Table of Contents

Advertisement

When work is being carried out on the engine such as adjusting drive belts, changing oil or

adjusting the clutch, it is important not to start the engine. The engine may be damaged and

!

For this reason, always secure the starting device or disconnect a battery cable before working on

This is especially important if the engine has a remote starter or automatic starting.

This warning symbol and text is reproduced beside those maintenance points where the risk of

When the commissioning report has been filled in and sent to Scania, you have a 1-year warranty from the date

of commissioning.

Also fill in the particulars below as this can make things easier if you need to contact for example a service

workshop.

Engine number

Date of commissioning

User's name and address

Signature

Engine type

Variant

Engine type and variant are indicated on the engine type plate

IMPORTANT INFORMATION

A SERIOUS RISK OF INJURY

injury is particularly great.

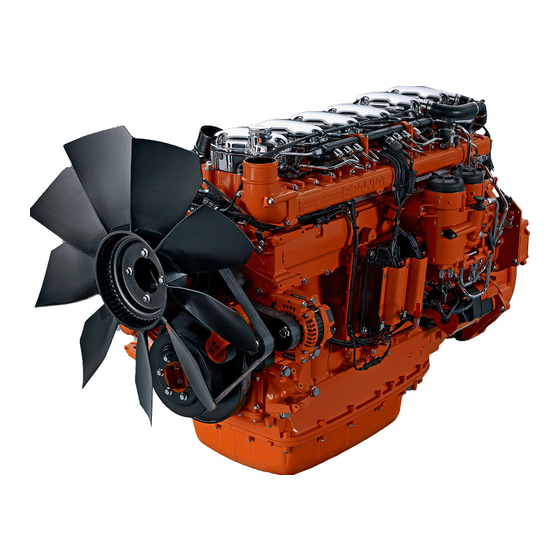

Operator's Manual

DI12, DC12

EMS with S6/PDE

Industrial engine

opm_d12ind_en-GB01

COMMISSIONING REPORT - WARRANTY

there is

the engine.

1 920 785

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the DC12 and is the answer not in the manual?

Questions and answers