Endress+Hauser Proline Promag 55 Operating Instructions Manual

Electromagnetic flow measuring system

Hide thumbs

Also See for Proline Promag 55:

- Operating instructions manual (162 pages) ,

- Operating manual (130 pages) ,

- Installation instruction (16 pages)

Summary of Contents for Endress+Hauser Proline Promag 55

-

Page 1: Operating Instructions

Operating Instructions Proline Promag 55 Electromagnetic Flow Measuring System BA119D/06/en/11.07 71064033 Valid as of version: V 1.01.XX (Device software) - Page 2 Brief operating instructions Proline Promag 55 Brief operating instructions These brief operating instructions show you how to configure the measuring device quickly and easily: Safety instructions Page 7 First of all, familiarize yourself with the safety instructions: here you can find information about e.g. the designated use of the measuring device, the operational safety and the safety icons and symbols used in the document.

- Page 3 Proline Promag 55 Brief operating instructions More detailed configuration Page 79 ff. Additionally, the following configuration possibilities are available: • Configuration of current outputs and inputs (active/passive) • Configuration of relay contacts (NC/NO) By using pluggable F-CHIP modules, special software packages can be installed, e.g.: •...

- Page 4 Brief operating instructions Proline Promag 55 Note! • The display returns to the cell SETUP COMMISSIONING (1002) if you press the ESC key combination (X) during parameter interrogation. The stored parameters remain valid. • The "Commissioning" Quick Setup must be carried out before one of the other Quick Setups described in these Operating Instructions is run.

-

Page 5: Table Of Contents

Proline Promag 55 Table of contents Table of contents Safety instructions ....7 Operation ..... . 53 Designated use . - Page 6 Proline Promag 55 Table of contents Troubleshooting ....92 Troubleshooting ......92 System error messages .

-

Page 7: Safety Instructions

• The device must be operated by persons authorized and trained by the facility's owner-operator. Strict compliance with the instructions in the Operating Manual is mandatory. • Endress+Hauser is willing to assist in clarifying the chemical resistance properties of parts wetted by special fluids, including fluids used for cleaning. However, small changes in temperature, concentration or the degree of contamination in the process can result in changes of the chemical resistance properties. -

Page 8: Return

Endress+Hauser distributor will supply you with current information and updates to this Operating Manual. Return The following steps must be taken before returning a flow measuring device to Endress+Hauser, e.g. for repair or calibration: • Always enclose a duly completed "Declaration of contamination" form. Only then can Endress+Hauser transport, examine and repair a returned device. -

Page 9: Identification

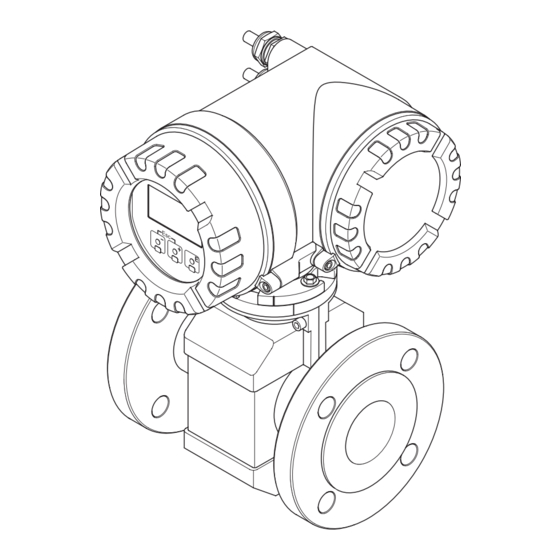

Proline Promag 55 Identification Identification Device designation The flow measuring system consists of the following components: • Promag 55 Transmitter • Promag S or Promag H Sensor Two versions are available: • Compact version: Transmitter and sensor form a single mechanical unit. -

Page 10: Nameplate Of The Sensor

Identification Proline Promag 55 2.1.2 Nameplate of the sensor PROMAG S Order Code: 55S1H-XXXXXXXXXXXX 12345678901 Ser.No.: ABCDEFGHJKLMNPQRST TAG No.: 1.0000/0000 0.2 CAL K-factor: DN100 DIN EN PN40 –20 °C ...+150°C/–4 ...+300°F °F Materials: 1.4435/316L EPD/MSÜ, R/B Electrodes: –20°C (–4°F)<Tamb<+50°C (+122°F) -

Page 11: Nameplate, Connections

Proline Promag 55 Identification 2.1.3 Nameplate, connections active See operating manual passive Betriebsanleitung beachten normally open contact Observer manuel d'instruction normally closed contact 12345678912 Ser.No.: L1/L+ Supply / Versorgung / N/L- Tension d'alimentation Active: 0/4...20mA, RL max. = 700 Ohm Passive: 4...20mA, max. -

Page 12: Certificates And Approvals

IEC/EN 61326. The measuring system described in these Operating Instructions therefore complies with the legal requirements of the EU Directives. Endress+Hauser confirms this by affixing the CE mark to it and by issuing the CE declaration of conformity. -

Page 13: Installation

Proline Promag 55 Installation Installation Incoming acceptance, transport and storage 3.1.1 Incoming acceptance On receipt of the goods, check the following points: • Check the packaging and the contents for damage. • Check the shipment, make sure nothing is missing and that the scope of supply matches your order. -

Page 14: Storage

Installation Proline Promag 55 Transporting flanged devices (DN > 300/12") Use only the metal eyes on the flanges for transporting the device, lifting it and positioning the sensor in the piping. " Caution! Do not attempt to lift the sensor with the tines of a fork-lift truck beneath the metal casing. This would buckle the casing and damage the internal magnetic coils. -

Page 15: Installation Conditions

Proline Promag 55 Installation Installation conditions 3.2.1 Dimensions All the dimensions and lengths of the sensor and transmitter are provided in the separate documentation "Technical Information". 3.2.2 Location The accumulation of air or gas bubbles in the measuring tube could result in an increase in measuring errors. - Page 16 Installation Proline Promag 55 Partially filled pipes Partially filled pipes with gradients necessitate a drain-type configuration. The Empty Pipe Detection function offers additional protection by detecting empty or partially filled pipes → Page 87. " Caution! Risk of solids accumulating. Do not install the sensor at the lowest point in the drain. It is advisable to install a cleaning valve.

-

Page 17: Orientation

Proline Promag 55 Installation 3.2.3 Orientation An optimum orientation position helps avoid gas and air accumulations and deposits in the measuring tube. Promag, nevertheless, supplies a range of functions and accessories for correct measuring of problematic fluids: • Electrode Cleaning Circuit (ECC) for applications with fluids producing build-up, e.g. electrically conductive deposits →... -

Page 18: Inlet And Outlet Runs

Installation Proline Promag 55 3.2.4 Inlet and outlet runs If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows, etc. Compliance with the following requirements for the inlet and outlet runs is necessary in order to ensure measuring accuracy. -

Page 19: Foundations, Supports

[mbar] 8 m/s 7 m/s 6 m/s 5 m/s 4 m/s max. 8° 3 m/s 2 m/s 1 m/s d / D a0003213 Fig. 15: Pressure loss due to adapters (for pressure losses in US units, please contact Endress+Hauser). Endress+Hauser... -

Page 20: Nominal Diameter And Flow Rate Promag S And Promag H

Installation Proline Promag 55 3.2.8 Nominal diameter and flow rate Promag S and Promag H The diameter of the pipe and the flow rate determine the nominal diameter of the sensor. The optimum flow velocity is between 2 and 3 m/s (6 to 10 ft/s). The flow velocity (v), moreover, has to be matched to the physical properties of the fluid: •... - Page 21 Proline Promag 55 Installation Flow rate characteristic values - Promag S (US units) Nominal Recommended flow rate Factory settings diameter min./max. full scale value Full scale value Pulse value Low flow cut off (v ≈ 1.0 or 33 ft/s) (v ≈ 8.2 ft/s) (v ≈...

- Page 22 Installation Proline Promag 55 Promag H Flow rate characteristic values - Promag H (SI units) Nominal Recommended flow rate Factory settings diameter min./max. full scale value Full scale value Pulse value Low flow cut off (v ≈ 0.3 or 10 m/s) (v ≈...

-

Page 23: Length Of Connecting Cable

Proline Promag 55 Installation 3.2.9 Length of connecting cable In order to ensure measuring accuracy, comply with the following instructions when installing the remote version: • Secure the cable run or route the cable in an armored conduit. Movement of the cable can falsify the measuring signal, particularly if the fluid conductivity is low. -

Page 24: Installation

Ground cable (DN 15 to 600 / ½ to 24") Ground cables are optionally available in different versions from Endress+Hauser: • Ground cable preinstalled at the flange → Order option (see price list) • Ground cable (not pre-installed) as an accessory → Page 90 Detailed assembly instructions →... - Page 25 Installation Installing ground disks / liner protection plates (DN 15 to 600 / ½ to 24") Ground disks / liner protection plates may be ordered from Endress+Hauser as a separate accessory → Page 90. These disks fulfill two different functions and are used under the following process conditions: •...

- Page 26 Installation Proline Promag 55 Screw tightening torques Note the following points: • The tightening torques listed below are for lubricated threads only. • Always tighten threaded fasteners uniformly and in diagonally opposite sequence. • Overtightening the fasteners will deform the sealing faces or damage the seals.

- Page 27 Proline Promag 55 Installation Promag S EN (DIN) Threaded Max. tightening torque [Nm] Nominal Pressure fasteners diameter rating [mm] [bar] Natural Polyurethane PTFE Hard rubber rubber PN 25 20 x M 33 – – PN 10 20 x M 27 –...

- Page 28 Installation Proline Promag 55 Promag S Threaded Max. tightening torque [Nm] Nominal Pressure fasteners diameter rating [mm] Natural Polyurethane PTFE Hard rubber rubber 4 x M 12 – – – – 4 x M 12 – – – – 4 x M 16 –...

- Page 29 Proline Promag 55 Installation Installing the high temperature version Promag S (with PFA lining) The high temperature version has a housing support for the thermal separation of sensor and transmitter. The high temperature version is always used for applications in which high ambient temperatures are encountered in conjunction with high fluid temperatures.

-

Page 30: Installing The Promag H Sensor

• The sensor might require support or additional attachments, depending on the application and the length of the piping run. When plastic process connections are used, the sensor must be additionally supported mechanically. A wall-mounting kit can be ordered separately from Endress+Hauser as an accessory → Page 90. a0004301 Fig. 21: Promag H process connections (DN 2 to 25 /1/12 to 1", DN 40 to 100 / 1½... - Page 31 • Ground rings can be ordered separately from Endress+Hauser as accessories → Page 90. When placing the order, make certain that the ground ring is compatible with the material used for the electrodes.

- Page 32 Tack-weld the Promag H sensor into the pipe. A suitable welding jig can be ordered separately from Endress+Hauser as an accessory → Page 90. Remove the threaded fasteners from the process-connection flange. Remove the sensor complete with seal from the pipe.

-

Page 33: Turning The Transmitter Housing

Proline Promag 55 Installation 3.3.3 Turning the transmitter housing Turning the aluminum field housing Loosen the two securing screws. Turn the bayonet catch as far as it will go. Carefully lift the transmitter housing as far as it will go. -

Page 34: Turning The Local Display

Installation Proline Promag 55 3.3.4 Turning the local display Turning the stainless-steel field housing Unscrew the electronics compartment cover from the transmitter housing. Press the latches on the side of the display module and pull the module out of the electronics compartment cover. -

Page 35: Installing The Wall-Mount Housing

Proline Promag 55 Installation 3.3.5 Installing the wall-mount housing There are various ways of installing the wall-mount transmitter housing: • Mounted directly on the wall • Installation in control panel (with separate mounting kit, accessories) → Page 36 • Pipe mounting (with separate mounting kit, accessories) → Page 36 "... - Page 36 Installation Proline Promag 55 Installation in control panel Prepare the opening in the panel as illustrated. Slide the housing into the opening in the panel from the front. Screw the fasteners onto the wall-mount housing. Place the threaded rods in the fasteners and screw them down until the housing is seated tightly against the panel.

-

Page 37: Post-Installation Check

Proline Promag 55 Installation Post-installation check Perform the following checks after installing the measuring device in the pipe: Device condition/specifications Notes Is the device damaged (visual inspection)? → Page 108 ff. Does the device correspond to specifications at the measuring point, including process temperature and pressure, ambient temperature, minimum fluid conductivity, measuring range, etc.? -

Page 38: Wiring

Warning! • When connecting Ex-certified devices, see the notes and diagrams in the Ex-specific supplement to these Operating Instructions. Please do not hesitate to contact your Endress+Hauser sales office if you have any questions. • If you use remote versions, connect each sensor only to the transmitter having the same serial number. - Page 39 Proline Promag 55 Wiring Connecting the remote version of Promag S Electrode circuit Coil circuit Meas.signal Pipe S1 E1 E2 S2GND E S n.c. n.c. n.c. E1 E2 GND E a0004323-en Fig. 29: Connecting the remote version of Promag S...

- Page 40 Wiring Proline Promag 55 Connecting the remote version of Promag H Coil circuit Electrode circuit Meas. signal Pipe S1 E1 E2 S2GND E S n.c. n.c. n.c. E1 E2 GND E DN 40 to 100 DN 2 to 25 1½"...

- Page 41 Proline Promag 55 Wiring Cable termination in remote version Promag S Terminate the signal and coil current cables as shown in the figure below (Detail A). Fit the fine-wire cores with wire end ferrules (Detail B). " Caution! When fitting the connectors, pay attention to the following points: •...

- Page 42 Wiring Proline Promag 55 Cable termination in remote version Promag H Terminate the signal and coil current cables as shown in the figure below (Detail A). Fit the fine-wire cores with wire end ferrules (Detail B). " Caution! When fitting the connectors, pay attention to the following points: •...

-

Page 43: Cable Specifications

Core jacket Core reinforcement Cable shield Outer jacket As an option, Endress+Hauser can also deliver reinforced connecting cables with an additional, reinforcing metal braid. We recommend such cables for the following cases: • Directly buried cable • Cables endangered by rodents •... -

Page 44: Connecting The Measuring Unit

Wiring Proline Promag 55 Connecting the measuring unit 4.2.1 Connecting the transmitter Warning! • Risk of electric shock. Switch off the power supply before opening the device. Do not install or wire the device while it is connected to the power supply. Failure to comply with this precaution can result in irreparable damage to the electronics. - Page 45 Proline Promag 55 Wiring – 27 + 26 – 25 + 24 – 23 + 22 – 21 + 20 N (L-) L1 (L+) a0004584 Fig. 33: Connecting the transmitter (stainless steel field housing). Cable cross-section: max. 2.5 mm (14 AWG) Cable for power supply: 20 to 260 V AC / 20 to 64 V DC Terminal No.

-

Page 46: Terminal Assignment

Wiring Proline Promag 55 4.2.2 Terminal assignment Electrical values of inputs → Page 109 Electrical values of outputs → Page 109 Terminal No. (inputs / outputs) Order version 20 (+) / 21 (–) 22 (+) / 23 (–) 24 (+) / 25 (–) 26 (+) / 27 (–) - Page 47 Proline Promag 55 Wiring Connection of the HART handheld communicator ³ Page Bksp Delete Page # % & A B C D E F Copy Paste Hot Key G H I J K L M N O Insert + Hot Key...

-

Page 48: Potential Equalization

Wiring Proline Promag 55 Potential equalization 4.3.1 Standard case Perfect measurement is only ensured when the medium and the sensor have the same electrical potential. Most Promag sensors have a reference electrode installed as standard, which guarantees the required potential equalization. This usually means that additional potential equalization measures are unnecessary. -

Page 49: Special Cases

Proline Promag 55 Wiring 4.3.2 Special cases Metal, ungrounded piping In order to prevent outside influences on measurement, it is necessary to use ground cables to connect each sensor flange to its corresponding pipe flange and ground the flanges. Connect the transmitter or sensor connection housing, as applicable, to ground potential by means of the ground terminal provided for the purpose (see diagram). - Page 50 Wiring Proline Promag 55 Pre-installed ground cable for DN ≤ 300 (order option) Ground cables which are preinstalled on the sensor flange, are also available. These ground cables can be mounted and connected electrically to the piping in different ways: •...

-

Page 51: Degree Of Protection

Proline Promag 55 Wiring Plastic pipes and isolating lined pipes In such cases, install the measuring instrument without potential in the piping: • When installing the measuring device, make sure that there is an electrical connection between the two piping runs (copper wire, at least 6 mm /10 AWG). -

Page 52: Post-Connection Check

Caution! Do not loosen the threaded fasteners of the sensor housing, as otherwise the degree of protection guaranteed by Endress+Hauser no longer applies. Note! The Promag S sensor can be supplied with IP 68 rating (permanent immersion in water to a depth of 3 meters). -

Page 53: Operation

Proline Promag 55 Operation Operation Display and operating elements The local display enables you to read all important parameters directly at the measuring point and configure the device using the "Quick Setup" or the function matrix. The display area consists of two lines; this is where measured values are displayed, and/or status variables (direction of flow, partially filled pipe, bar graph, etc.). -

Page 54: Display (Operation Mode)

Operation Proline Promag 55 5.1.1 Display (operation mode) The display area consists of three lines in total. This is where measured values and/or status variables (direction of flow, bar graph, etc.) are displayed. You can change the assignment of display lines to variables at will in order to customize the display to suit your needs and preferences (→... -

Page 55: Icons

Proline Promag 55 Operation 5.1.2 Icons The icons which appear in the field on the left make it easier to read and recognize measured variables, device status, and error messages. Icon Meaning Icon Meaning System error Process error Fault message... -

Page 56: Brief Operating Instruction To The Function Matrix

Operation Proline Promag 55 Brief operating instruction to the function matrix Note! • See the general notes → Page 57 • Function descriptions → see the "Description of Device Functions" manual HOME position → F → Enter the function matrix →... -

Page 57: General Notes

• If programming is disabled and the O/S keys are pressed in any function, a prompt for the code automatically appears on the display. • If "0" is entered as the customer’s code, programming is always enabled. • The Endress+Hauser service organization can be of assistance if you mislay your personal code. " Caution! Changing certain parameters such as all sensor characteristics, for example, influences numerous functions of the entire measuring system, particularly measuring accuracy. -

Page 58: Error Messages

Operation Proline Promag 55 Error messages 5.3.1 Type of error Errors which occur during commissioning or measuring operation are displayed immediately. If two or more system or process errors occur, the error with the highest priority is the one shown on the display. -

Page 59: Confirming Error Messages

Proline Promag 55 Operation 5.3.3 Confirming error messages For the sake of plant and process safety, the measuring device can be configured in such a way that fault messages ($) always have to be rectified and acknowledged locally by pressing F. Only then do the error messages disappear from the display. -

Page 60: Operating Options

• Controlling the "Fieldcheck" tester/simulator Operating program "FieldCare" Fieldcare is Endress+Hauser’s FDT-based plant Asset Management Tool and allows the configuration and diagnosis of intelligent field devices. By using status information, you also have a simple but effective tool for monitoring devices. The Proline flow measuring devices are accessed via a service interface or via the service interface FXA193. -

Page 61: Current Device Description Files

Handheld terminal DXR375 • Use update function of handheld terminal ToF Tool - Fieldtool Package • www.tof-fieldtool.endress.com • Update CD-ROM (Endress+Hauser order number 50099820) • www.endress.com (→ Download → Software → Device driver) FieldCare / DTM • CD-ROM (Endress+Hauser order number 56004088) •... -

Page 62: Device And Process Variables

Operation Proline Promag 55 5.4.3 Device and process variables Device variables: The following device variables are available using the HART protocol: Device and process Device variable variables OFF (not assigned) Volume flow Mass flow Conductivity Target mass flow % Target mass flow... -

Page 63: Universal / Common Practice Hart Commands

Proline Promag 55 Operation 5.4.4 Universal / Common practice HART commands Command No. Command data Response data HART command / Access type (numeric data in decimal form) (numeric data in decimal form) Universal Commands Read unique device identifier none Device identification delivers information on the device Access type = read and the manufacturer. - Page 64 Operation Proline Promag 55 Command No. Command data Response data HART command / Access type (numeric data in decimal form) (numeric data in decimal form) Set HART shortform address Byte 0: desired address (0 to 15) Byte 0: active address...

- Page 65 Proline Promag 55 Operation Command No. Command data Response data HART command / Access type (numeric data in decimal form) (numeric data in decimal form) Write user message You can save any 32-character long text in the device Displays the current user message in the device:...

- Page 66 Operation Proline Promag 55 Command No. Command data Response data HART command / Access type (numeric data in decimal form) (numeric data in decimal form) Read assignment of the device none Display of the current variable assignment of the process...

-

Page 67: Device Status / Error Messages

Proline Promag 55 Operation 5.4.5 Device status / Error messages You can read the extended device status, in this case, current error messages, via Command "48". The command delivers information which are partly coded in bits (see table below). Note! For a detailed explanation of the device status and error messages and their elimination, see →... - Page 68 Operation Proline Promag 55 Short description of error → Page 92 ff. Byte-Bit Error No. not assigned – not assigned – not assigned – Coil current of the sensor is outside the tolerance. The deviation of the decay time on measuring electrode 1 has exceeded the warning level.

- Page 69 Proline Promag 55 Operation Short description of error → Page 92 ff. Byte-Bit Error No. not assigned 10-0 not assigned – 10-1 not assigned – 10-2 not assigned – 10-3 not assigned – 10-4 not assigned – 10-5 not assigned –...

- Page 70 Operation Proline Promag 55 Short description of error → Page 92 ff. Byte-Bit Error No. 14-7 15-0 Simulation current output active 15-1 15-2 15-3 15-4 Simulation frequency output active 15-5 15-6 15-7 16-0 Simulation pulse output active 16-1 16-2 16-3...

-

Page 71: Switching Hart Write Protection On And Off

Proline Promag 55 Operation Short description of error → Page 92 ff. Byte-Bit Error No. 20-2 not assigned – 20-3 not assigned – 20-4 not assigned – 20-5 not assigned – 20-6 not assigned – 20-7 not assigned – 22-4... -

Page 72: Commissioning

Commissioning Proline Promag 55 Commissioning Function check Make sure that all final checks have been completed before you start up your measuring point: • Checklist for "Post-installation check" → Page 37 • Checklist for "Post-connection check" → Page 52 Switching on the measuring device Once the connection checks have been successfully completed, it is time to switch on the power supply. -

Page 73: Quick Setup

Proline Promag 55 Commissioning Quick Setup In the case of measuring devices without a local display, the individual parameters and functions must be configured by means of a configuration program, such as FieldCare or ToF Tool - Fieldtool Package from Endress+Hauser. - Page 74 Commissioning Proline Promag 55 Note! • The display returns to the cell SETUP COMMISSIONING (1002) if you press the ESC key combination during parameter interrogation. The stored parameters remain valid. • The "Commissioning" Quick Setup must be carried out before any of the other Quick Setups described in this Operating Instructions are run.

-

Page 75: Pulsating Flow" Quick Setup Menu

Proline Promag 55 Commissioning 6.3.2 "Pulsating flow" Quick Setup menu Certain pumps of a construction which necessitates a pulsating pumping action, such as reciprocating, peristaltic and cam-type pumps, create a flow characterized by severe periodic fluctuations. Negative flows can occur with pumps of these types on account of the closing volume of the valves or valve leaks. - Page 76 Commissioning Proline Promag 55 Using the "Pulsating Flow" Quick Setup menu This Quick Setup menu guides you systematically through the setup procedure for all the device functions that have to be configured for measuring pulsating flows. Note that this has no effect on values already configured, such as measuring range, current range or full scale value.

- Page 77 Proline Promag 55 Commissioning " "Pulsating flow Quick Setup menu HOME position → F → MEASURED VARIABLE → O → QUICK SETUP → N→ QS PULSATING FLOW (1003) Select using OS Function No. Function name Go to next function using F...

-

Page 78: Data Backup/Transmission

Commissioning Proline Promag 55 6.3.3 Data backup/transmission Using the T-DAT SAVE/LOAD function, you can transfer data (device parameters and settings) between the T-DAT (exchangeable memory) and the EEPROM (device storage unit). This is required in the following instances: • Creating a backup: current data are transferred from an EEPROM to the T-DAT. -

Page 79: Configuration

Proline Promag 55 Commissioning Configuration 6.4.1 Current outputs: active/passive The current outputs can be configured as "active" or "passive" by means of various jumpers on the I/O board or on the current submodule. Warning! Risk of electric shock. Exposed components carry dangerous voltages. Make sure that the power supply is switched off before you remove the cover of the electronics compartment. - Page 80 Commissioning Proline Promag 55 a0006361 Fig. 53: Configuring the current output with the aid of jumpers (fixed I/O board) Active current output (factory setting) Passive current output Endress+Hauser...

-

Page 81: Current Input: Active/Passive

Proline Promag 55 Commissioning 6.4.2 Current input: active/passive The current input can be configured as "active" or "passive" by means of various jumpers on the current input submodule. Warning! Risk of electric shock. Exposed components carry dangerous voltages. Make sure that the power supply is switched off before you remove the cover of the electronics compartment. -

Page 82: Relay Contacts: Normally Closed/Normally Open

Commissioning Proline Promag 55 6.4.3 Relay contacts: Normally closed/normally open The relay contact can be configured as normally open (NO or make) or normally closed (NC or break) contacts by means of two jumpers on the I/O board or on the relay submodule respectively. -

Page 83: Measuring Solids Content Flow

• Software option "Solids content flow" (F-CHIP) • Current input (order option, I/O module no. 4 or 5) • A density meter, e.g. "Gammapilot M" from Endress+Hauser, for recording total fluid density (i.e. including solids) • Knowledge of solid density e.g. resulting from laboratory tests •... - Page 84 Commissioning Proline Promag 55 Calculation formula (example) The mass flow of the target fluid is calculated, for example, as follows: = V ⋅ (ρ − ρ ) / (1 − ρ /ρ Mass flow target fluid (solids), e.g. in kg/h Volume flow (total fluid), e.g.

-

Page 85: Advanced Diagnostic Functions

Proline Promag 55 Commissioning 6.4.5 Advanced diagnostic functions With the aid of the optional software package "Advanced Diagnostics" (F-CHIP, accessories → Page 90), changes in the measuring system can be detected early on, e.g. as a result of build-up (coating) or corrosion at the measuring electrodes. Such factors cause a reduction in accuracy under normal circumstances, or cause system errors in extreme cases. - Page 86 VOLUME FLOW. As build-up typically develops over a period of months, it is useful to present and analyze the relevant measurement data and parameters using appropriate software, for example using the Endress+Hauser software packages "FieldCare" or "ToF Tool - Fieldtool Package". Endress+Hauser...

-

Page 87: Adjustment

Proline Promag 55 Commissioning Adjustment 6.5.1 Empty-pipe/full-pipe adjustment Flow cannot be measured correctly unless the measuring tube is full. This state can be permanently monitored by means of empty pipe detection (EPD). " Caution! A detailed description and other helpful hints for the empty-pipe/full-pipe adjustment procedure can be found in the separate "Description of Device Functions"... -

Page 88: Data Storage Devices

Proline Promag 55 Data storage devices At Endress+Hauser, the term HistoROM refers to various types of data storage modules on which process and measuring device data are stored. By plugging and unplugging such modules, device configurations can be duplicated onto other measuring devices to cite just one example. -

Page 89: Maintenance

Proline Promag 55 Maintenance Maintenance No special maintenance work is required. Exterior cleaning When cleaning the exterior of measuring devices, always use cleaning agents that do not attack the surface of the housing and the seals. Endress+Hauser... -

Page 90: Accessories

Accessories Proline Promag 55 Accessories Various accessories, which can be ordered separately from Endress+Hauser, are available for the transmitter and the sensor. The Endress+Hauser service organization can provide detailed information on the order codes of your choice. Device-specific accessories Accessory... -

Page 91: Communication-Specific Accessories

Hand-held terminal for remote parameterization and for DXR375 - * * * * DXR375 hand-held fetching measured values via the current output HART terminal (4 to 20 mA). Contact your Endress+Hauser representative for more information. Communication-specific accessories Accessory Description Order code Applicator Software for selecting and configuring flowmeters. -

Page 92: Troubleshooting

Troubleshooting Proline Promag 55 Troubleshooting Troubleshooting Always start troubleshooting with the checklist below, if faults occur after startup or during operation. The routine takes you directly to the cause of the problem and the appropriate remedial measures. Check the display 1. -

Page 93: System Error Messages

Caution! In the event of a serious fault, a flowmeter might have to be returned to the manufacturer for repair. The necessary procedures must be carried out before you return the device to Endress+Hauser → Page 8. Always enclose a duly completed "Declaration of contamination" form. You will find a preprinted blank of the this form at the back of this manual. - Page 94 Troubleshooting Proline Promag 55 Error message / Type Cause Remedy / spare part 041 S: TRANSM. HW-DAT Transmitter DAT: 1. Check whether the T-DAT is correctly $: # 041 plugged into the amplifier board. 1. T DAT is not correctly plugged into the amplifier 2.

- Page 95 Proline Promag 55 Troubleshooting Error message / Type Cause Remedy / spare part S: STACK The temporarily buffered flow 1. Change the upper or lower limit setting, CURRENTOUTPUT n portions (measuring mode for as applicable. $: # 339 to 342 pulsating flow) could not be 2.

- Page 96 Troubleshooting Proline Promag 55 Error message / Type Cause Remedy / spare part No. # 5xx → Application error S: SW.-UPDATE ACT. New amplifier or communication Wait until the procedure is finished. The !: # 501 module software version is being device is restarted automatically.

-

Page 97: Process Error Messages

Proline Promag 55 Troubleshooting Process error messages Process errors can be defined as either "Fault" or "Notice" messages and can thereby be weighted differently. Determination of this is done via the function matrix (see the "Description of Device Functions" Manual). -

Page 98: Process Errors Without Message

The following options are available for tackling problems of this nature: other fault not described above has • Request the services of an Endress+Hauser service technician arisen. If you contact our service organization to have a service technician sent out,... -

Page 99: Response Of Outputs To Errors

Proline Promag 55 Troubleshooting Response of outputs to errors Note! The failsafe mode of current, pulse and frequency outputs can be customized by means of various functions in the function matrix. You will find detailed information on these procedures in the "Description of Device Functions"... - Page 100 Troubleshooting Proline Promag 55 Error response mode of outputs System/process error is current Positive zero return is activated Totalizer STOP Totalizer stops The totalizers are paused until the fault is rectified. ACTUAL VALUE The fault is ignored . The totalizers continue to count in accordance with the current flow value.

-

Page 101: Spare Parts

Note! You can order spare parts directly from your Endress+Hauser service organization by providing the serial number printed on the transmitter nameplate → Page 9. Spare parts are shipped as sets comprising the following parts: •... -

Page 102: Removing And Installing Printed Circuit Boards

" Caution! Use only original Endress+Hauser parts. Removing and installing the boards → Fig. 59: Unscrew cover of the electronics compartment from the transmitter housing. Remove the local display (1) as follows: –... - Page 103 Proline Promag 55 Troubleshooting T / O T / O T / O a0002656 Fig. 59: Field housing: removing and installing printed circuit boards Local display Latch Ribbon cable (display module) Screws for electronics compartment cover Aperture for installing /removing boards...

- Page 104 " Caution! Use only original Endress+Hauser parts. Installing and removing the boards → Fig. 60: Remove the screws and open the hinged cover (1) of the housing. Loosen the screws securing the electronics module (2). Then push up electronics module and pull it as far as possible out of the wall-mounted housing.

- Page 105 Proline Promag 55 Troubleshooting a0005520 Fig. 60: Wall-mounted housing: removing and installing printed circuit boards Housing cover Electronics module Ribbon cable (display module) Screws for electronics compartment cover Aperture for installing /removing boards Power unit board Amplifier board Electrode signal cable (sensor)

-

Page 106: Replacing The Device Fuse

– 20 to 260 V AC / 20 to 64 V DC → 2.0 A slow-blow /250 V; 5.2 x 20 mm – Ex-rated devices → see the Ex documentation. Installation is the reverse of the removal procedure. " Caution! Use only original Endress+Hauser parts. a0001148 Fig. 61: Replacing the device fuse on the power supply board Protection cap... -

Page 107: Return

Proline Promag 55 Troubleshooting Return The following steps must be taken before returning a flow measuring device to Endress+Hauser, e.g. for repair or calibration: • Always enclose a duly completed "Declaration of contamination" form. Only then can Endress+Hauser transport, examine and repair a returned device. -

Page 108: Technical Data

Technical data Proline Promag 55 Technical data 10.1 Technical data at a glance 10.1.1 Application The measuring device described in this Operating Manual is to be used only for measuring the flow rate of conductive fluids in closed pipes. All fluids (inclusive demineralized water) can be metered, provided they have a minimum conductivity of 5 μS/cm, for example:... -

Page 109: Output

Proline Promag 55 Technical data Operable flow range Flow rate: Over 1000 : 1 Input signal Status input (auxiliary input): U = 3…30 V DC, R = 5 kΩ, galvanically isolated Configurable for: totalizer(s) reset, positive zero return, error-message reset Current input: active/passive selectable, galvanically isolated, full scale value adjustable, resolution: 3 μA,... -

Page 110: Power Supply

Technical data Proline Promag 55 10.1.5 Power supply → Page 38 ff. Electrical connections Supply voltage 20 to 260 V AC, 45 to 65 Hz 20 to 64 V DC Cable entries Power-supply and signal cables (inputs/outputs): • Cable gland M20 x 1.5 (8 to 12 mm / 0.31 to 0.47 inch) •... -

Page 111: Performance Characteristics

Proline Promag 55 Technical data 10.1.6 Performance characteristics Reference conditions To DIN EN 29104 and VDI/VDE 2641: • Fluid temperature: +28 °C ± 2 K • Ambient temperature: +22 °C ± 2 K • Warm-up time: 30 minutes Installation: • Inlet run >10 x DN •... -

Page 112: Operating Conditions: Installation

Technical data Proline Promag 55 10.1.7 Operating conditions: Installation → Page 15 ff. Installation instructions Inlet run: typically ≥ 5 x DN Inlet and outlet runs Outlet run: typically ≥ 2 x DN Length of connecting cable The permissible cable length L for the remote version depends on the conductivity of the medium →... -

Page 113: Operating Conditions: Process

Proline Promag 55 Technical data SIP cleaning Promag S: possible with PFA (note max. temperature) not possible with PU, PTFE, hard rubber, natural rubber Promag H: possible (note max. temperature) Electromagnetic compatibility According to IEC/EN 61326 and NAMUR recommendation NE 21 (EMC) 10.1.9... - Page 114 Technical data Proline Promag 55 [°F] [°C] PTFE 40 60 80 120 140 160 [°C] 360 [°F] a0002671-ae Fig. 64: Promag S remote versions (with PFA or PTFE lining) Ambient temperature Fluid temperature High temperature version with insulation Gray shaded area → temperature range from –10 to –40 °C (–14 to –40 °F) applies only to stainless steel flanges ➀...

- Page 115 Proline Promag 55 Technical data Pressure tightness (lining) Resistance to partial vacuum in SI units [mbar] Promag S Measuring tube Resistance of measuring tube lining to partial vacuum (SI units) Nominal lining Limit values for abs. pressure [mbar] at various fluid temperatures...

- Page 116 Technical data Proline Promag 55 Pressure tightness in US units [psia = pounds/inch Promag S Measuring tube Resistance of measuring tube lining to partial vacuum (US units) Nominal lining Limit values for abs. pressure [mbar] at various fluid temperatures diameter [inch] 77 °F...

-

Page 117: 10.1.10 Mechanical Construction

Proline Promag 55 Technical data 10.1.10 Mechanical construction Design / dimensions The dimensions and face-to-face length of the sensor and transmitter can be found in the separate "Technical Information" for each device which can be downloaded in PDF format from www.endress.com. - Page 118 Technical data Proline Promag 55 Weight data of Promag H in SI units [kg] Weight of Promag H in kilograms [kg] Nominal diameter Compact version Remote version (without cable) Sensor Transmitter [mm] [inch] (Wall housing) 1/12" 5/32" 5/16" ½" 1"...

- Page 119 Proline Promag 55 Technical data Weight data of Promag H in US units [lbs = pounds] Weight of Promag H in pounds [lbs] Nominal diameter Compact version Remote version (without cable) Sensor Transmitter [mm] [inch] (Wall housing) 1/12" 5/32" 5/16"...

- Page 120 Technical data Proline Promag 55 Promag H Transmitter housing: • Compact housing: powder coated die-cast aluminium or stainless-steel field housing 1.4301/316L • Wall-mounted housing: powder coated die-cast aluminium Sensor housing: 1.4301 Wall mounting (holder panel): 1.4301 Measuring tube: stainless steel 1.4301 or 1.4306/304L Flange: •...

-

Page 121: 10.1.11 Human Interface

CE mark The measuring system described in these Operating Instructions therefore complies with the legal requirements of the EU Directives. Endress+Hauser confirms this by affixing the CE mark to it and by issuing the CE declaration of conformity. C-tick mark The measuring system meets the EMC requirements of the "Australian Communications and Media... -

Page 122: 10.1.13 Ordering Information

Various accessories are available for the transmitter and the sensor. These can be ordered separately from Endress+Hauser → Page 90. Note! For detailed information on specific order codes, please contact the Endress+Hauser service organization. 10.1.15 Supplementary documentation • Flow Measurement (FA005D/06/en) •... -

Page 123: Index

Proline Promag 55 Index Index Current output Active/passive configuration..... 79 Accessories ........90 Electrical connection . - Page 124 Proline Promag 55 Index Error types (system and process errors) ....58 Installation conditions European Pressure Equipment Directive....121 Dimensions .

- Page 125 Proline Promag 55 Index Transmitter ........9 Promag H .

- Page 126 Proline Promag 55 Index Welding work grounding welding equipment ....32 Promag H with weld nipples ....32...

- Page 127 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 128 www.endress.com/worldwide BA119D/06/en/11.07 71064033 FM+SGML6.0 ProMoDo...