Table of Contents

Advertisement

Quick Links

Middleby

Middleby

Middleby

Middleby

Middleby

Marshall

Marshall

Marshall

Marshall

Marshall

A MIDDLEBY COMPANY

owner's

operating

& installation

manual

PS624-Series OVENS

Model PS624E

©2009 Middleby Marshall

®

PS624 (Single)

Inc.

PS624-Series Electric Ovens: English

June 2, 2009

PS624 (Double)

PS624 (Triple)

Part No. 61584

Price $30.00

P: 12/08

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Middleby Marshall PS624E

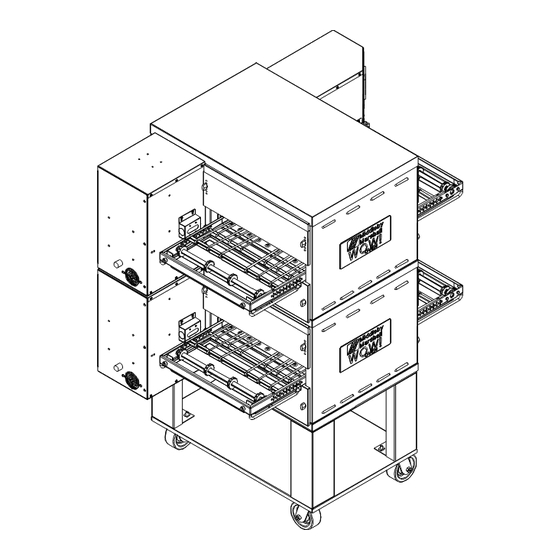

- Page 1 Marshall Marshall Marshall Marshall Marshall A MIDDLEBY COMPANY owner's operating & installation manual PS624-Series OVENS Model PS624E PS624 (Single) Inc. ©2009 Middleby Marshall ® PS624-Series Electric Ovens: English June 2, 2009 PS624 (Double) PS624 (Triple) Part No. 61584 Price $30.00...

- Page 2 This manual must be kept in a prominent, easily reachable location near the oven. It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent. FOR YOUR SAFETY, DO NOT STORE OR USE...

- Page 3 © 2003 - Middleby Marshall, A Middleby Company. The Middleby Marshall logo is a registered trademark of Middleby Marshall, A Middleby Company. Middleby Marshall Inc. • 1400 Toastmaster Drive • Elgin, Illinois 60120-9272 U.S.A. • (847) 741-3300 • FAX: (847) 741 4406 Serial No.

-

Page 4: Table Of Contents

SECTION 5 TROUBLESHOOTING Troubleshooting Charts ... 37 SECTION 6 ELECTRICAL SCHEMATICS Wiring Diagrams ... 39 Wiring Diagrams are in Section 6 of this Manual. The diagram for each oven is also inside the left side control box door. (Continued) Page NOTE... -

Page 5: Model Identification

DESCRIPTION SECTION 1 DESCRIPTION I. MODEL IDENTIFICATION The Middleby Marshall PS624-Series may be used either as a single oven or stacked for use as double or triple ovens. A single PS624-Series Oven (Figure 1-1) can be mounted on an insulated base with short legs for countertop use, or on a leg stand with a lower shelf and casters for a free standing unit. -

Page 6: Series Ps624 Electric Specifications

PS624 SERIES OVEN SPECIFICATIONS Conveyor Belt Width Heating Zone Length Baking Area Square Feet Overall Dimension – Standard Single Oven w/Legs - 8″ Exit tray Installed Overall Dimension – Double Oven Overall Dimension – Triple Oven Weight of Single Oven... - Page 7 SECTION 1 DESCRIPTION Figure 1-4. PS624-Series Oven Components Locations...

-

Page 8: Component Function

The blowers force heated air through the air fingers. The MAIN / BLOWER switch must be set to “ON” or “I” for oven warmup and baking. C. Cooling Fan — See Figure 1-5 and Figure 1-6 Cooling fans are located at the rear of each (left and right) control box. - Page 9 SECTION 1 DESCRIPTION Figure 1-6. Cooling Fan...

- Page 10 SECTION 1 DESCRIPTION Outer Plate Inner Plate Figure 1-7. Air Finger. Finger Manifold Assembly Baffle...

-

Page 11: Section 2 Installation

Recommended minimum clearances are specified in the Description section of Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no obstructions around or underneath the oven. Constructional changes to the area where the oven is installed shall not affect the air supply to the oven. -

Page 12: Section 2 I. Unloading

Do not obstruct the fan holes in the rear of the unit. I. UNLOADING Your Middleby Marshall PS624-Series Oven is shipped partially assembled. It will arrive in a carton on a crate. Carton size for a PS624-Series Oven is: 56.3″... - Page 13 CE-approved ovens include 4 non-braking casters (Item 5) SOLELY for the purpose of moving the oven to the installation location. Casters are NOT suitable for use as part of CE oven installations. Refer to the notice on the preceding page.

- Page 14 SECTION 2 INSTALLATION...

- Page 15 SECTION 2 INSTALLATION...

- Page 16 SECTION 2 INSTALLATION...

-

Page 17: Utility Rough-In Dimensions And Positioning For Ps624-Series Ovens

SUGGESTED If space permits, service should be located near the control console end of the oven(s) to allow convenient access to safety switches. II. VENTILATION GUIDELINES Use of a ventilation hood is not required for proper operation, but installation must conform with all local codes and regulations. -

Page 18: Electrical Connection Information For Ps624-Series Ovens

Following these connections, the factory-authorized installer can perform the initial startup of the oven. Check the oven data plate (Figure 2-10) before making any electric supply connections. Electric supply connections must agree with data on the oven data plate. -

Page 19: Control Functions

A possibility of injury from rotating parts and electric shock exists in this oven. Never disassemble or clean the oven with the BLOWER switch or any other oven control turned “ON” or “I”. Turn “OFF” or “O” and lockout or tagout all electric power to the oven before attempting to clean or service this oven. -

Page 20: Component Information And Location

The blower switch has two positions. The switch must be “ON” or “I” for the main blowers to come on and permit the oven to run. The fan circulates the air throughout the oven and must stay on during baking and during the cool down cycle above 200°F (93°C) to prevent blower... -

Page 21: Conveyor

This should be the conveyor speed shown on the conveyor speed digital control. NOTE: In Figures 3-4 and 3-5, the oven shown is with the conveyor running right to left. WARNING Possibility of injury from rotating parts and electrical shock exist in this oven. -

Page 22: Step-By-Step Operation

If the blowers return to the lower, energy saving speed before the product fully exits the oven, contact your local Middleby Marshall Service Agent for timing adjust- ment. Power Failure In case of power failure, turn off all switches and remove product. - Page 23 SECTION 3 OPERATION Figure 3-6. Control Panel...

-

Page 24: Normal Operation - Step-By-Step

This al- lows you to monitor the oven temperature as it rises to the setpoint. Allow the oven to preheat for 10 minutes after it has reached the set point temperature. DAILY SHUTDOWN PROCEDURE Turn "HEAT/ CONVEYOR"... - Page 25 Lights when the set point is locked out from changes. This setting can only be changed by service personnel. OVERTEMP Light Lights when the oven temperature is greater than 650°F (343°C). Refer to Quick Reference: Troubleshooting in this section. Temperature...

-

Page 26: Quick Reference: Troubleshooting

Controls may be set incor- overcooked or rectly. undercooked. IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN. PROBLEM • Follow the procedures under Daily Shutdown Procedures in this section to shut down the oven. -

Page 27: Section 4 Maintenance

Before ANY cleaning or servicing of the oven, perform the following procedure: Switch off the oven and allow it to cool. Do NOT service the oven while it is warm. Turn off the electric supply circuit breaker(s) and disconnect the electric supply to the oven. -

Page 28: Maintenance - Daily

Allow oven to cool before removing crumb pan. When the oven is cool remove and clean the crumb pan at each end of the oven. Each crumb pan can be removed by sliding it out, as shown in Figure 4-2. Reinstall the crumb pans after cleaning. -

Page 29: Maintenance - Monthly

For heavier cleaning of baked on grease and carbon deposits use a non-caustic cleaner that will not react with the aluminized finger manifold surfaces. You can order non-caustic cleaner from your local autho- rized Middleby Marshall Parts Distributor in the quantities listed below: Part # 27170-0244... - Page 30 SECTION 4 MAINTENANCE Figure 4-4. Figure 4-5. Figure 4-6. Figure 4-7. CAUTION Be careful not to bump the drive sprocket while handling the conveyor, to avoid damaging the drive shaft.

-

Page 31: Air Fingers Disassembly For Cleaning

(refer to Figure 1-9). Fingers are marked in the order shown; as viewed from the front of the oven. (The marks for an upper oven should be preceded with a “U”, example UB1, UT2, etc.) Standard Fingers 2. -

Page 32: Reassembly Of Air Fingers

SECTION 4 MAINTENANCE Figure 4-11. Standard Lower Finger Figure 4-12. Standard Upper Finger C. Reassembly of Air Fingers 1. Air fingers are made up of one inner plate, one outer plate and the finger housing manifold. Be sure to match up the markings (T1, T2, T3, etc.) on all the parts of the air fingers as you are reassembling. - Page 33 SECTION 4 MAINTENANCE 5. Install fingers with center spacer between the two finger back plates to insure proper spacing Center Spacer Extended Lip Flange of Finger Manifold Figure 4-16.

-

Page 34: Reinstall End Plugs

MAINTENANCE D. Reinstall End Plugs 1. Reinstall lower end plug (has flange that extends into oven). Place and secure plastic wing nuts on the end plug. 2. Reinstall conveyor. 3. Reinstall upper end plug (no inner flange). Place and secure plastic wing nuts on the end plug. -

Page 35: Conveyor Reassembly Into Oven

Oven conveyor belt must be cool when adjusting belt. Do not adjust belt if HOT. 1. With the conveyor assembly in the oven, stand at one end of conveyor and check tension by lifting the conveyor belt at the center of the oven chamber opening. The belt should not lift higher that 1″... -

Page 36: Conveyor Belt Link Removal

MAINTENANCE G. Conveyor Belt Link Removal 1. Using long nose pliers, an entire link can be removed with the conveyor assembly either in or out of the oven. Position master links at end of conveyor as shown in Figure 4-22. -

Page 37: Attaching Drive Chain

Direction of travel Figure 4-28. 7. Reconnect the outside master links. 8. Replace all parts removed from the oven. Figure 4-29. H. Attaching Drive Chain 1. If drive sprocket assembly was removed reassemble it into the conveyor drive shaft. Be sure flat on end of drive shaft aligns with set screw in conveyor shaft collar. -

Page 38: Maintenance (3 And 6 Month)

Middleby Marshall technician. IMPORTANT NOTICES: • Installation of replacement parts requiring access to the interior of the oven is permitted only by an authorized service technician. • If there are any problems with the operation of the oven, the authorized service technician must be called. -

Page 39: Ps624-Series Electric Oven Key Spare Parts

KEY SPARE PARTS KIT Replacement parts can be purchased from your Middleby Marshall Authorized Parts Distibutor. Keeping these key parts on hand can prevent long downtime for your oven. PS624-SERIES ELECTRIC OVEN KEY SPARE PARTS KIT ITEM PART NO. 44549... - Page 40 SECTION 4 MAINTENANCE NOTES...

-

Page 41: Section 5 Troubleshooting

OVEN BLOWER AND CONVEYOR OPERATE, YET THE OVEN IS NOT HEATING Start the oven again. If the oven still does not heat, call your Middleby Marshall Service Agency. setting. CONVEYOR WILL NOT HOLD PROPER SPEED OR WILL NOT RUN AT ALL Check for proper tension of conveyor drive chain and conveyor belt. - Page 42 SECTION 5 TROUBLESHOOTING NOTES...

-

Page 43: Section 6 Electrical Schematics

SECTION 6 ELECTRICAL SCHEMATICS SECTION 6 ELECTRICAL SCHEMATICS... - Page 44 SECTION 6 ELECTRICAL SCHEMATICS...

- Page 45 SECTION 6 ELECTRICAL SCHEMATICS...

- Page 46 SECTION 6 ELECTRICAL SCHEMATICS...

- Page 47 SECTION 6 ELECTRICAL SCHEMATICS NOTES...

- Page 48 During the warranty period, ALL parts replacement and servicing should be performed by your Middleby Marshall Authorized Service Agent. Service that is performed by parties other than your Middleby Marshall Authorized Service Agent may void your warranty.

Need help?

Do you have a question about the PS624E and is the answer not in the manual?

Questions and answers