Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Yazoo/Kees KKFW48171

-

Page 1: Operators Manual

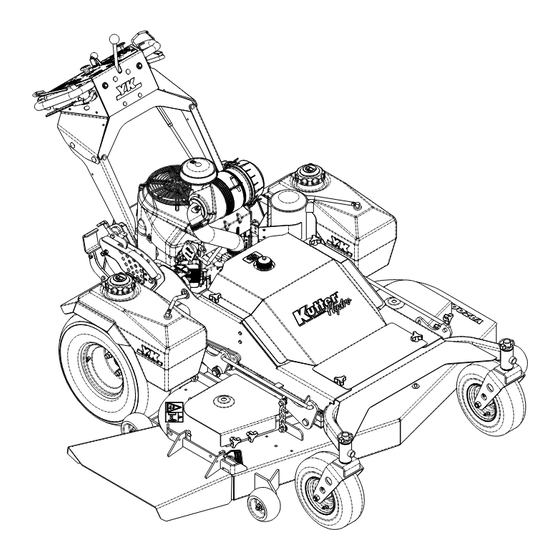

Operators Manual Models: KKFW48171 KKFW52211 MANUAL NO. 110583 REV. IR (03/03/04) - Page 2 Thank you for buying a Yazoo/Kees! Before operating your new mower, read, understand and follow the important safety instructions and the other instructions contained in this manual. Lawnmowers and all power equipment, can be potentially dangerous if used improperly. SAFETY REQUIRES GOOD JUDGEMENT, CAREFUL USE IN ACCORDANCE WITH INSTRUC- TIONS AND COMMON SENSE.

-

Page 3: Table Of Contents

Tire presure ............14 Belts ..............14 Lubrication ............. 14 Fuel filter ..............14 Hydraulic filter and oil ..........15 Cutter housing ............16 Maintenance Chart ..........17 TROUBLE SHOOTING: ........... 18 ©2004 Yazoo/Kees Power Equipment. All rights reserved. Beatrice, NE. Printed U.S.A. -

Page 4: Safety

SAFETY DECALS SHUT OFF ENGINE AND REMOVE KEY BEFORE STAY A SAFE DISTANCE FROM THE MACHINE PERFOMORMING ANY MAINTENANCE OR REPAIR DO NOT OPEN OR REMOVE RISK OF SEVERING OF SAFETY SHIELDS WHILE TOES OR FINGERS MOWER BLADES ENGINE IS RUNING READ OPERATORS RISK OF THROWN OR MANUAL BEFORE... -

Page 5: Training

SAFETY TRAINING: Read this manual carefully and question your dealer if something is not clear. Be thoroughly familiar with the controls and proper use of the equipment. Never allow children, teenagers, or people unfamiliar with these instructions to use the mower. -

Page 6: Transportation

To reduce the risk of fire, keep the mower free of grass, leaves and excessive grease or oil. Have your mower inspected and serviced each year by an authorized Yazoo/Kees dealer. Use only authentic Yazoo/Kees replacement parts to insure the safety and quality of your mower is maintained. -

Page 7: Setup And Adjustments

EQUIPMENT SETUP AND ADJUSTMENTS 1. Uncrate mower 2. Cut the plastic wire ties holding the operator presence levers down. 3. Check tire pressure in all four tires. (15 PSI in all tires) 4. Check engine oil with dipstick. Add if needed per engine manufactures specifications.(See engine manual) 5. -

Page 8: Motion Control Linkage

MOTION CONTROL ADJUSTMENT This adjustment must be made with the drive wheels rotating. 1. Raise rear of the unit off of the ground until the tires can rotate freely. Secure the unit with jack stands. CAUTION: Keep hands, feet and clothing away from rotating tires. 2. -

Page 9: Tracking

TRACKING ADJUSTMENTS This adjustments must be made with the drive wheels rotating. 1. Raise the rear of the unit off of the ground until the tires can rotate freely. Secure the unit with jack stands. CAUTION: Keep hands, feet and clothing away from rotating tires. 2. -

Page 10: Mower Deck Leveling

MOWER DECK LEVELING: 1. Position mower on a flat surface and stop engine. 2. Check the tire pressure of all four tires. Inflation should be 15 psi. 3. Place two 2x4’s on edge under the blades from side side and lower the deck down onto the 2x4’s. -

Page 11: Pump Belt

PUMP BELT 1. Before performing adjustments on pump belt, turn the mower off and disconnect spark plug wire or wires. 2. Check tension on the belt. If it feels loose adjustment will need to be made. 3. Loosen the nut on the bottom of the idler pulley. 4. -

Page 12: Operating Instructions

OPERATING INSTRUCTIONS CONTROLS: Be thoroughly familiar with all controls their function and how to operate them before operating the mower. FIGURE 4 Drive levers: Located on each side of the handle control direction of movement. The left lever controls the flow of oil from the left hydro pump to the left wheel motor. The right lever controls the flow of oil from the right hydro pump to the right wheel motor. -

Page 13: Starting And Operation

Blade engagement switch: Located in the center of the console. To engage the blades pull up on the switch. Push down on the switch to disengage the blades. Throttle control: Located in the middle of the console. Use the throttle to control the engine RPM. Choke control: Use when starting cold engine do not run choke when engine is warm. -

Page 14: Maintenance

MAINTENANCE 1. Engine oil level: Check daily with engine cold and on a flat surface. Remove the dipstick and wipe clean. Reinsert the dipstick all the way,but do not screw down. Remove the dipstick and check oil level. If oil level is low add oil. Use engine manufacturers specs for type of oil. 2. -

Page 15: Hydraulic Filter And Oil

Then replace with new filter. Use only Yazoo/Kees p/n 102606, filter which has a bypass valve and the correct micron filter. Remove the cap nut from the bottom of the tank and allow the tank to drain, reinstall the cap nut. -

Page 16: Cutter Housing

MAINTENANCE CUTTER HOUSING SPINDLE ASSEMBLYS Grease housings once weekly or every 40 to 50 hours of use. Use a good synthetic grease. Pump grease in until a small amount purges from the popet on the underside of the deck. Check the torque of the pulley bolt (45 ft/lbs) should be maintained. -

Page 17: Maintenance Chart

MAINTENANCE CHART Maintenance Maintance Interval (hours) Daily Engine (4) Check oil level Change oil and filter (1) Clean the air filter’s (2) Replace air filter’s (2) Check for fuel and oil leakage Clean cooling flanges (2) Check cooling air inlet Replace fuel filter Replace plugs Electrical... -

Page 18: Trouble Shooting

TROUBLE SHOOTING PROBLEM POSSIBLE CAUSES 1. Blade switch engaged. Engine won’t start 2. Drive levers not locked in thumb latches. 3. Fuel valve closed or turned to empty tank. 4. No fuel. 5. Spark plug wires off. 6. Bad spark plugs. 7.

Need help?

Do you have a question about the KKFW48171 and is the answer not in the manual?

Questions and answers