Summary of Contents for A&D GX-300

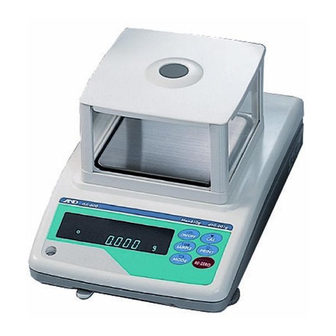

- Page 1 GX SERIES GX-200/GX-300/GX-400 GX-600/GX-800/GX-1000 GX-2000/GX-3000/GX-4000/GX-6100 GX-6000/GX-8000 Multi-Function Balance INSTRUCTION MANUAL 1WMPD4000087D...

- Page 2 © 2008 A&D Company Ltd. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or translated into any language in any form by any means without the written permission of A&D Company Ltd. The contents of this manual and the specifications of the instrument covered by this manual are subject to change for improvement without notice.

-

Page 3: Table Of Contents

CONTENTS Basic Operation 1. INTRODUCTION ..........................3 1-1 About This Manual..........................3 1-2 Features ............................. 3 1-3 Compliance............................4 2. UNPACKING THE BALANCE ......................6 2-1 Unpacking............................6 2-2 Installing the Balance ......................... 7 3. PRECAUTIONS ..........................8 3-1 Before Use............................8 3-2 During Use............................9 3-3 After Use ............................ - Page 4 10-3 Details of the Function Table ......................35 10-4 Description of the Class “Environment, Display” ................38 10-5 Description of the Item “Data output mode” ................... 40 10-6 Description of the Item “Data format” ..................... 41 10-7 Description of the Data Format Added to the Weighing Data ............... 43 10-8 Data Format Examples ........................

-

Page 5: Basic Operation

1. INTRODUCTION This manual describes how the GX series balance works and how to get the most out of it in terms of performance. Read this manual thoroughly before using the balance and keep it at hand for future reference. 1-1 About This Manual This manual consists of the following five parts: Basic operation .......Describes precautions on handling the balance, balance... -

Page 6: Compliance

Hold Function, provided for weighing a moving object such as an animal. Underhook, for measuring density and weighing magnetic materials. Density Mode, for calculating the density of a solid. Multiple Weighing Units, with most of the common units used around the world. Reference Card, provided for a quick reference to the balance operation. -

Page 8: Unpacking The Balance

2. UNPACKING THE BALANCE 2-1 Unpacking The balance is a precision instrument. Unpack the balance carefully. Keep the packing material to be used for transporting the balance in the future. The packing contents depend on the balance model. See the illustrations to confirm that everything is contained. -

Page 9: Installing The Balance

GX-2000/3000/4000/6100/6000/8000 Weighing pan Breeze ring Main unit Display Bubble spirit level Pan support receptor Main unit rear side Grounding Reference card terminal Keys RS-232C Leveling foot serial interface AC adapter jack (External input terminal) AC adapter plug Windows communication tools (WinCT) AC adapter ID label Note... -

Page 10: Precautions

3. PRECAUTIONS To get the optimum performance from the balance and acquire accurate weighing data, note the following: 3-1 Before Use Install the balance in an environment where the temperature and humidity are not excessive. The best operating temperature is about 20°C / 68°F at about 50% relative humidity. -

Page 11: During Use

3-2 During Use Discharge static electricity from the material to be weighed (hereinafter referred to as sample). When a sample could have a static charge, the weighing data is influenced. Ground the balance and try the following: Eliminate the static electricity by AD-1683 as an accessory. Or try to keep the ambient humidity above 45%RH. -

Page 12: After Use

3-3 After Use Avoid mechanical shock to the balance. Do not disassemble the balance. Contact the local A&D dealer if the balance needs service or repair. Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth that is moistened with warm water and a mild detergent. -

Page 13: Display Symbols And Key Operation

4. DISPLAY SYMBOLS AND KEY OPERATION Key operation Key operation affects how the balance functions. The basic key operations are: “Press and release the key immediately” or “Press the key” = normal key operation during measurement “Press and hold the key” Display symbols Response indicators ・Displays data stored in memory... -

Page 14: Weighing Units

5. WEIGHING UNITS 5-1 Units With the GX series balance, the following weighing units and weighing modes are available : Counting mode Percent mode Density mode (To use this mode, it must be stored in the function table as described on page 15. - Page 15 The tables below indicate the weighing capacity and the minimum display for each unit, depending on the balance model. GX-200 GX-300 GX-400 GX-600 GX-800 GX-1000 Minimum Unit display Capacity Gram 1100 0.001 Ounce (Avoir) 7.40 10.93 14.46 21.51 28.57 38.80 0.00005...

- Page 16 GX-6000 GX-8000 Minimum Unit display Capacity Gram 6100 8100 Ounce (Avoir) 0.005 Pound 13.4 17.8 0.0005 Pound/Ounce 13Lb 7.17oz 17Lb 13.72oz 0.01oz Troy Ounce 0.005 Metric Carat 30500 40500 Momme 1626 2160 0.05 Pennyweight 3922 5208 Grain (UK) 94136 125002 Tael (HK general, 0.005 Singapore)

-

Page 17: Storing Units

5-2 Storing Units The units or modes can be selected and stored in the function table. The sequence of displaying the units or modes can be arranged to fit the frequency of use. The units stored are maintained in non-volatile memory, even if the AC adapter is removed. Select a unit or mode and arrange the sequence of display as follow s: 1 Press and hold the SAMPLE key until ba5fnc of... - Page 18 Unit setting example The example below sets the units in the order with g (gram) as the first unit followed by pc (counting mode). Press and hold the SAMPLE key until ba5fnc of the function table is displayed, then release the key. Press and hold Press Press the SAMPLE key several times to display...

-

Page 19: Weighing

6. WEIGHING 6-1 Basic Operation (Gram Mode) Weighing 1 Place a container on the weighing pan, if necessary. Press the RE-ZERO key to cancel the weight (tare). The 0. 0 0 g. (The decimal point position balance displays Container depends on the balance model.) Sample 2 Place a sample on the pan or in the container. -

Page 20: Counting Mode (Pc)

6-2 Counting Mode (PC) This is the mode to determine the number of objects in a sample based on the standard sample unit mass. Unit mass means the mass of one sample. The smaller the variables in each sample unit mass is, the more accurate the counting will be. - Page 21 Notes If the balance judges that the mass of the samples is too light and is not adequate to be used as the unit mass, it displays lo . Do not use the samples. If the balance judges that the mass of the samples is too light to aquire accurate weighing, it displays an error requiring the addition of more samples to the specified number.

-

Page 22: Percent Mode (Pct)

6-3 Percent Mode (Pct) This is the mode to display the weight value in percentage compared to a 100% reference mass and is used for target weighing or checking the sample variable. Selecting the percent mode 1 Press the MODE key to select pct (percent mode). If the percent mode can not be selected, refer to “5. -

Page 23: Animal Weighing Mode (Hold Function)

6-4 Animal Weighing Mode (Hold Function) This is the mode to weigh a moving object such as an animal, even when the display of the weighing data fluctuates. The hold function allows the average weight of the animal to be displayed. To use the hold function, set the function in the function table. -

Page 24: Response Adjustment / Self Check Function

7. RESPONSE ADJUSTMENT / SELF CHECK FUNCTION This function detects the influence on weighing that is caused by drafts and/or vibration at the place where the balance is installed and sets the response characteristic automatically. When this function is selected, the balance self-checks the performance at the same time. Two modes of response adjustment are available: automatic and manual. -

Page 25: Manual Response Adjustment

Notes If improper performance is found in the self check, the balance displays CH no . Contact the local A&D dealer for repair. If the automatic response adjustment fails, the CH ng . Check the ambient balance displays conditions such as breeze and vibration, also check the weigning pan. -

Page 26: Calibration

Model Usable calibration weight Adjustable range GX-200 200 g, 100 g GX-300 300 g, 200 g, 100 g GX-400 400 g, 300 g, 200 g -0.015 g to +0.015 g GX-600 600 g, 500 g, 400 g, 300 g, 200g... -

Page 27: Automatic Self Calibration (Calibration Due To Changes In Temperature)

8-2 Automatic Self Calibration (Calibration due to changes in temperature) This function automatically calibrates the balance when the balance detects an ambient temperature change. If GLP output is selected in the function table, the balance outputs the calibration report or stores the data in memory. -

Page 28: Calibration Using An External Weight

8-4 Calibration Using an External Weight This function calibrates the balance using an external weight. Operation 1 Connect the AC adapter and warm up the balance for at least 30 minutes with nothing on the pan. Press and 2 Press and hold the CAL key until Calout hold the key displayed, then release the key. - Page 29 From previous page 5 Confirm that there is nothing on the pan and press the PRINT key. The balance measures the zero point. Do not allow vibration or drafts to affect the balance. The balance displays the calibration weight value. 6 Place the displayed calibration weight on the pan Calibration and press the PRINT key.

-

Page 30: Calibration Test Using An External Weight

8-5 Calibration Test Using an External Weight This function tests the balance weighing accuracy using an external mass and outputs the result. This is available only when the “GLP output (info)” parameter is set to “1” or “2”. (Calibration test does not perform calibration.) Operation 1 Connect the AC adapter and warm up the balance... - Page 31 From previous page 5 Confirm that there is nothing on the pan and press the PRINT key. The balance measures the zero point and displays the measured value. Do not allow vibration or drafts to affect the balance. The balance displays the target weight value. Target weight 6 Place the displayed target weight on the pan and press the PRINT key.

-

Page 32: Correcting The Internal Mass Value

AC adapter is removed. The internal mass value is corrected as follows: Model Correction reference value Correction range GX-200 200.000 g GX-300 GX-400 400.000 g -0.020 g to +0.020 g GX-600 GX-800 500.000 g... - Page 33 4 Press the PRINT key. Then the balance displays the function switches. Set the function table switch and internal mass correction switch to “1” as shown above using the following keys. SAMPLE key To select the switch to change the value. RE-ZERO key To change the parameter of the switch selected.

-

Page 34: Function Switch And Initialization

9. FUNCTION SWITCH AND INITIALIZATION 9-1 Permit or Inhibit The balance stores parameters that must not be changed carelessly (e.g. Calibration data for accurate weighing, Data for adapting to the operating environment, Control data for the RS-232C interface). There are five switches for the purpose of protecting these parameters. Each switch can select either “permit”... -

Page 35: Initializing The Balance

9-2 Initializing the Balance This function returns the following parameters to factory settings. Calibration data Function table The sample unit mass value (counting mode), 100% reference mass value (percent mode) The data that is stored in the balance using the data memory function External calibration weight and target weight value Function switch settings Liquid density and temperature in the density mode... -

Page 36: Function Table

10. FUNCTION TABLE The function table reads or rewrites the parameters that are stored in the balance. These parameters are stored in non-volatile memory, and are maintained even if the AC adapter is removed. 10-1 Structure and Sequence of the Function Table The function table menu consists of two layers. -

Page 37: Details Of The Function Table

10-3 Details of the Function Table Param- Class Item Description eter Cond Fast response, sensitive value Can be changed by FAST response adjustment. Condition MID. With "Hold 1", sets the Slow response, stable value averaging time. SLOW 5t-b The stabilization indicator Stable when within 1 digit illuminates with the display Stability band width... - Page 38 Param- Class Item Description eter Key mode Accepts the PRINT key only when the display is stable. dout Auto print mode A Outputs data when the (Reference = zero) Data output Data output mode dispaly is stable and conditions of ap-p, ap-b Auto print mode B and the reference value are (Reference = last stable value)

- Page 39 aram- Class Item Description eter *600 bps 1200 bps Serial interface Baud rate 2400 bps 4800 bps 9600 bps btpr 7 bits, even Data bit, parity bit 7 bits, odd 8 bits, none Crlf CR LF CR: ASCII code 0Dh Terminator LF: ASCII code 0Ah type...

-

Page 40: Description Of The Class "Environment, Display

10-4 Description of the Class “Environment, Display” Condition ( Cond Cond 0 This parameter is for sensitive response to the fluctuation of a weight value. Used for powder target weighing, weighing a very light sample or when quick response weighing is required. After setting, the balance displays FAST. - Page 41 Zero tracking ( trc ) This function tracks zero point drift caused by changes in the environment and stabilizes the zero point. When zero has difficulty stabilizing, select a greater value. When the weighing data is only a few digits, turn the function off for accurate weighing. trc 0 The tracking function is not used.

-

Page 42: Description Of The Item "Data Output Mode

10-5 Description of the Item “Data output mode” The parameter setting of the “Data output mode ( prt )” applies to the performance when the “Data memory ( data )” parameter is set to “2” (to store the weighing data)and when the data is transmitted using the RS-232C interface. -

Page 43: Description Of The Item "Data Format

Interval memory mode The weighing data is periodically stored in memory. dout prt 3 Required setting Interval memory mode dout data 2 Data memory function is used. Stores weighing data. dout Interval time dout 5-td1, 2, or 3 Adds the time and date. Optional setting Example “For periodical weighing without a computer command and... - Page 44 5if type 2 KF format This is the Karl-Fischer moisture meter format and is used when the peripheral equipment can only communicate using this format. This format consists of fourteen characters excluding the terminator. This format has no header characters. The polarity sign is placed before the data, with spaces in place of leading zeros, if the data is not zero or overloaded.

-

Page 45: Description Of The Data Format Added To The Weighing Data

10-7 Description of the Data Format Added to the Weighing Data Data number dout d-no 1 This format outputs the data number just before the data is transmitted using the RS-232C interface. This format consists of six characters excluding the terminator. When CSV format (5if type 5) is selected, the period ( . -

Page 46: Data Format Examples

10-8 Data Format Examples A&D Stable C R L F S T , + 0 0 0 0 1 C R L F C R L F C R L F + 0 0 0 0 1 C R L F Unstable A&D U S ,... - Page 47 Units D.P . A&D Counting mode Precent mode Ounce (Avoir) Pound Pound Ounce Troy Ounce Metric Carat Momme Pennyweight Grain (HK general, T ael Singapore) T ael (HK, jewelry) T ael (T aiwan) T ael (China) T ola (India) Messghal Density Multi (Blank)

-

Page 48: Clock And Calendar Function

10-9 Clock and Calendar Function The balance is equipped with a clock and calendar function. When the “GLP output (info)” parameter is set to “1” or “2” and the “Time/Date output (5-td)” parameter is set to “1”, “2” or “3”, the time and date are added to the output data. - Page 49 Confirming the date 6 The current date is displayed with all the digits blinking. To change the display order of year (y), month (n) and day (d), press the MODE key. The date is output in the order as specified. When the date is correct and the operation is to be finished, press the CAL key and proceed to step 8.

-

Page 50: Comparator Function

10-10 Comparator Function The results of the comparison are indicated by HI OK LO on the display. Operating conditions: No comparison Comparison when the weighing data is stable or overloaded, excluding “near zero” Comparison when the weighing data is stable or overloaded, including “near zero”... - Page 51 9 With Cp lnt displayed, press the PRINT key. The current setting is displayed. When the current setting is to be changed, change the setting using the following keys. Enter the tolerance value in percentage to the reference value as 100%. SAMPLE key To select the digit to change the value.

-

Page 52: Id Number And Glp Report

11. ID NUMBER AND GLP REPORT The ID number is used to identify the balance when Good Laboratory Practice (GLP) is used. The ID number is maintained in non-volatile memory even if the AC adapter is removed. The GLP output format is selected at “GLP output (info)” of the function table and can be output to a personal computer or printer using the RS-232C serial interface. -

Page 53: Glp Report

11-2 GLP Report Set the following parameters to output the report. To print the report, set the “GLP output ( info )” parameter to “1” and use MODE 3 of the AD-8121B. For details on using the printer, refer to “17-1 Connection to the AD-8121B Printer”. To output the report to a personal computer using the RS-232C interface, set the “GLP output ( info )”... - Page 54 Calibration report using an external weight When the setting is “info 1”: When the setting is “info 2”: Calibration test report using an external weight (Calibration test does not perform calibration.) When the setting is “info 1”: When the setting is “info 2”:...

- Page 55 Title block and end block When a weight value is recorded as the GLP data, “Title block” and “End block” are inserted at the beginning and at the end of a group of weight values, in the GLP report. Note To output the report to an AD-8121B , use MODE 3 of the AD-8121B.

-

Page 56: Data Memory

12. DATA MEMORY Data memory is a function to store weighing data, calibration data and unit mass in memory. Of the data in memory, the balance can only display the weighing data. The weighing data and calibration data in memory are available for outputting at one time to a printer or personal computer. One of the following data set can be stored: Weighing data (Up to 200 sets. -

Page 57: Memory For Weighing Data

12-2 Memory for Weighing Data The data memory function can store 200 sets of weighing data (100 set if time and date are added). Even if the AC adapter is removed, the data is maintained in non-volatile memory. It is not necessary that the printer or computer be continually connected to the balance, because the balance stores the weighing data in memory. - Page 58 The following commands can not be used during data storage. Query command for weighing data. Query command for stable weighing data. Query command for weighing data. Query command for continuous weighing data. Setting the function table Parameter settings for each output mode are as follows: Item Data output Auto...

- Page 59 Transmitting all memory data at one time Confirm that the “Serial interface ( 5if )” parameters are set properly. For details, refer to “10. FUNCTION TABLE” and “17. CONNECTION TO PERIPHERAL EQUIPMENT”. 1 Press and hold the PRINT key until reCall is displayed. 2 Press the SAMPLE key to display out .

-

Page 60: Memory For Calibration And Calibration Test Data

12-3 Memory for Calibration and Calibration Test Data Calibration data (when and how it is performed) and calibration test data can be stored in memory. All the data in memory is available to be output at one time to a printer or personal computer. Up to 50 data sets of the latest calibration or calibration test can be stored. -

Page 61: Memory For Unit Mass In The Counting Mode

12-4 Memory for Unit Mass in the Counting Mode The data memory function can store 20 sets of unit mass for the counting mode. Even if the AC adapter is removed, the data is maintained in non-volatile memory. Among the 20 sets, “p01”... -

Page 62: Underhook

13. UNDERHOOK The underhook can be used for weighing large samples, magnetic materials or for measuring density. The built-in underhook is revealed by removing the plastic cap on the bottom of the balance. Use the underhook as shown below. Caution Do not apply excessive force to the underhook. -

Page 63: Programmable-Unit

14. PROGRAMMABLE-UNIT This is a programmable unit conversion function. It multiplies the weighing data in grams by an arbitrary coefficient set in the function table and displays the result. The coefficient must be within the range between the minimum and maximum shown below. If the coefficient set is beyond the range, an error is displayed and the balance returns to the coefficient setting mode, prompting to enter an appropriate value. -

Page 64: Density Measurement

15. DENSITY MEASUREMENT The GX series balance is equipped with a density mode. It calculates the density of a solid using the weight of a sample in air and the weight in liquid. The density mode was not selected for use when the balance was shipped from the factory. To use the mode, change the function table and activate the density mode. - Page 65 The relation between the water temperature and density is shown below. Entering the density directly ( ldin 1 ) In the density mode, press and hold the MODE key until the density currently set (unit : g / cm factory setting : 1.000g / cm ) is displayed.

- Page 66 Measuring procedure 1 Confirm that the balance is in the mode to measure the weight of the sample in air. (“g” displayed and processing indicator blinking) 2 Confirm that the balance indicates zero. If it does not indicate zero, press the RE-ZERO to reset the displayed value to zero.

-

Page 67: Rs-232C Serial Interface / External Input

16. RS-232C SERIAL INTERFACE / EXTERNAL INPUT RS-232C The balance is a DCE device. Connect the balance to a personal computer (DTE), using a straight through cable or a modem cable. Transmission system EIA RS-232C Transmission form Asynchronous, bi-directional, half duplex Data format Baud rate 600, 1200, 2400, 4800, 9600 bps... - Page 68 External input Pin 18 and pin 19 perform the same function as pressing the PRINT and RE-ZERO keys respectively by connecting each pin to pin 7 for at least 100 m seconds. Use of example external input connector (AX-HDB-25P/CTF) foot switch (AX-SW128) are sold separately.

-

Page 69: Connection To Peripheral Equipment

17. CONNECTION TO PERIPHERAL EQUIPMENT 17-1 Connection to the AD-8121B Printer Set the following parameters to use the AD-8121B printer. Function setting Description dout prt 0-3 Selects a print mode. dout ap-p 0-2 Selects the polarity for the auto print mode. dout ap-b 0-2 Selects the auto print difference. -

Page 70: Using Windows Communication Tools (Winct)

17-3 Using Windows Communication Tools (WinCT) When Windows is used as an operating system in a personal computer, the provided WinCT can be used to transmit the weighing data to the personal computer. The WinCT has two communication methods: “RsCom” and “RsKey”. For details on WinCT, refer to the WinCT instruction manual. - Page 71 5 Using the GX series balance memory function The weighing data, instead of outputting it immediately to an external device, can be stored in the balance’s memory. Later, all of the weighing data stored can be output to a personal computer at one time.

-

Page 72: Commands

18. COMMANDS 18-1 Command List Commands to query weighing data Cancels the S or SIR command. Requests the weighing data immediately. Requests the weighing data when stabilized. Requests the weighing data immediately. Requests the weighing data continuously. Requests the weighing data when stabilized. Note: The “Q”... -

Page 73: Acknowledge Code And Error Codes

Commands to control the comparator function HI:∗∗∗. ∗∗ Sets the upper limit value. e.g.,HI:+2.34 g (to set the upper limit value to 2.34 g: represents a space.) LO:∗∗∗. ∗∗ Sets the lower limit value. e.g.,LO:+1.23 g (to set the lower limit value to 1.23 g: represents a space.) Outputs the upper limit value. -

Page 74: Command Example

18-3 Command Examples ON command Personal computer Time Balance Standby mode ON command C R L F Command received AK C R L F All segments are displayed All segments Command completed AK C R L F Zero display R command Personal computer Time Balance... - Page 75 CAL command Personal computer Time Balance Zero display CAL command C R L F AK C R L F Command received Command completed AK C R L F Zero display Error code Personal computer Time Balance Weighing mode (unstable) R command C R L F Command received AK C R L F...

- Page 76 Weighing with a tare Personal computer Time Balance R command Sets the display to zero C R L F Command received AK C R L F In process Command completed AK C R L F Zero display Place a container TR command Tares C R L F...

- Page 77 Setting a negative target value and filling with a sample until the display becomes zero Personal computer Time Balance Place a container Before command execution R command Command received AK C R L F In process Command completed AK C R L F AK C R L F Zero display PT: command to set a target weight of 100 g...

-

Page 78: Control Using Cts And Rts

18-4 Control Using CTS and RTS Depending on the “Ct5” parameter of “Serial interface ( 5if )”, the balance performs as follows: Ct5 0 Regardless of whether the balance can receive a command or not, the balance keeps the CTS line HI. -

Page 79: Maintenance

19. MAINTENANCE Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth that is moistened with warm water and a mild detergent. The mass of the internal mass may change due to corrosion or other damage caused by the operating environment, or due to aging. -

Page 80: Error Codes

Weighing method Does the weighing pan touch the breeze ring or anything? Is the weighing pan installed correctly? Is the RE-ZERO key pressed before placing a sample on the weighing pan? Is the sample placed in the center of the weighing pan? Has the balance been calibrated using the internal mass (one-touch calibration)? Has the balance been warmed up for 30 minutes before weighing? Sample and container... - Page 81 Display Error code Description EC, E20 Calibration weight error The calibration weight is too heavy. Confirm the calibration weight value. Press the CAL key to return to the weighing mode. EC, E21 Calibration weight error The calibration weight is too light. Confirm the calibration weight value.

- Page 82 Display Error code Description Clock battery error The clock backup battery has been depleted. Press any key and set the time and date. The clock and calendar function works normally as long as the AC adapter is connected to the balance. If this error appears frequently, contact the local A&D dealer.

-

Page 83: Asking For Repair

Display Error code Description EC, E06 Format error A command includes incorrect data. e.g. The data is numerically incorrect. Confirm the command. EC, E07 Parameter setting error The received data exceeds the range that the balance can accept. Confirm the parameter range of the command. Other errors If the errors described above can not be released or other errors are displayed, contact the local A&D dealer. -

Page 84: Specifications

21. SPECIFICATIONS GX-200 GX-300 GX-400 GX-600 GX-800 GX-1000 Weighing capacity 210 g 310 g 410 g 610 g 810 g 1100 g Maximum display 210.084 g 310.084 g 410.084 g 610.084 g 810.084 g 1100.084 g Minimum weighing value (1 digit) 0.001 g... - Page 85 GX-2000 GX-3000 GX-4000 GX-6100 GX-6000 GX-8000 Weighing capacity 2100 g 3100 g 4100 g 6100 g 6100 g 8100 g Maximum display 2100.84 g 3100.84 g 4100.84 g 6100.84 g 6108.4 g 8108.4 g Minimum weighing value (1 digit) 0.01 g 0.1 g Repeatability (Standard deviation) 0.01 g...

-

Page 86: Options

22. OPTIONS Glass Breeze Break Glass Breeze Break Animal Weighing Bowl Kit Density Determination (GX-10) (GX-11) (GX-12) Kit (GX-13) For GX-200/300/400/600 For GX-2000/3000/4000/ For all models except GX-200 Only for GX-200/300/400/600 800/1000 6100/6000/8000 The mass of the Animal Weighing 800/1000 Bowl Kit is approx. - Page 87 AD-8920 Remote display Connected to the GX series using the RS-232C interface to display the weighing data away from the balance. AD-8922 Remote controller Connected to the GX series using the RS-232C interface to display the weighing data and to remotely control the balance.

- Page 88 AD-1683 DC static eliminator Used to minimize weighing errors due to static electricity on the material. AD-1684 Electrostatic field meter This option measures the amount of the static charge on the sample, tare or peripheral equipment and displays the result. If those are found to be charged, discharge them using the AD-1683 DC static eliminator.

-

Page 89: External Dimensions

23. EXTERNAL DIMENSIONS... -

Page 90: Terms/Index

24. TERMS/INDEX Terms Stable value The weight data when the stabilization indicator appears. Environment Ambient conditions such as vibration, drafts, temperature, static electricity and magnetic fields which affect the weighing operation. Store To save the weighing data, unit mass or calibration data using the data memory function. - Page 91 Index - C - Keys and symbols Calibration..........24, 25 CAL key ........11, 15 Calibration test ........24, 29 MODE key ......11, 12, 15 Capacity indicator ......3, 11, 39 ON/OFF key ....... 11, 32 Comparator function ........48 PRINT key ........11, 15 CSV format ..........42 RE-ZERO key......

- Page 92 Repeatability ......77, 82, 83, 88 - I - RESPONSE ..........22 ID number............ 50 Response characteristic ......22 Inhibit ............32 RS-232C serial interface......65 Initializing the Balance......... 33 RsCom ............68 Interval memory mode......... 41 RsKey ............68 - K - Key mode ............ 40 - S - KF format.............