Summary of Contents for Duplo DF-505N

- Page 1 Duplo Folder DF-505N Instruction Manual [120V] Please let our service people install the machine. DUPLO CORPORATION...

- Page 2 This page is a blank page.

-

Page 3: Table Of Contents

INTRODUCTION Thank you for your purchase. To ensure correct usage, please read this instruction manual thoroughly, especially the section Safety Precautions. After reading, please store this instruction manual in a safe place for future reference. CONTENTS 1. Safety Precautions ....... 2 10.Cross Folding ........ -

Page 4: Safety Precautions

1. SAFETY PRECAUTIONS Always observe the cautions and warnings given below to prevent personal injury or property damage. The degree of danger and damage that could occur is indicated on two levels by the following marks. WARNING: Ignoring this mark could result in the possibility of serious injury or even death. - Page 5 1. Safety Precautions Do not use flammable sprays inside or near the unit (e.g. when cleaning the unit). Such flammable gas may ignite and cause a fire or combustion. Make sure that the combined power consumption of the appliances to be connected does not exceed the capacity rating of the power outlets or plug receptacles.

-

Page 6: Usage Precautions

2. USAGE PRECAUTIONS 2-1. Power supply • This equipment shall be installed near the socket-outlet where the plug on the power supply cord is easily accessible. • Make sure the power supply used is always within the following range. 120V AC, 60Hz •... -

Page 7: Installing The Unit

3. INSTALLING THE UNIT 3-1. REMOVING THE PRESS RELEASE LEVE This press release level is attached to the unit at shipment to prevent the rubber roll from becoming distorted. Be sure to remove it when installing the unit. Take note that the unit will be damaged if it is used without removing the lever. Remember to remove it in the following order when installing the unit. -

Page 8: Component Parts

3. INSTALLING THE UNIT 3-2. COMPONENT PARTS After checking that you have following parts, attach them to the unit. Name Qty. Name Qty. First folding plate Instruction Manual Second folding plate Guide plate unit Cross folding lever 3-3. BEARING SUPPORT LEVERS Support the bearing with the two bearing support levers. -

Page 9: Attaching The Parts

3. INSTALLING THE UNIT 3-4. ATTACHING THE PARTS First, attach the second folding plate. • Before starting, push the lock lever at the side of the folding plate to “UNLOCK”. • Next, insert the folding plate into the unit. • After inserting it properly, push the lock lever to “LOCK”. -

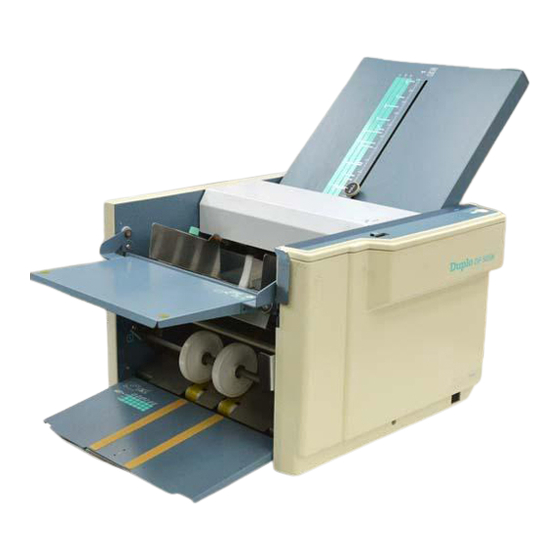

Page 10: Names Of The Parts

4. NAMES OF THE PARTS Rubber roll Paper feed ring (For moving) First folding plate Top cover Control panel Paper feed table Guide Second folding plate Auxiliary paper feed plate Stacker roller Power switch Paper set lever Paper receiving stopper Paper feed pressure adjusting knob Slant correction... -

Page 11: Names And Functions Of The Control Panel Parts

5. NAMES AND FUNCTIONS OF THE CONTROL PANEL PARTS Name Function Reset button The counter is reset to "0" when the reset button is pressed. Counter Counts and shows the number of sheets that have been folded. Table of Stacker The stacker rollers of the paper discharge section are positioned differently according Roller Positions to the paper size and folding style. -

Page 12: Precautions Before Use

6. PRECAUTIONS BEFORE USE 6-1. PAPER TO BE USED • Straighten folded or curled paper before use. • Make sure that the ink on the paper has dried up properly before use. If the ink has not dried properly, it may dirty the machine, and cause other problems such as dirtying the folded surface with ink. - Page 13 6. PRECAUTIONS BEFORE USE • If the paper is not stacked properly lengthwise, mis-feed or chain feed may occur. • When stacking just a few sheets of paper on the paper Paper Guide plate feed table, lower the paper set lever while pressing the back edge of the paper.

-

Page 14: Operation Procedures

7. OPERATION PROCEDURES 7-1. FIXED FOLDING OF FIXED PAPER Start the various fixed folding operations for fixed paper as follows. Insert the power cord in the electrical outlet and turn on the power. • Press “ I ” to turn on the power. •... - Page 15 7. OPERATION PROCEDURES Adjust the rough adjustment knob of Rough adjustment knob Rough adjustment knob the folding plates to the mark of any folding mode. • Adjust the rough adjustment knobs of first and second folding plates to the desired marks according to the style in which the paper is to be folded.

- Page 16 7. OPERATION PROCEDURES Set the position of the stacker rollers. • Referring to the table of stacker roller positions, position the stacker rollers. As the figures in this table of stacker roller positions are approximations, select the best position taking into consideration the folding speed and paper quality.

- Page 17 7. OPERATION PROCEDURES Press the start button to test the folding. Set the paper on the paper feed table, and with the paper set lever raised, press the start button. The paper feed ring slips and the machine stops. Press the start button after lowering the paper set lever.

- Page 18 7. OPERATION PROCEDURES • If the sheets of paper have not been folded Fine adjustment knob Fine adjustment knob satisfactorily, refer to the following steps. 1 If there is folding slippage in the vertical direction, rotate the fine adjustment knob and correct the folding slippage.

-

Page 19: Single-Folding Paper Neatly

7-2. SINGLE-FOLDING PAPER NEATLY In DF-505N, paper is single-folded by folding plate 1. The rough adjustment knob of folding plate 2 must therefore be set to ''Press" position as shown in the figure. To single-fold paper, perform the following procedure. - Page 20 7. OPERATION PROCEDURES Adjust the stopper of second folding plate. 1 While lifting the rough adjustment knob of second folding plate, slide it to the ''Press" position shown in the figure and set it there. 2 Rotate the fine adjustment knob to the left until the rough adjustment knob presses against it lightly but completely. Note : Rotating the fine adjustment knob excessively will result in paper jamming, improper folding, and other mechanical malfunctions.

-

Page 21: Single-Folding Hard Paper Neatly

7. OPERATION PROCEDURES 7-3. SINGLE-FOLDING HARD PAPER NEATLY When single-folding drawing paper or fine quality thick paper (127g/m ), the edge of Bent at edge the folding line of the paper or a part near the center may bend due to environmental conditions (temperature, humidity), paper size, paper jamming, paper size, paper fiber direction, etc. -

Page 22: Double Folding Thick Paper

7. OPERATION PROCEDURES After completing the single-folding Fine adjustment knob operations for hard paper, rotate the fine adjustment knob to the left until stopper presses against it lightly but completely. Note : If thin paper is single-folded with the folding stopper of second folding plate moved to the position for thick Folding plate 2 paper, the thin paper will not be folded neatly,... - Page 23 7. OPERATION PROCEDURES Adjust the stacker rollers to “5”. Stacker rollers Next, while lifting up the stacker Stacker roller rollers with your hand, pull the levers Lever (left and right) attached to the stacker Stacker lever lever in the direction of the arrow, and adjust so that the stacker rollers are above the belt.

- Page 24 7. OPERATION PROCEDURES If folding slippage occurs, rotate the Fine adjustment knob Fine adjustment knob fine adjustment knob of the folding plate 1 or 2 and correct the folding slippage. <Second folding plate> <First folding plate> After completing all adjustments, press the “reset button”...

-

Page 25: Folding 5 (W) X 7 (L) Medium Thickness Paper (Below 81.4 G/M 2 )

7. OPERATION PROCEDURES 7-5. FOLDING 5(W) X 7 (L) MEDIUM THICKNESS PAPER (BELOW 81.4 g/m Paper jam may occur when folding 5(W) X 7(L) size medium thickness paper such as fine paper (below 81.4g/m ) into fours. If Belt this occurs, attach the guide plate unit Paper ejection provided. - Page 26 7. OPERATION PROCEDURES If the paper is not ejected out smoothly, change the position of the stacker roller. Stacker rollers If the paper slips when folded, rotate Fine adjustment knob Fine adjustment knob the fine adjustment knob of the first folding plate or second folding plate, and adjust the folding slippage.

- Page 27 Note : When folding 52.3 g/m paper in fours, do not use the guide plate unit. Store the guide plate unit removed in Guide plate unit the DF-505N as shown in the figure.

-

Page 28: Specil Folding Of Fixed Paper

7. OPERATION PROCEDURES 7-6. SPECIAL FOLDING OF FIXED PAPER Stack some paper on the paper feed Paper table. Fold the paper as desired and measure the folded paper. Adjust the Accordion fold setting position of the rough adjustment knob of the folding plate accordingly. - Page 29 7. OPERATION PROCEDURES Adjust the rough adjustment knob of the second folding plate to the mark corresponding to measurement B. • When carrying out special folding, folding sizes should be within the following ranges. Rough adjustment knob Folding range (A) for the first folding plate: 1-5/8 to 12-7/8 inch Folding range (B) for the second folding plate: 1-5/8 to 8-1/2 inch...

- Page 30 7. OPERATION PROCEDURES Press the start button to test the folding. • Check that the paper has been folded properly. Check the second piece of paper folded first. Paper for testing folding • If the sheets of paper have not been folded Fine adjustment knob Fine adjustment knob satisfactorily, refer to the following steps.

-

Page 31: Folding Adjustments

8. FOLDING ADJUSTMENTS 8-1. ADJUSTING THE FOLDING SLIPPAGE IN THE VERTICAL DIRECTION To adjust the folding slippage in the vertical direction, rotate the fine adjustment knob of first folding plate. First Folding Plate Folding Style Fold Surface A Adjustment Fine Adjustment Knob When A Rotate the fine adjustment knob counterclockwise... - Page 32 8. FOLDING ADJUSTMENTS Second Folding Plate Folding Style Fold Surface B Adjustment Fine Adjustment Knob Rotate the fine adjustment When B knob counterclockwise is longer Double Fold When B Rotate the fine adjustment is shorter knob clockwise. When B Rotate the fine adjustment is longer knob counterclockwise Irregular...

-

Page 33: Adjusting The Folding Slippage In The Horizontal Direction

8. FOLDING ADJUSTMENTS 8-2. ADJUSTING THE FOLDING SLIPPAGE IN THE HORIZONTAL DIRECTION • If folding slips as shown in the figure because the paper is not cut straight, rotate the “slant correction” knob to adjust the folding slippage. Rotate the “slant correction” knob to adjust the folding slippage. -

Page 34: Using Non-Fixed Paper

9. USING NON-FIXED PAPER 9-1. FIXED FOLDING PROCEDURES Start fixed folding operations for non-fixed paper according to the following procedures. The procedures are described by taking an example of folding a sheet of 12 inch paper. Measure the length of the paper. •... - Page 35 9. USING NON-FIXED PAPER Adjust the position of the stacker rollers. • As the length of the paper fold is 6 inch, adjust the position of the stacker rollers to “2”. Reference: Refer to “Table of Stacker Roller Positions”. Stacker rollers Place the paper on the paper feed Paper table.

-

Page 36: Cross Folding

10. CROSS FOLDING • As shown in the figure, cross folding Folded means folding single folded paper Cross single folding again. • Paper can be cross folded into various Cross letter shapes depending on use. folding 10-1. PRECAUTIONS UPON USE The maximum paper thickness is 104.7g/m . - Page 37 10. CROSS FOLDING (Optional-Cross Folding kit is required) Adjust the position of the stacker rollers. • Referring to the table of stacker roller positions, position the stacker rollers. As the figures in this table of stacker roller positions are approximations, select the best position taking into consideration the folding speed and paper quality.

- Page 38 10. CROSS FOLDING (Optional-Cross Folding kit is required) Set the single fold paper on the paper feed table. Place the paper with the folded edge to the back of the unit as shown in the figure. • To prevent folding slippage in the horizontal direction and misfeeding, press the folded edge of the paper with your hand firmly.

-

Page 39: Cross Folding Of Non-Fixed Paper

10. CROSS FOLDING (Optional-Cross Folding kit is required) From here, refer to “7. Operation Cross folding lever Procedures”. • When replenishing paper, raise the cross folding lever as shown in the figure first. Cross folding consists of not only the single folding of LD, double folding of LT, but the letter folding of LT. - Page 40 10. CROSS FOLDING (Optional-Cross Folding kit is required) Set the paper feed pressure adjusting Paper feed pressure adjusting knob knob to “thin paper”. • If the paper slips, and no paper is conveyed, raise the paper feed pressure from “thin paper” to “thick paper”.

- Page 41 10. CROSS FOLDING (Optional-Cross Folding kit is required) Adjust the rough adjustment knob of Rough adjustment knob Rough adjustment knob first folding plate to the mark which has a value half of this length. • Adjust the rough adjustment knob of the second folding plate to “End”.

- Page 42 10. CROSS FOLDING (Optional-Cross Folding kit is required) Lower the paper set lever. While pressing the back edges of the Paper paper. • Adjust so that the front part of the paper touches the paper feed ring in front lightly. Paper set lever Close the top cover and adjust the Top cover...

- Page 43 10. CROSS FOLDING (Optional-Cross Folding kit is required) Press the start button to begin operations. When replenishing paper, raise the Cross folding lever cross folding lever as shown in the figure first. Cross folding consists of not only the single folding of LD, double folding of LT, but the letter folding of LT.

-

Page 44: Troubleshooting

11. TROUBLESHOOTING 11-1. PAPER HAS JAMMED NEAR THE PAPER FEED RING If paper has jammed near the paper Paper feed table feed ring, raise the paper set lever and lower the paper feed table downwards. Paper Paper set lever Pull the jammed paper towards you. 11-2. -

Page 45: Paper Has Coiled Around The Rubber Roll Inside The Unit

11. TROUBLESHOOTING 11-3. PAPER HAS COILED AROUND THE RUBBER ROLL INSIDE THE UNIT • Open the top cover, pull the wound paper towards you and remove it. Rubber roll • If the paper does not come out easily, insert a ruler,etc. at the tip of the paper wound around the lower rubber roll from the gap between the rubber rolls and remove the paper. -

Page 46: Paper Has Jammed At The Second Folding Plate

11. TROUBLESHOOTING After removing the paper, return the folding plate and top cover to their original positions. Check that the folding plate has been set correctly. Always remove and return folding plates with both hands. First folding plate 11-5. PAPER HAS JAMMED AT THE SECOND FOLDING PLATE Release the lock of the second folding plate and remove this plate from the unit. -

Page 47: Paper Has Jammed Near The Stacker

11. TROUBLESHOOTING 11-6. PAPER HAS JAMMED NEAR THE STACKER • Remove the paper stuck in the stacker section towards you. Paper... -

Page 48: Emergency Stops

12. EMERGENCY STOPS An emergency stop device to ensure safety has been installed to the top cover of this unit. Take note that this emergency stop device will function as follows. If the top cover is open while the unit Top cover is operating, the unit will stop promptly. -

Page 49: Troubleshooting Guide

13. TROUBLESHOOTING GUIDE Problem Check Correct (1) The unit does not start when 1 Is the power cord • Insert the power cord properly ‰ ‰ into the outlet. the start button is pressed. disconnected ? ‰ ‰ 2 Is the power switch on ? •... - Page 50 13. TROUBLESHOOTING GUIDE Problem Correct Check 1 Is the paper feed pressure too • Lower the paper feed pressure ‰ ‰ (5) Double feed occurs frequently. high? gradually until the optimum pressure is obtained. • Clean with neutral detergent or ‰...

- Page 51 13. TROUBLESHOOTING GUIDE Problem Check Correct (8) When paper slips in the • Adjust each folding stopper ‰ vertical direction. finely. 1 Was the paper type (quality, • Adjust each folding stopper ‰ ‰ amount) changed halfway? finely again. • Stack the paper neatly on the 1 Is paper...

-

Page 52: Cleaning The Unit

14. CLEANING THE UNIT • As paper shreds, ink of printed paper on the rubber roll and paper feed ring will cause problems, clean these parts according to the following procedures. • To ensure safety, always turn off the power of the unit first before cleaning. 14-1. -

Page 53: Cleaning The Paper Feed Ring

14. CLEANING THE UNIT 14-2. CLEANING THE PAPER FEED RING Open the top cover. Top cover While rotating the paper feed ring with your hand in the direction of the Paper feed ring arrow, clean it with a cloth moistened with neutral detergent or alcohol. -

Page 54: Specifications

15. SPECIFICATIONS DF-505N Model Office use, desktop Type Max. 11 (W) x 17 (L) inch Paper size that can be folded Min. 5 (W) x 7 (L) inch Rough paper, fine quality paper, stencil paper, recycled paper, Paper quality drawing paper. - Page 55 This page is a blank page.

- Page 56 This manual is printed on recycled paper to help protect the environment. 96V-94370-01040050S-0...

Need help?

Do you have a question about the DF-505N and is the answer not in the manual?

Questions and answers