Table of Contents

Advertisement

Quick Links

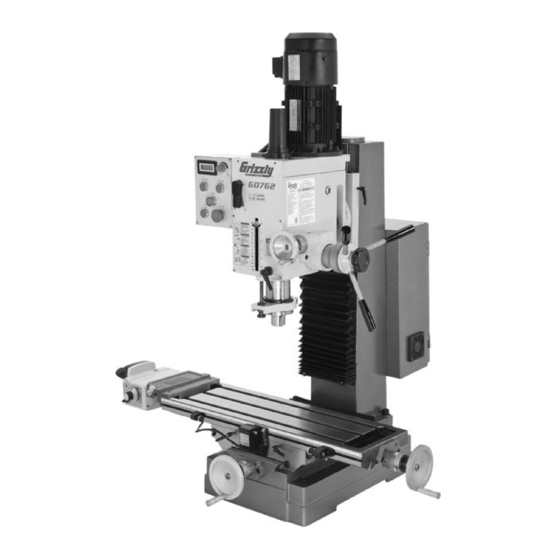

MODEL G0762

HEAVY-DUTY VARIABLE-SPEED

MILL/DRILL w/POWER FEED

OWNER'S MANUAL

(For models manufactured since 5/14)

COPYRIGHT © JUNE, 2014 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#TSDM16171 PRINTED IN CHINA

V1.06.14

Advertisement

Table of Contents

Summary of Contents for Grizzly G0762

- Page 1 (For models manufactured since 5/14) COPYRIGHT © JUNE, 2014 BY GRIZZLY INDUSTRIAL, INC. WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC. #TSDM16171 PRINTED IN CHINA V1.06.14...

- Page 2 This manual provides critical safety instructions on the proper setup, operation, maintenance, and service of this machine/tool. Save this document, refer to it often, and use it to instruct other operators. Failure to read, understand and follow the instructions in this manual may result in fire or serious personal injury—including amputation, electrocution, or death.

-

Page 3: Table Of Contents

Table of Contents INTRODUCTION ..........2 Installing Tooling ............Machine Description ........2 Removing Tooling ............. Contact Info............ 2 Spindle Speed..........29 Manual Accuracy ........... 2 Determining Spindle Speed ........Identification ........... 3 Setting Spindle Speed ..........Controls & Components ......... 4 SECTION 5: ACCESSORIES ...... -

Page 4: Introduction

We want your feedback on this manual. What did you like about it? Where could it be improved? Please take a few minutes to give us feedback. Grizzly Documentation Manager P.O. Box 2069 Bellingham, WA 98227-2069 Email: manuals@grizzly.com Model G0762 (Mfd. Since 5/14) -

Page 5: Identification

Spindle Power Feed X-Axis Stop Power Feed Table Power Feed X-Axis Stop Handwheel Y-Axis Handwheel X-Axis Y-Axis Table Locks Table Lock To reduce your risk of serious injury, read this entire manual BEFORE using machine. Model G0762 (Mfd. Since 5/14) -

Page 6: Controls & Components

C. High/Low Range Lever: Selects either high or low spindle speed range. D. SPINDLE REVERSE Button: Starts coun- terclockwise spindle rotation (as viewed from above). The spindle must be completely stopped before this button is pushed. Model G0762 (Mfd. Since 5/14) - Page 7 P. Depth Stop and Scale: Shows the position X. Limit Switch: Stops table movement when of the spindle and can limit spindle travel. either side plunger contacts a limit stop. Figure 5. Limit switch and limit stops. Model G0762 (Mfd. Since 5/14)

-

Page 8: Machine Data Sheet

Machine Data Sheet MACHINE DATA SHEET Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901 MODEL G0762 HEAVY-DUTY BENCHTOP MILL/DRILL WITH VARIABLE-SPEED AND POWER FEED Product Dimensions: Weight................................728 lbs. Width (side-to-side) x Depth (front-to-back) x Height............... 49-5/8 x 36-5/8 x 61 in. - Page 9 The information contained herein is deemed accurate as of 9/9/2014 and represents our most recent product specifications. Model G0762 PAGE 2 OF 2 Due to our ongoing improvement efforts, this information may not accurately describe items previously purchased. Model G0762 (Mfd. Since 5/14)

-

Page 10: Section 1: Safety

Everyday ery. Never operate under the influence of drugs or eyeglasses are NOT approved safety glasses. alcohol, when tired, or when distracted. Model G0762 (Mfd. Since 5/14) - Page 11 Contact our debris. Make sure they are properly installed, Technical Support at (570) 546-9663. undamaged, and working correctly. Model G0762 (Mfd. Since 5/14)

-

Page 12: Additional Safety For Mill/Drills

OFF to avoid a possible sudden startup once risk of entanglement, always allow spindle to stop on its own. DO NOT stop spindle using your hand power is restored. or any other object. -10- Model G0762 (Mfd. Since 5/14) -

Page 13: Section 2: Power Supply

To reduce the risk of these hazards, avoid over- loading the machine during operation and make sure it is connected to a power supply circuit that meets the requirements in the following section. -11- Model G0762 (Mfd. Since 5/14) -

Page 14: Grounding Requirements

Minimum Gauge Size ......14 AWG local codes and ordinances. Maximum Length (Shorter is Better)..50 ft. -12- Model G0762 (Mfd. Since 5/14) -

Page 15: Section 3: Setup

Mineral Spirits (Page 19) .... As Needed • Block of Wood (Page 19) ......1 SUFFOCATION HAZARD! Keep children and pets away from plastic bags or packing materials shipped with this machine. Discard immediately. -13- Model G0762 (Mfd. Since 5/14) -

Page 16: Inventory

N. Cap Screws M8-1.25 x 12 (Handwheels) ... 2 O. Handwheel Flat Washers 8mm ....2 Power Feed Assembly (Not Shown) ... 1 Q. Cap Screws M8-1.25 x 20 (Not Shown; Power Feed) ......2 -14- Model G0762 (Mfd. Since 5/14) -

Page 17: Cleanup

Figure 9. T23692 Orange Power Degreaser. off the rest with the rag. Repeat Steps 2–3 as necessary until clean, then coat all unpainted surfaces with a quality metal protectant to prevent rust. -15- Model G0762 (Mfd. Since 5/14) -

Page 18: Site Considerations

Only install in an Shadows, glare, or strobe effects that may distract access restricted location. or impede the operator must be eliminated. Wall 30" Minimum Clearance ⁄ " ⁄ " ⁄ " Figure 10. Minimum working clearances. -16- Model G0762 (Mfd. Since 5/14) -

Page 19: Lifting & Placing

Lag Screw Flat Washer Figure 11. Recommended lifting sling position. Machine Base Workbench Figure 13. Example of a "Direct Mount" setup. -17- Model G0762 (Mfd. Since 5/14) -

Page 20: Assembly

Thread handwheel handles into handwheels. Slide handwheels onto right end of X-axis leadscrew and Y-axis leadscrew (see Assembly of the Model G0762 consists of attach- Figure 16), then secure them with (2) M8-1.25 ing the power feed to the table and installing the x 12 cap screws and (2) 8mm handwheel flat handwheels. -

Page 21: Joining Drill Chuck & Arbor

Figure 17. Figure 17. Tapping drill chuck/arbor on block of wood. Try to separate drill chuck and arbor by hand . If you can pull them apart, repeat this proce- dure. -19- Model G0762 (Mfd. Since 5/14) -

Page 22: Test Run

Rotate variable-speed dial all the way coun- terclockwise to set spindle speed to lowest value. Connect machine to power supply. Twist EMERGENCY STOP button clock- wise until it pops out. This resets button and enables power to control panel. -20- Model G0762 (Mfd. Since 5/14) - Page 23 Congratulations! The Test Run is should rotate clockwise (as viewed from top) complete. Continue to the next subsection, and machine should run smoothly with little to Spindle Bearing Break-In. no vibration or rubbing noises. -21- Model G0762 (Mfd. Since 5/14)

-

Page 24: Spindle Bearing Break-In

Change headstock oil while it is still warm (refer to Lubrication on Page 32 for detailed instructions). This ensures you start opera- tion with clean headstock oil. The spindle break-in of the machine is now com- plete! -22- Model G0762 (Mfd. Since 5/14) -

Page 25: Section 4: Operations

Read books/magazines or get formal training before beginning any proj- ects. Regardless of the content in this sec- tion, Grizzly Industrial will not be held liable for accidents caused by lack of training. -23- Model G0762 (Mfd. Since 5/14) -

Page 26: Spindle Movement

The fine downfeed handwheel graduated dial measures spindle movement in 0.001" incre- ments, with one full revolution equaling 0.10" of spindle travel. The graduated dial can be rotated to zero for a relative starting point. -24- Model G0762 (Mfd. Since 5/14) -

Page 27: Headstock Movement

Figure 24. Hex nut underneath headstock. Using scale shown in Figure 23 as a guide, swivel headstock and retighten the three hex nuts to secure it. Z-Axis Crank Figure 22. Z-axis crank. Tighten Z-axis lock levers to secure setting. -25- Model G0762 (Mfd. Since 5/14) -

Page 28: Graduated Dials

Y-axis, loosen the Y-axis table Thumb Screw lock shown in Figure 27, then use the handwheel in front of the table in the same manner as the Figure 26. Graduated dial and thumb screw. X-axis handwheel. -26- Model G0762 (Mfd. Since 5/14) -

Page 29: X-Axis Power Feed

OFF. Installing/Removing Tooling X-Axis Table Locks The Model G0762 includes the following spindle tools (see Figure 30): A. 1–13mm Drill Chuck w/R-8 x B16 Arbor. Figure 28. Table locks and limit stops. Joined with the drill chuck. -

Page 30: Installing Tooling

Working from the top, thread drawbar by hand into tooling until it is snug, then use wrench to tighten it. Note: overtighten drawbar. Overtightening makes tool removal difficult and will damage arbor and threads. Re-install drawbar cap. -28- Model G0762 (Mfd. Since 5/14) -

Page 31: Spindle Speed

Also, there are a large number of easy-to-use spindle speed calculators that can be found on the internet. These sources will help you take into account the applicable variables in order to deter- mine the best spindle speed for the operation. -29- Model G0762 (Mfd. Since 5/14) -

Page 32: Section 5: Accessories

To reduce this risk, only install accessories their lubricity under a variety of conditions—as recommended for this machine by Grizzly. well as reduce chatter or slip. Buy in bulk and save with 5-gallon quantities. -

Page 33: Section 6: Maintenance

• Worn or damaged wires. regular applications of ISO 68 way oil (see • Clean debris and built up grime off of machine. Page 30 for offerings from Grizzly). • Any other unsafe condition. Every 8 Hours of Operation: Lubrication Check/add headstock oil (Page 32). -

Page 34: Headstock

Add oil until sight glass is halfway full, then DISCONNECT MACHINE FROM POWER! replace fill plug. Remove fill plug (see Figure 38). Clean up any spilled oil to prevent slipping hazards. -32- Model G0762 (Mfd. Since 5/14) -

Page 35: Ball Oilers

(see and headstock to access the entire length of the Page 30 for offerings from Grizzly). We do not table and column ways for this procedure (see recommend using metal needle or lance tips, as Figure 41). -

Page 36: Quill Outside Surface

Figure 44. Y-axis leadscrew. When dry, use a clean brush to apply a thin coat of oil to the leadscrew threads, then move the table through the X- and Y-axis paths to distribute the oil. -34- Model G0762 (Mfd. Since 5/14) -

Page 37: Z-Axis Leadscrew & Pinion Gear

Note: Re-apply oil to the quill outside smooth the leadscrew. Move the headstock up and down a few times to evenly distribute the lubricant. surface that may have been removed during the Re-install way cover. cleaning process. -35- Model G0762 (Mfd. Since 5/14) -

Page 38: Section 7: Service

9. Motor bearings at fault. 9. Test by rotating shaft; rotational grinding/loose shaft requires bearing replacement. 10. Spindle extended too far down. 10. Lower headstock so that only a minimum amount of spindle needs to be extended. -36- Model G0762 (Mfd. Since 5/14) - Page 39 3. Check for proper cutting rotation for tooling. 4. Workpiece not secure. 4. Properly clamp workpiece on table or in vise. 5. Spindle extended too far down. 5. Fully retract spindle and lower headstock. This increases rigidity. -37- Model G0762 (Mfd. Since 5/14)

-

Page 40: Adjusting Gibs

Figure 48. X-axis leadscrew nut adjusting cap screw. X-Axis Gib Screw Y-Axis Gib Screw (1 of 2) (1 of 2) Figure 47. Location of table gib screws. -38- Model G0762 (Mfd. Since 5/14) -

Page 41: Tightening Return Spring Tension

Figure 49. Return spring components. If return spring should come loose from spring cap and rapidly unwind, laceration or impact inju- ries could occur. Always wear heavy leather gloves and safety glasses when adjusting return spring ten- sion. -39- Model G0762 (Mfd. Since 5/14) -

Page 42: Section 8: Wiring

Technical source. Support at (570) 546-9663. The photos and diagrams included in this section are best viewed in color. You can view these pages in color at www.grizzly.com. READ ELECTRICAL SAFETY -40- Model G0762 (Mfd. Since 5/14) ON PAGE 40! -

Page 43: Wiring Overview

Wiring Overview Fan Junction Motor Junction RPM Sensor Control Panel Electrical Cabinet Figure 50. Electrical component wiring overview. -41- Model G0762 (Mfd. Since 5/14) -

Page 44: Electrical Cabinet Wiring

14N0 22NC 32NC 44N0 14N0 22NC 32NC 44N0 Right Side L1 N1 Master Power Switch Left Side PE PE L3 L3 Master Power Switch Electrical Cabinet To Power Cord Page 44 To Power Feed -42- Model G0762 (Mfd. Since 5/14) - Page 45 Figure 51. Electrical cabinet. -43- Model G0762 (Mfd. Since 5/14)

-

Page 46: Control Panel & Motor Wiring

JD009B REVA 100223 Emergency Spindle Circuit Board Stop Button Stop Button Rear Panel (Viewed From Behind) Front Panel (Viewed From Behind) Ground Terminal Bar Bottom Panel (Viewed From Above) READ ELECTRICAL SAFETY -44- Model G0762 (Mfd. Since 5/14) ON PAGE 40! - Page 47 Figure 52. Control panel with circuit board. Figure 53. Motor junction box. Figure 54. Motor fan junction box. READ ELECTRICAL SAFETY -45- Model G0762 (Mfd. Since 5/14) ON PAGE 40!

-

Page 48: Section 8: Parts

Please Note: We do our best to stock replacement parts whenever possible, but we cannot guarantee that all parts shown here are available for purchase. Call (800) 523-4777 or visit our online parts store at www.grizzly.com to check for availability. -

Page 49: Headstock Parts List

SHOULDER STUD-UDE M12-1.75 X 145 15,20 P0762041 EXT RETAINING RING 18MM P0762092 TAPERED KNOB M12-1.75 P0762042 SPEED SENSOR P0762093 FINE DOWNFEED HANDWHEEL P0762043 SET SCREW M6-1 X 12 P0762094 HANDWHEEL HANDLE P0762044 SPINDLE SHAFT -47- Model G0762 (Mfd. Since 5/14) - Page 50 P0762119 DRAWBAR ASSEMBLY 7/16-20 X 17-3/4 P0762105 LOCK LEVER SHAFT P0762120 CONTROL PANEL CABINET P0762106 INNER LOCK PLUNGER P0762121 CONTROL PANEL CABINET FRONT COVER P0762107 OUTER LOCK PLUNGER P0762122 CONTROL PANEL CABINET SIDE COVER P0762108 ADJUSTABLE HANDLE -48- Model G0762 (Mfd. Since 5/14)

-

Page 51: Table & Column Diagram

Table & Column Diagram 274-1 274-2 274-4 274-3 274-5 274-6 274-7 274-8 274-15 274-9 274-14 274-10 274-11 274-12 274-13 -49- Model G0762 (Mfd. Since 5/14) - Page 52 P0762245 CAP SCREW M5-.8 X 20 P0762280 Y-AXIS WAY COVER P0762246 CAP SCREW M8-1.25 X 45 P0762281 TABLE SCALE P0762248 X-AXIS GIB P0762282 ELECTRICAL CABINET W/DOOR P0762249 CAP SCREW M8-1.25 X 25 P0762283 HANDWHEEL COMPRESSION SPRING P0762252 Y-AXIS GIB -50- Model G0762 (Mfd. Since 5/14)

-

Page 53: Electrical Component Diagram

Electrical Component Diagram Electrical Cabinet Control Panel -51- Model G0762 (Mfd. Since 5/14) - Page 54 314 P0762314 E-STOP MINGER LA125HBE 102C P0762306 ROTARY SWITCH LW26-25 315 P0762315 STOP BUTTON MINGER LA125HBE 102C P0762307 TERMINAL BAR 1P 316 P0762316 CIRCUIT BOARD JD009B REV-A 100223 P0762308 GROUND TERMINAL BAR 1P 317 P0762317 GROUND TERMINAL BAR 8P -52- Model G0762 (Mfd. Since 5/14)

-

Page 55: Included Accessories

405-1 P0762405-1 DRILL CHUCK KEY 8MM STD 11 SD-16MM P0762414 HEX WRENCH 3MM P0762406 SPINDLE SLEEVE MT#3-MT#2 P0762415 WRENCH 17 X 19 OPEN-ENDS P0762407 DRILL CHUCK ARBOR R8-B16 P0762416 WRENCH 22 X 24 OPEN-ENDS P0762408 SPINDLE SLEEVE R8-MT#3 P0762417 HEX WRENCH 2.5MM -53- Model G0762 (Mfd. Since 5/14) -

Page 56: Labels & Cosmetics

Safety labels help reduce the risk of serious injury caused by machine hazards. If any label comes off or becomes unreadable, the owner of this machine MUST replace it in the original location before resuming operations. For replacements, contact (800) 523-4777 or www.grizzly.com. -54-... -

Page 57: Warranty Card

Would you recommend Grizzly Industrial to a friend? _____ Yes _____No Would you allow us to use your name as a reference for Grizzly customers in your area? Note: We never use names more than 3 times. _____ Yes _____No 10. - Page 58 FOLD ALONG DOTTED LINE Place Stamp Here GRIZZLY INDUSTRIAL, INC. P.O. BOX 2069 BELLINGHAM, WA 98227-2069 FOLD ALONG DOTTED LINE Send a Grizzly Catalog to a friend: Name_______________________________ Street_______________________________ City______________State______Zip______ TAPE ALONG EDGES--PLEASE DO NOT STAPLE...

-

Page 59: Warranty & Returns

WARRANTY & RETURNS Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance.

Need help?

Do you have a question about the G0762 and is the answer not in the manual?

Questions and answers