Table of Contents

Advertisement

Quick Links

Welcome

You have selected one of the finest marine power packages available. It incorporates numerous design features to

ensure operating ease and durability.

With proper care and maintenance, you will enjoy using this product for many boating seasons. To ensure maximum

performance and carefree use, we ask that you thoroughly read this manual.

The Operation and Maintenance Manual contains specific instructions for using and maintaining your product. We

suggest that this manual remain with the product for ready reference whenever you are on the water.

Thank you for purchasing one of our products. We sincerely hope your boating will be pleasant!

Mercury Marine, Fond du Lac, Wisconsin, U.S.A.

Name / function:

John Pfeifer, President,

Mercury Marine

Read This Manual Thoroughly

IMPORTANT: If you do not understand any portion of this manual, contact your dealer. Your dealer can also provide a

demonstration of actual starting and operating procedures.

Notice

Throughout this publication, and on your power package, warnings, cautions, and notices, accompanied by the

International Hazard Symbol

particular service or operation that may be hazardous if performed incorrectly or carelessly. Observe them carefully.

These safety alerts alone cannot eliminate the hazards that they signal. Strict compliance with these special instructions

while performing the service, plus common sense operation, are major accident prevention measures.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Indicates a situation which, if not avoided, could result in engine or major component failure.

IMPORTANT: Identifies information essential to the successful completion of the task.

NOTE: Indicates information that helps in the understanding of a particular step or action.

IMPORTANT: The operator (driver) is responsible for the correct and safe operation of the boat, the equipment aboard,

and the safety of all occupants aboard. We strongly recommend that the operator read this Operation and Maintenance

Manual and thoroughly understand the operational instructions for the power package and all related accessories before

the boat is used.

The engine exhaust from this product contains chemicals known to the state of California to cause cancer, birth

defects or other reproductive harm.

The serial numbers are the manufacturer's keys to numerous engineering details that apply to your Mercury Marine

power package. When contacting Mercury Marine about service, always specify model and serial numbers.

Descriptions and specifications contained herein were in effect at the time this was approved for printing. Mercury

Marine, whose policies are based on continuous improvement, reserves the right to discontinue models at any time or to

change specifications or designs without notice and without incurring obligation.

!

, may be used to alert the installer and user to special instructions concerning a

WARNING

!

CAUTION

!

NOTICE

WARNING

!

Advertisement

Table of Contents

Summary of Contents for Mercury TDI 4.2L

-

Page 1: Read This Manual Thoroughly

The engine exhaust from this product contains chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. The serial numbers are the manufacturer’s keys to numerous engineering details that apply to your Mercury Marine power package. When contacting Mercury Marine about service, always specify model and serial numbers. - Page 2 Warranty Message The product you have purchased comes with a limited warranty from Mercury Marine; the terms of the warranty are set forth in the Warranty Manual included with the product. The Warranty Manual contains a description of what is covered, what is not covered, the duration of coverage, how to best obtain warranty coverage, important disclaimers and limitations of damages, and other related information.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Section 1 - Getting to Know Your Power Package Features and Controls............... 2 Digital Throttle and Shift............. 7 TDI 4.2L Engine Description..........2 Engine Electrical System Overload Protection......7 Identification................ 2 Fuses..................7 Audio Warning System............2 Vessel Adapter Assembly Fuse Replacement..... - Page 4 Power Steering and Power Trim Fluids......32 Approved Power Trim Fluids........32 Approved Power Steering Fluids......... 32 Approved Paints..............32 Section 4 - Maintenance Owner and Operator Responsibilities........34 Replacing the Filter............48 Dealer Responsibilities............34 Purging the Fuel System............49 Maintenance................

- Page 5 Excessive Engine Temperature........73 Operate)................75 Insufficient Engine Temperature........74 Section 7 - Customer Assistance Information Owner Service Assistance............78 Contact Information for Mercury Marine Customer Service Local Repair Service............78 ................... 79 Service Away From Home..........78 Customer Service Literature............ 79 Stolen Power Package............

- Page 6 Page iv 90-8M0114081 DECEMBER 2015...

- Page 7 Section 1 - Getting to Know Your Power Package Table of Contents Features and Controls............2 Digital Throttle and Shift..........7 TDI 4.2L Engine Description..........2 Engine Electrical System Overload Protection....... 7 Identification..............2 Fuses ................7 Audio Warning System............ 2 Vessel Adapter Assembly Fuse Replacement ....

-

Page 8: Section 1 - Getting To Know Your Power Package

When contacting Mercury Marine about service, always specify model and serial numbers. Audio Warning System Your Mercury Diesel power package may be equipped with an audio warning system. The audio warning system will not protect the engine from damage. It is designed to warn the operator that a problem has occurred. -

Page 9: Testing The Audio Warning System

Listen for the alarm. The alarm will sound if the system is functioning correctly. Digital Throttle and Shift Digital Throttle and Shift (DTS) operating instructions are provided in a separate manual. Refer to Mercury Diesel's SmartCraft and DTS Operator's Manual. -

Page 10: System Link Digital Gauges

Section 1 - Getting to Know Your Power Package SmartCraft tachometer and speedometer Tachometer Speedometer LCD display 50400 The SmartCraft instrument package also aids in identifying the fault codes associated with the engine audio warning system. The SmartCraft instrument package displays critical engine alarm data and other potential problems on its LCD display. For basic operation information on the SmartCraft instrument package and for details on the warning functions monitored by the system, refer to the manual provided with your gauge package. -

Page 11: Controls

Section 1 - Getting to Know Your Power Package Controls Switches Four‑Position Key Switch • "OFF" ‑ In the "OFF" position, all electrical circuits are off. The engine will not operate with the key switch in the "OFF" position. • "ACC"... -

Page 12: Emergency Stop Switch

30 seconds will restart the engine but cause fault codes to be set. Unless you are in a potentially hazardous situation, turn the key switch off and wait at least 30 seconds before restarting the engine or engines. If after restarting, some fault codes are still being displayed, contact your authorized Mercury Diesel repair facility. Lanyard Stop Switch A lanyard switch is designed to shut down the engine in the event the operator unexpectedly moves away from the helm, as may happen in an accidental ejection. -

Page 13: Keep The Lanyard Stop Switch And Lanyard Cord In Good Operating Condition

Check that the clips on the ends of the cord are in good condition. Replace any damaged or worn lanyard cords. Digital Throttle and Shift Digital Throttle and Shift (DTS) operating instructions are provided in a separate manual. Refer to Mercury Diesel's SmartCraft and DTS Operator's Manual. Engine Electrical System Overload Protection... -

Page 14: Vessel Adapter Assembly Fuse Replacement

Section 1 - Getting to Know Your Power Package Two fuses are located on the top of the engine. Remove the engine cover to access these fuses. Be certain to replace an open fuse only with one of the same rating. 15‑amp fuse 25‑amp fuse 52201... -

Page 15: Keep The Lanyard Stop Switch And Lanyard Cord In Good Operating Condition

Section 1 - Getting to Know Your Power Package The lanyard cord is usually 122–152 cm (4–5 feet) in length when stretched out, with an element on one end made to be inserted into the switch and a clip on the other end for attaching to the operator's PFD or wrist. The lanyard is coiled to make its at‑rest condition as short as possible to minimize the likelihood of lanyard entanglement with nearby objects. -

Page 16: Power Trim

Section 1 - Getting to Know Your Power Package Power Trim Power trim allows the operator to adjust the sterndrive angle while underway to provide the ideal boat angle for varying load and water conditions. Also, the trailering feature allows the operator to raise and lower the sterndrive for trailering, beaching, launching, low‑speed (below 1200 RPM engine speed), and shallow water operation. -

Page 17: Dual-Engine Trim And Trailer

If the fuse burns out, the electrical overload has not been eliminated. Further checks must be made on the electrical system. Contact your Mercury Diesel authorized repair facility. The power trim system is protected from overload by a 110‑amp fuse and a 20‑amp in‑line fuse on the power trim pump. -

Page 18: Emissions Information

Boatbuilders and dealers may not remove the label or the part it is affixed to before sale. If modifications are necessary, contact Mercury Diesel about the availability of replacement decals before proceeding. -

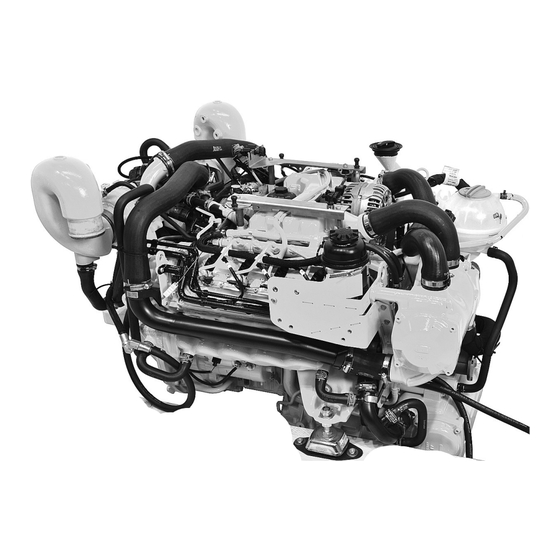

Page 19: Engine Components

Section 1 - Getting to Know Your Power Package Engine Components 52199 Exhaust outlet Turbocharger Oil filter Engine oil filler cap Sacrificial anode (hidden) Intercooler Seawater pump Heat exchanger Starter 90-8M0114081 DECEMBER 2015 Page 13... - Page 20 Fuel injection pump drive belt (hidden) NOTE: The fuel injection pump drive belt is located at the rear of the engine and is protected by a cover. Refer to your Mercury Diesel–authorized repair facility for servicing. Electronic control units Page 14...

- Page 21 Section 2 - On The Water Section 2 - On The Water Table of Contents Safe Boating Recommendations.......... 16 While Boat is in Operation ........22 Carbon Monoxide Exposure..........17 While the Boat is Stationary ........23 Be Alert To Carbon Monoxide Poisoning ..... 17 High Speed and High Performance.......

-

Page 22: Safe Boating Recommendations

Most boats are rated and certified for maximum load (weight) capacities (refer to your boat's capacity plate). Know your boat's operating and loading limitations. Know if your boat will float if it is full of water. When in doubt, contact your authorized Mercury Marine dealer or the boat manufacturer. Ensure that everyone in the boat is properly seated. -

Page 23: Carbon Monoxide Exposure

Section 2 - On The Water Be alert. • The operator of the boat is responsible by law to maintain a proper lookout by sight and hearing. The operator must have an unobstructed view particularly to the front. No passengers, load, or fishing seats should block the operator's view when the boat is above idle or planing transition speed. -

Page 24: Poor Ventilation

(WOT) at the rated engine RPM. The power package must also be applied in accordance with recommendations indicated in the appropriate applications manual. Use of Mercury Diesel engines in other than the applications indicated by the following information and in the appropriate applications manual requires written approval from an authorized Mercury Diesel application engineer. -

Page 25: Basic Boat Operation

Freezing Temperature and Cold Weather Operation IMPORTANT: If the boat is operated during periods of freezing temperature, take precautions to prevent freezing damage to the power package. Damage caused by freezing is not covered by the Mercury Marine Limited Warranty. 90-8M0114081... -

Page 26: Drain Plug And Bilge Pump

• If operating in arctic temperatures of –29° C (–20° F) or lower, consult your Mercury Diesel authorized repair facility for information about special cold weather equipment and precautions. Refer to Section 6 for cold weather or extended storage related information. -

Page 27: Starting A Cold Engine

Check for coolant leaks. Check the coolant hoses and connection pipes of the heat exchanger, fluid coolers, aftercooler, water pump, and drain fittings for leaks. Correct any problems found, or see your Mercury Diesel‑authorized repair facility if you are unable to determine the problem. -

Page 28: Shifting

If adequate road clearance is a problem, place the sterndrive unit in full trailer position and support it with an optional trailer kit, available at your Mercury Diesel authorized repair facility. Protecting People In The Water While Boat is in Operation People in the water cannot take quick action to avoid a boat heading in their direction. -

Page 29: While The Boat Is Stationary

For additional information, refer to the High Performance Boat Operation booklet (90‑849250‑R2) from your authorized Mercury Diesel repair facility. Passenger Safety in Pontoon Boats and Deck Boats Whenever the boat is in motion, observe the location of all passengers. -

Page 30: Wave And Wake Jumping

After striking a submerged object, stop the engine as soon as possible and inspect the drive system for any broken or loose parts. If damage is present or suspected, the power package should be taken to a Mercury Diesel‑authorized repair facility for a thorough inspection and any necessary repair. -

Page 31: Conditions Affecting Operation

Operating a boat or engine with impact damage can result in product damage, serious injury, or death. If the vessel experiences any form of impact, have an authorized Mercury Marine dealer inspect and repair the vessel or power package. Conditions Affecting Operation... -

Page 32: Propeller Selection

Section 2 - On The Water Propeller Selection NOTICE Operating the engine with the wrong propeller installed can limit power, increase fuel consumption, overheat the engine, or cause internal powerhead damage. Choose a propeller that allows the engine to operate at the specified wide open throttle RPM. -

Page 33: After The 20-Hour Break-In Period

End of First Season Checkup At the end of the first season of operation, contact an authorized Mercury Diesel repair facility regarding scheduled maintenance items. If the product is operated on a continuous, or year‑round basis, contact the dealer at the end of the first 100 hours of operation or once yearly, whichever occurs first. - Page 34 Section 2 - On The Water Notes: Page 28 90-8M0114081 DECEMBER 2015...

-

Page 35: Section 3 - Specifications

Section 3 - Specifications Section 3 - Specifications Table of Contents Fuel Requirements............... 30 Engine................32 Nonferrous Metals and the Fuel System ...... 30 Bravo Sterndrive Fluid Specifications—Diesel....32 Diesel Fuel in Cold Weather..........30 Power Steering and Power Trim Fluids......32 Antifreeze/Coolant.............. -

Page 36: Fuel Requirements

Mercury diesels are required to use Grade No. 2‑D ULSD (ultra‑low sulphur diesel) fuel meeting ASTM Standards D975 (or fuel rated Diesel DIN EN 590), and having a minimum cetane rating of 40. -

Page 37: Engine Oil

*Battery manufacturers may rate and test their batteries to different standards. MCA, CCA, Ah, and Reserve Capacity (RC) are the ratings recognized by Mercury Marine. Manufacturers that use standards different than these, such as equivalent MCA, do not meet Mercury Marine battery requirements. -

Page 38: Fluid Specifications

Power Trim and Steering Fluid 92‑802880A1 SAE Engine Oil 30W Obtain locally SAE Engine Oil 40W Obtain locally Approved Paints Description Part Number Mercury Light Gray Primer 92‑802878 52 Mercury Phantom Black 92‑802878Q 1 Diesel White 8M0071082 Page 32 90-8M0114081 DECEMBER 2015... -

Page 39: Section 4 - Maintenance

Section 4 - Maintenance Section 4 - Maintenance Table of Contents Owner and Operator Responsibilities........34 Draining Water from the Filter ........48 Dealer Responsibilities............34 Replacing the Filter ............48 Maintenance................. 34 Purging the Fuel System............49 Replacement Parts Warning..........35 Fuel System................ -

Page 40: Owner And Operator Responsibilities

IMPORTANT: Refer to Maintenance Schedule for a complete listing of all scheduled maintenance to be performed. Some tasks can be done by the owner or operator, while others should be performed by an authorized Mercury Diesel repair facility. Before attempting maintenance or repair procedures not covered in this manual, we recommended that you purchase the appropriate Mercury Diesel service manual and read it thoroughly. -

Page 41: Replacement Parts Warning

Check for loose, damaged, or missing parts, hoses, and clamps; tighten or replace as necessary. Check electrical connections and leads for damage. Remove and inspect the propeller. If it is badly nicked, bent, or cracked, contact your Mercury Diesel–authorized repair facility. -

Page 42: Scheduled Maintenance

IMPORTANT: Due to the risk of damaging equipment if they are performed incorrectly, we highly recommended that the following scheduled maintenance items be performed only by a Mercury Diesel authorized repair facility. Every 5 Years or 500 Hours (Whichever Occurs First) In addition to the Once–a–Year or Every 200 Operating Hours interval:... -

Page 43: Checking

Section 4 - Maintenance Checking NOTICE With the engine running, the crankshaft journals or rod journals may strike and break the dipstick, resulting in damage to internal engine components. Stop the engine completely before removing or inserting the dipstick. If it becomes necessary to check the engine oil level during operation, stop the engine and allow five minutes for the oil to drain into the pan. -

Page 44: Changing Oil And Filter

Section 4 - Maintenance Loosen the oil filter to vent the oil system. 7284 Bilge drain plug Tether Clip Oil drain hose plug Oil drain hose Bilge drain flange Remove the bilge drain plug. Pull the tether through the bilge drain. Place the oil drain hose in a suitable container. -

Page 45: Sterndrive Gear Lube

IMPORTANT: If more than 59 ml (2 fl oz) of High Performance Gear Lube is required to fill the gear lube monitor, a seal may be leaking. Damage to the sterndrive may occur due to lack of lubrication. Contact your Mercury Diesel–authorized repair facility. -

Page 46: Changing

Section 4 - Maintenance Fill the gear lube monitor with the specified gear lube so that the gear lube level is in the operating range. Do not overfill. Gear lube monitor Gear lube level at the "ADD" mark Gear lube level at the "OPERATING RANGE" mark Gear lube monitor cap 19947 Tube Ref No. - Page 47 IMPORTANT: If any water drains from the fill and drain plug hole, or if the gear lube appears milky, the sterndrive is leaking and should be checked immediately by your Mercury Diesel–authorized repair facility. Lower the sterndrive so that the propeller shaft is level.

- Page 48 Section 4 - Maintenance Install the vent plug and sealing washer. 10. Continue to pump gear lube into the drive through the fill and drain plug hole until the gear lube appears in the gear lube monitor. 11. Fill the gear lube monitor so that the gear lube level is in the operating range. Do not overfill. Gear lube monitor Gear lube level at the "ADD"...

-

Page 49: Power Trim Fluid

Section 4 - Maintenance 14. Quickly install the sealing washer and the fill and drain plug. Tighten the plug to the specified torque. mc79506-1 14621 All Bravo models shown Fill and drain plug Sealing washer 19777 Description lb‑in lb‑ft Fill and drain plug —... -

Page 50: Filling

Section 4 - Maintenance Observe the fluid level. The fluid level must be between the "MIN" and "MAX" lines on the reservoir. 7876 Reservoir "MIN" and "MAX" lines Fill as necessary with the specified fluid. Refer to Filling. Tube Ref No. Description Where Used Part No. -

Page 51: Changing

92-858074K01 Install the fill cap. Changing Power trim fluid does not require changing unless it becomes contaminated with water or debris. Contact your Mercury Diesel authorized repair facility. Power Steering Fluid The power steering fluid level should be checked at regular intervals. -

Page 52: Changing

Obtain Locally Transmission Fluid Install the fill cap/dipstick. Changing Power‑assisted steering fluid does not require changing unless it becomes contaminated. See your Mercury Diesel‑authorized repair facility. Engine Coolant CAUTION A sudden loss of pressure can cause hot coolant to boil and discharge violently resulting in serious injury from burns. Allow the engine to cool down before removing the coolant pressure cap. -

Page 53: Checking The Coolant Level

Verify that the coolant level is above the "min" mark on the coolant expansion tank. If the coolant level is below the "min" mark: Inspect the closed‑cooling system for leaks. If any leaks are found, contact your Mercury Diesel authorized repair facility for further diagnosis and repair. -

Page 54: Installation

Section 4 - Maintenance Installation Install the rubber side covers onto the air filter element. Align the marks as shown by the arrows in the air filter mounting illustration. Install the tension springs. Install the large clamps onto the rubber side covers. Tighten the fasteners to retain the boots. Place the small clamps onto the small openings on the rubber side covers. -

Page 55: Purging The Fuel System

Seawater Pump Impeller Inspection The seawater pump impeller must be inspected (and replaced, if necessary) at the interval specified by the maintenance schedule. It is recommended this task be performed at a Mercury Diesel–authorized repair facility. Close the seacock. 90-8M0114081... -

Page 56: Sterndrive Water Inlets Check

Section 4 - Maintenance Remove the four screws on the front side of the seawater pump and remove the cover. Discard the O‑ring. 50717 Seawater pump cover screws Mark the direction of rotation of the impeller and remove the protective cap from the middle of the impeller. Seawater pump Impeller Protective cap... -

Page 57: Flushing And Draining The Seawater System

Section 4 - Maintenance Remove the wire from the sterndrive and retain for periodic water inlet checks. Dual water pickup water inlets Side pickup water inlets 22495 Flushing and Draining the Seawater System Close the seacock. Open and clean the seawater filter. Fill the seawater filter with fresh water and operate the engine at idle. -

Page 58: Checking The Seawater Pickups

Section 4 - Maintenance Checking the Seawater Pickups Verify that the water inlet holes for the seawater pickup are clean and unobstructed. 16776 Typical through-the-hull seawater pickup Typical through-the-transom seawater pickup Water inlet holes Cleaning the Seawater Strainer, if Equipped NOTICE An open seawater strainer or seacock during some service or maintenance procedures can introduce water into the boat, causing damage or sinking the boat. -

Page 59: Corrosion Protection

To help control the effects of galvanic corrosion, Mercury Diesel power packages come with several sacrificial anodes and other corrosion protection devices. For a more comprehensive explanation of corrosion and corrosion protection refer to the Marine Corrosion Protection Guide. -

Page 60: Antifouling Paint

IMPORTANT: Corrosion damage that results from the improper application of anti‑fouling paint is not covered by the limited warranty. In some areas it may be advisable to paint the bottom of the boat to help prevent marine growth. Contact a Mercury Diesel authorized repair facility for recommendations for your boat. -

Page 61: Throttle Cable

The throttle‑control system for the TDI 4.2L engine is electronic and requires no maintenance. See your Mercury Diesel authorized repair facility for diagnosis or repair. Shift Cable The shift‑control system for the TDI 4.2L engine is electronic and requires no maintenance. See your Mercury Diesel authorized repair facility for diagnosis or repair. Transom Assembly Lubricate the gimbal bearing by applying approximately 8–10 pumps of grease from a typical hand‑operated grease gun. -

Page 62: Engine Coupler

Section 4 - Maintenance • Apply a generous coating of one of the following lubricants to the propeller shaft. 20335 Propeller shaft Tube Ref No. Description Where Used Part No. Extreme Grease Propeller shaft 8M0071842 2-4-C with PTFE Propeller shaft 92-802859A 1 Engine Coupler IMPORTANT: These engines are equipped with a sealed engine coupler. -

Page 63: Driveshaft Extension Models

Section 4 - Maintenance Driveshaft Extension Models Lubricate the transom end grease fitting and engine end grease fitting by applying approximately 10–12 pumps of grease from a typical hand‑operated grease gun. Lubricate the driveshaft grease fittings by applying approximately 3–4 pumps of grease from a typical hand‑operated grease gun. -

Page 64: Engine Mounts

Section 4 - Maintenance Engine Mounts Loosen the rear engine mount bolts 1 to 1‑1/2 turns. Tighten the rear engine mount bolts to the specified torque. Rear engine mount Transom plate mount Rear engine mount bolt 19622 Description lb‑in. lb‑ft Rear engine mount bolts –... -

Page 65: Bravo Two Models

Section 4 - Maintenance Place a block of wood between the propeller blade and the sterndrive's anti‑ventilation plate. Wood block Propeller Propeller nut under socket Turn the propeller shaft nut counterclockwise and remove the nut. Slide the propeller and the attaching hardware from the propeller shaft. Bravo One models Propeller shaft splines Forward thrust hub... -

Page 66: Bravo Three Models

Section 4 - Maintenance Slide the propeller and attaching hardware from the propeller shaft. Bravo Two Propeller shaft splines Forward thrust hub Propeller Spline washer Tab washer Propeller nut 8566 Bravo Three Models Place a block of wood between the propeller blade and the sterndrive's anti‑ventilation plate. Remove the bolt and washers securing the propeller shaft anode. -

Page 67: Bravo Sterndrive Propeller Installation

Section 4 - Maintenance Bravo Sterndrive Propeller Installation WARNING Rotating propellers can cause serious injury or death. Never operate the boat out of the water with a propeller installed. Before installing or removing a propeller, place the drive unit in neutral and engage the lanyard stop switch to prevent the engine from starting. -

Page 68: Bravo Three

Section 4 - Maintenance Bend the three tabs down into the grooves. Propeller Tab washer Drive sleeve adapter Tab bent down Propeller nut 4750 Bravo Three Liberally coat the propeller shaft spline with one of the following lubricants. Tube Ref No. Description Where Used Part No. -

Page 69: Drive Belts

Inspecting the belts with the engine running may cause serious injury or death. Turn off the engine and remove the ignition key before inspecting the belts. In the event that the drive belt requires replacement, it is recommended that the drive belt replacement be performed by a Mercury Diesel–authorized repair facility. Drive Belt Failure Identification Appearance... -

Page 70: Battery

Section 4 - Maintenance Appearance Description Cause Solution The belt should be replaced immediately. Improper belt installation is a Ensure all ribs of the Improper installation common cause of premature The belt ribs begin separating replacement belt fit into failure. One of the outermost belt from the joined strands. -

Page 71: Battery Precautions For Multiple Engines

Section 4 - Maintenance WARNING An operating or charging battery produces gas that can ignite and explode, spraying out sulfuric acid, which can cause severe burns. Ventilate the area around the battery and wear protective equipment when handling or servicing batteries. Battery Precautions for Multiple Engines Alternators Alternators are designed to charge a single battery that supplies electrical power to the individual engine on which the... - Page 72 Section 4 - Maintenance Notes: Page 66 90-8M0114081 DECEMBER 2015...

-

Page 73: Section 5 - Storage

Section 5 - Storage Section 5 - Storage Table of Contents Cold Weather (Freezing Temperature), Seasonal Storage, Seasonal Storage Instructions........68 and Extended Storage............68 Extended Storage Instructions........69 Preparing Your Power Package for Seasonal or Battery Storage.............. 70 Extended Storage............68 Recommissioning the Power Package......... -

Page 74: Cold Weather (Freezing Temperature), Seasonal Storage, And Extended Storage

Section 5 - Storage Cold Weather (Freezing Temperature), Seasonal Storage, and Extended Storage IMPORTANT: Mercury Diesel strongly recommends that this service be performed by a Mercury Diesel–authorized repair facility. Damage caused by freezing is not covered by the Mercury Diesel Limited Warranty. -

Page 75: Extended Storage Instructions

If the boat is not fitted with a seacock, leave the water inlet hose disconnected and plugged. IMPORTANT: Mercury Diesel recommends that propylene glycol antifreeze be used in the seawater section of the cooling system for cold weather (freezing temperature), seasonal storage, or extended storage. Make sure that the propylene glycol antifreeze contains a rust inhibitor and is recommended for use in marine engines. -

Page 76: Battery Storage

Section 5 - Storage Read all precautions and perform all procedures found in Seasonal Storage Instructions. Remove the seawater pump impeller and store away from direct sunlight. See a Mercury Diesel–authorized repair facility for additional information and service. IMPORTANT: The seawater pump impeller material can be damaged by prolonged exposure to direct sunlight. - Page 77 Section 6 - Troubleshooting Section 6 - Troubleshooting Table of Contents Troubleshooting..............72 Low Engine Oil Pressure..........74 Troubleshooting Charts............72 Battery Will Not Charge..........74 Starter Motor Will Not Crank Engine, or Cranks Slow... 72 Remote Control Operates Hard, Binds, Has Excessive Engine Will Not Start, or Is Hard to Start.......

-

Page 78: Troubleshooting

The broad network of Mercury Diesel service partners with trained professionals, modern equipment, and all of the required special tools is available to you for the care and service of your Mercury Diesel engine. If repairs must be made, the engine should be brought to an authorized Mercury Diesel repair facility. -

Page 79: Poor Performance

Boat overloaded or improperly distributed. Reduce load or redistribute more evenly. Boat bottom fouled or damaged. Clean or repair as necessary. Have electronic fuel system checked by a Mercury Diesel–authorized repair Electronic fuel system fault. facility. No Fuel or Faulty Fuel Supply... -

Page 80: Insufficient Engine Temperature

Drive belt loose or in poor condition. Replace and/or adjust. Insufficient lubrication on the steering components. Lubricate. Check all parts and fasteners; if any are loose or missing, see a Mercury Loose or missing steering fasteners or parts. Diesel–authorized repair facility immediately. -

Page 81: Power Trim Does Not Operate (Electric Motor Does Not Operate)

Section 6 - Troubleshooting Possible Cause Remedy The drive unit is binding in the gimbal ring. Check for obstruction. See a Mercury Diesel–authorized repair facility. Power Trim Does Not Operate (Electric Motor Does Not Operate) Possible Cause Remedy Blown fuse. - Page 82 Section 6 - Troubleshooting Notes: Page 76 90-8M0114081 DECEMBER 2015...

-

Page 83: Section 7 - Customer Assistance Information

Section 7 - Customer Assistance Information Section 7 - Customer Assistance Information Table of Contents Owner Service Assistance............ 78 Contact Information for Mercury Marine Customer Local Repair Service ............ 78 Service ................. 79 Service Away From Home ..........78 Customer Service Literature..........79 Stolen Power Package .......... -

Page 84: Owner Service Assistance

If your power package is stolen, immediately inform the local authorities and Mercury Marine of the model and serial numbers and to whom the recovery is to be reported. This information is maintained in a database at Mercury Marine to aid authorities and dealers in recovery of stolen power packages. -

Page 85: Contact Information For Mercury Marine Customer Service

Attn: Publications Department W6250 Pioneer Road P.O. Box 1939 Fond du Lac, WI 54936-1939 Outside the United States and Canada, contact the nearest Mercury Marine or Marine Power International Service Center for further information. When ordering be sure to: •... -

Page 86: Other Languages

Section 7 - Customer Assistance Information Other Languages To obtain an Operation, Maintenance and Warranty Manual in another language, contact the nearest Mercury Marine or Marine Power International Service Center for information. A list of part numbers for other languages is provided with your power package. -

Page 87: Section 8 - Maintenance Log

Section 8 - Maintenance Log Section 8 - Maintenance Log Table of Contents Scheduled Maintenance Log..........82 Vessel Maintenance Notes........... 83 90-8M0114081 DECEMBER 2015 Page 81... -

Page 88: Scheduled Maintenance Log

Section 8 - Maintenance Log Scheduled Maintenance Log 100 Hours Actual Hours Service Notes Dealer Name Signature Date 200 Hours Actual Hours Service Notes Dealer Name Signature Date 300 Hours Actual Hours Service Notes Dealer Name Signature Date 400 Hours Actual Hours Service Notes Dealer Name... -

Page 89: Vessel Maintenance Notes

Section 8 - Maintenance Log Vessel Maintenance Notes Record all general maintenance performed on your power package here. Save all work orders and receipts. Engine Date Maintenance Completed Servicing Dealer Hours 90-8M0114081 DECEMBER 2015 Page 83...

Need help?

Do you have a question about the TDI 4.2L and is the answer not in the manual?

Questions and answers