Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Carver 360 SPORT SEDAN

- Page 1 2004 360 Sport Sedan Owner’s Guide HIN - CDR 2004 Version 1...

- Page 3 U.S. Coast Guard Auxiliary, United States Power Squad- ron, or any enterprise experienced in conducting safe boating courses. Thank you for choosing Carver. We’re confident your new boat will provide you and your family with years of enjoyable cruising.

- Page 5 Model Designation 360 Sport Sedan Carver Boat Corporation declares that the 360 Sport Sedan complies with EC directive 94/25/EC, and in accordance with the following harmonized standards and the recreational craft sectoral guidelines in effect at the time of construction.

-

Page 7: Table Of Contents

ABLE OF ONTENTS Preface ..................i Using Your Owner’s Information Kit ........... i Owner’s Guide ................i OEM Information ................ ii Pre-Delivery Service Record ............ii Warranty Registration ............... iii Boating Safety ................. 1.0 Safe Operation ................ 1.1 Adverse Conditions ..............1.2 Weather ............... - Page 8 ABLE OF ONTENTS Boating Regulations ............ 1.5.8 Garbage ............1.5.8.1 Oil ..............1.5.8.2 Septic Waste ........... 1.5.8.3 State and Local Ordinances ......1.5.8.4 Pre-Departure Actions ..........1.5.9 Carbon Monoxide (CO) Warnings ..........1.6 Preventing CO Exposure ..........1.6.1 Identifying CO Exposure ..........1.6.2 Treating CO Exposure ..........

- Page 9 ABLE OF ONTENTS Salon Accessories .......... 2.2.2.9 Wiper Port ............2.2.2.10 Wiper Center ..........2.2.2.11 Wiper Starboard ..........2.2.2.12 DC Outlet Lower Helm ........2.2.2.13 Forward Stateroom Head Fan ....... 2.2.2.14 Propane ............2.2.2.15 Forward Stateroom Lights ......2.2.2.16 Salon Lights ........... 2.2.2.17 Exterior Lights ..........

- Page 10 ABLE OF ONTENTS Battery Maintenance .............. 2.3 Troubleshooting the DC Electrical System ......2.4 DC Wiring Schematic............... 2.5 AC Electrical System ............... 3.0 System Organization ............... 3.1 Wiring System ............. 3.1.1 AC Power Sources ..............3.2 Shore Power ..............3.2.1 Generator Power ............

- Page 11 ABLE OF ONTENTS AC Wiring Schematic ............... 3.8 Internal Systems ..............4.0 Air Conditioning System ............4.1 Producing Heat ............4.1.1 Powering the Air Conditioning ........4.1.2 Fresh Water System ..............4.2 Filling the Water Tank ..........4.2.1 Pressurizing and Priming the Water System ....4.2.2 Using the Water System ..........

- Page 12 ABLE OF ONTENTS Cooling System ................ 5.3 Exhaust System ..............5.4 Fire Suppression System ............5.5 Engine Gauges ................ 5.6 Tachometer ..............5.6.1 Temperature Gauge ............ 5.6.2 Oil Pressure Gauge ............5.6.3 Voltmeters ..............5.6.4 Fuel Gauges ..............5.6.5 Gauge Maintenance ............ 5.6.6 Helm Controls ................

- Page 13 ABLE OF ONTENTS Anchoring ................6.4 Stern Anchors ............. 6.4.1 Mooring Lines .............. 6.4.2 Getting Underway ..............6.5 Shakedown Cruise ............6.5.1 Operating at Planing Speed ........6.5.2 Trim Tabs ..............6.5.3 Maintenance ................7.0 Maintenance Schedule ............7.1 Type A Maintenance ........... 7.1.1 Type B Maintenance ...........

- Page 14 ABLE OF ONTENTS Props ................7.4.4 Struts ................7.4.5 DC Electrical System ........... 7.4.6 Fresh Water System ............ 7.4.7 Shower ............. 7.4.7.1 Water Taps ............7.4.7.2 Sump ..............7.4.7.3 Pressure Water Pump ........7.4.7.4 Water Tank Vent Screen ......... 7.4.7.5 Bilge System ..............

- Page 15 Safety Equipment ............8.5.6 After Launch ..............8.5.7 Warranty and Parts ..............9.0 Warranty Information .............. 9.1 Carver Dealer’s Responsibilities ......... 9.1.1 Warranty Information ........9.1.1.1 Pre-Delivery Service Procedure ..... 9.1.1.2 Boat and Systems Review ......9.1.1.3 Owner’s Responsibilities ..........9.1.2 Pre-Delivery Service Record ......

-

Page 17: Preface

NOTE: Provides important information that can help you avoid problems. ARVER There are many people within the Carver organization who are avid boaters. Some of the experience gained during our years of boating are presented in this Owner's Guide. This information is presented in the left margin and is entitled “A TIP FROM CARVER.”... -

Page 18: Oem Information

Dealer for any parts or service required for your boat. The information contained in this Owner’s Guide was complete and accurate at the time the guide was printed. Carver reserves the right to change materials, part numbers, specifications, or system designs at any time without notice. -

Page 19: Warranty Registration

The Warranty Registration that follows this page is the first step in activating your Carver limited warranty. This document must be com- pleted and signed by you and your Carver Dealer before you take deliv- ery of your new Carver yacht. Failure to complete and register this Warranty Registration could void your Carver limited warranty. - Page 21 Zip Code: Telephone: ( Date of Purchase: Purchased From: Boat Hull Identification Number: Third Owner Registration does not extend, alter, or transfer the Carver Limited Warranty. Refer to the Carver Limited Warranty for details. SECOND OWNER REGISTRATION ’ Owner s Name:...

- Page 22 CARVER BOAT CORPORATION P O BOX 1010 PULASKI WI 54162-1010 CARVER BOAT CORPORATION P O BOX 1010 PULASKI WI 54162-1010...

-

Page 25: Boating Safety

ECTION OATING AFETY 1.0 Boating Safety Boating safety is your responsibility. You must fully understand the operating procedures and safety precautions in the Owner’s Information kit and this owner’s guide before you operate your new boat. Safe boating is no accident. 1.1 Safe Operation Safe operation includes, but is not limited to, the following. - Page 26 OATING AFETY ECTION • Instruct at least one passenger onboard in the basic operation of your boat. This person can take over if you unexpectedly become unable to do so. • Do not allow passengers to ride on parts of your boat other than desig- nated seating areas.

-

Page 27: Adverse Conditions

ECTION OATING AFETY 1.2 Adverse Conditions 1.2.1 Weather At all times, the boat operator should be aware of present weather condi- tions and the weather forecast. Check the forecast before you begin a day of boating. Be aware, however, that weather conditions can change rapidly. If you have a marine radio, listen to the weather reports issued by the U.S. - Page 28 OATING AFETY ECTION EATHER IGNALS Small Craft Adv Gale Warning Winds to 38 mph Winds to 54 mph 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7...

-

Page 29: Emergency Procedures

ECTION OATING AFETY 1.3 Emergency Procedures The following is not an exhaustive list of situations which may be encoun- tered while boating. You should obtain training to handle any emergen- cies which may arise. 1.3.1 Fire Any fire onboard your boat is serious. Explosion is possible. Develop a fire response plan. -

Page 30: Flooding

OATING AFETY ECTION • Keep the fire downwind if possible. If the fire is aft, head into the wind. • Have all persons onboard put on their personal flotation devices. • If you can get at the fire, aim the fire extinguisher at the base of the flames and use a sweeping motion to put out the fire. -

Page 31: Collision

ECTION OATING AFETY 1.3.4 Collision If a serious collision occurs, check everyone onboard for injuries, then inspect the boat to determine the extent of the damage. • Prepare to help the other craft unless your boat or its passengers are in danger. -

Page 32: Medical Emergency

OATING AFETY ECTION ATER URVIVAL HART Water Exhaustion/ Expected Time Temp. (°F) Unconsciousness of Survival 32.5 Under 15 min. Under 45 min. 32.5-40 15-30 min. 30-90 min. 40-50 30-60 min. 1-3 hr. 50-60 1-2 hr. 1-6 hr. 60-70 2-7 hr. 2-40 hr. -

Page 33: Distress Signals

ECTION OATING AFETY 1.3.10 Distress Signals The operator is required to lend assistance to a craft in distress as long as your life or boat is not put in harm’s way in the process. Good Samari- tan laws protect you from any liability incurred while giving aid. 3428 5/03... -

Page 34: Safety Equipment

OATING AFETY ECTION 1.4 Safety Equipment NOTE: Federal law requires you to provide and maintain safety equipment onboard your boat. Consult U.S. Coast Guard, state and local regulations to ensure your boat has all required safety equipment onboard. You must learn about any additional recommended equipment before operating the boat. -

Page 35: Sound Signaling Device

Your boat must have an operable device that can produce a sound signal if conditions require. A horn is standard equipment on all Carver models. Boats longer than 39 feet, 4 inches, must have a bell and a whistle. These devices must meet the requirements of the Inland Navigational Rules Act of 1980. -

Page 36: Recommended Equipment

OATING AFETY ECTION Boats longer than 40' and shorter than 65': Because your boat has a fixed fire extinguishing system approved by the U.S. Coast Guard, Two Type B-I or one Type B-II extinguisher is required. All fire extinguishers should be mounted in a readily accessible location away from the engine room. -

Page 37: Owner's Responsibilities

“Boating Safety Training Manual” and “Federal Requirements For Recreational Boats.” Check with your local U.S. Coast Guard station, your Carver Dealer, or a local marina about navigational aids unique to your area. -

Page 38: Drugs And Alcohol

OATING AFETY ECTION In addition to required documents, it is strongly recommended that you maintain the following logs. Log books are available from maritime supply stores. • A navigation log containing engine speeds, compass courses and time records, which are essential for both cruising and maintenance pur- poses. -

Page 39: Boating Accidents

ECTION OATING AFETY 1.5.7 Boating Accidents The operator of a vessel used for recreational purposes is required to file a report whenever an accident results in loss of life or disappearance from a vessel, an injury requiring medical treatment beyond first aid, property damage in excess of $200 or complete loss of the vessel. -

Page 40: State And Local Ordinances

OATING AFETY ECTION 1.5.8.4 State and Local Ordinances Your state or locality may have laws limiting speed, noise, or your boat’s wake. Check with your harbor master to find out whether your boat’s opera- tion is restricted in any way by local ordinances or state laws. Check with state and local authorities to make sure that you are in compliance with local regulations regarding marine sanitation, noise, speed and wake. -

Page 41: Carbon Monoxide (Co) Warnings

Prolonged exposure to CO can result in unconsciousness, brain damage and death. Carver has installed CO detectors on your boat. Have these detectors pro- fessionally calibrated at regular intervals. 1.6.1 Preventing CO Exposure To help prevent the accumulation of CO in your boat’s cabin and in enclosed... -

Page 42: Identifying Co Exposure

OATING AFETY ECTION Under certain speed and operating conditions, the low pressure area may form in other areas of the boat and permit CO to enter through openings that are not near the stern. To avoid backdrafting: - Maintain the proper trim angle; avoid a high bow angle. - Distribute the boat’s load evenly. -

Page 43: Treating Co Exposure

ECTION OATING AFETY 1.6.3 Treating CO Exposure If you suspect that someone is suffering from exposure to CO, take the following actions immediately: • Thoroughly ventilate the area if possible • Evacuate the area and move the affected person(s) to a fresh air envi- ronment •... -

Page 44: Warning Labels

OATING AFETY ECTION 1.7 Warning Labels Warning labels are posted throughout your boat to protect you, your pas- sengers, your boat and its equipment, and any personal property on the boat. It is important to read, understand and obey all warning labels. Failure to obey a warning label may result in serious injury or damage to the boat, its equipment, or any personal property on the boat. - Page 45 ECTION OATING AFETY 3428 5/03...

- Page 46 OATING AFETY ECTION 3428 5/03...

-

Page 47: Dc Electrical System

DC E ECTION LECTRICAL YSTEM 2.0 DC Electrical System Your boat is equipped with a 12-volt DC (Direct Current) electrical system. This is a comprehensive system that is designed to meet your present and future 12-volt electrical needs. Wire-runs and connections are positioned to prevent abrasion and exposure to moisture, as well as to remain accessible for inspection, repairs, and the addition of aftermar- ket electrical accessories. -

Page 48: Generator Battery

DC E LECTRICAL YSTEM ECTION Refer to 9.7.4 Engine Room and 9.7.1 Interior Hatches for the exact locations of the “house” battery and its master disconnect switch. 2.1.3 Generator Battery The generator has its own dedicated battery. This battery is located beneath a hatch in the cockpit. -

Page 49: Charging The Batteries

DC E ECTION LECTRICAL YSTEM 2.1.5 Charging the Batteries While the engines are running, their alternators generally supply enough power to replace the power used by the boat’s 12-volt equipment. Without an engine running, however, the 12-volt equipment will eventu- ally drain the batteries they are using. - Page 50 DC E LECTRICAL YSTEM ECTION To operate the battery charger: 1. Provide AC power to the boat, from either a shore power source or the generator. Refer to 3.2.1 Shore Power or 3.2.2 Generator Power for more information. 2. On the AC Control Center, switch the Battery Charger 2 circuit breaker “ON.”...

-

Page 51: Operating The 12-Volt Equipment

DC E ECTION LECTRICAL YSTEM 2.2 Operating the 12-Volt Equipment Power to your boat’s 12-volt equipment is controlled by circuit breakers and, in most cases, individual controls for each piece of equipment. Your boat contains three 12-volt circuit breaker panels: •... -

Page 52: Safety Breaker Panel

DC E LECTRICAL YSTEM ECTION AFETY REAKER ANEL R2008B 2.2.1.1 Auto Bilge Pump - Forward, Mid and Aft These breakers control the flow of electricity to the bilge pumps. Each pump is activated automatically by a float switch whenever water within the bilge rises to a predetermined level. -

Page 53: High Water

Owner’s Guide for information on minimizing, detecting and controlling carbon monoxide accumulation. Carver has installed carbon monoxide (CO) detectors on your boat for your safety. The CO detectors monitor the air throughout the boat’s cabin for the presence of carbon monoxide. This breaker must be “ON” for the CO detectors to operate. -

Page 54: Oil Changer

DC E LECTRICAL YSTEM ECTION 2.2.1.7 Oil Changer This breaker controls the flow of electricity to the optional oil change system. This system is located in the engine room on the aft centerline and is designed to assist you in changing the propulsion and generator engine oil. -

Page 55: Dc Main

DC E ECTION LECTRICAL YSTEM R2071BU DC C ONTROL ENTER 2.2.2.4 DC Main This breaker controls the flow of electricity to all of the other circuit breakers on this panel. To supply power to the other circuit breakers, switch the System DC Main breaker “ON.” To cut the power to the other breakers, switch this breaker “OFF.”... -

Page 56: Spare

DC E LECTRICAL YSTEM ECTION 2.2.2.8 Spare This breaker is reserved for aftermarket accessories you install on your boat. 2.2.2.9 Salon Accessories This breaker controls the flow of electricity to any aftermarket accesso- ries installed in the salon. Switch this breaker “ON” to activate these accessories. -

Page 57: Forward Stateroom Lights

DC E ECTION LECTRICAL YSTEM 2.2.2.16 Forward Stateroom Lights This breaker controls the flow of electricity to the light switches in the master stateroom, guest stateroom, and head. To supply power to the switches, switch this breaker “ON.” 2.2.2.17 Salon Lights This breaker controls the flow of electricity to the light switches in the salon, galley, and dinette. -

Page 58: Spare

DC E LECTRICAL YSTEM ECTION 2.2.2.24 Spare This breaker is reserved for aftermarket accessories you install on your boat. 2.2.2.25 Water Monitor This breaker controls the flow of electricity to the fresh water tank’s monitoring system, including the water level gauge. To supply power to the system, switch this breaker “ON.”... -

Page 59: Bridge Breaker Panel

DC E ECTION LECTRICAL YSTEM 2.2.3 Bridge Breaker Panel The Bridge Breaker Panel, located in a cabinet in the port outboard bulkhead of the bridge, manages the power supply to the bridge’s 12-volt equipment and the bilge blowers. To provide power to this breaker panel, turn the “house” battery master disconnect switch to the “ON”... -

Page 60: Fuel Transfer Pump

DC E LECTRICAL YSTEM ECTION R2020B RIDGE REAKER ANEL R2075B 2.2.3.7 Fuel Transfer Pump This breaker controls the flow of electricity to the fuel transfer pump switch at the helm. This pump is present only if your boat has optional diesel engines. -

Page 61: Bilge Blower (1 - 4)

DC E ECTION LECTRICAL YSTEM 2.2.3.9 Bilge Blower (1 - 4) Always run the bilge blowers for at least 4 minutes before starting the boat’s engines or the generator. These four breakers control the flow of electricity to the Bilge Blower switch at the helm and on the DC Control Center. -

Page 62: Radar

DC E LECTRICAL YSTEM ECTION 2.2.3.15 Radar This breaker controls the flow of electricity to the optional radar system. To supply power to the radar, switch this breaker “ON.” Refer to the OEM information for details on operating the radar. 2.2.3.16 VHF Radio This breaker controls the flow of electricity to the optional VHF radio. -

Page 63: Battery Maintenance

DC E ECTION LECTRICAL YSTEM 2.3 Battery Maintenance The batteries contain electrolyte which is an acid. Wear gloves and protective eyewear when working on and around the batteries. When servicing the batteries avoid spilling electrolyte into the engine room or bilge. Also, avoid getting any salt water in or on the battery. Either of these conditions can create a poisonous gas that is harmful if inhaled. - Page 64 DC E LECTRICAL YSTEM ECTION TILLED water only until the electrolyte is at the correct level. DO NOT OVERFILL the cells. • Remove the batteries from the boat during periods of extended storage. Store your batteries in a cool (above freezing temperature), dry area.

-

Page 65: Troubleshooting The Dc Electrical System

DC E ECTION LECTRICAL YSTEM 2.4 Troubleshooting the DC Electrical System Problem Possible Cause Possible Solution 12-volt equipment “House” battery master Turn the switch to the “ON” does not function. disconnect switch is in the position. “OFF” position. DC Main circuit breaker on the Turn the circuit breaker “ON.”... -

Page 66: Dc Wiring Schematic

DC E LECTRICAL YSTEM ECTION 2.5 DC Wiring Schematic R2082D-1 3428 5/03... - Page 67 DC E ECTION LECTRICAL YSTEM R2082D-2 3428 5/03...

- Page 68 DC E LECTRICAL YSTEM ECTION 3428 5/03...

-

Page 69: Ac Electrical System

AC E ECTION LECTRICAL YSTEM 3.0 AC Electrical System Your boat is equipped with a 30 amp AC (alternating current) electrical system. The power for this system is supplied by either a shore power source or the generator. The procedures for connecting to a shore power source and to the generator are explained later in this section. -

Page 70: Ac Power Sources

AC E LECTRICAL YSTEM ECTION 3.2 AC Power Sources You can supply power to your boat’s AC electrical system by using either a shore power source or the onboard generator. 3.2.1 Shore Power You can use a shore power source to supply AC power to your boat’s AC electrical system. - Page 71 AC E ECTION LECTRICAL YSTEM Do not allow the end of the shore power cord(s) to hang in the water. This can cause an electrical field to form which can kill or seriously injure nearby swimmers or passengers. 5. Choose a neat and safe way to route the shore power cord(s) to the shore power source box.

-

Page 72: Generator Power

AC E LECTRICAL YSTEM ECTION 12. Monitor the voltmeter(s) and ammeter(s) on the AC Control Center while your boat is connected to the shore power source. The operation of the voltmeter and ammeter is described later in this section. Only people who are trained and experienced in working with electricity should service your boat’s high voltage AC electrical system. - Page 73 AC E ECTION LECTRICAL YSTEM 3. The generator engine uses a seawater cooling system. This system includes a strainer that prevents debris in the seawater from enter- ing the cooling system’s water pump. Make sure the cooling system’s seacock is closed. Remove and clean the strainer. The seacock and strainer are located just inboard of the generator.

- Page 74 AC E LECTRICAL YSTEM ECTION ENERATOR AYOUT ASOLINE Fuel Supply Port Fuel Tank Valve Fuel Solenoid Valve Generator Battery Master Disconnect Generator Switch Battery Cooling System Generator Seacock Seawater Exhaust Thru- Strainer Hull Fitting / Seawater Outlet Muffler R2030C ENERATOR AYOUT IESEL Port Fuel Tank...

- Page 75 AC E ECTION LECTRICAL YSTEM continue to hold the switch in its “START” position after the generator starts, you may damage the starter. While you are attempting to start the generator, never hold the STOP/ START switch in the “START” position for more than 10 seconds. 10.

-

Page 76: Operating Ac Equipment

AC E LECTRICAL YSTEM ECTION 3.3 Operating AC Equipment Power to your boat’s AC equipment is controlled by circuit breakers and, in most cases, individual controls for each component. Your boat contains one AC circuit breaker panel: the AC Control Center. The circuit breakers on this panel enables you to control the electricity to either the equipment itself or to the equipments’... -

Page 77: Shore #1 And #2 Safe Indicators

AC E ECTION LECTRICAL YSTEM If a voltmeter reads zero voltage, it means that no electricity is reaching the AC Control Center for the respective line circuit. If you are using the generator, make sure: • It is operating properly. •... -

Page 78: Shore #1 And #2 Main

AC E LECTRICAL YSTEM ECTION R2071BU AC C ONTROL ENTER As you switch the circuit breakers on the AC Control Center “ON” and turn on their associated equipment or turn on equipment plugged into the AC receptacles, the ammeter readings increase above zero amps. Refer to 3.5 Electrical Loads for information on the AC electrical system load limits. -

Page 79: Range

AC E ECTION LECTRICAL YSTEM R2086C 3.3.1.8 Range This breaker controls the flow of electricity to the galley’s stove top. Switch this breaker “ON” to supply power to the stove top. Refer to the OEM information for details on operating the stove top. 3428 5/03... -

Page 80: Microwave

AC E LECTRICAL YSTEM ECTION 3.3.1.9 Microwave This breaker controls the flow of electricity to the galley’s convection microwave. Switch this breaker “ON” to supply power to the microwave. Refer to the OEM information for details on operating the microwave. 3.3.1.10 Water Heater Do not supply power to the water heater when it is empty. -

Page 81: Central Vacuum

AC E ECTION LECTRICAL YSTEM 3.3.1.15 Central Vacuum This breaker controls the flow of electricity to the optional central vacuum system. Switch this breaker “ON” to supply power to the system. The central vacuum hose connection is located in the salon. Refer to the OEM information for details on operating the central vacuum system. -

Page 82: Spare

AC E LECTRICAL YSTEM ECTION This breaker controls the flow of electricity to the air conditioning unit in the salon. Before switching this breaker “ON” to supply power to the unit, switch the A/C System Water Pump breaker “ON.” 3.1.1.20 Spare This breaker is reserved for aftermarket accessories you install on your boat. -

Page 83: Ground Fault Circuit Interrupters

AC E ECTION LECTRICAL YSTEM 3.4 Ground Fault Circuit Interrupters When someone receives an electrical shock through a GFCI recep- tacle, the current flowing to the receptacle continues flowing through the person’s body and into any grounded object the person is touching or standing on. - Page 84 AC E LECTRICAL YSTEM ECTION 3. Repeat Step 2 for each receptacle on the same circuit as the GFCI receptacle. 4. Press the Reset button to restore power to the GFCI receptacle and to all other receptacles on that circuit. GFCI R ECEPTACLE OCATIONS...

-

Page 85: Electrical Loads

AC E ECTION LECTRICAL YSTEM 3.5 Electrical Loads When operating AC powered devices through your boat’s AC electrical system, be aware that each device exerts a “load” on the system. This load is equal to the amount of current (amps) that the device draws from the AC electrical system. -

Page 86: Bonding System

50% of their original size. Do not allow the zinc anodes to completely deteriorate. Refer to “7.1 Mainte- nance Schedule” for recommended inspection intervals. NOTE: Damage resulting from stray current or galvanic corrosion is NOT covered under the Carver limited warranty. 3428 5/03... -

Page 87: Troubleshooting The Ac Electrical System

Locate the tripped GFCI and press A GFCI tripped. the Reset button. The Shore #1 or Shore The circuit breaker failed. Contact your Carver Dealer to #2 Main circuit breaker have the circuit breaker replaced. on the AC Control Center trips immedi- ately after being reset. -

Page 88: Ac Wiring Schematic

AC E LECTRICAL YSTEM ECTION 3.6 AC Wiring Schematic R2081B 3428 5/03... - Page 89 AC E ECTION LECTRICAL YSTEM 3428 5/03...

- Page 90 AC E LECTRICAL YSTEM ECTION 3428 5/03...

-

Page 91: Internal Systems

As seawater temperature decreases so does the air conditioning system’s ability to produce warm air. Carver recommends that the air conditioning system not be operated in reverse cycle mode when the seawater temperature is below 40 degrees F. - Page 92 NTERNAL YSTEMS ECTION Safety Breaker Panel must be “ON” whenever the air conditioning system is operating. 5. On the Safety Breaker Panel, switch the Auto Sump - Forward circuit breaker “ON.” Do not run the air conditioning system’s water pump when the seacock that supplies seawater to the system is closed.

-

Page 93: Fresh Water System

ECTION NTERNAL YSTEMS 4.2 Fresh Water System The capacity of your boat’s fresh water system is approximately 86 gal- lons. The water is divided between one 75-gallon fresh water tank and an 11-gallon water heater. The water tank and water heater are located beneath a hatch in the cockpit. - Page 94 NTERNAL YSTEMS ECTION RESH ATER YSTEM Fresh Water Washdown Head Sink Head Shower Head Toilet Galley Sink Pressure Water Pump Icemaker Fresh Water Water Heater Tank Fresh Water Water Filter Tank Fill Plate and Vent Fresh Water Washdown Transom Hand Shower Shore Water Inlet R2045D...

-

Page 95: Using The Water System

ECTION NTERNAL YSTEMS ARVER If your boat will be left unattended for at least a few days, switch the Pressure Water Pump circuit breaker on the DC Control Center “OFF.” If this breaker is left on, pressure in the fresh water system may fall and cause the water pressure pump to engage. -

Page 96: Shower And Sinks

NTERNAL YSTEMS ECTION To operate the water heater: 1. Fill, pressurize, and prime the fresh water system. This automati- cally fills the water heater. 2. On the AC Control Center, switch the Shore #1 Main circuit breaker “ON,” then switch the Water Heater circuit breaker “ON.” 3. -

Page 97: Fresh Water Washdowns

ECTION NTERNAL YSTEMS YSTEM Master State- room A/C Unit Condensation Drain Shower Drain Sump with Pump Sump Overboard Drain R2060B 4.2.3.4 Fresh Water Washdowns The optional bow and transom fresh water washdowns enable you to use water from the fresh water tank to washdown and clean your boat. -

Page 98: Shore Water

NTERNAL YSTEMS ECTION ARVER Remember that the fresh water washdown system draws its water from the boat’s fresh water tank. Prolonged use of the washdown system quickly re- duces the amount of fresh water in the water tank. 4.2.4 Shore Water Your boat has a shore water fitting that enables your fresh water system to draw water from a land water source while your boat is docked. -

Page 99: Raw Water Washdowns

ECTION NTERNAL YSTEMS 4.3 Raw Water Washdowns The optional bow and transom raw water washdowns enable you to use seawater to washdown and clean your boat. To use the raw water washdowns: 1. Locate the bow- and transom-mounted hose fittings. The bow- mounted fitting is located on the starboard bow toe rail. - Page 100 NTERNAL YSTEMS ECTION ATER ASHDOWN YSTEM Bow-Mounted Hose Fitting Pump Seawater Strainer Transom- Seawater Mounted Hose Seacock Fitting R2043B point at which the pump automatically shuts off. When the hose nozzle is open, releasing water from the system, the pressure in the system decreases.

-

Page 101: Bilge System

ECTION NTERNAL YSTEMS 4.4 Bilge System Your boat contains two bilges and three automatic bilge pumps. The bilge is the lowest point in the interior of the boat’s hull where any water that finds its way into the hull will accumulate. Each bilge pump can remove up to 1500 gallons of water per hour. - Page 102 NTERNAL YSTEMS ECTION ILGE YSTEM Forward Bilge Pump with High Forward Bilge Water Sensor Pump Discharge Amidships Bilge Amidships Bilge Pump Pump Discharge Manual Bilge Manual Bilge Pump Handle Pump Discharge Manual Bilge Aft Bilge Pump Pump Discharge Aft Bilge Pump with High Water Sensor R2011B...

-

Page 103: Automatic Operation

ECTION NTERNAL YSTEMS Your boat is equipped with a high bilge water alarm. If the alarm sounds, there is most likely a hull breach, faulty bilge pump, or faulty seacock/ hose. Immediately identify and correct the cause of the high water, and remove the water. -

Page 104: Hull Drain

NTERNAL YSTEMS ECTION 4.4.2 Hull Drain Your boat is equipped with one hull drain. The drain allows water to drain from the bilges while the boat is in dry storage. The boat and cradle should be positioned to allow water to flow toward the hull drain. The drain is located in the transom in the deepest portion of the hull’s “V.”... -

Page 105: Sanitation System

ECTION NTERNAL YSTEMS 4.5 Sanitation System Your boat’s sanitation system includes the head, waste tank, and the optional overboard waste discharge system. When properly used, this system conforms to all United States antipollution laws. 4.5.1 Toilet The toilet uses fresh water and vacuum pressure to remove waste from the head. - Page 106 NTERNAL YSTEMS ECTION ANITATION YSTEM Toilet Drain Waste Tank Vent Vent Filter Waste Tank Toilet Vacuum Generator Y-Valve Overboard Discharge Seacock Overboard Waste Tank Discharge Pump Deck Plate R2044D 1. Locate a dockside pumpout station. 2. If your boat has the optional overboard discharge system, turn the overboard discharge Y-valve so that it points to the deck plate hose.

-

Page 107: Overboard Discharge

If you do lose the plate, you can order a replacement from your Carver Dealer. WASTE deck plates are dropped overboard frequently enough that we suggest you carry an extra in your onboard spare parts kit. - Page 108 NTERNAL YSTEMS ECTION 3. Turn the “house” battery master disconnect switch to the “ON” position. 4. On the DC Control Center, switch the DC Main circuit breaker “ON,” then switch the Forward Waste Pump circuit breaker “ON.” 5. Turn the overboard discharge pump switch “ON.” The switch is located above the Y-valve.

-

Page 109: Grey Water Holding System

ECTION NTERNAL YSTEMS 4.6 Grey Water Holding System Certain areas of the United States and Europe have initiated antipollu- tion regulations that require the use of a grey water holding system on boats. When the optional grey water holding system is installed, all sink and shower drain water, as well as condensation from the master stateroom air conditioning unit, drains into a 56-gallon grey water tank rather than directly overboard. - Page 110 NTERNAL YSTEMS ECTION ATER OLDING YSTEM Grey Water Deck Plate Master Stateroom Air Conditioning Unit Condensation Drain Head Sink Drain Grey Water Holding Tank Head Shower Drain Grey Water Holding Tank Vent Sump Galley Sink Drain R2104B 3428 5/03...

- Page 111 ECTION NTERNAL YSTEMS using your boat’s overboard discharge system. People who discharge grey water overboard in restricted areas are subject to significant penalties. With the overboard discharge method, grey water is stored in the grey water tank until you enter an area where it is legal to pump the grey water directly overboard.

- Page 112 NTERNAL YSTEMS ECTION 3428 5/03...

-

Page 113: Propulsion

ECTION ROPULSION 5.0 Propulsion Your boat can be equipped with several types of inboard engine pack- ages. The engines may be gas or diesel. This section gives a general overview of your propulsion system and how it works. For a detailed explanation of the engines installed in your boat, including how to oper- ate and maintain them, refer to the OEM information. -

Page 114: Fuel Tanks

Additionally, the entire fuel system passed Carver’s own pressure testing and inspection. Before your boat is delivered, your Carver Dealer also makes a full inspection of the fuel system. An entry on the Carver Pre-Delivery Service Record verifies the dealer’s completion of this inspection. - Page 115 ECTION ROPULSION YSTEM ASOLINE Port Fuel Tank Stbd Fuel Tank Port Engine Stbd Engine Fuel Shut-Off Fuel Shut-Off Valve Valve Port Fuel Tank Fill Fitting Stbd Fuel Tank Fill Fitting Port Fuel Tank Vent Stbd Fuel Tank Vent R2032C YSTEM IESEL Port Fuel Tank Fuel Transfer...

-

Page 116: Engine Room Ventilation

ROPULSION ECTION 5.2 Engine Room Ventilation Your boat’s engine room is equipped with a ventilation system consisting of intake ducts, exhaust ducts and bilge blowers. This system is designed to remove any fuel vapor from the engine room. The bilge blowers oper- ate whenever the engines are running, as long as the four Bilge Blower circuit breakers on the DC Control Center are “ON.”... -

Page 117: Cooling System

If you are not sure which type of cooling system is installed on your boat, contact your Carver Dealer. Both open and closed cooling systems require seawater to function. Before each cruise, make sure the cooling system seacocks are closed, then make sure the optional strainers are free of seaweed and other debris. -

Page 118: Exhaust System

ROPULSION ECTION 5.4 Exhaust System The exhaust system for each engine consists of an exhaust manifold, a muffler, and the exhaust pipes used to remove exhaust from the engine to the atmosphere. If the exhaust system contains leaks or obstructions, or has any other problem that prevents it from venting exhaust properly, carbon monoxide may escape and endanger you and your passengers. -

Page 119: Fire Suppression System

ECTION ROPULSION 5.5 Fire Suppression System An automatic fire suppression system is installed in the engine room. This system provides extra security in the event of an engine room fire. Refer to the OEM information for details on operating the fire suppres- sion system. -

Page 120: Engine Gauges

ROPULSION ECTION 5.6 Engine Gauges Each helm is equipped with a complete set of gauges on the instrument panel. The gauges allow you to monitor the operation and condition of your boat’s propulsion systems while underway. The side of the instru- ment panel that the gauges are on (port or starboard) determines the respective engine that the gauges are for. -

Page 121: Oil Pressure Gauge

ECTION ROPULSION Even with high temperature alarms installed, it is important that you visually monitor both temperature gauges while running the engines. If a temperature gauge indicates excessive engine temperature, immediately shut off the affected engine. The engine manufacturer has established a maximum coolant tempera- ture rating for your engines, as listed in the engine OEM information. -

Page 122: Voltmeters

NOTE: Small beads of moisture (condensation) can form behind the glass bezel on some gauges. This does not mean the gauge is defective. The Carver Limited Warranty does not cover the replacement of gauges that are cosmetically affected by condensation. -

Page 123: Helm Controls

ECTION ROPULSION 5.7 Helm Controls The helm controls allow you to engage the boat’s engines, control the boat’s speed and engine RPMs, and control the direction in which the boat is traveling. 5.7.1 Shift/Throttle Levers Two shift/throttle levers allow you to both shift the engines from neutral to forward or reverse and control the engine RPMs. - Page 124 ROPULSION ECTION The cylinder is connected to the tiller tie rod. Extending and retract- ing the cylinder moves the rudders, enabling you to steer the boat. With hydraulic steering, the effort needed to turn the helm remains the same regardless of the boat’s speed. For the hydraulic steering system to operate properly, it must have an adequate supply of hydraulic fluid and sufficient pressure within the hydraulic pump and lines.

-

Page 125: Preparing For Cruising

ECTION ROPULSION 5.8 Preparing for Cruising Follow the steps below to safely fuel your boat and operate its engines. 5.8.1 Fueling 1. Make sure that your boat is securely moored. 2. Close all portlights, windows, hatches, and doors. 3. Turn “OFF” all devices that could create a spark, including fans, motors, the galley range, and the generator. -

Page 126: Pre-Start Checklist

ROPULSION ECTION and 75% full. During this time the pressure inside the tank must not exceed 4 psi. Be aware that many marine fuel pumps can deliver fuel at rates up to 35 GPM. This high fueling rate should never be used with your boat as it could damage your fuel system. -

Page 127: Starting The Engines

ECTION ROPULSION 6. On the Bridge Breaker Panel, switch the System DC Main circuit breaker “ON,” then switch the four Bilge Blower circuit breakers “ON.” Also switch “ON” any other circuit breakers for equipment you may need. 7. Turn the bilge blowers “ON” using the blower switch at the helm or on the DC Control Center. -

Page 128: After The Engines Have Started

ROPULSION ECTION 4. Place one hand on the shift/throttle lever of the engine you are starting. With the other hand, turn the ignition key. The oil pressure alarm sounds for the first few seconds after the engine has started. This is normal. The alarm is silenced as soon as the oil pressure increases to within the normal operating range. - Page 129 ECTION ROPULSION 3428 5/03...

- Page 130 ROPULSION ECTION 3428 5/03...

-

Page 131: Operating And Maneuvering

ECTION PERATING AND ANEUVERING 6.0 Operating and Maneuvering 6.1 Launching the Boat Have a professional launch your boat. Your dealer can either provide experienced people to do this or recommend someone. 3428 5/03... -

Page 132: Navigation

Understanding navigation is very important when operating your boat on the open seas. Instructions on how to navigate your boat are beyond the scope of this guide. Carver encourages you to read Chapman’s Pilot- ing and Seamanship and obtain instruction regarding how to navigate your boat. - Page 133 ECTION PERATING AND ANEUVERING If your boat runs aground, radio for help and wait until it arrives. Do not attempt to relaunch your boat. You may do serious damage to your hull or underwater gear. 3428 5/03...

-

Page 134: Controlling The Boat

PERATING AND ANEUVERING ECTION 6.3 Controlling the Boat Every boat owner should know how to perform the following procedures competently. Do not attempt any of these procedures without first re- ceiving appropriate training. 6.3.1 Loading When you load items onto the boat, have someone on the pier hand them to you after you have boarded the boat. -

Page 135: Picking Up A Mooring

ECTION PERATING AND ANEUVERING engine to check headway. Leave the starboard engine in forward gear to swing the boat parallel to the pier. For landings on the port side, turn the rudders to starboard and put the starboard engine into reverse as the boat comes in. -

Page 136: Maneuvering

PERATING AND ANEUVERING ECTION into the wind or current and your approach course should be roughly parallel to their heading. Stay clear of other moorings to avoid fouling them. If you tow your dinghy, station a crew member at the helm to keep the dinghy line from fouling the propeller. - Page 137 ECTION PERATING AND ANEUVERING RACKING ORWARD PROPS ONLY RACKING STERN PROPS ONLY 3428 5/03...

-

Page 138: Close Quarters Turns

PERATING AND ANEUVERING ECTION distance. You can check headway by shifting engines to neutral and coming to a complete stop over a long distance, or by reversing engines and stopping within a shorter distance. 6.3.3.3 Close Quarters Turns To execute a close quarters turn, check your headway, then shift one engine into reverse while shifting the other into forward gear. -

Page 139: Anchoring

ECTION PERATING AND ANEUVERING 6.4 Anchoring An anchor’s holding power depends on its weight and the length of the anchor line. The most effective length is six to seven times the depth of the water you intend to anchor in. For example, if the water is 10 feet deep, you should have 60-70 feet of anchor line. -

Page 140: Stern Anchors

PERATING AND ANEUVERING ECTION 6.4.1 Stern Anchors In some anchorages, boats use bow and stern anchors at the same time. To get these anchors down, drop the bow anchor first, then pay out extra anchor line (15-18 times the depth). Drop the stern anchor and adjust the length of line payed out on both anchors as necessary. - Page 141 ECTION PERATING AND ANEUVERING lines are useful in preventing undesired movement ahead or astern in a berth; they also keep a moored vessel in position when there is a signifi- cant rise or fall in tide. 3428 5/03...

-

Page 142: Getting Underway

Bring only those people (spouse and children) who will make up your regular crew. Invite the sales person who sold you the boat or a member of your Carver Dealer’s service staff along for the ride. -

Page 143: Operating At Planing Speed

ECTION PERATING AND ANEUVERING This may be the first time you have been in total command of your new boat. Proceed slowly. Have fun but remember that the objective of the cruise is to learn more about how your boat operates and handles. Oper- ate the engines at different RPMs. - Page 144 PERATING AND ANEUVERING ECTION “BOW UP” and “BOW DOWN.” Before advancing the throttles, press both switches on the “BOW UP” side for 5 seconds. This lifts the trim tabs to the full “up” position. 4. Advance the throttles to bring the boat on plane. Adjust the engine RPMs for cruising speed.

- Page 145 ECTION PERATING AND ANEUVERING 3428 5/03...

- Page 146 PERATING AND ANEUVERING ECTION 3428 5/03...

-

Page 147: Maintenance

ECTION AINTENANCE 7.0 Maintenance 7.1 Maintenance Schedule The maintenance activities and their intervals listed on the following pages are provided as guidelines only. The ideal maintenance activities and maintenance schedule depend on the components installed in your boat and the manner and environment in which you use your boat. The more frequently you use your boat, the more often maintenance needs to be performed. - Page 148 AINTENANCE ECTION Type A Type B Type C Type D Engines and Drive System Perform maintenance as outlined Refer to OEM Refer to OEM Refer to OEM Refer to OEM in the engine OEM information. information. information. information. information. Inspect water intake hoses and connections.

- Page 149 ECTION AINTENANCE Type A Type B Type C Type D Electrical System Inspect and clean batteries. Check battery fluid levels. Check operation of all 12-volt equipment. Check operation of all AC equip- ment. Inspect shore power cord(s). Inspect generator water intake and discharge.

-

Page 150: Fabrics ......................................................................... 7

AINTENANCE ECTION Type A Type B Type C Type D Interior Perform maintenance on the Refer to OEM Refer to OEM Refer to OEM Refer to OEM heads. information. information. information. information. Inspect thru-hull fittings. Clean refrigerator. Clean stove. Lubricate door hinges and locks. Clean vinyl fabrics and wall coverings. -

Page 151: Exterior Maintenance

Gelcoat eventually dulls with age, much like the paint on your car. When it does this, you can restore the gelcoat’s luster using an electric buffer and a very fine grade polishing compound. Ask your Carver Dealer what brand and grade of polish to use. -

Page 152: Gelcoat Repair

Failure to do so can void your bottom paint warranty. Also make sure the paint is formulated for the type of water you operate the boat in. See your Carver Dealer for assistance in selecting an appropriate bottom paint. -

Page 153: Underwater Metal Components

Inspect the underwater metal components once a year. If you see bare metal showing through the paint, repaint the component. To obtain the best results when repainting, Carver recommends that you use Interlux products in the steps listed below. IMPORTANT: When repainting the propellers, all primers and paints must be applied by spraying only. -

Page 154: Stainless Steel Rails And Hardware

7.2.6 Decorative Striping Tape A variety of decorative stripes are used on the exterior of your boat. Striping tapes are custom-made to Carver’s color and size specifications. Replacement striping tape is only available through Carver Dealers. To remove a damaged section of tape, heat the area with a hair dryer. This softens the adhesive and makes the tape easier to remove. -

Page 155: Exterior Vinyl Upholstery

ECTION AINTENANCE The cabin windows are made from tempered glass. Clean them with a soft cloth and glass cleaner. The bridge wind screen is made from formed plexiglass. Clean it with a solution of fresh water and mild soap. 7.2.8 Exterior Vinyl Upholstery If you have used Dr. -

Page 156: Deck Enclosure Windows

AINTENANCE ECTION Do not subject Sunbrella fabric to excessive heat. To store the fabric: The fabric must be completely dry before you store it. Moisture on stored fabric can cause the glass to cloud, and the fabric and thread to break down. -

Page 157: Interior Maintenance

The interior woodwork was finished at the factory with a special indus- trial/commercial grade finish. If you need to refinish any woodwork, contact your Carver Dealer to order the appropriate product. Follow the manufacturer’s instructions on the product package when applying the finish. -

Page 158: Interior Fiberglass

AINTENANCE ECTION When your boat is new, the carpet sheds and needs to be vacuumed frequently. This is normal. The shedding stops after a few weeks. 7.3.5 Interior Fiberglass Some of your boat’s interior components, such as the shower stalls and stateroom berth platforms, are made of gelcoated fiberglass. -

Page 159: Mechanical Systems

The propeller shaft extends through a watertight fitting called a shaft seal. Check the shaft seal every month; if the seal is leaking, contact your Carver Dealer. 7.4.4 Props Wear gloves when handling a propeller. Its blades are sharp. -

Page 160: Struts

AINTENANCE ECTION speed, causing steering problems, and creating vibrations. Vibrations can lead to drive train damage. Have the propellers balanced by an established propeller repair shop at least once a year. Repair or replace damaged props. ARVER Consider purchasing and carrying a spare set of props onboard your boat. Many marine dealers do not carry a full inventory of replacement propellers. -

Page 161: Fresh Water System

ECTION AINTENANCE • Do not charge the batteries if they are already fully charged. The engine alternators can not overcharge the batteries. The onboard battery charger can overcharge the batteries because, when it deter- mines the batteries are fully charged, it does not shut off but rather switches to trickle charge mode. -

Page 162: Sump

• Clean the bilge pumps twice a season by wiping any dirt or oil from their exterior surfaces. • Remove any oil, dirt or debris from the bilges. Treat the bilges with a commercial bilge cleaner, available from your Carver Dealer, twice a season. 7.4.9 Sanitation System Unlike the other systems in your boat, the sanitation system requires ongoing maintenance to avoid problems. - Page 163 ECTION AINTENANCE • Your boat’s sanitation system is not like the toilet and sewer in a home. Do not flush any items down the toilet that the toilet was not designed to accommodate. Refer to the OEM information for details on maintaining the toilet.

- Page 164 AINTENANCE ECTION 3428 5/03...

-

Page 165: Winterization And Storage

Carver recommends that you hire a professional to winterize your boat and its systems. Carver also recommends that you place your boat in dry (out-of-water), as opposed to wet, storage. Some of the winterizing proce- dures can only be completed when the boat is out of the water. -

Page 166: Blocking

When your boat is placed in dry storage its hull must be properly blocked to avoid damaging it. You can either use a cradle designed specifically by Carver to support your model of boat or build your own blocking supports. -

Page 167: Winterization

Refer to the OEM information for details on winterizing the generator. 8.3.3 Air Conditioning System Refer to the OEM information for details on winterizing the air condi- tioning system. Carver recommends that you have a qualified marina winterize your air conditioning system for you. 8.3.4 Fresh Water System When winterizing your boat’s fresh water system, drain the entire system... -

Page 168: Winterizing The System

Using the wrong type of antifreeze can dam- age the fresh water system. The repair of such damage is not included under the terms of the Carver Limited Warranty. 1. Pour 25 gallons of nontoxic recreational vehicle antifreeze into your boat’s fresh water tank. -

Page 169: Preparing The System For Use Again

You must use a nontoxic, non-alcohol, RV-type (pink) antifreeze in your boat’s raw water washdown system. Using the wrong type of antifreeze can damage the raw water washdown system. The repair of such damage is not included under the terms of the Carver Limited Warranty. 3428 5/03... -

Page 170: Bilge

INTERIZATION AND TORAGE ECTION 3. Place the disconnected hose end into a bucket that contains about a gallon of nontoxic recreational vehicle antifreeze. 4. Remove the hose(s) from the bow and transom raw water washdown fittings. 5. Place a bucket under the washdown fittings to catch the antifreeze, which can be reused. - Page 171 Using the wrong type of antifreeze can damage the sanitation system. The repair of such damage is not included under the terms of the Carver Limited Warranty. 2. Flush 4 gallons of nontoxic recreational vehicle antifreeze through the toilet and allow it to remain in the waste tank while the boat is in storage.

-

Page 172: Grey Water Holding System

Empty the waste tank as described in 4.5.2 Emptying the Waste Tanks. c. Charge the waste tank by adding deodorizer. Use the brand of deodorizer recommended by your Carver Dealer. 8.3.8 Grey Water Holding System Before performing this procedure on the optional grey water holding system, your boat should be pulled from the water. -

Page 173: Overboard Discharge System

Using the wrong type of antifreeze can damage the grey water holding system. The repair of such damage is not included under the terms of the Carver Limited Warranty. 4. Pour 3 gallons of nontoxic recreational vehicle antifreeze through the shower and each sink drain. -

Page 174: Exterior

Remove everything from the boat that could spoil or freeze while the boat is stored. Also remove all dried food. Food attracts mice and insects. To give your boat the maximum protection while it is in storage, Carver recommends that you place your boat in dry, as opposed to wet, storage. -

Page 175: Storage

8.4.2 Wet Storage Wet storage procedures vary from region to region. Consult your Carver Dealer before preparing to leave your boat in the water over the winter. 3428 5/03... -

Page 176: Spring Recommissioning Checklist

INTERIZATION AND TORAGE ECTION 8.5 Spring Recommissioning Checklist Before launching your boat, complete the following. 8.5.1 Hull Fill gelcoat nicks and gouges Inspect props, struts, rudders Inspect thru-hull fittings Apply new antifouling bottom paint or touch up failing areas Buff out minor hull scratches Remove dirt, stains Apply wax 8.5.2 Deck and Cabin... -

Page 177: Safety Equipment

ECTION INTERIZATION AND TORAGE Inspect seacocks Inspect heads Chemically charge waste and grey water tanks Fill fresh water tank 8.5.6 Safety Equipment Inspect PFDs Replace old distress signals Inspect fire extinguishers Inspect, test bilge pumps Inspect mooring lines, fenders Test, recalibrate and/or replace CO detectors 8.5.7 After Launch Check for engine cooling water flow Check propeller shaft alignment... - Page 178 INTERIZATION AND TORAGE ECTION 3428 5/03...

-

Page 179: Warranty And Parts

Limited Warranty. Your copy of the warranty is located at the end of this section. Please review the warranty carefully. To ensure that the warranty remains in effect during its lifetime, Carver Boat Corporation, your Carver Dealer, and you must each uphold specific responsibilities. -

Page 180: Oem Components

OEM information. Many of these OEMs also have programs designed to resolve any problems you may experience with their products. Your Carver Dealer can assist you when necessary in gaining access to these programs. -

Page 181: Obtaining Warranty Service

NOTE: Your Carver Dealer is the ONLY person authorized to ap- prove warranty work. If warranty service is needed you MUST con- tact your Carver Dealer first. There are no exceptions to this policy. Your Carver Dealer has knowledgeable professionals who are familiar with your boat and are capable of providing the highest level of service. -

Page 182: Second And Third Owner Registration

Registration of a previously-owned Carver boat does not extend or in any way modify the boat's original limited warranty. However, purchasers of a previously-owned Carver boat should register the boat so that, if it is ever necessary, Carver can contact you. -

Page 184: Oems

9.5 OEMs Whenever you need information about a system or component on your boat, contact your Carver Dealer first. If your Dealer is unable to provide the information, contact the manufacturer (OEM) of the system or com- ponent. Refer to the OEM information for telephone numbers and ad- dresses. -

Page 185: Specifications

ECTION ARRANTY AND ARTS 9.6 Specifications The specifications listed here are based on a standard model with no op- tions installed. Certain options may change some of these specifications. Length Overall (LOA) with boarding platform..........37'8" (11,48 m) Beam ................13'2" (4,01 m) Bridge Clearance (waterline to arch) ............ -

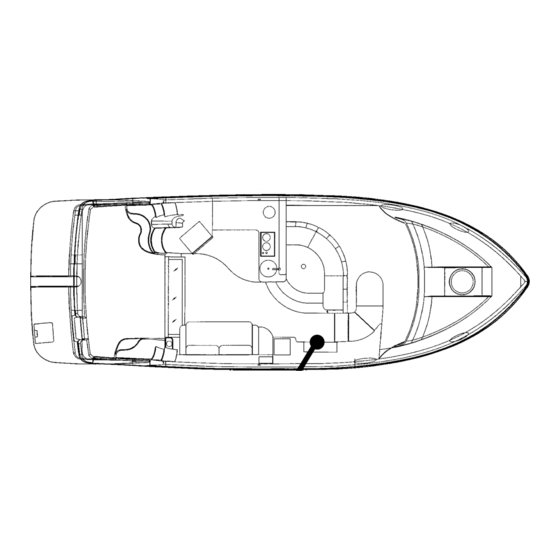

Page 186: Component Locations

ARRANTY AND ARTS ECTION 9.7 Component Locations The illustrations on the following pages show the locations of various components, deck plates, and thru-hull fittings discussed throughout this guide. 9.7.1 Interior Hatches 1 2 3 4 5 6 Master Stateroom 1 2 3 4 5 6 1 2 3 4 5 6 Air Conditioning Bow Thruster... - Page 187 ECTION ARRANTY AND ARTS OCKPIT ATCH ENTERLINE Cockpit Drain Seacocks (2) Aft Bilge Pump Air Conditioning Seawater Seacock Air Conditioning Seawater Strainer PIC09 OCKPIT ATCH ORWARD Generator Generator Battery Master Disconnect Switch Generator Battery Generator Cooling System Seawater Strainer Generator Cooling System Seacock PIC10 3428 5/03...

- Page 188 ARRANTY AND ARTS ECTION OCKPIT ATCH ORWARD TARBOARD Pressure Water Pump Raw Water Washdown Pump Fresh Water Tank Fresh Water Filter Air Conditioning Seawater Pump Raw Water Washdown Strainer PIC11 Raw Water Water Heater Washdown Seacock OCKPIT ATCH TARBOARD Oveboard Dis- charge Pump Switch Overboard Dis-...

-

Page 189: Deck Plates

ECTION ARRANTY AND ARTS 9.7.2 Deck Plates Fresh Water Washdown Raw Water Washdown Grey Water Holding Tank Pumpout (WASTE) Shore #2 Power Cord/ TV-Telephone Port Fuel Tank Fill Connectors/ (GAS or DIESEL) Raw Water Washdown Fresh Water Tank Fill (WATER) Starboard Fuel Tank Fill (GAS or Shore #1 Power... -

Page 190: Thru-Hull Fittings

ARRANTY AND ARTS ECTION 9.7.3 Thru-Hull Fittings Starboard Overboard Forward Bilge Pump Propulsion Discharge Discharge Engine Vented Loop Exhaust Amidships Bilge Water Heater Pump Discharge Drain Rope Locker Drain R2016D-1 Sump Discharge Aft Bilge Pump or Grey Water Discharge Salon A/C Unit Tank Vent Condensation Drip Pan Drain... - Page 191 ECTION ARRANTY AND ARTS Generator Seawater Port Propulsion Engine Pick-Up Seawater Pick-Up Aft Deck Drains (2) R2016D-3 A/C Seawater Pick-Up Depth Sounder Waste Tank Over- Triducer board Discharge Starboard Propulsion Raw Water Engine Seawater Pick-Up Washdown Pick-Up Salon A/C Unit Seawater Discharge R2016D-4 Hull Drain...

-

Page 192: Engine Room

ARRANTY AND ARTS ECTION 9.7.4 Engine Room ENTERLINE Engine Oil Change System Waste Tank (aft end) PIC01 FT OF NGINE Bilge Blowers Port Engine Cooling System Seacock Port Engine PIC02 3428 5/03... - Page 193 ECTION ARRANTY AND ARTS FT OF TARBOARD NGINE Fuel Solenoid Valve Manual Bypass Switch (mounted on floor frame) Starboard Engine Cooling System Seacock Starboard Engine Bilge Blowers PIC03 ORWARD ENTERLINE Fire Suppression Chemical Tank Amidships Bilge Pump Waste Tank (forward end) PIC05 3428 5/03...

- Page 194 ARRANTY AND ARTS ECTION ORWARD ULKHEAD Engine / “House” Battery Charger Generator Battery Charger Safety Breaker Panel Vacuum Flush System Waste Tank Vent Filter PIC04 TARBOARD ORWARD ULKHEAD Starboard Engine Battery Master Disconnect Switch Port Engine Bat- tery Master Discon- nect Switch “House”...

-

Page 195: Bill Of Material

ECTION ARRANTY AND ARTS 9.8 Bill of Material Any component that begins with a letter or has a category number lower than 50 is a manufactured component and therefore may not have all of its subcomponents listed. Category Number Part Description Engines and V-Drives Inboard Engine Equipment Propellers... -

Page 196: Carver Limited Warranty

ARRANTY AND ARTS ECTION 9.9 Carver Limited Warranty 3428 5/03...

Need help?

Do you have a question about the 360 SPORT SEDAN and is the answer not in the manual?

Questions and answers