Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for roundhouse TALIESIN

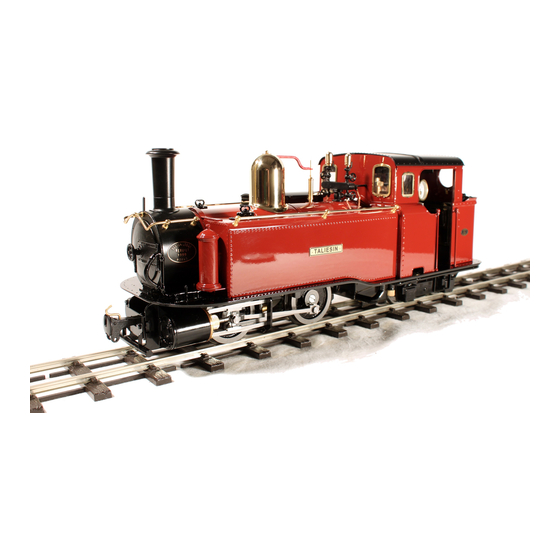

- Page 1 TALIESIN Owners Handbook For the Taliesin Locomotive...

- Page 2 OPERATING INSTRUCTIONS IMPORTANT: Read these instructions carefully before operating the locomotive. The following items are required for running this engine and are not included with the model. Fuel Butane gas. See 'Filling the gas tank' Water See 'Filling the boiler' Lubricating oil See 'Lubrication' SAFETY PRECAUTIONS This is a working model locomotive using steam under pressure...

-

Page 3: Table Of Contents

Taliesin Instruction Booklet CONTENTS Tool kit. Page 4 Running in. Page 4 Access to the controls. Page 4 Identification of parts of the locomotive. Page 5 Preparing for operation. Page 6 1. Charging the batteries Page 6 2. Filling the Gas Tank. -

Page 4: Tool Kit

TOOL KIT The following items are included with your locomotive. One 60ml bottle of special steam oil for use in the lubricator. One 60ml syringe with plastic tube for filling the boiler with water. One water top-up pump bottle. One gas filling adapter. One set of spare washers and ‘0’... -

Page 5: Identification Of Parts Of The Locomotive

IDENTIFICATION OF PARTS OF THE LOCOMOTIVE a) Boiler filler and top-up valve (dome removed). b) Safety valve. c) Steam regulator. d) Gas regulator. e) Gas filler valve. f) Gas jet holder. g) Pressure gauge. h) Water gauge. i) Lubricator filler cap. j) Lubricator drain screw (under footplate). -

Page 6: Preparing For Operation

A special brass gas filler adapter is obtainable from your local garden railway supplier or direct from ROUNDHOUSE. Mixed gasses are also available and may be used if ordinary butane or Iso-butane are not available, but see ‘Gas System’... -

Page 7: Filling The Boiler

Before attempting to fill the gas tank, make sure that the gas control valve is closed by turning it clockwise. The filler valve for the gas tank is on top of the tank under the dummy coal load. Invert the gas canister and place its nozzle over the gas filler valve. -

Page 8: 3B. Filling Using The Pump Bottle

3b) Filling using the Pump bottle when hot or cold. The brass steam dome is open at the top and access to the filler valve can be gained with the pump bottle tube without removing the dome. Fill the pump bottle with clean water and pass the end of the tube down through the hole in the dome and into the top-up valve. -

Page 9: Lighting The Burner

Any water in the lubricator will run out through the drain screw. Tighten the drain screw and refill with the steam oil supplied, then replace the cap. Take time filling the lubricator, especially when cold, as the oil takes time to run down and may trap an air bubble. Both cap and drain screw are fitted with ‘0’... -

Page 10: Running The Locomotive

Roundhouse steam locomotives, you may find Taliesin a little different. All models have a unique ‘feel’ and this single Fairlie is no exception and requires a little more driving than some of our other locomotives. Several factors come into play e.g. large... - Page 11 turned up. After a few minutes of running it may be noticed that the gas pressure through the burner has increased. This is due to the gas tank becoming warmer and so increasing the gas pressure. Simply turn the gas down – this may need to be performed several times during a run.

- Page 12 sprung loaded to return to its central position. Moving up or down has no function. Using the transmitter, select the desired direction of travel and then slowly open the regulator. The locomotive will now move off as described in the manual control section. The art of fine control will soon be learnt with a little practice.

-

Page 13: Water Top-Up System

WATER TOP UP SYSTEM A water top up system is fitted to this model. This enables the water level in the boiler to be monitored and topped up to keep the engine in steam for long periods. Once the locomotive is in operation as detailed in the previous sections, water must be added to the boiler from time to time during the run as follows. - Page 14 water top-up valve. The steam dome can be lifted off if preferred - NOTE: when the locomotive is in service, the steam dome will be hot and a pair of cotton gloves are provided in the tool kit. Push the end of the plastic tube down through the hole in the top of the steam dome and into the socket in the top of the water filling valve.

-

Page 15: Storage Between Operating Sessions

Re-fill the gas tank as detailed earlier whenever it is empty. In this way, you can keep the loco in steam and at working pressure as long as you like. Don’t forget to re-fill the displacement lubricator about every 45 minutes. -

Page 16: Trouble Shooting & Maintenance

TROUBLE SHOOTING & MAINTENANCE On a working model of this nature, it is important to keep all working parts well lubricated. With constant heating up, cooling down and the stresses of hard work, screws etc. can work loose so, it is good practice to check all fixings and cylinder screws regularly but remember, never over tighten. -

Page 17: Radio Control

freely. Place a spot of motor oil between the gland nut and the regulator arm and work the regulator a few times. Contact the factory for further advice. Periodic oiling of the gland will help keep the regulator working freely. Place a spot of motor oil between the gland nut and the regulator arm and work the regulator a few times. -

Page 18: Gas System

GAS SYSTEM Taliesin locomotives are fitted with our 'FG' type gas burner, which is set up and fully tested at the factory. This system is designed for use with Butane or Iso-Butane gas. Mixed gasses, i.e. Butane with a proportion of Propane mixed in, are available, and may be used if straight Butane is unavailable. - Page 19 Wash out the jet in fast evaporating thinner (Cellulose or similar). Blow through the jet from the front, which should clear most blockages. Although the hole through the jet is tiny, if you hold it up to the light you should be able to see quite clearly if it is blocked or not.

-

Page 20: Water Top Up Valve

Clean the tube and valve body and replace the tube. If the tube is damaged, a replacement is available from the Roundhouse factory. Replace the filler valve in the top of the filler plug, not forgetting the copper washer. - Page 22 Please refer to the ‘owner’s handbook’ for your particular model of locomotive, for details on correct use of these pressure vessels. Pressure vessel care and maintenance Gas tank The gas tank is used for the storage of LPG (liquefied petroleum gas) in the form of butane, iso-butane or as set out in the ‘owners handbook’.

- Page 23 Gas Burner 1). Superheater Pipe. 2). Lubricator Pipe. 3). Gas Jet Holder retaining screw. 4). Gas Jet. 5). Gas Jet Holder. 6). Gas Pipe. 7). Gas Burner fixing screw. 8). Air Inlet Holes.

- Page 24 Your dealer is; ROUNDHOUSE If your dealer is unable to help, you may contact the Factory directly: ROUNDHOUSE ENGINEERING CO. LTD. Units 6-9 Churchill Business Park. Churchill Road. Wheatley. Doncaster. DN1 2TF. England Telephone 01302 328035 Fax 01302 761312 email support@roundhouse-eng.com...

Need help?

Do you have a question about the TALIESIN and is the answer not in the manual?

Questions and answers