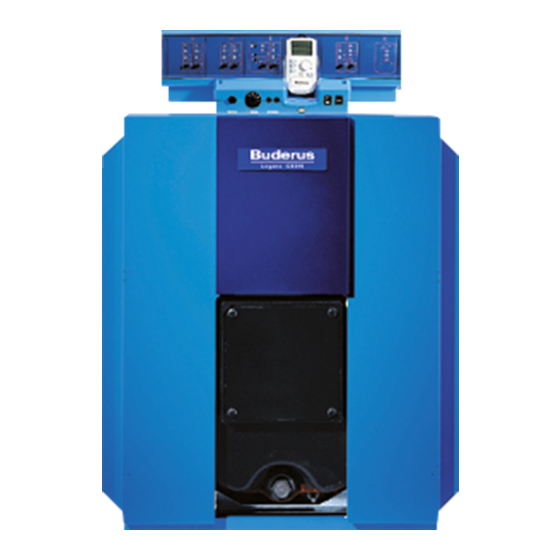

Buderus Logano GE315 Installation And Maintenance Instructions Manual

Cast iron sectional boiler for oil or gas pressure jet burners

Hide thumbs

Also See for Logano GE315:

- Technical manual (80 pages) ,

- Installation and maintenance instructions manual (52 pages)

Summary of Contents for Buderus Logano GE315

- Page 1 6300 9651 – 02/2006 GB For the installer Installation and maintenance instructions Logano GE315 Cast iron sectional boiler for oil or gas pressure jet burners Please read thoroughly prior to installation and maintenance...

- Page 2 We reserve the right to make any technical modifications! Constant development may lead to minor deviations of illustrations, functional steps and specifications from those described/shown. We reserve the right to make changes due to technical modifications! Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 3 Management of Health and & Safety at work regulations 1992 – Guidance note PM5 Health & Safety at work act 1974 Manual Handling Regulations 1992 The Electricity at Work Regulations, 1989 We reserve the right to make changes due to technical modifications! Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 4: Table Of Contents

Contents Regulations and guidelines ......6 1.1 General ........6 1.2 Boiler application . - Page 5 Ratings and system handover ......50 We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 6: Regulations And Guidelines

– temperature controller 40 secs. – contactor/limiter 40 secs. Observe the details on the boiler data plate, which are crucial. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 7: Installation

Installation Installation Standard delivery The Logano GE315 boiler can be supplied as ready assembled block or in individual boiler segments. 2.1.1 Pre-assembled delivery Pallet: Boiler block with burner door and feed pipe Cartons: Casing (depending on boiler size) Foil packaging: Thermal insulation 2.1.2... -

Page 8: Tools And Additional Materials As Required For Assembly

For the correct arrangement of flanges for the compression step, see Page 14. Fig. 2 Boiler compression tool size 2.3 We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 9: Positioning

1370 Fig. 1 Dimensions of plinth and length of angular or flat steel section Fig. 3 Plinth dimensions [mm] We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 10: Clearance From Walls Recommended For Installation And Maintenance

As an alternative we would recommend the use of shorter (length approx. 1 m) cleaning devices or wet cleaning. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 11: Installation Of Boiler Sections

Secure the rear section against tipping! Where available you can use lifting gear to safely position the boiler sections. Fig. 6 Rear section We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 12: Fitting The Boiler Sections (Unassembled)

Finish coating the outer surface of the nipple with orange sealing compound. Fig. 9 Hammering the nipples home We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 13 (Marked as (LEINOMENNIGE)) (Fig. 12, Item 1). Coat the sealing grooves with primer (Fig. 12, Item 2). Fig. 12 Preparation of the central section We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 14 This would lead to leaks at the nipple joints. Fig. 15 Boiler compression tool at the rear section We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 15 Assemble all other boiler sections as described. Fig. 16 Boiler compression tool size 2.3 The front section is assembled last. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 16 The next step refers to the installation of the return header (see chapter "2.4.4 Slide the return header into place (carton of installation components)", page 18). We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 17: Aligning The Boiler Block For Pre-Assembled Deliveries

The return header and sensor well installation described on the following pages applies to boilers delivered as pre-assembled in sections. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 18: Slide The Return Header Into Place (Carton Of Installation Components)

Item 1) from above into the ¾" threaded hole of the flow connection (Fig. 20, Item 2). Fig. 20 Sensor well installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 19: Leak Test

These could be damaged by high pressure. Fig. 21 Flange installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 20: Test Pressure

(Fig. 23, Item 2) are required for the flow connections which is fitted later (Fig. 23, Item 1). Fig. 23 Connection flange installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 21: Installation Of Fittings And Burner Door (Only For Unassembled Boilers)

(Fig. 25, Item 3 & 4). All cleaning covers are fitted in the factory. Fig. 25 Rear section with mounted fittings We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 22: Install The Burner Door

140/ 6 – 7 upper l.h. lower r.h. lower l.h. Fig. 27 Hot gas baffle plates We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 23: Burner Installation

Connect the breather tube on the sight glass with the burner to keep the glass free from condensation. Fit burner according to the manufactures instructions. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 24: Fit The Flue Gas Pipe Sealing Collar (Optional Accessory)

Install the flue gas temperature sensor (Fig. 29, Item 2) in accordance with separate installation instructions. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 25: Boiler Casing

The edge of the lower support bracket must point to the rear. Fig. 31 Installation of the rear support brackets We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 26: Thermal Insulation

Close the gap below the flue gas coupling with spring hooks (Fig. 33, Item 3). Fig. 33 Installation of thermal insulation at the rear section We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 27: Side And Top Casing

With two self-tapping screws each secure the side walls at the bottom (Fig. 35, Item 3). Fig. 35 Side casing installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 28 (Fig. 38, Item 1 & 3). Fig. 38 Installation of the front plinth rail We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 29 Hook the front wall at the top into the edge of the front hood (Fig. 41, Item 1). Fig. 41 Front wall installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 30: Control Unit

(Fig. 43, Item 6) in the front boiler hood with two self-tapping screws (Fig. 43, Item 7). Fig. 43 Control unit installation We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 31: Installation Of The Temperature Sensor

Observe all local requirements, e.g. current I.E.E Wiring Regulations in GB! Secure all cables with cable clips. Fig. 46 Electrical connection We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 32 Fit the terminal cover (Fig. 43, Item 1) with two self- tapping screws and secure on the control unit base (Fig. 48). Fig. 48 Boiler with control unit installed We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 33: System Start-Up

8.2–9.5 ⎝ ⎠ 350 < Q ≤ 1000 > 1.5 Tab. 2 Requirements of filling, make-up and heating water We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 34 Temporary connection to e removed after filling (filling loop) Control valve (stop valve) on the heating system pipework Fig. 50 Requirements Fluid Category 3 systems We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 35 Notify your installer, if you need to regularly add top- up water to your system. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 36: Making The System Operational

(danger of condensation). We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 37: Commissioning Report

USER NOTE Enter the fuel to be used into the table (see operating instructions "Preamble", page 2). We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 38: System Shutdown

Isolate the main fuel valve. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 39: System Inspection And Maintenance

USER NOTE You may order spare parts from the Buderus spare parts catalogue. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 40: Maintenance

(see chapter "2.6.3 Burner door installation", page 20). Open the burner door. Fig. 53 Remove the front wall We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 41 You will find an illustration of the various types of brushes offered by Buderus (optional accessory) in Fig. 53. Fig. 56 Cleaning brushes We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

- Page 42 We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 43: Wet-Cleaning The Boiler

NOTE! For details on water treatment see the instruction sheet K8 "Water treatment for heating systems". We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 44: Checking The System Water Pressure

Fig. 51 Pressure gauge for sealed systems Item 1: Red needle Item 2: Pressure gauge needle Item 3: Green range We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 45 W.R.A.S. approved method). Top up with water as required. Vent the heating system. Check the water pressure once more. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 46: Inspection And Maintenance Reports

Final check of the inspection work; document the measurement and test results Confirm the professional inspection with signature, date and company stamp We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 47 10. Check the function and safety in operation See burner documentation Confirm the professional maintenance with signature, date and company stamp We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006...

-

Page 48: Correcting Burner Faults

See the technical burner documentation for information regarding the resetting of the burner, if the burner will not start after three attempts. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 49: Appendix

5) Note for Switzerland: In reality the stated max. values will – regarding compliance with the 3) Full load details relate to the upper and lower rated output range. LRV – not be reached. We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... -

Page 50: Ratings And System Handover

The user was advised of all safety requirements and was instructed in the use and maintenance of the above system. Date, signature (user) We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Logano GE315 • Issue 02/2006... - Page 51 Notes We reserve the right to make any changes due to technical modifications. Installation and maintenance instructions Oil- and gas-fired special boilers Logano GE515 • Issue 02/2006...

- Page 52 Your installer: Buderus BBT Thermotechnik GmbH Cotswold Way, Warndon, Worcester WR4 9SW D-35573 Wetzlar Tel.: 01905 752794, Fax: 01905 753130 www.heiztechnik.buderus.de www.buderus-commercial.co.uk info@heiztechnik.buderus.de In the UK, Buderus is a trading name of BBT Thermotechnology Ltd.