Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for roundhouse SR&RL 24

- Page 1 SR&RL#24 Owners Handbook For the Sandy River and Rangely Lakes #24 Locomotive...

- Page 2 INTRODUCTION The Sandy River & Rangely Lakes Railroad was a two foot gauge line in Franklin County, Maine, USA. Set in the hills and forests of this New England State, it was aptly named, “The Scenic Route”. Building started in the 1870s and the line reached its peak around the time of the First World War when it had some sixteen locomotives operating on the 113 miles of track that made up the system Falling revenue during the late 1920s and the effects of the great...

-

Page 3: Table Of Contents

SR&RL Instruction Booklet CONTENTS Tool kit. Page 4 Running in. Page 4 Access to controls. Page 4 Coupling engine and tender. Page 4 Identification of parts of the locomotive. Page 5 Preparations for operation. Page 6 1. Filling the Gas Tank. Page 6 2. -

Page 4: Tool Kit

TOOL KIT The following items are included with your locomotive. One 60ml bottle of special steam oil for use in the cylinder lubricator. One 60ml syringe with plastic tube for filling the boiler with water. One set of spare washers and ‘0’ rings. One pair of protective gloves. -

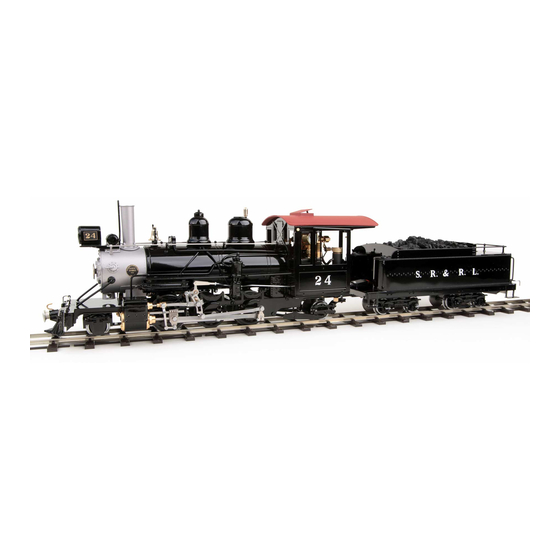

Page 5: Identification Of Parts Of The Locomotive

IDENTIFICATION OF PARTS OF THE LOCOMOTIVE Radio controlled version illustrated 1) Pressure gauge. 2) Boiler filler plug. 3) Safety valve. 4) Boiler top up valve. 5) Gas filler valve 6) Gas regulator. 7) Gas burner. 8) Lubricator cap. 9) Water gauge. OPERATING INSTRUCTIONS IMPORTANT: Read these instructions carefully before operating the locomotive... -

Page 6: Preparations For Operation

EN417 threaded self sealing valve on top and require a special adapter to couple up to the filler valve on the locomotive. A special brass gas filler adapter is obtainable from your local garden railway supplier or direct from ROUNDHOUSE. Mixed gasses are also available and may be used... -

Page 7: Filling The Boiler

if ordinary butane or iso-butane are not available, but see the ‘Gas System’ section for more information on this subject. Before attempting to fill the gas tank, make sure that the gas control valve is closed by turning it clockwise. The filler valve for the gas tank is on top of the tank under the cab roof. -

Page 8: Lubrication

3) LUBRICATION Regular lubrication of all working parts is important and should be carried out before each operating session. There are two types of lubrication required: The external moving linkages and bearings are lubricated with a medium oil such as motor engine oil, and the internal steam mechanisms such as cylinders, pistons and valves are lubricated with a special steam oil that is mixed with the steam. -

Page 9: Running The Locomotive

NOTE as stated above, the gas regulator should be opened slowly until the burner ignites. If opened too quickly, particularly when the engine is cold or if the gas tank has just been filled, it is possible that the flame may not travel back into the boiler flue but stay in the smokebox. -

Page 10: Driving Manually

the water. Always keep an eye on the water level as indicated by the boiler water gauge. Extra water can be pumped into the boiler at regular intervals to maintain the level about 1/2 to 3/4 up the glass. A top up valve is fitted to the top of the boiler inside the cab. Push the end of the plastic pipe on the pump bottle into the fitting and pump the handle. -

Page 11: Driving By Radio Control

run in the reverse direction. It should be parked in the centre (mid gear) when the locomotive is stationary for any length of time. When in mid gear position, the valve gear is effectively in neutral and the engine will not move under steam power. -

Page 12: Storage Between Operating Sessions

manufacturer’s instruction booklet supplied with the Radio Control Set. The art of fine control will soon be learnt with a little practice NOTE: Ensure that the valve gear is fully in gear for the required direction when the engine is moving. The model is fitted with a simplified Walschaerts type valve gear which is not suitable for 'notching up' (altering the cut off). -

Page 13: Altering Wheel Gauge

accumulations of dirt or grit. After washing with paraffin, leave to dry thoroughly overnight before re-oiling. It is most important that clean oil is applied and allowed to penetrate fully into all moving parts before the locomotive is run again. Manually moving the locomotive back and forth will assist in distributing the oil fully. -

Page 14: Steam Leaks

check all fixings and cylinder screws regularly but remember, never over tighten. STEAM LEAKS The cylinders are fitted with '0' rings in the glands sealing both piston and valve rods. These can be adjusted with a spanner if steam leaks develop. They should only be tightened just enough to stop the leak, as over tightening will affect the running of the model. -

Page 15: Gas System

GAS SYSTEM SR&RL#24 locomotives are fitted with our 'FG' type gas burner, which is set up and fully tested at the factory. This system is designed for use with Butane or Iso-Butane gas. Mixed gasses, i.e. Butane with a proportion of Propane mixed in, are available, and may be used if straight Butane is unavailable. - Page 16 delicate balance of the gas system. Reassemble in the reverse order, putting a small amount of PTFE tape round the thread of the jet. Ensure all connections are tight. When re- positioning the gas jet holder in the burner, ensure that it is pushed in as far as it will go.

-

Page 17: Boiler And Gas Tank Certificate, Pages 17

ROUNDHO ENGINEER ING CO. LTD. Model: S.R. & R.L. #24 Serial No.: Stea Model: Type 10 boiler Serial No.: Test date: ator socia Vessel Model Serial No.: Group 1 Test date: gasses and asso- ciated pipe work and fit- tings. Signe Dated R. - Page 18 Please refer to the ‘owners handbook’ for your particular model of locomotive, for details on correct use of these pressure vessels. Pressure vessel care and maintenance Gas tank The gas tank is used for the storage of LPG (liquefied petroleum gas) in the form of butane, iso-butane or as set out in the ‘owners handbook’.

- Page 19 BOILER FILLING SYSTEM The boiler filling system is comprised of a hand held pump bottle which feeds through a flexible water pipe to a check valve on top of the boiler. No special maintenance is required, though the end of the plastic tube will require trimming back occasionally.

-

Page 20: Service And Parts

Your dealer is; ROUNDHOUSE If your dealer is unable to help, please contact the Factory directly: ROUNDHOUSE ENGINEERING CO. LTD. Units 6-10 Churchill Business Park. Churchill Road. Wheatley. Doncaster. DN1 2TF. England Telephone: 01302 328035 Fax: 01302 761312 Email: mail@roundhouse-eng.com...

Need help?

Do you have a question about the SR&RL 24 and is the answer not in the manual?

Questions and answers