please check for:

Any damage occurred during transportation;

Check whether the rated values on the nameplate of the drive are in accordance with your order.

Our product is manufactured and packed at factory with great care. If there is any error, please contact us or

distributors.

The user manual is subject to change without notifying the customers due to the continuous process of product

improvements

VFD model rule

VFD code

FV:FV Series

CV:CV Series

The first generation

00:Standard model

Power supply

2:220V

4:380V

Preface

FV 1 00 – 4 T– 0075G/0110L – U –000

Software custom code

Hardware custom code

0075G:7.5KW

constant torque

0110L:11KW

constant power

S:Signal phase

T:Three-phase

Advertisement

Table of Contents

Summary of Contents for Kinco FV100-2S-0004G

- Page 1 Preface Thank you for using FV100 series Variable Frequency Drive made by Kinco Automation. FV100 satisfies the high performance requirements by using a unique control method to achieve high torque, high accuracy and wide speed-adjusting range. Its anti-tripping function and capabilities of adapting to severe power network, temperature, humidity and dusty environment exceed those of similar product made by other companies, which improves the product’s reliability noticeably;...

-

Page 2: Table Of Contents

5.2Operation mode of VFD............................28 5.2.1 Control mode of VFD..........................28 5.2.2 Operating Status............................28 5.2.3 Control mode and operation mode of Kinco VFD..................28 5.2.4 The channels to set the VFD frequency....................29 5.3Power on the Drive for the first time........................30 5.3.1 Checking before power on........................ - Page 3 6.2 Group A1................................33 6.3 Group A2................................36 6.4 Group A3................................37 6.5 Group A4................................40 6.6 Group A5................................41 6.7 Group A6................................43 6.8 Group A7................................53 6.9 Group A8................................54 6.10 Group b0................................55 6.11 Group b1................................57 6.12 Group b2................................

-

Page 4: Chapter 1 Safety

parts inside the drive so as to avoid the risk of fire. Chapter 1 Safety · Parameter settings of the control panel that has been changed must be revised, otherwise accidents may occur. 1.1 Safety · The bare portions of the power cables must be bound Operations without following instructions with insulation tape Danger... -

Page 5: About Variable Frequency Drive

The mechanical resonance point of load FV100 series drives are voltage type variable frequency drive. The output voltage is in PWM wave with some The drive system may encounter mechanical resonance harmonics. Therefore, temperature rise, noise and with the load when operating within certain band of vibration of motor are higher compared to the power output frequency. -

Page 6: Disposing Unwanted Driver

1.4 Disposing Unwanted Driver FV100 When disposing the VFD, pay attention to the following issues: The electrolytic capacitors in the driver may explode when they are burnt. Poisonous gas may be generated when the plastic parts like front covers are burnt. Fig. -

Page 7: Chapter 2 Product Introduction

Chapter 2 Product introduction In this chapter we introduce the basic product information of specifications, model, and structure and so on. 2.1 General specifications Table 2-1 General specifications Item Description 4T:3-phase,380V ~ 440V AC; 50Hz/60Hz; 2T: 3-phase, 200V~240V;50Hz/60Hz Rated voltage and frequency 2S:Single-phase,200V~240V;50Hz/60Hz Input... -

Page 8: Introduction Of Product Series

Air cooling, with fan control. Installation method Wall-mounted Power under 45kW≥93%;Power above 55kW≥95% Efficiency 2.2 Introduction of product series Table 2-1 Series of Kinco VFD Rated capacity Rated input current Rated output current Model of VFD Motor power (kW) (kVA)... - Page 9 FV100-2S-0075G 12.5 45.0 30.0 FV100-2S-0110G 19.0 70.0 46.0 FV100-2S-0150G 25.0 90.0 60.0 FV100-2S-0185G 31.0 110.0 75.0 18.5 FV100-2S-0220G 35.6 125.0 85.0 FV100-2T-0004G FV100-2T-0007G FV100-2T-0015G FV100-2T-0022G FV100-2T-0037G FV100-2T-0055G 24.5 FV100-2T-0075G FV100-2T-0110G FV100-2T-0150G FV100-2T-0185G 18.5 FV100-2T-0220G FV100-4T-0007G/0015L 1.5/3.0 3.4/5.0 2.3/3.7 0.75/1.5 FV100-4T-0015G/0022L 3.0/4.0 5.0/5.8 3.7/5.5...

-

Page 10: Structure Of Vfd

FV100-4T-1600G/1850L 200.0/230.0 282.0*/326.0 304.0/355.0 160/185 FV100-4T-1850G/2000L 230.0/250.0 326.0*/352.0 355.0/380.0 185/200 FV100-4T-2000G/2200L 250.0/280.0 352.0*/385.0 380.0/426.0 200/220 FV100-4T-2200G/2500L 280.0/355.0 385.0*/437.0 426.0/500.0 220/250 FV100-4T-2500G/2800L 355.0/396.0 437.0*/491.0 500.0/540.0 250/280 FV100-4T-2800G/3150L 396.0/445.0 491.0*/580.0 540.0/600.0 280/315 FV100-4T-3150G/3550L 445.0/500.0 580.0*/624.0 600.0/700.0 315/355 FV100-4T-3550G/4000L 500.0/565.0 624.0*/670.0 700.0/780.0 355/400 FV100-4T-4000G/4500L 565.0/630.0 670.0*/792.0... -

Page 11: External Dimension And Weight

2.4 External dimension and weight 2.4.1 External dimension and weight External dimension and weight is as following figure. Fig 2-2 FV100-4T-0037G/0055L and lower power VFD Fig 2-3 FV100-4T-0055G/0075L~FV100-4T-4000G/4500L... - Page 12 Table 2-2 Mechanical parameters VFD model External dimension and (mm) (G: Constant torque load; Weight Installation (kg) L: Draught fan and hole(d) water pump load) FV100-2S-0004G FV100-2S-0007G FV100-2S-0015G FV100-2S-0022G FV100-2S-0037G FV100-2T-0004G FV100-2T-0007G FV100-2T-0015G FV100-2T-0022G FV100-2T-0037G FV100-4T-0007G/0015L FV100-4T-0015G/0022L FV100-4T-0022G/0037L FV100-4T-0037G/0055L FV100-2S-0055G...

- Page 13 FV100-2T-0220G FV100-4T-0220G/0300L FV100-4T-0300G/0370L FV100-4T-0370G/0450L 88.5 FV100-4T-0450G/0550L FV100-4T-0550G/0750L 102.5 FV100-4T-0750G/0900L FV100-4T-0900G/1100L FV100-4T-1100G/1320L FV100-4T-1320G/1600L FV100-4T-1600G/1850L FV100-4T-1850G/2000L FV100-4T-2000G/2200L FV100-4T-2200G/2500L FV100-4T-2500G/2800L 1006 FV100-4T-2800G/3150L FV100-4T-3150G/3550L FV100-4T-3550G/4000L 1228 1196 FV100-4T-4000G/4500L...

-

Page 14: Operation Panel And Installation Box

2.4.2 Operation panel and installation box Fig 2-4 Operation panel dimension Fig 2-5 Installation box dimension... -

Page 15: Braking Resistor Selection

2.4.3 Braking Resistor Selection Braking resistor VFD Model Braking Unit Standard Qty. Min. resistance Standard power resistance FV100-2S/2T-0004G 200Ω 100Ω 100W FV100-2S/2T -0007G 150Ω 100Ω 150W FV100-2S/2T -0015G 150Ω 100Ω 150W FV100-2S/2T -0022G 50Ω 35Ω 400W FV100-2S/2T -0037G 45Ω 35Ω 450W FV100-2S/2T-0055G 50Ω... -

Page 16: Chapter 3 Installation Environment

Chapter 3 Installation Environment In this chapter we introduce the installation environment of VFD Please mount the drive vertically inside a well-ventilated location. When considering mounting environment, the following issues should be taken into account: Ambient temperature should be within the range of-10℃~40℃. If the temperature is higher than 40 ℃, the drive ... -

Page 17: Chapter 4 Wiring Guide Of Vfd

·The drive should be connected to the AC supply via a circuit breaker or fuse to provide convenience to input over-current protection and maintainance. 4.1 Wiring and Configuration of Main circuit terminal 4.1.1 Terminal Type of Main Loop’s Input and Output Terminal Type Applicable models: FV100-2S-0004G~FV100-2S-0037G FV100-2S-0055G~FV100-2S-0110G Application models:... - Page 18 FV100-2S-0150G~FV100-2S-0220G Application models: Applicable models:FV100- 2T -0004G~FV100- 2T -0037G FV100- 4T -0007G/0015L~FV100- 4T -0037G /0055L Applicable models:FV100- 2T -0055G~FV100- 2T -0110G FV100-4T-0055G/0075L~FV100-4T-0185G/0220L Applicable models: FV100- 2T -0150G~FV100-2T-0220G FV100-4T-0220G/0300L~FV100-4T-0370G/0450L Applicable models:FV100-4T-0450G/0550L~FV100-4T-0750G/0900L Applicable models:FV100-4T-0900G/1100L~FV100-4T-1320G/1600L Applicable models:FV100-4T-1600G/1850L~FV100-4T-4000G/4500L Table 4-1 Description of main loop terminal Terminal Function description name...

-

Page 19: Wiring Of Vfd For Basic Operation

reactor External braking unit 、 B1、B2 Braking resistor terminal U、V、W 3-phase AC output terminal Shield PE terminal 4.1.2 Wiring of VFD for Basic Operation Applicable model: FV100-4T-0055G /0075L Fig.4-1 Basic wiring chart... -

Page 20: Wiring And Configuration Of Control Circuit

4.2 Wiring and configuration of control circuit 4.2.1 Wiring of control circuit terminal. Wire the terminals correctly before using the Drive. Refer to the table 4-2 for control circuit terminal function Table 4-2 Control circuit terminal function Sequence No. Function Analog input and output terminal, RS232 and RSRS485 communication port Note It is recommended to use cables bigger than 1mm2 to connect to the terminals. - Page 21 Category Terminals Name Function description Specification Analog voltage differential input AI3+ or analog When connected to the analog voltage AI3+ voltage differential input, AI3+ is the single-ended same-phase input and AI3- is the Input voltage range: -10V~+10V input inverted phase input; (Input resistor: 15kΩ) Analog voltage when connected to the analog voltage...

- Page 22 Category Terminals Name Function description Specification Multi-function +24V +3.3V input terminal 6 Multi-function X1、。。。X7 input terminal 7 Bi-direction Can be defined as multi-function digital Optocoupler isolation output open-collector output terminal , refer to the A6.14 for Maximum working voltage: 30v Multi-fun output detail (Com port: CME)

- Page 23 FV100 AI1,AI2 -10~+10V Shield cable connect Or 0~20mA to PE Fig 4-3 AI1,AI2 terminal wiring 2) AI3+,AI3- can be connected to the analog differential or single-ended input , the wiring is as follows: FV100 FV100 -10V~+10V AI3+/AI3- - 0V ~ +10V Shield cable Analog differential AI3+/AI3-...

- Page 24 Wiring of multiple function input terminal and External controller FV100 operation terminal +3.3V ¡ ¡ FV100 multi-function input terminal uses a full-bridge ¡ rectifying circuit as shown in Fig.4-7. PLC is the ¡ ¡ common terminal of terminals X1~X7, The current +3.3 flows through terminal PLC can be pulling current and the feeding current.

- Page 25 FV100 +24V +3.3V ¡ñ Relay 24V DC ¡ñ ¡ñ ¡ñ ¡ñ +3.3V FV100 ¡ñ ¡ñ Fig 4-13 Wiring method 1 of multi-function ¡ñ output terminal Y1 ¡ñ Shielded cable's end near the drive should be connected to the PE 2. Multi-function output terminal Y1can use the external 24 power supply too, the wiring is as shown in Fig.4-14.

- Page 26 FV100 +24V +24V 4.7k Fig.4-19 Wiring of push-pull output encoder Fig.4-16 Wiring method 2 of output terminal Y2 Wiring of relay output terminals R1a, R1b and R1c Note If the drive drives an inductive load (such as 1. Don’t short circuit terminals 24V and COM, electromagnetic relays and contactor), then a surge otherwise the control board may be damaged.

-

Page 27: Chapter 5 Operation Instructions Of Kinco Vfd

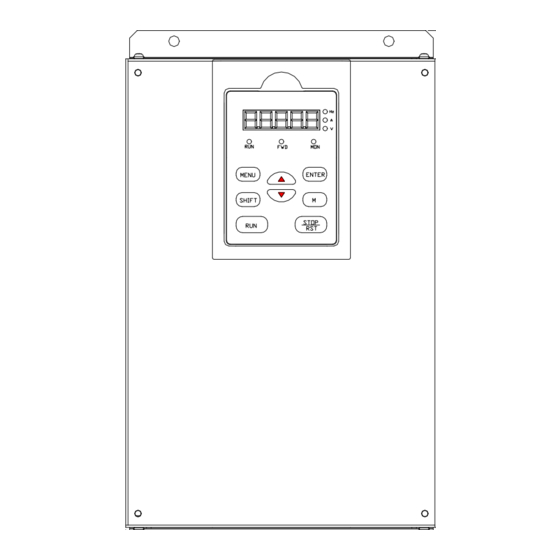

Chapter 5 Operation Instructions of Kinco VFD In this chapter we introduce the necessary knowledge of Kinco VFD and related operations. 5.1 Using Operation Panel 5.1.1 Operation panel appearance and keys’ function description Operation panel is used to setup the drive and display parameters, it is LED display. As shown in Fig.5-1 Fig.5-1 Illustration of operation panel... -

Page 28: Function Descriptions Of Led And Indicators

5.1.2 Function Descriptions of LED and Indicators The operation panel consists of a 5-digits eight segments LED display, 3 LED indicators for unit and 3 LED indicators for status which is as shown in Fig.5-1. The LED display can display the status parameters, function codes and error codes of the drive. -

Page 29: Panel Operation

5.1.4 Panel Operation Various operations can be completed on the operation panel; the following are 5 common examples. Refer to function code list in chapter 9 for detail function code description. Example 1:Set parameters Example: Change the value in A0.03 from 50.00Hz to 30Hz 1. - Page 30 Fig 5-3 Modify the setting frequency After modification, if there are no operations in 5 seconds, The LED will back to display the voltage, it means to display the status before modification. Example 3: Set the password To protect parameters, the VFD provides password protection function. The user needs to input the right password to edit the parameters if the VFD has been set password.

-

Page 31: Operation Mode Of Vfd

3. Motor parameters auto-tuning status: If there is an operating command after b0.11 is set to 1 or 2, the drive then enters motor parameters auto-tuning status, and then enters stopping status after auto-tuning process finishes. 5.2.3 Control mode and operation mode of Kinco VFD Control mode FV100 VFD has three control methods, it is set by A0.01:... -

Page 32: The Channels To Set The Vfd Frequency

3. V/F control: It is used in the applications that do not require very high performance, such as one VFD controls multiple motors. Operation mode Speed control: Control the speed of motor accurately, related function codes in A5 group should be set. Torque control: Control the torque of motor accurately, related function codes in A5 group should be set. -

Page 33: Power On The Drive For The First Time

3) PLC operation This function is customized, description is omitted. 4) Multi-step (MS) speed operation: Select Multiple frequency 1~15 ( C0.00~C0.14) to start Multiple speed operation by the ON/OFF combinations of the multi-function terminals (No.27, 28, 29 and 30 function). If all the terminals are “OFF”,it is in simple operation. Note: About the frequency setting channel under speed mode, please refer to the chapter 6 for detail information 5.3 Power on the Drive for the first time... -

Page 34: Chapter 6 Parameter Introductions

It is used to make the voltage and frequency in a constant ratio. It is applicable to most application, Chapter 6 Parameter Introductions especially for the application of one drive to drive multiple motors. Note: XX .XX YYYYYY N1 ~ N2 【 D 】 A0.02 Main reference 0~4【0】... - Page 35 time 2~4 will be defined in A4.01~A4.06),and the Range: Lower limit of A0.03 Set the operating frequency ~upper limit Acc/Dec time 1~4 can be selected via the combination frequency in digital mode of frequency 【50.00Hz】 of multiple function input terminals,please refer to When the main reference frequency is set in digital A6.00~A6.07.

-

Page 36: Group A1

Note: Note: 1 . Please set Fmax, F and F carefully according to 1. Wrong parameter setting can cause overheat or motor parameters and operating states. over-current protection of the motor. 2. F and F is invalid for JOG mode and auto tuning 2. - Page 37 A1.05 Stopping mode 0、1、2【0】 Frequency(Hz) 0: Dec-to-stop After receiving the stopping command, the drive reduces its output frequency according to the Dec time, and stops when the frequency decreases to 0. 1: Coast-to-stop After receiving the stopping command, the drive stops outputting power immediately and the motor stops under Time( t) the effects of mechanical inertia.

- Page 38 Stop Output Freqency Table 6-1 shows the drive’s action under different Initial Frequency of braking conditions. “0” means the drive enter ready status and “1” means the drive start operation automatically. Waiting time Output Voltage Note: (RMS value) Braking energy 1.

-

Page 39: Group A2

Preset frequency only determined by main reference A1.14 Switch mode of run 0、1【0】 frequency,auxiliary reference frequency is 0Hz by reverse/forward default. 0:Switch when pass 0Hz 1:Set by AI1 terminal 1:Switch when pass starting frequency The auxiliary frequency is set by AI1 terminal. 2:Set by AI2 terminal A1.15 Detecting frequency of 0.00~150.00Hz... -

Page 40: Group A3

A2.02 is used to define the change rate of reference executed. frequency that is changed by terminal UP/DN or ▲/▼ The jog command sent during the interval will not be key. executed. If this command exists, until the end of the interval, will it be executed. - Page 41 reference of inflection point 1 A3.03 Min reference of curve 1 0.0%~A3.01【0.0%】 of curve 4 A3.04 Actual value 0.0%~100.0% A3.19 Min reference of curve 4 0.0%~A3. 17 【0.0%】 corresponding to the Min 【0.0%】 reference of curve 1 A3.20 Actual value 0.0%~100.0% corresponding to the Min A3.07~110.0%...

- Page 42 9)A3.17=8÷20×100%=40.0%,the reference of inflection 1 of curve 4 is actually the percentage of 8kHz AI1 Curve selection 0:Curve 1 1:Curve 2 to 20kHz(A6.10). 2:Curve 3 3:Curve 4 10)A3.18=10.00Hz÷A0.08*100%,set the percentage AI2 Curve selection 0:Curve 1 1:Curve 2 of frequency that corresponds to the reference of 2:Curve 3 3:Curve 4 inflection 1 of curve 4 (8kHz).

-

Page 43: Group A4

Note: Frequency 1.If user set the reference of inflection point 2 of curve 4the same as Max. reference(A3.15=A3.13),then the drive will force A3.16=A3.14,means the setting of Time inflection point 2 is invalid.If reference of inflection Fig.6-12 Linear Acc/Dec point 2 is the same as reference of inflection point 1: S curve Acc/Dec mode. -

Page 44: Group A5

10.0%~50.0% (Acc time) A4.07 S curve acceleration A5.06 ASR2 output filter 0~8【0】 A4.07+ A4.08≤90 【20.0%】 starting time A5.07 ASR1/2 switching 0~100.0%【10.0%】 10.0%~70.0% (Acc time) frequency A4.08 S curve acceleration A4.07+ A4.08≤90 【20.0%】 ending time The parameters A5.00~A5.07 are only valid for vector 10.0%~50.0% (Dec time) control mode. - Page 45 When increasing proportional gain P,it can speed up the 1)Select a suitable switching frequency( A5.07). system’s dynamic response.But if P is too big,the system 2 ) Adjust the proportional gain (A5.01) and integral will become oscillating. time(A5.02) when running at high speed,ensure the When decreasing integral time I,it can speed up the system doesn’t become oscillating and the dynamic system’s dynamic response.But if I is too small,the...

-

Page 46: Group A6

speed and torque Setting Function Setting Function Forward jog A5.16 Filter for torque 0~65535mS【0】 Reverse setting operation Reverse jog 3-wire operation operation control A5.17 ACR-P 1~5000【1000】 External RESET External fault A5.18 ACR-I 0.5~100.0mS【8.0ms】 signal input signal input External interrupt Drive operation A5.17 and A5.18 are the parameters for PI regulator of signal input prohibit... - Page 47 This stopping command is active in all control Setting Function Setting Function modes.When terminal 35 is enabled, the drive will stop Main frequency in the mode defined in A1.05. switch to digital PLC pause 11: DC injection braking command. setting If the setting is 11, the terminal can be used to perform PLC stop memory DC injection braking to the motor that is running so as to...

- Page 48 ON/OFF combinations of these terminals K4,K3,K2 and Speed 15 Output frequency K1. Refer to Group C0 to set the value of Preset frequency. Switch Acc/Dec time along with multi-step speed(Terminal of Preset frequency 1 is closed, terminal of Acc/Dec time selection is closed). Common Speed 1 Operating...

- Page 49 Table 6-4 On/Off combinations for voltage selection The drive will coast to stop if the terminal activate when running forward.If the terminal activate before the drive Voltage setting Determined by run forward,the drive will run in 0Hz. C1.01 38: Reverse prohibit. Preset close-loop The drive will coast to stop if the terminal activate when reference 1...

- Page 50 should be defined as No.1 (Forward) No.2 (Reverse) No.5 function (3-wire operation). First, set the key SB1 in normal close status to make this function(3-wire operation mode 2) enable. Second, press the key SB2 once to give Xf a pulse signal ( ) then the running Fig.6-17 2-wire operating mode 1 direction is forward, at this moment, the key K is in...

- Page 51 A6.13 defines the input terminal’s positive and negative Corresponding value logic Positive logic: Terminal Xi is enabled if it is connected to the common terminal; Frequency A 6.10 Negative logic: Terminal Xi is disabled if it is connected to the common terminal; If the bit is set at 0, it means positive logic;...

- Page 52 1: Frequency arriving signal (FAR) A6.15 Reserved See A6.19. A6.16 Output functions of relay R1 Same as A6.14 2: Frequency detection threshold (FDT1) A6.17 Reserved See A6.20~A6.21. Refer to chapter 3 for the output characteristics of Y1 3: Frequency detection threshold (FDT2) that are bi-direction open-collector output terminal and See A6.22~A6.23.

- Page 53 The terminal outputs the indicating signal if the drive has faults. 17~18: Reserved. 19:Torque limiting The terminal outputs the indicating signal if the torque reach drive torque limit or brake torque limit. 20:Drive running forward/reverse Fig.6-26 Frequency arriving signal The terminal outputs the indicating signal according to 0.00~300.00Hz A6.21 Frequency arriving the drive’s current running direction.

- Page 54 Setting Function Range AI3 Voltage -10V~10V 0~100KHz DI pulse input Percentage 0~4095 host computer 66~88 Reserved Reserved A6.28 Max. output pulse 0.1~100kHz【10.0】 frequency A6.27 Y2 terminal output 0~100【000】 This parameter defines the permissible maximum pulse 0~50: Y2 is used as Y terminal output, its function is the frequency of Y2.

- Page 55 There is a center point in pulse output.The value of the Setting Function Range center point is a half of max. output pulse frequency Bus voltage 0~800V (A6.28).The corresponding value is positive when the 0~Max. analog input input pulse frequency is greater than center point. 0~Max.

-

Page 56: Group A7

input terminal or the analog input terminal is connected Value after adjustment(V) to GND. A6.31=50% A6.31=0 0.00~200.00% A6.40 AI1 gain -10 【110.00%】 Value before adjustment(V) 0.00~200.00% A6.41 AI2 gain 【110.00%】 0.00~200.00% A6.42 AI3 gain -10 【110.00%】 Fig.6-32 The relationship curve between analog AI gain is used for the relationship between analog input output and zero offset and internal value.When increasing the AI gain, then the... -

Page 57: Group A8

board and PG is the same as the direction which decided by the wiring sequence between drive and motor,then set this parameter as 0 (Forwards),or set it as 1 (Reverse). By changing this parameter,the user can change the direction without re-wiring. A7.03 Encoder signal filter 0~99H【30H】... -

Page 58: Group B0

The overload protection is disabled. Be careful to use 1.00 ~ 300.00Hz 【 dependent b0.03 Rated frequency this function because the drive will not protect the motor on drive’s model】 when overload occurs. b0.04 Number of 2~24【4】 1: Common motor (with low speed compensation) polarities of motor Since the cooling effects of common motor deteriorates b0.05 Rated speed... - Page 59 setting of b0.07 is the sum of stator’s leakage inductance leakage inductance (%X1) will be detected and written and rotor’s inductance. into b0.06、b0.07 and b0.08 automatically. The settings of b0.06 ~b0.09 are all percentage values 2: Rotating auto-tuning calculated by the formula below: Values on the motor’s nameplate must be input correctly before starting auto-tuning (...

-

Page 60: Group B1

4. In some applications, for example, the motor cannot b0.13 Motor’s overload 0.0~6000.0s【0.0】 break away from the load or if you have no special protection time requirement on motor’s control performance, you can When b0.13 is not set as 0 and drive outputs current select stationary auto-tuning. - Page 61 according to the actual load so as to achieve best energy-saving effects. 0~2【1】 b1.08 AVR function 0: Disable 1: Enable all the time 2: Disabled in Dec process AVR means automatic voltage regulation. The function can regulate the output voltage and make it constant.

-

Page 62: Group B2

0~1【1】 b2.01Auto adjusting of CWF 0: Disable 1: Enable b2.02 Voltage adjustment 000~111H【001H】 selection Fig.6-38 Offset of output voltage The output voltage corresponding to the setting b2.03 Overvoltage point at 120~150%【140.0%】 frequency in the V/F curve is V/F, then the relationship stall between analog input and offset voltage is as follows: If analog input VAI is -10V~0V or 4mA, then the... - Page 63 b2.07 = 1, Auto current limiting function is enabled in constant speed operating process; In auto current limiting process, the drive’s output frequency may change; therefore, it is recommended not to enable the function when the drive’s output frequency is required stable. When the auto current limiting function is enabled, if b2.05 is set too low, the output overload capacity will be Fig.6-39 Over-voltage at stall...

-

Page 64: Group B3

and then activate the internal temperature detecting b4.04 Parameter copy 0~3【0】 program. 0: No action 1: The fan operates continuously when the power is on. 1: parameters upload 2: parameters download 3: parameters download (except the parameters related 6.13 Group b3 to drive type) Details please refer to the Group b3 of function list in b4.05 Display parameters... -

Page 65: Group C0

6.15 Group C0 Lower limit of frequency~ C0.12 Preset frequency upper limit of frequency Lower limit of frequency~ 【30.00Hz】 upper limit of frequency C0.00 Preset frequency 1 Lower limit of frequency~ C0.13 Preset frequency upper limit of frequency 【5.00Hz】 【40.00Hz】 Lower limit of frequency~ Lower limit of frequency~ upper limit of frequency... - Page 66 In the Fig。, KP: proportional gain; Ki: integral gain Note: The reference can also be input via panel or serial port. In Fig. 6-41, refer to C1.00~C1.14 for the definitions of close-loop reference, feedback, error limit proportional and Integral parameters. Operating principles of internal process close-loop of FV100 is shown in the Fig.

- Page 67 C1.03 Digital setting of Note: -10.00~10.00V【0.00】 reference 1.Fig.6-43,0%~100% in X axis is corresponding to This function can realize digital setting of reference via analog input - 10V ~ 10V,10V of analog input is panel or serial port. corresponding to 100 % ,and - 10V is corresponding to 0%,6V is corresponding to 80%.

- Page 68 This function can make the close-loop regulation enter 0.0~20%【2.0%】 C1.14 Error limit stable status quickly. This parameter defines the max. deviation of the output When the close-loop function is enabled, the frequency from the reference, as shown in Fig. 6-44. Close-loop will ramp up to the preset close-loop frequency (C1.17) regulator stops operation when the feedback value is within the Acc time, and then the drive will start...

-

Page 69: Group C2

will start.When the output frequency is larger than the C1.29 Preset close-loop -10.00~10.00V 【0.00V】 sleep level,the timer for sleep latency will stop and reference 11 clear.If the time of the situation that the output frequency C1.30 Preset close-loop -10.00~10.00V 【0.00V】 is lower than the sleep level is longer than sleep reference 12 latency(C1.37),then the driver will stop.When the actual... - Page 70 In Fig.6-46, a1~a15 and d1~d15 are the acceleration and deceleration of the steps.f1~f15 and T1~T15 are the setting frequency and operating time of the steps.There parameters are defined in group C2. PLC step finish signal and PLC cycle finish signal can be output with pulse signal which last 500ms by bi-direction open collector output Y1, open collector output Y2 or relay.

- Page 71 The ten’s place of LED: Start modes 1: Save the segment frequency after power off 0: Start from first step It will save the PLC operating status including If the drive stop while it was running (Caused by stop step,operating frequency and operating time,then it will command, fault or power failure), then it will start from restart according the the setting in ten’s place of LED first step when it restart.

-

Page 72: Group D0

The unit’s place of LED: selector 0: Multiple frequency N(N:corresponding to current 0.0~6500.0【20.0】 C2.18 Step 9 operating time step)The frequency of current step depends on the C2.19 Step 10 setting mode multiple frequency N.About the details of multiple 0~323H【0000】 selector frequency setting,please refer to Group C0. - Page 73 This parameter is used to monitor the frequency combined by main reference frequency and auxiliary d0.10 Motor estimated -300.00~300.00Hz reference frequency.Positive indicates running forwards, frequency 【0.00】 negative indicates running reverse. This parameters is used to monitor the estimated motor rotor frequency under the condition of open-loop vector d0.03 Frequency after control.

- Page 74 d0.19 ~ d0.21 are used to display the percentage of d0.14 Input terminals status 00~FFH【00】 analog input after regulation. 0.0%~100.0%【0.0】 d0.22 AO1 output BIT0 : X1terminal status BIT1 : X2terminal status BIT2 : X3terminal status 0.0%~100.0%【0.0】 d0.23 AO2 output BIT3 : X4terminal status d0.22、...

-

Page 75: Group D1

(Corresponding d2.01 Software version 0.00~99.99【1.00】 rated torque of motor number d0.35 Zero offset of AI1 0~65535 d2.02 Custom-made version 0~9999【0】 number d0.36 Zero offset of AI2 0~65535 This group of parameters can’t be changed by user. d0.37 Zero offset of AI3 0~65535 d0.38~d0.45 Reserved Reserved... -

Page 76: Chapter 7 Troubleshooting

Chapter 7 Troubleshooting Table 7-1 list the possible faults of FV100, the fault code varies from E001 to E050. Once a fault occurs, you may check it against the table and record the detailed phenomena before seeking service from your supplier. Table 7-1 Faults and actions Fault code Fault categories... - Page 77 Fault code Fault categories Possible reasons for fault Actions Drive’s control Abnormal AC supply voltage Check the AC supply voltage E007 power supply or seek service over voltage Any of phase R, S and T cannot be detected Check the wiring and Input phase installation E008...

- Page 78 Fault code Fault categories Possible reasons for fault Actions the braking time Too short acceleration time Prolong acceleration time Low AC supply voltage Check the AC supply voltage Adjust V/F curve or torque Improper V/F curve boost value Modify the motor’s overload Improper motor’s overload protection threshold protection threshold.

- Page 79 the parameters. Panel’s EEPROM is damaged Seek service Improper settings of parameters on the Set the parameters correctly according to the nameplate nameplate Prohibiting contrarotation Auto-tuning during rollback Cancel prohibiting rollback Check the motor’s wiring Auto-tuning E024 Check the set value of fault A0.10(upper limiting Overtime of auto-tuning...

- Page 80 Table 7-2 Abnormal phenomena and handling methods Phenomena Conditions Possible reasons of fault Actions In stopping status, first press ENTER and hold on, then press ∨ 3 times continuously to unlock the panel Panel is locked up No response Part of the keys or Power-on the drive after it shuts down of operation all the keys are...

- Page 81 Phenomena Conditions Possible reasons of fault Actions when the “RUN” running running of the drive is enabled. key is pressed. of the drive is enabled. Check the terminal used for stopping the Terminal used for stopping the drive is enabled drive In 3-wire control mode, the terminal used to control the 3-wire...

-

Page 82: Chapter 8 Maintenance

Chapter 8 Maintenance Many factors such as ambient temperature, humidity, dust, vibration, internal component aging, wear and tear will give rise to the occurrence of potential faults. Therefore, it is necessary to conduct routine maintenance to the drives. Notes: As safety precautions, before carrying out check and maintenance of the drive, please ensure that : The drive has been switched off;... -

Page 83: Replacing Wearing Parts

General Inspection: 1. Check whether the screws of control terminals are loose. If so, tighten them with a screwdriver; 2. Check whether the main circuit terminals are properly connected; whether the mains cables are over heated; 3. Check whether the power cables and control cables are damaged, check especially for any wear on the cable tube; 4. -

Page 84: Storage

8.4 Storage The following points must be followed for the temporary and long-term storage of drive: 1. Store in locations free of high temperature, humidity, dust, metal powder, and with good ventilation. 2. Long-term storage will cause the deterioration of electrolytic capacitors. Therefore, the drive must be switched on for a test within 2 years at least for 5 hours. -

Page 85: Chapter 9 List Of Parameters

Chapter 9 List of Parameters FV100 series VFD’s parameters are organized in groups. Each group has several parameters that are identified by “Group No.+ Function Code. There are AX,YZ letters in other content in this manual,it indicate the YZ function code in group X.For example,“A6.08”... - Page 86 Function Factory Setting Name Descriptions Unit Modif. code setting range A0.02 Main reference ○ 0:Digital setting frequency selector 1:AI1 2:AI2 3:AI3 4:Set via DI terminal(PULSE) 5:Reserved A0.03 Set the operating A0.11~A0.10 0.01Hz 50.00 ○ 0~30000 frequency in digital mode A0.04 Methods of ○...

- Page 87 Function Factory Setting Name Descriptions Unit Modif. code setting range A0.13 Torque boost 0.1% 0.0% ○ 0~300 0.0%(Auto),0.1%~30.0% Group A1:Start and stop parameters A1.00 Starting mode 0 Start from the starting × frequency 1 Brake first and then start 2 Start on the fly(including direction judgement), start at starting frequency A1.01...

- Page 88 Function Factory Setting Name Descriptions Unit Modif. code setting range restart after power failure A1.12 Anti-reverse × 0:Disabled running function 1: Enabled (It will operate at zero frequency when input a reverse command) A1.13 Delay time of run 0.00~360.00s 0.01s 0.00s ○...

- Page 89 Function Factory Setting Name Descriptions Unit Modif. code setting range calculation Auxiliary reference) 3 : MIN ( Main reference , Auxiliary reference) A2.02 UP/DN rate 0.01~99.99Hz/s 0.01 1.00 ○ 1~9999 A2.03 UP/DN regulating Unit’s place of LED: ○ 0~111H control 0: Save reference frequency upon power outage 1: Not save reference frequency...

- Page 90 Function Factory Setting Name Descriptions Unit Modif. code setting range 3:Curve 4 LED ten’s place: AI2 curve selection 0:Curve 1 1:Curve 2 2:Curve 3 3:Curve 4 LED hundred’s place: AI3 curve selection 0:Curve 1 1:Curve 2 2:Curve 3 3:Curve 4 LED thousand’s place:Pulse input curve selection 0:Curve 1...

- Page 91 Function Factory Setting Name Descriptions Unit Modif. code setting range the Max reference of curve 2 A3.07 Min reference of 0.0%~A3.05 0.01% 0.00% ○ 0~11000 curve 2 A3.08 Actual value The same as A3.02 0.01% 0.00% ○ 0~10000 corresponding to the Min reference of curve 2 A3.09...

- Page 92 Function Factory Setting Name Descriptions Unit Modif. code setting range A3.18 Actual value The same as A3.02 0.01% 0.00% ○ 0~10000 Corresponding to the Min reference of inflection point 1 of curve 4 A3.19 Min reference of 0.0%~A3.17 0.01% 0.00% ○...

- Page 93 Function Factory Setting Name Descriptions Unit Modif. code setting range 1:S curve A4.01 Acc time 2 0.0~6000.0 0.1S 20.0S ○ 0~60000 A4.02 Dec time 2 0.0~6000.0 0.1S 20.0S ○ 0~60000 A4.03 Acc time 3 0.0~6000.0 0.1S 20.0S ○ 0~60000 A4.04 Dec time 3 0.0~6000.0 0.1S...

- Page 94 Function Factory Setting Name Descriptions Unit Modif. code setting range A5.06 ASR2 output filter ○ 0~8(Corresponding to 0~2^8/12.5ms) A5.07 ASR1/2 switching 0.0%~100.0% ○ 0~1000 10.0% frequency A5.08 Maximum speed 0.0%~+100.0% ○ 0~1000 0.1% 100.0% limit for forward running when torque control A5.09 Maximum speed 0.0%~+100.0%...

- Page 95 Function Factory Setting Name Descriptions Unit Modif. code setting range 2:Reverse 3:Forward jog operation 4:Reverse jog operation 5:3-wire operation control 6:External RESET signal input 7:External fault signal input 8:External interrupt signal input 9:Drive operation prohibit 10:External stop command 11:DC injection braking command 12:Coast to stop 13:Frequency ramp up (UP)

- Page 96 Function Factory Setting Name Descriptions Unit Modif. code setting range 26: Auxiliary reference frequency via DI (Reserved) 27:Preset frequency 1 28:Preset frequency 2 29:Preset frequency 3 30:Preset frequency 4 31:Acc/Dec time 1 32:Acc/Dec time 2 33:Multiple close-loop reference selection 1 34:Multiple close-loop reference selection 2 35:Multiple close-loop reference...

- Page 97 Function Factory Setting Name Descriptions Unit Modif. code setting range 3:3-wire operation mode 2 A6.10 Max. frequency of 0.1~100.0(Max.100k) 0.1kHz 10.0 ○ 1~1000 input pulse Only valid when X7 is defined as pulse input. A6.11 Center point of ○ 0:No center point pulse setting 1:Center point mode 1,the center selection...

- Page 98 Function Factory Setting Name Descriptions Unit Modif. code setting range 6: External fault stop signal(EXT) 7: Frequency high limit(FHL) 8: Frequency low limit(FLL) 9: Zero-speed running 10: Terminal X1 (Reserved) 11: Terminal X2(Reserved) 12: PLC running step complete signal 13: PLC running cycle complete signal 14: Reserved 15: Drive ready (RDY)

- Page 99 Function Factory Setting Name Descriptions Unit Modif. code setting range BIT0:Y2 A6.21 Frequency arriving 0.00~300.00Hz 0.01Hz 2.50Hz ○ 0~30000 signal (FAR) A6.22 FDT1 level 0.00~300.00Hz 0.01Hz 50.00Hz ○ 0~30000 A6.23 FDT1 lag 0.00~300.00Hz 0.01Hz 1.00Hz ○ 0~30000 A6.24 FDT2 level 0.00~300.00Hz 0.01Hz 25.00Hz...

- Page 100 Function Factory Setting Name Descriptions Unit Modif. code setting range 14:Reserved 15:Drive ready (RDY) 16:Drive fault 17:Switching signal of host 18:Reserved 19:Torque limiting 20:Drive running forward/reverse 21~50:Reserved 51:Output frequency(0~ Max. output frequency) 52 :Preset frequency (0~ Max. output frequency) 53:Preset frequency (After Acc/Dec)(0~ Max.

- Page 101 Function Factory Setting Name Descriptions Unit Modif. code setting range when frequency less than center point. 2: Center point mode 2.The center point is (A6.26)/2.It is negative when frequency less then center point. A6.30 Functions of ○ 0~36 0:No function terminal AO1 1:Output frequency(0~ Max.

- Page 102 Function Factory Setting Name Descriptions Unit Modif. code setting range calibration of AO2 A6.36 AI1 filter 0.01~10.00s 0.01s 0.05 ○ 1~1000 A6.37 AI2 filter 0.01~10.00s 0.01s 0.05 ○ 1~1000 A6.38 AI3 filter 0.01~10.00s 0.01s 0.05 ○ 1~1000 A6.39 Analog input zero ○...

- Page 103 Function Factory Setting Name Descriptions Unit Modif. code setting range interval fault indication. 0:Disable 1:Enable Hundred’s place of LED: Selection for fault locked function 0:Disable 1:Enable Thousand’s place of LED: Reserved A8.01 Fault masking Unit’s place of LED: 2000 × 0~2222H selection 1 Communication fault masking...

- Page 104 Function Factory Setting Name Descriptions Unit Modif. code setting range when fault happen 2:Enable A8.03 Motor overload 0: Disabled × protection mode 1:Common mode (with low speed selection compensation) 2: Variable frequency motor (without low speed compensation) A8.04 Auto reset times ×...

- Page 105 Function Factory Setting Name Descriptions Unit Modif. code setting range model b0.09 Exciting 0.0%~2000.0% 0.1% Dependent × 0~20000 inductance %Xm on drive’s model b0.10 Current 0.1~999.9A 0.1A Dependent × 1~9999 without load I0 on drive’s model b0.11 Auto-tuning 0: Auto-tuning is disabled ×...

- Page 106 Function Factory Setting Name Descriptions Unit Modif. code setting range b1.07 Cut-off point used 0.0%~50.0%( Corresponding to 0.1% 10.0% ○ 0~500 for manual torque A0.12) boost b1.08 AVR function × 0:Disable 1:Enable all the time 2:Disabled in Dec process b1.09 VF Output Voltage ×...

- Page 107 Function Factory Setting Name Descriptions Unit Modif. code setting range b2.03 Overvoltage point 120.0%~150.0%Udce 0.1% 140.0% × 1200~150 at stall b2.04 Droop control 0.00~10.00Hz 0.00 0.00Hz ○ 0~1000 b2.05 Auto current 20.0%~200.0%Ie 0.1% 150.0% × 200~2000 limiting threshold b2.06 Frequency 0.00~99.99Hz/s 0.01Hz 1.00...

- Page 108 Function Factory Setting Name Descriptions Unit Modif. code setting range drive of power above 7.5KW. Group b3:Communication parameter b3.00 Communication Unit’s place of LED: × 0~155H configuration Baud rate selection 0:4800BPS 1:9600BPS 2:19200BPS 3:38400BPS 4:115200BPS 5:125000BPS Ten’s place of LED: Data format 0:1-8-2-N format,RTU 1:1-8-1-E format,RTU...

- Page 109 Function Factory Setting Name Descriptions Unit Modif. code setting range selection are not locked, and all the keys are usable. 1:The keys on the operation panel are locked, and all the keys are unusable. 2:All the keys except for the multi-functional key are unusable.

- Page 110 Function Factory Setting Name Descriptions Unit Modif. code setting range b4.05 Display Binary setting: 1007H ○ 0~7FFFH parameters BIT1:Operating selection 0:No display;1:Display Unit’s place of LED: BIT0:Output frequency(No display at stop.Display power frequency at energy feedback mode) BIT1:Setting frequency (Flicking.No display at energy feedback mode) BIT2:Output current(No display at stop.Display power frequency...

- Page 111 Function Factory Setting Name Descriptions Unit Modif. code setting range BIT0:Bus voltage BIT1:Speed(R/MIN)(No display at feedback mode) BIT2:Setting speed(R/MIN) (Flicking, no display at feedback mode) Note:If all the BITs are 0,the drive will display setting frequency at stop,display output frequency at operating and display bus voltage at energy feedback mode.

- Page 112 Function Factory Setting Name Descriptions Unit Modif. code setting range C1.00 Close-loop control × 0:Disable function 1:Enable C1.01 Reference channel ○ 0:Digital input selection 1:AI1; 2:AI2; 3:AI3; C1.02 Feedback channel ○ 0:AI1; selection 1:AI2; 2:AI1+AI2; 3:AI1-AI2; 4:MIN(AI1,AI2); 5:MAX(AI1,AI2); 6: DI C1.03 Digital setting of -10.00V~10.00V...

- Page 113 Function Factory Setting Name Descriptions Unit Modif. code setting range C1.13 Output filter 0.01~10.00s 0.01s 0.05 ○ 1~1000 C1.14 Error limit 0.0~20.0% 0.1% 2.0% ○ 0~200 (Corresponding to close-loop reference) C1.15 Close-loop × 0:Positive regulation 1:Negative characteristic C1.16 Integral regulation 0: Stop integral regulation when ×...

- Page 114 Function Factory Setting Name Descriptions Unit Modif. code setting range C1.28 Preset close-loop -10.00V ~10.00V 0.01V 0.00V ○ 0~2000 reference 10 C1.29 Preset close-loop -10.00V ~10.00V 0.01V 0.00V ○ 0~2000 reference 11 C1.30 Preset close-loop -10.00V ~10.00V 0.01V 0.00V ○ 0~2000 reference 12 C1.31...

- Page 115 Function Factory Setting Name Descriptions Unit Modif. code setting range 2: Start from the step and frequency before stop(or alarm) Hundred’s place of LED: Storage after power off 0: Disable 1:Save the segment frequency when power off Thousand’s place of LED: Time unit selector for each step 0: Second 1: Minute...

- Page 116 Function Factory Setting Name Descriptions Unit Modif. code setting range C2.08 Step 4 operating 20.0 ○ 0.0~6500.0 0~65000 time C2.09 Step 5 setting Same as C2.01 ○ 0~323H C2.10 Step 5 operating 20.0 ○ 0.0~6500.0 0~65000 time C2.11 Step 6 setting Same as C2.01 ○...

- Page 117 Function Factory Setting Name Descriptions Unit Modif. code setting range C3.00~C3 Reserved Group d0:Status display d0.00 Main reference -300.00~300.00Hz 0.01Hz 0.00 0~60000 frequency d0.01 Auxiliary -300.00~300.00Hz 0.01Hz 0.00 0~60000 reference frequency d0.02 Preset frequency -300.00~300.00Hz 0.01Hz 0.00 0~60000 d0.03 Frequency after -300.00~300.00Hz 0.01Hz 0.00...

- Page 118 Function Factory Setting Name Descriptions Unit Modif. code setting range bit9:DC over-voltage limiting bit10:Torque limiting bit11:Speed limiting bit12:Drive fault bit13:Speed control bit14:Torque control bit15:Position control (Reserved) d0.14 Input terminals 0~FFH 0~FFH,0:OFF;1:ON status d0.15 Output terminals 0~1FH 0~1FH,0:OFF;1:ON status d0.16 AI1 input -10.00~10.00V 0.01V 0.00...

- Page 119 Function Factory Setting Name Descriptions Unit Modif. code setting range heatsink 2 d0.30 Total conduction 0~65535 hours 1 hours 0~65535 time d0.31 Total operating 0~65535 hours 1 hours 0~65535 time d0.32 Total fan’s 0~ 65535 hours 1 hours 0~65535 operating time d0.33 ASR controller -300.0~300.0% (Corresponding to...

- Page 120 Function Factory Setting Name Descriptions Unit Modif. code setting range (E010) 11:IGBT module’s heatsink overheat (E011) 12:Rectifier’s heatsink overheat (E012) 13:Drive overload (E013) 14:Motor over-load (E014) 15:External equipment fails (E015) 16:EEPROM R/W fault (E016) 17: RS232/RS485 communication failure (E017) 18:Contactor not closed (E018) 19:Current detection circuit has fault,Hall sensor or amplifying circuit(E019 )

- Page 121 Function Factory Setting Name Descriptions Unit Modif. code setting range appears.(For example,when contactor failure,the keypad will display E018 if it is action protection,and the keypad will display A018 if it is warning and continue to run). d1.01 Bus voltage of the 0~999V 0~999 latest failure...

- Page 122 Function Factory Setting Name Descriptions Unit Modif. code setting range U0.00 Factory password **** Factory 0~FFFF - Note:Other parameters in this setting group can’t display until entering the right password. Note:○: Can be modified during operation; ×: Cannot be modified during operating; *: Actually detected and cannot be revised;...

-

Page 123: Communication Protocol

Communication Protocol 1. Networking Mode According to the following pic 10-1, there are two networking modes: Single master and multi-slave, Single master and single slave. Pic 10-1 2. Interfaces RS485 or RS232: asynchronous, semi-duplex Default: 8-N-1, 9600bps, RTU. See Group b3 for parameter settings. 3. -

Page 124: Protocol Format

4. Protocol Format FV100 support Modbus RTU and ASCII, its frame format is shown in Fig.10-2. RTU Format Modbus Mode Start(The space of End(The space of Slave Function Check sum the frame is 3.5 frame is 3.5 Data code address characters at least) characters at least) ASCII Mode... -

Page 125: Protocol Function

Response frame: Frame Slave Function Data Check Frame trail header address code code Register address Setting value Character : ASCII VFD can set different delay time for response according to different application.For RTU mode,the actual delay time for response is 3.5 characters interval at least.For ASCII mode,the actual delay time for response is 1 ms at least. 5. -

Page 126: Control Parameters And Status Parameters Of Vfd

6.Control parameters and status parameters of VFD The control parameters of VFD can achieve the function such as startup,stop,setting operating frequency and so on.Retrieving the status parameters of VFD can obtain the parameters such as operating frequency,output current,output torque and so on. 1.Control parameter The control parameters of VFD are shown in following table. - Page 127 (2)In control parameters,the preset value,range of input/output setting value and decimal point scaling should refer to the corresponding function code. The bits for the control command word 1 are defined as follows: Value Function Note Start VFD(enable when jog is disable) bit2~bit0 111B Running command...

- Page 128 The bits definitions of control word 2 are shown as follows: Value Function Note bit0 VFD operation disable Selection bit for VFD operation enable/disable VFD operation enable bit1 Running(The direction refer to function code) Running direction Other operation status(Refer to control word 1) bit2 Auxiliary reference enable...

- Page 129 Register address Parameters name Note 0x3319 0x331A 0x331B Length setting Not support 0x331C Acceleration time 1 setting 0x331D Deceleration time 1 setting 0x331E Methods of inputting operating commands 0:Panel control 1:Terminal control 2:Communication control 0x331F VFD operating status word 2 0x3320 Main reference frequency selector 0:Digital setting 1(Keypad ∧∨...

- Page 130 bit2 PLC running Non-PLC running bit3 Multi-section frequency operation Non multi-section frequency operation. bit4 Common operation Non-common operation bit5 Swing frequency Non-swing frequency bit6 Under voltage Normal voltage bit7 Reserved bit8 Servo operation bit9 Customized operation bit10 Synchronous speed operation Others Reserved The bit definitions of VFD operating status word 3 are shown as following table:...

- Page 131 Function code Description B4.02 Parameters protection setting A6.00~A6.07 Selection of input terminal X1~X7 A2.03 Main reference frequency control A2.03 Auxiliary reference frequency control C2.00 PLC operation mode C3.00 Swing frequency operation mode B0.00 Motor rated power U0.01 Machine model setting(Factory parameter) U0.09 VFD series selection(Factory parameter) 3....

- Page 132 2)Host computer can only access function code of Group U0 after decryption(write correct factory password into U0.00).If there is no communication for 5 minutes after acquiring access right,the right will disable automatically,and it need to enter password again to access Group U0. 3)After acquiring the access right of Group U0,if host computer read U0.00,it will return 0000 instead of actual factory password.

- Page 133 Data frame Address Function code Register address Register content Checksum Request 0x05 0x06 0x0006 0x0064 0x69A4 Response 0x05 0x06 0x0006 0x0064 0x69A4 Read the output current of No.5 VFD and the response output current of the VFD is 30.0A. Data frame Address Function code Register...

Need help?

Do you have a question about the FV100-2S-0004G and is the answer not in the manual?

Questions and answers